Environment-friendly glass fiber reinforced AS composite material and preparation method thereof

A composite material and environmentally friendly technology, applied in the field of plastic modification, can solve the problems of high odor and limitation of glass fiber reinforced AS composite materials, and achieve excellent antibacterial effect, low cost, and the effect of enhancing bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of jellyfish pellets:

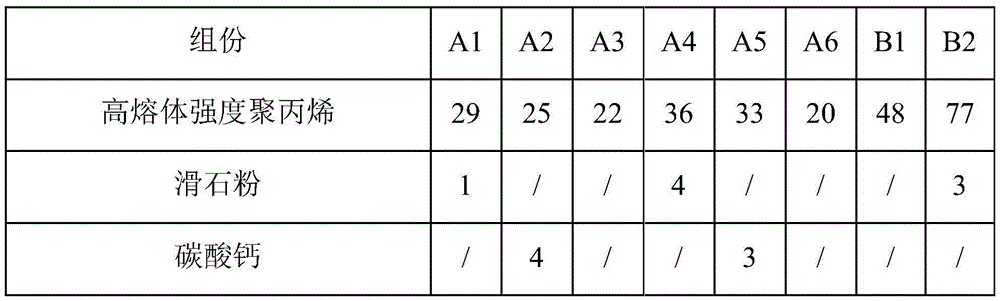

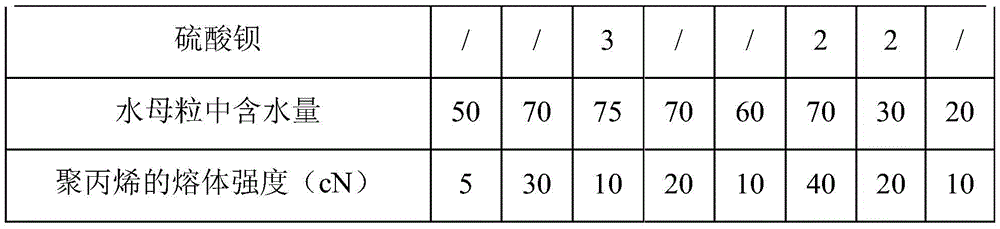

[0038] Fully mix high-melt-strength polypropylene with different melt strengths and mineral fillers according to the ratio shown in Table 1, extrude strip-shaped polypropylene in the extruder, and then chop it into polypropylene pre-foaming Particles; using water as a foaming agent, the polypropylene pre-expanded particles are expanded to prepare expanded polypropylene with high melt strength; the expanded polypropylene with high melt strength and water are mixed in a high-speed mixer 5-10min, prepare jellyfish pellets with the water content shown in Table 1, and release them for use.

[0039] Each component content (weight percent) of table 1 jellyfish grain

[0040]

[0041]

Embodiment 1-6, comparative example 6

[0043] A kind of glass fiber reinforced AS composite material with excellent mechanical properties, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0044] Weigh AS resin, compatibilizer, jellyfish granules, silane coupling agent, antibacterial agent and auxiliary agent in a high mixer for 1-3 minutes by weight percentage; mix evenly to obtain a premix; put the premix in double In the main feed port of the screw extruder, glass fiber is added from the side feed port for melt extrusion, granulation and drying. Determination of its performance, the specific data are listed in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com