Low-floating fiber glass fiber reinforced AS (Acrylonitrile Styrene) composition as well as preparation method and application thereof

A composition and low-floating fiber technology, applied in the field of modified plastics, can solve the problems of complex components of the treatment liquid, high process control requirements, and affecting the appearance of the product, so as to achieve good promotion and application value, reduce exposure, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

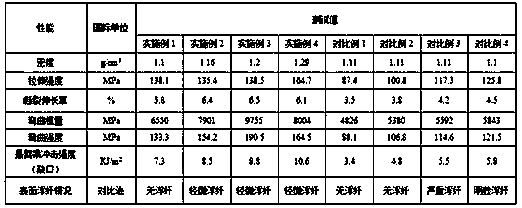

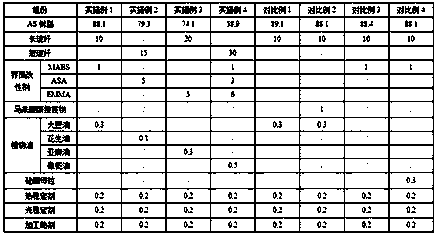

Embodiment 1~4 and comparative example 1~4

[0038] A kind of glass fiber reinforced AS composition, its raw material formula is as shown in table 1, and its preparation method comprises the following steps:

[0039](1) Weigh the AS resin, interface modifier, vegetable oil and additives by weight percentage and mix them in a high-speed mixer for 1-3 minutes; mix them evenly to obtain a premix;

[0040] (2) Put the premixed material in the main feed port of the twin-screw extruder, add glass fiber from the side feed port, carry out melt extrusion, granulate and dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com