Method for liquid drainage and gas recovery using oil-foam-resistant drainage agent composition

A technology for liquid drainage and gas production and composition, which is applied in the directions of drilling composition, chemical instrument and method, and production fluid, etc., can solve the problems of poor drainage performance of foam, stop spraying, insufficient oil resistance and temperature resistance of foam, etc. , to achieve the effect of good salt tolerance and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

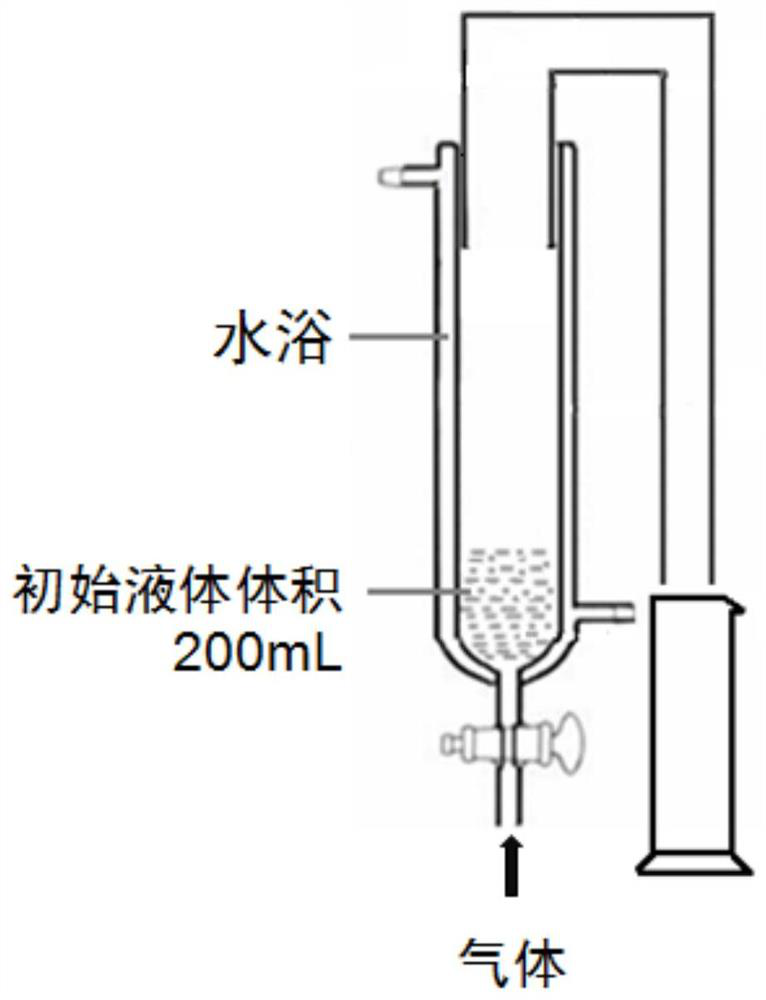

Method used

Image

Examples

Embodiment 1

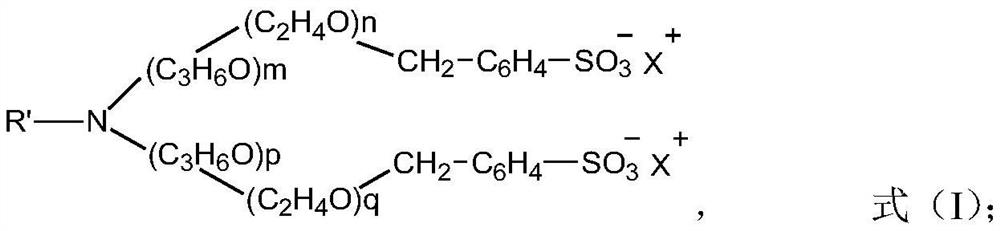

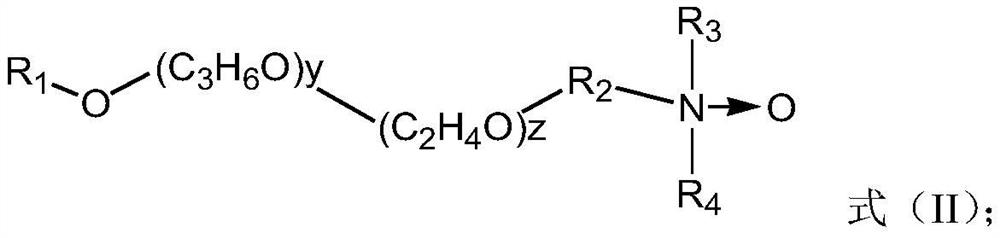

[0034] Under normal temperature and pressure, weigh alkylamine polyether benzene sulfonate, long-chain polyether nitrogen-containing compounds, and dissolve nano-silica in an aqueous solution with a salinity of 100,000 mg / L according to a mass ratio of 1:2:1. Prepare a 1.0wt% solution to obtain the foam drainage composition HF-1. The composition structure is shown in Table 1.

Embodiment 2

[0036] Under normal temperature and pressure, weigh alkylamine polyether benzene sulfonate, long-chain polyether nitrogen-containing compounds, and dissolve nano-silica in an aqueous solution with a salinity of 100,000mg / L according to a mass ratio of 1:10:5. Prepare a 1.0 wt% solution to obtain the foam drainage composition HF-2. The composition structure is shown in Table 1.

Embodiment 3

[0038] Under normal temperature and pressure, weigh alkylamine polyether benzene sulfonate, long-chain polyether nitrogen-containing compound, and dissolve nano-silica in an aqueous solution with a salinity of 100,000 mg / L according to a mass ratio of 1:0.2:0.5. Prepare a 1.0wt% solution to obtain the foam drainage composition HF-3. The composition structure is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com