Coiled tube fracturing and well completion integration technological method for vertical gas well

A process method and oil tubing technology, applied in the field of integrated gas well vertical well coiled tubing fracturing and well completion technology, can solve the problems affecting gas well production and recovery rate, poor liquid carrying capacity, large construction risk, etc., and shorten gas testing The effect of operating cycle, prolonging production cycle and improving liquid carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

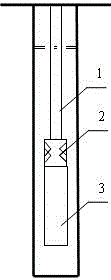

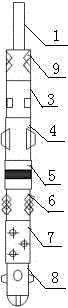

[0025] This embodiment is through such as figure 1 , 2 The tubing string shown is implemented, and the tubing string is connected sequentially from top to bottom by the coiled tubing 1, the hydraulic hand 2, and the fracturing tool string 3, wherein the coiled tubing 1 and the hydraulic fracturing hand 2 are connected through a connector 9, The fracturing tool string 3 is composed of a casing collar positioner 4 , a packer 5 , an anchor 6 , an injector 7 and a pilot check valve 8 connected in sequence.

[0026] An integrated process method for coiled tubing fracturing and well completion for vertical gas wells, comprising the following steps:

[0027] Step 1), after the well flushing operation, run the coiled tubing 1, hydraulic control 2, and fracturing tool string 3 connected sequentially from top to bottom to the bottom of the well, and adjust the depth of the pipe string through the casing collar positioner 4 ;

[0028] Step 2), drag the coiled tubing 1 from bottom to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com