Foaming agent with corrosion inhibiting function for acidic gas field, preparation and applications thereof

A foaming agent, gas field technology, applied in the directions of organic chemistry, drilling compositions, chemical instruments and methods, etc., can solve the problem of affecting the corrosion protection performance, affecting the foaming performance of the foaming agent, without mentioning the formula and applicable Gas, water quality and other problems, to achieve the effect of good liquid-carrying performance, good foam stability, and strong anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

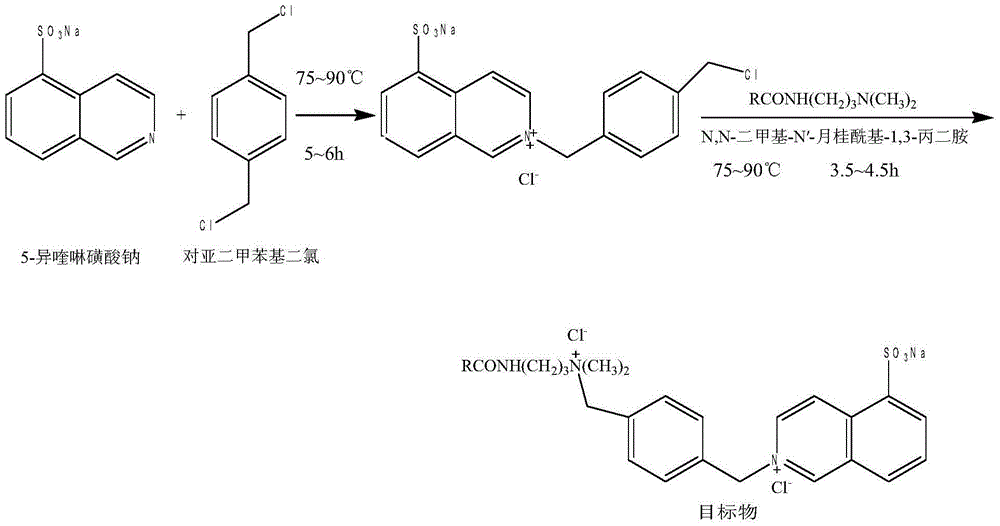

Embodiment 1

[0019] The molar ratio of 5-isoquinoline sulfonate, p-xylylene dichloride and N,N-dimethyl-N'-lauroyl-1,3-propanediamine is 1.1:1.0:1.1. The first step was reacted at 80°C for 6 hours, and the second step was reacted at 80°C for 4 hours to prepare a foaming agent with a mass concentration of 30%. Take on-site salinity of 293g / L, CaCl 2 Add 0.5 g of the foaming agent (mass percentage concentration: 0.1%) product of the present invention to 500 mL of water-type water sample. The foaming power (initial foam height) measured at 90°C by the Roche method is 108 mm, and the foam stability ( 3min bubble height) 40mm and liquid carrying capacity 142mL / 15min, 80℃, normal pressure, test piece material BG95SS, water phase hydrogen sulfide content 1400ppm, water phase carbon dioxide content 250ppm, the corrosion rate is 0.0383mm / a, and the corrosion inhibition rate is 78.7 %, the test piece is bright.

Embodiment 2

[0021] With the blowing agent that example 1 makes, get on-site salinity 30.76g / L, CaCl 2 Add 0.5 g of the foaming agent (mass percentage concentration: 0.1%) of the water-type water sample to 500 mL. The foaming power (initial foam height) measured by the Roche method at 90 ° C is 230 mm, and the foam stability ( 3min bubble height) 35mm and liquid carrying capacity 135mL / 15min, 80℃, normal pressure, test piece material BG95SS, water phase hydrogen sulfide content 1400ppm, water phase carbon dioxide content 250ppm, the corrosion rate is 0.0398mm / a, and the corrosion inhibition rate is 83.3 %, the test piece is bright.

Embodiment 3

[0023] With the blowing agent that example 1 makes, get on-site salinity 3.34g / L, CaCl 2 Add 0.5 g of the foaming agent (mass percentage concentration: 0.1%) of the water-type water sample to 500 mL. The foaming power (initial foam height) measured by the Roche method at 90 ° C is 145 mm, and the foam stability ( 3min bubble height) 25mm and liquid carrying capacity 130mL / 15min, 80℃, normal pressure, test piece material BG95SS, water phase hydrogen sulfide content 1400ppm, water phase carbon dioxide content 250ppm, the corrosion rate is 0.0158mm / a, and the corrosion inhibition rate is 91.0 %, the test piece is bright.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com