Wear-resistant and anti-corrosion rubber strip for treadmill

An anti-corrosion rubber and wear-resistant technology, which is applied in the field of treadmill rubber strips, can solve problems such as surface shedding, anti-corrosion, poor wear resistance, corrosion, etc., and achieve the effects of reducing gravity, ensuring service life, and improving cushioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

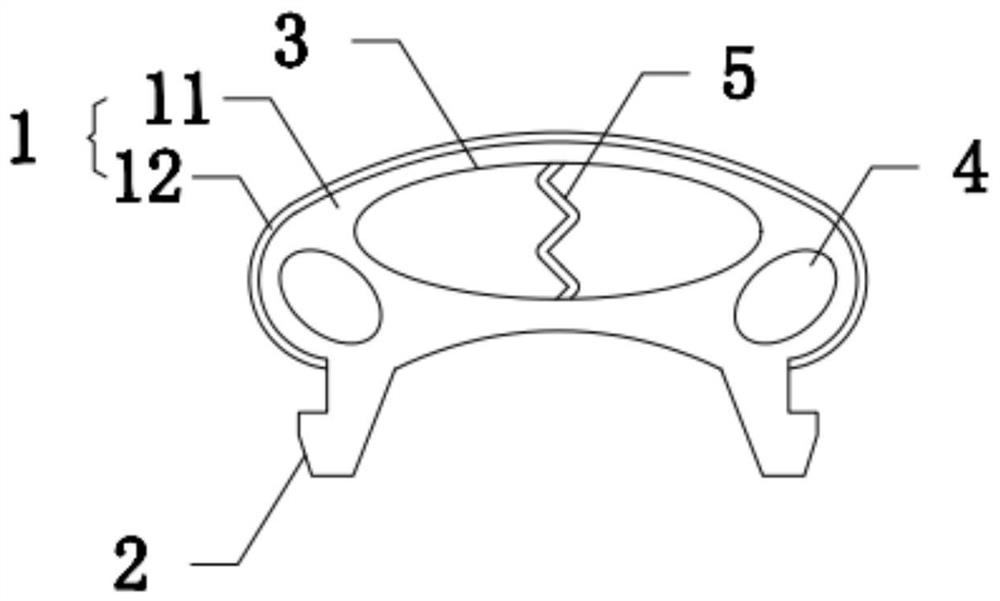

[0032] S1: Mix and knead the rubber raw materials of the internal vulcanized rubber body 11, the hook 2, the buffer chamber 3, the mass reduction hole 4, and the buffer support plate 5, and extrude them into one body;

[0033] S2: knead the raw materials of the outer anti-corrosion and wear-resistant layer 12, and vulcanize and extrude the kneaded raw materials on the outer wall of the inner vulcanized rubber body 11, so that the connection between the inner vulcanized rubber body 11 and the outer anti-corrosion wear-resistant layer 12 is stable;

[0034] The anti-corrosion rubber base material is styrene-butadiene rubber and preservative according to the ratio of 90:1. The wear-resistant additives are glass fiber, alumina powder and silicon oxide powder. The anti-corrosion rubber base material and wear-resistant additive are respectively Anti-corrosion rubber substrate 40Kg and wear-resistant additive 8Kg;

[0035] S3: It can be cut to length after cooling.

Embodiment 2

[0037] S1: Mix and knead the rubber raw materials of the internal vulcanized rubber body 11, the hook 2, the buffer chamber 3, the mass reduction hole 4, and the buffer support plate 5, and extrude them into one body;

[0038] S2: knead the raw materials of the outer anti-corrosion and wear-resistant layer 12, and vulcanize and extrude the kneaded raw materials on the outer wall of the inner vulcanized rubber body 11, so that the connection between the inner vulcanized rubber body 11 and the outer anti-corrosion wear-resistant layer 12 is stable;

[0039] The anti-corrosion rubber substrate is nitrile rubber and preservative according to the ratio of 90:1, and the wear-resistant additives are glass fiber, alumina powder and silicon oxide powder. The anti-corrosion rubber substrate and wear-resistant additive are respectively according to the mass proportion Anti-corrosion rubber substrate 45Kg and wear-resistant additive 10Kg;

[0040] S3: It can be cut to length after cooling...

Embodiment 3

[0042] S1: Mix and knead the rubber raw materials of the internal vulcanized rubber body 11, the hook 2, the buffer chamber 3, the mass reduction hole 4, and the buffer support plate 5, and extrude them into one body;

[0043] S2: knead the raw materials of the outer anti-corrosion and wear-resistant layer 12, and vulcanize and extrude the kneaded raw materials on the outer wall of the inner vulcanized rubber body 11, so that the connection between the inner vulcanized rubber body 11 and the outer anti-corrosion wear-resistant layer 12 is stable;

[0044] The anti-corrosion rubber base material is butyl rubber and preservative according to the ratio of 90:1, and the wear-resistant additives are glass fiber, alumina powder and silicon oxide powder. The anti-corrosion rubber base material and wear-resistant additive are respectively Anti-corrosion rubber substrate 50Kg and wear-resistant additive 12Kg;

[0045] S3: It can be cut to length after cooling.

[0046] application:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com