Foam scrubbing agent with gas condensate resistance and salt resistance and preparation method of foam scrubbing agent

An anti-condensate oil and salt bubble technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor foaming effect and high liquid carrying capacity of foaming agent, so as to enhance stability and reduce drainage liquid, wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

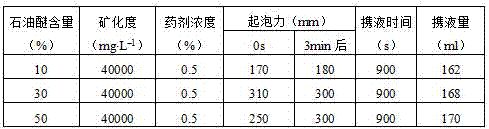

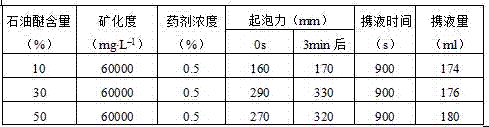

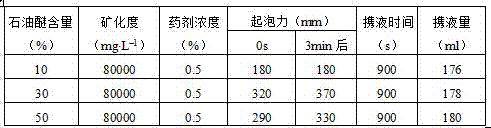

Image

Examples

Embodiment 1

[0020] An anti-condensate oil and anti-salt foaming agent is composed of the following raw materials in terms of mass percentage:

[0021] Cocamidopropyl Hydroxysultaine 20%;

[0022] Erucamide propyl betaine 10%;

[0023] Lauramide propylamine oxide 5%;

[0024] Sodium lauryl sulfate 2%;

[0025] Polyvinylpyrrolidone 1%;

[0027] The rest is water.

[0028] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0029] A. Weigh cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium lauryl sulfate, polyvinylpyrrolidone, sodium salt and water according to the formula, and set aside ;

[0030] B. Add the cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium salt and water weighed in step A into a reaction kettle with a stirring paddle and stir , and heated to 30°C;

[0031] C. Add the sodium lauryl sulfate an...

Embodiment 2

[0034] An anti-condensate oil and anti-salt foaming agent is composed of the following raw materials in terms of mass percentage:

[0035] Cocamidopropyl Hydroxysultaine 30%;

[0036] Erucamide propyl betaine 20%;

[0037] Lauramide propylamine oxide 15%;

[0038] Sodium Lauryl Sulfate 5%;

[0039] Polyvinylpyrrolidone 2%;

[0040] Sodium chloride 2%;

[0041] The rest is water.

[0042] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0043] A. Weigh cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium lauryl sulfate, polyvinylpyrrolidone, sodium salt and water according to the formula, and set aside ;

[0044] B. Add the cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium salt and water weighed in step A into a reaction kettle with a stirring paddle and stir , and heated to 30°C;

[0045] C. Add the sodium lauryl sulfate a...

Embodiment 3

[0048] An anti-condensate oil and anti-salt foaming agent is composed of the following raw materials in terms of mass percentage:

[0049] Cocamidopropyl Hydroxysultaine 25%;

[0050] Erucamide propyl betaine 15%;

[0051] Lauramide propylamine oxide 10%;

[0052] Sodium Lauryl Sulfate 3.5%;

[0053] Polyvinylpyrrolidone 1.5%;

[0054] Sodium chloride 1.5%;

[0055] The rest is water.

[0056] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0057] A. Weigh cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium lauryl sulfate, polyvinylpyrrolidone, sodium salt and water according to the formula, and set aside ;

[0058] B. Add the cocamidopropyl hydroxysultaine, erucamide propyl betaine, lauryl amidopropyl amine oxide, sodium salt and water weighed in step A into a reaction kettle with a stirring paddle and stir , and heated to 50°C;

[0059] C. Add the sodium lauryl sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com