A kind of anti-condensate oil anti-salt foam discharge agent and preparation method thereof

A technology for anti-condensate oil and salt bubbles, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high liquid-carrying capacity of foaming agent and poor foaming effect, so as to enhance stability and reduce The effect of drainage, good liquid carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

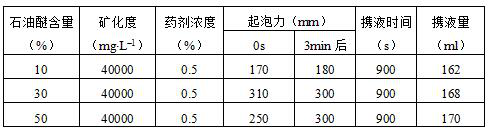

Image

Examples

Embodiment 1

[0020] An anti-condensate anti-salt foam discharge agent is composed of the following raw materials by mass percentage:

[0021] Cocamidopropyl hydroxysulfobetaine 20%;

[0022] Erucamidopropyl Betaine 10%;

[0023] Lauramidopropylamine oxide 5%;

[0024] Sodium Lauryl Sulfate 2%;

[0025] Polyvinylpyrrolidone 1%;

[0027] The rest is water.

[0028] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0029] A. Weigh cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauramidopropyl amine oxide, sodium lauryl sulfate, polyvinyl pyrrolidone, sodium salt and water according to the formula, for subsequent use ;

[0030] B. Cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauryl amidopropyl amine oxide, sodium salt and water that take by weighing in step A are added in the reactor with stirring paddle, stir , and heated to 30°C;

[0031] C. add the sodium lauryl sulfat...

Embodiment 2

[0034] An anti-condensate anti-salt foam discharge agent is composed of the following raw materials by mass percentage:

[0035] Cocamidopropyl hydroxysulfobetaine 30%;

[0036] Erucamidopropyl Betaine 20%;

[0037] Lauramidopropylamine oxide 15%;

[0038] Sodium Lauryl Sulfate 5%;

[0039] Polyvinylpyrrolidone 2%;

[0040] Sodium chloride 2%;

[0041] The rest is water.

[0042] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0043] A. Weigh cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauramidopropyl amine oxide, sodium lauryl sulfate, polyvinyl pyrrolidone, sodium salt and water according to the formula, for subsequent use ;

[0044] B. Cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauryl amidopropyl amine oxide, sodium salt and water that take by weighing in step A are added in the reactor with stirring paddle, stir , and heated to 30°C;

[0045] C. add the sodium lauryl sulfa...

Embodiment 3

[0048] An anti-condensate anti-salt foam discharge agent is composed of the following raw materials by mass percentage:

[0049] Cocamidopropyl hydroxysulfobetaine 25%;

[0050] Erucamidopropyl Betaine 15%;

[0051] Lauramidopropylamine oxide 10%;

[0052] Sodium Lauryl Sulfate 3.5%;

[0053] Polyvinylpyrrolidone 1.5%;

[0054] Sodium chloride 1.5%;

[0055] The rest is water.

[0056] The preparation method of the foam discharge agent of the present embodiment, the steps are as follows:

[0057] A. Weigh cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauramidopropyl amine oxide, sodium lauryl sulfate, polyvinyl pyrrolidone, sodium salt and water according to the formula, for subsequent use ;

[0058] B. Cocamidopropyl hydroxysulfobetaine, erucamidopropyl betaine, lauryl amidopropyl amine oxide, sodium salt and water that take by weighing in step A are added in the reactor with stirring paddle, stir , and heated to 50°C;

[0059] C. add the sodium lauryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com