Underground oil and gas nozzle

An oil and gas and oil nozzle technology is applied in the field of throttling devices for high-pressure oil and gas wells, which can solve problems such as unfavorable popularization and application, and achieve the effects of increasing wellhead temperature, reducing production pressure, and reducing unloading flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

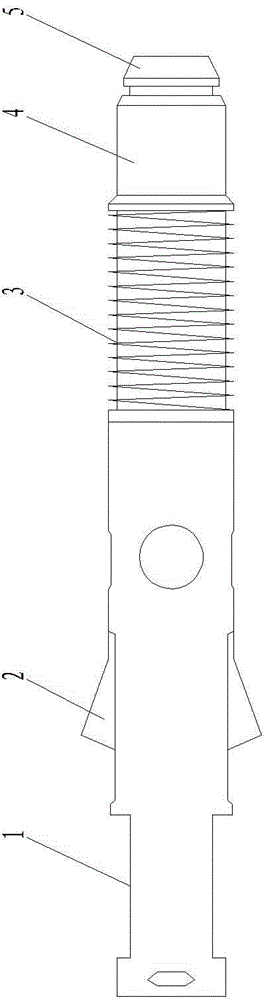

[0014] A downhole oil and gas nozzle according to the present invention includes a hollow cylindrical body 1, one end of the body 1 is provided with a nozzle 4, the nozzle 4 is a hollow cone, and the nozzle 4 is also provided with a bottom cap 5 matching its shape .

[0015] The main body 1 is further provided with a locking block 2, which is obliquely arranged on the main body 1 through a spring. The angle formed between the lock block 2 and the body 1 is α, and α is 15°.

[0016] In addition, the outer surface of the main body 1 is provided with an external thread 3 matching with the thread of the setting nipple.

[0017] When in use, the present invention is put into the setting sub-joint, the setting sub-joint is lowered to the design depth along with the completion pipe string, and then the well is opened for production. When it is necessary to change the specifications of downhole oil nozzle 4 according to the production situation of oil and gas wells, first fish it ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com