Patents

Literature

57results about How to "Increase fluid production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

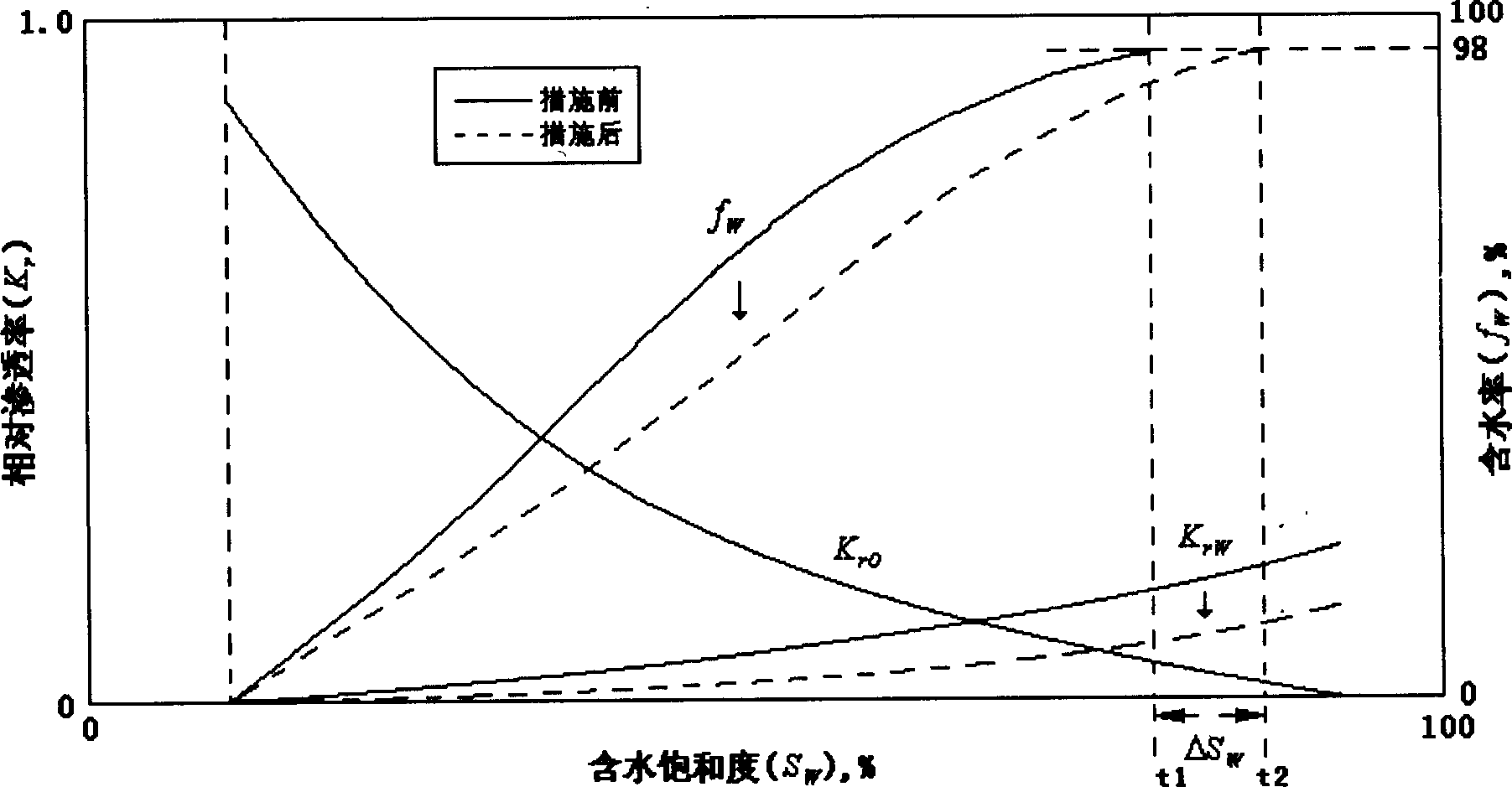

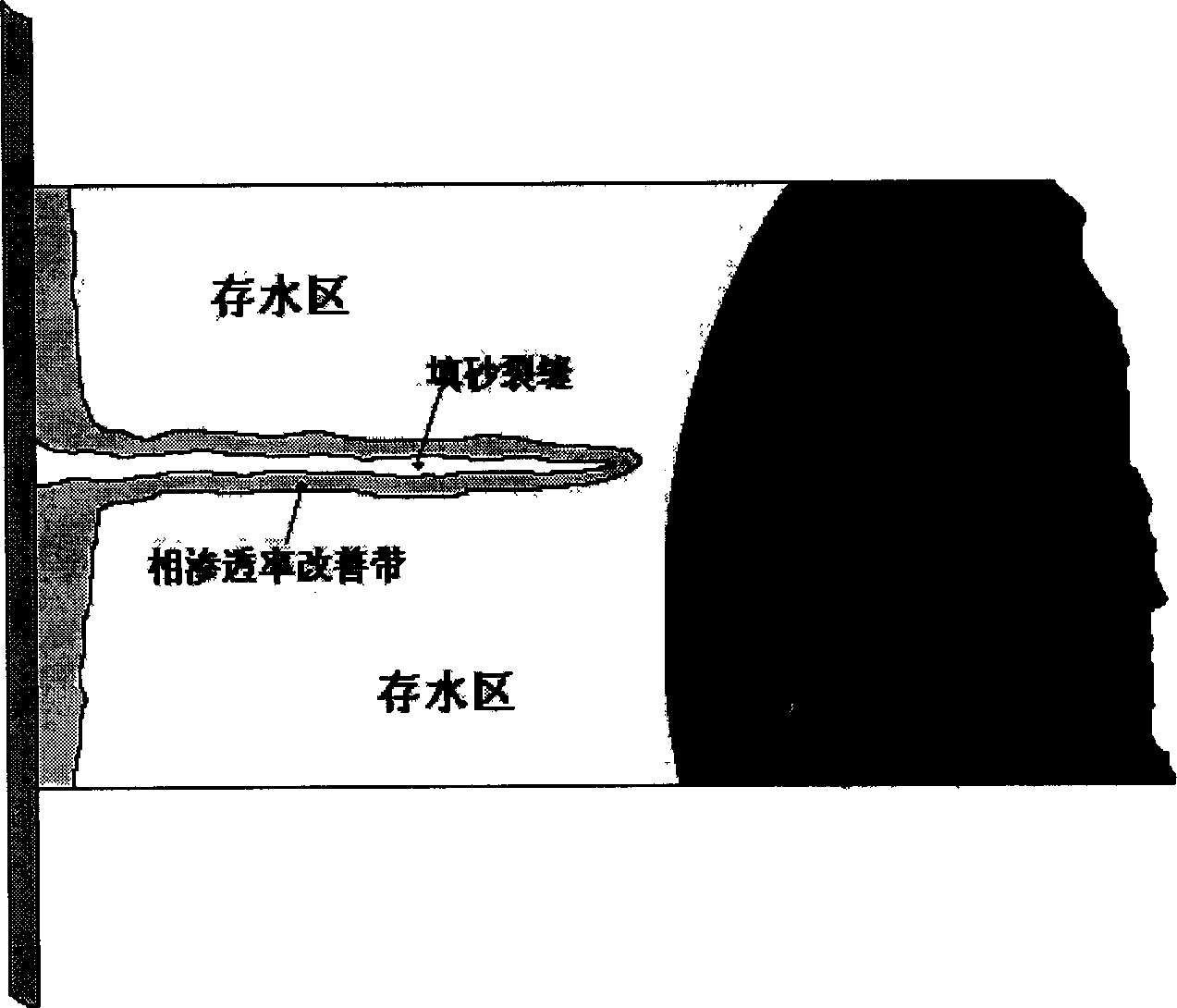

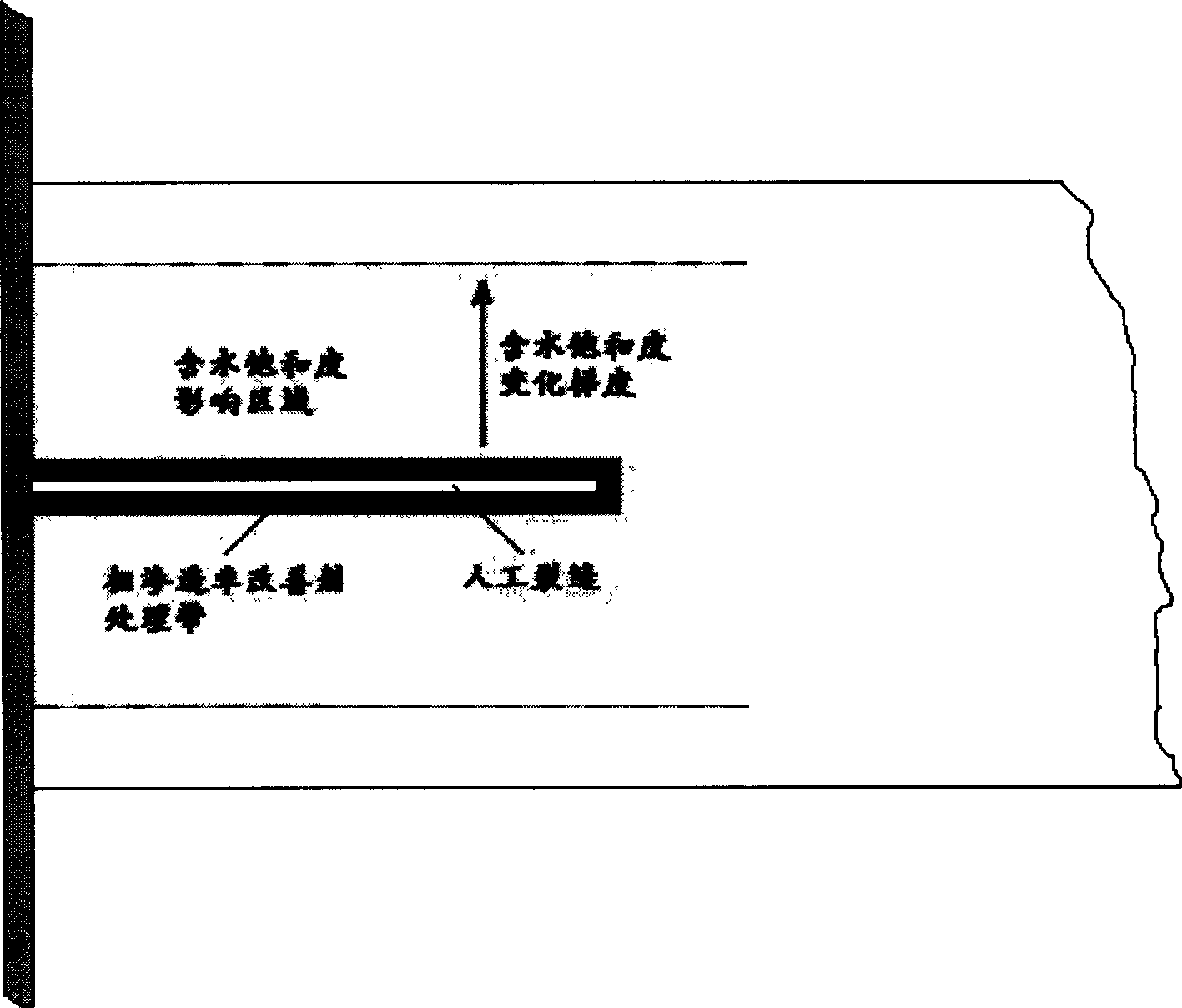

Fracturing method for improving recovering ratio by phase permeability improver

InactiveCN1614193AReduce water contentIncrease fluid productionFluid removalHydraulic fracturingOil water

A fracturing method for increasing the recovering rate of oil well by use of phase permeability improver features that the hydraulic fracturing method is used to generate artificial crack and the phase permeability improver is filled in the stratum via oil well to form a phase permeability improved zone around the artificial crack, which has the selectivity to the osmotic oil-water flow, reducing the relative permeability of water.

Owner:DAQING OILFIELD CO LTD

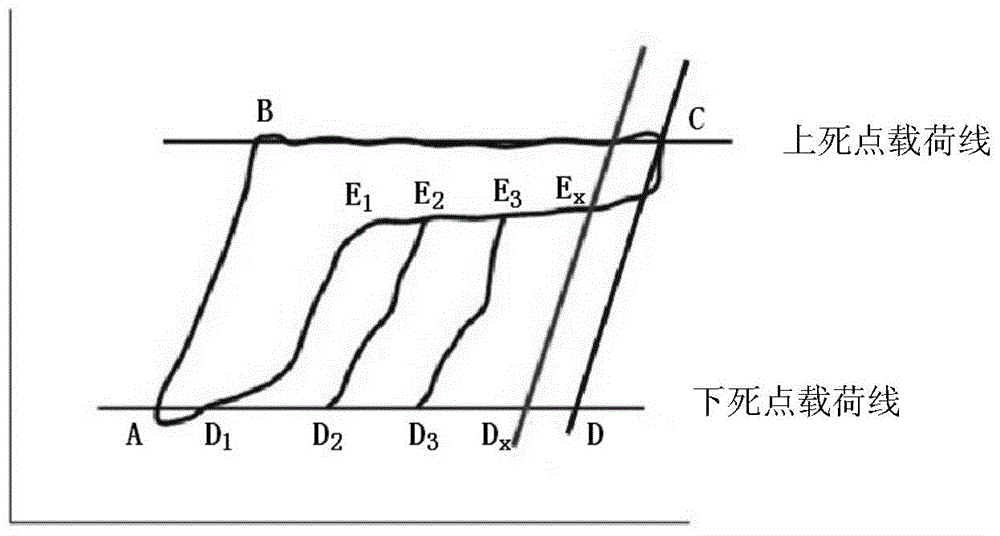

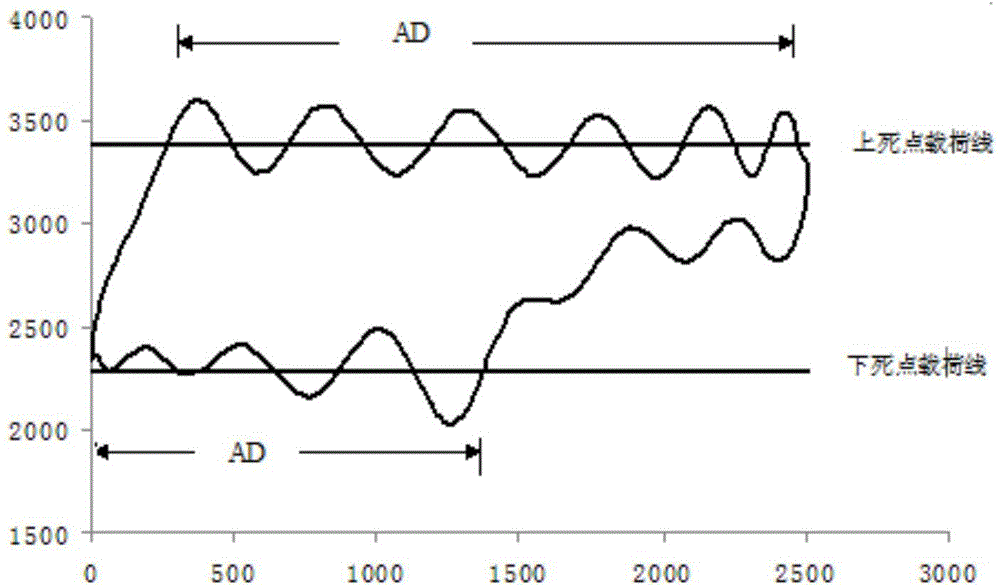

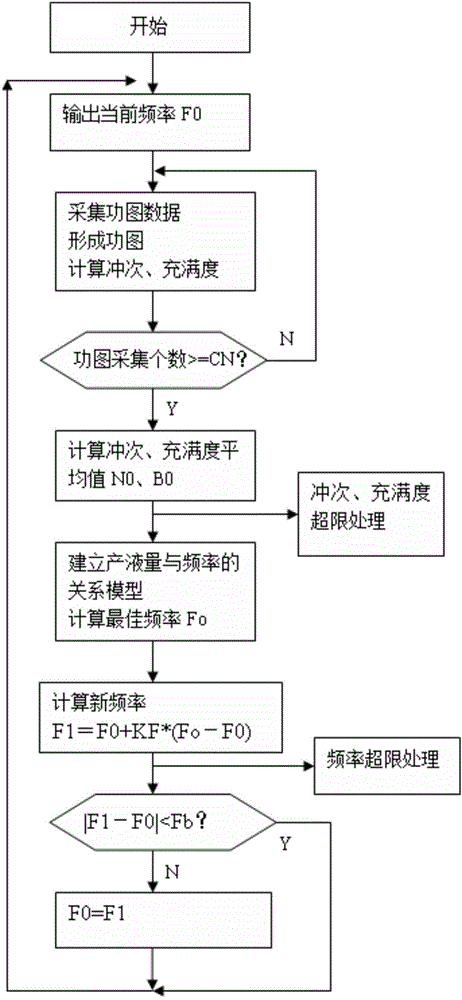

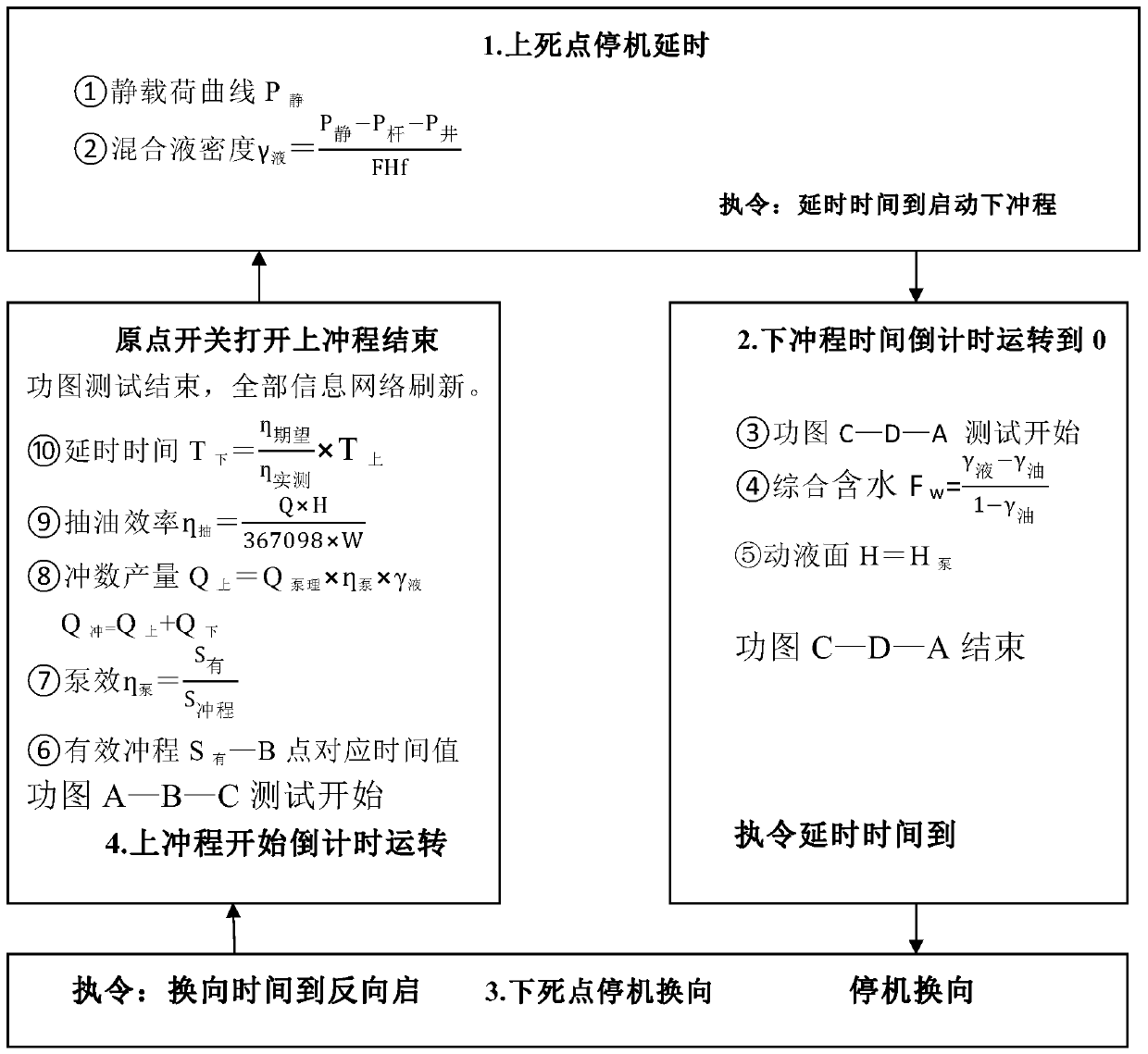

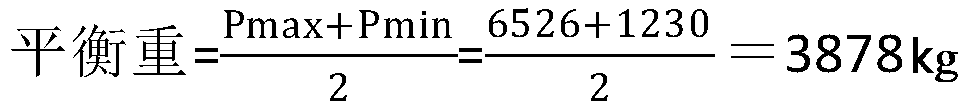

Optimum stroke process suitable for super-low permeability reservoir digital oil pumping unit

ActiveCN105093930AExtended service lifeLow maintenanceFluid removalAdaptive controlOil fieldEnergy conservation

Provided is an optimum stroke process suitable for a super-low permeability reservoir digital oil pumping unit, belonging to the technical field of oil field digitalization. The process includes that the oil pumping unit stroke is determined and adjusted; and the optimum stroke is automatically found based on the production capacity of an oil well under the condition of guaranteeing the production capacity, the stroke is adjusted to the minimum to achieve the optimum work state, and the self-adjustment and the remote manual adjustment can be realized. The process is particularly suitable for the condition of a super-low permeability oil field low-production well, the low-production well can be continuously pumped, the pump inspection period is prolonged, the service lives of a sucker rod and the oil pumping unit are prolonged, the management is convenient, and the maintenance cost is low. The process can be applied to various types of oil pumping units, such as a compound oil pumping unit or a camber beam variable torque oil pumping unit, the low-stroke operation can be realized, the oil pumping unit stroke is changed by adjusting the variable frequency, the pump fullness and the approximate production capacity are calculated to make the production capacity the largest, and meanwhile, energy can be saved.

Owner:PETROCHINA CO LTD

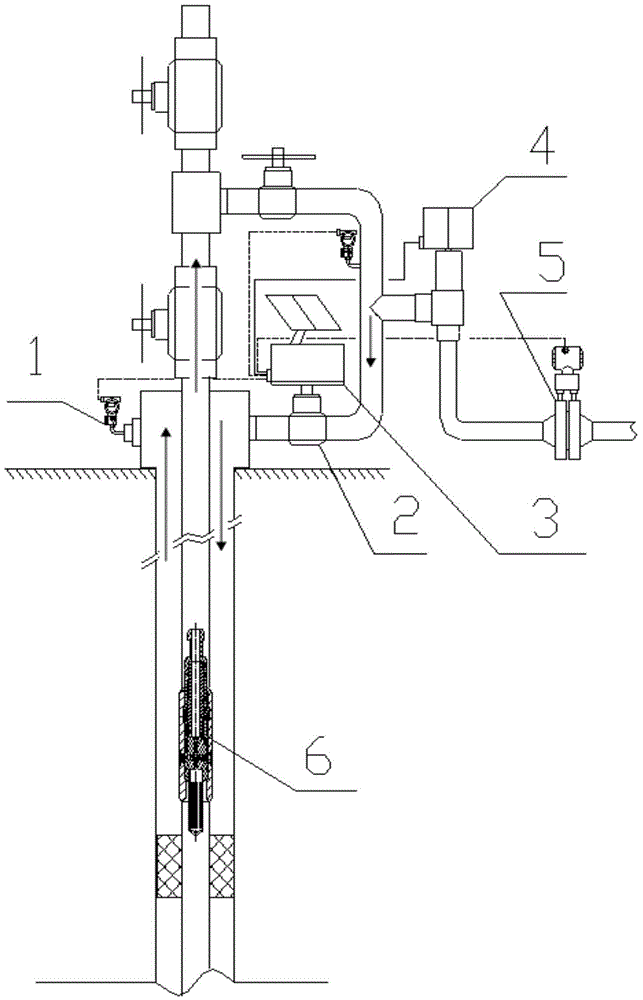

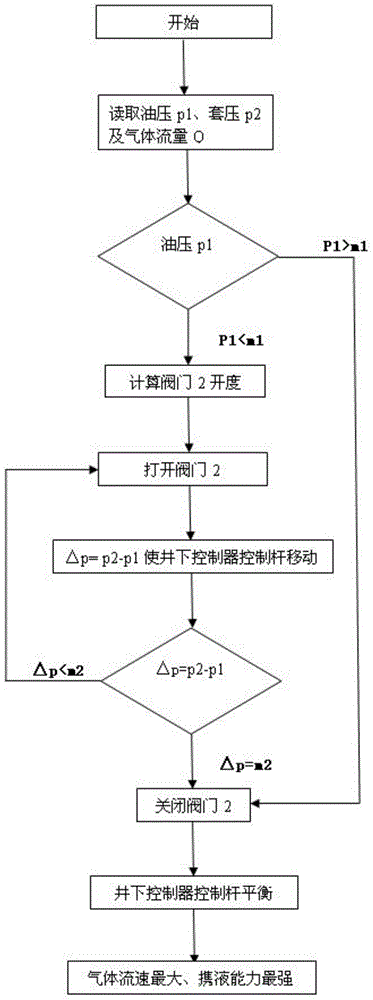

Intelligent production adjusting method and device for gas wells

ActiveCN105089572AChange flow rateGood drainage and gas recoveryFluid removalProduction rateOil pressure

The invention provides an intelligent production adjusting method and device for gas wells and belongs to the technical field of oil field digitization. When oil pressure is higher than a certain pressure value P1, the liquid carrying capability of gas is in a strong state, a control valve is in a circulation-closed state, and at the moment, an underground controller has the maximal opening degree; when the oil pressure is lower than a certain pressure value P2, the liquid carrying capability of gas is poor, or gas cannot carry liquid, and at the moment, the opening degree of the throttling hole of the underground controller is controlled to increase the gas flow rate so as to enhance the liquid carrying capability; and. therefore, the oil pressure value and the casing pressure value of a pressure gauge are read, a reasonable valve opening degree is calculated in combination with the gas production rate, a control box sends a command to the control valve to enable the control valve to reach an appropriate opening degree, a control rod of the underground controller, of which the left face receives a smaller stress than the right face, moves leftwards till a balance is achieved, and the opening degree of the throttling hole is between the maximal opening degree and the minimal opening degree, so that the gas flow rate is the maximal, and the goal of carrying the largest volume of liquid is achieved.

Owner:PETROCHINA CO LTD

Method for completing well by cementing top of expandable screen

InactiveCN103089194ALow costShorter completion cycleFluid removalSealing/packingWell cementingEngineering

The invention relates to the technical field of oilfield well completion, in particular to a method for completing a well by cementing the top of an expandable screen. The method comprises the following steps of: running a casing string comprising a casing tail pipe, a drilling plug-free system and the expandable screen into the well, performing cementing operation on the top of the expandable screen, and running an expansion diameter variation device to expand the expandable screen to cling to the wall of the well, wherein a packing rubber sleeve, an inner pipe device, a cementing hole and a blind plate are machined on the drilling plug-free system. Compared with the conventional screen, the expandable screen has the advantage that the external diameter of the expandable screen is increased after the expandable screen is expanded to enlarge an open area between formation fluid and a shaft and increase a fluid inlet volume, so that the fluid yield of a single well can be improved; and in addition, the high expandability of the expandable screen is used for forming a sand prevention screen system, gravels are not required to be filled into a horizontal well, and when a perforation tunnel or the well is blocked by formation sand to reduce the yield, the perforation tunnel is not required to be pre-filled, so that the repeated operation of sand prevention and well washing is eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

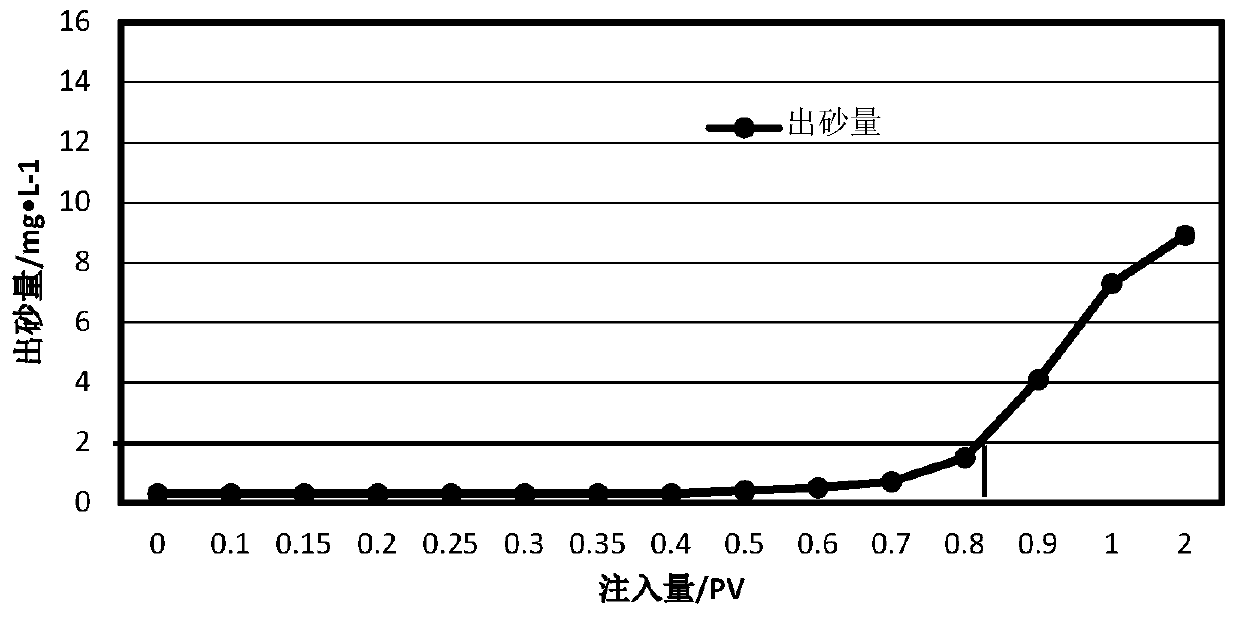

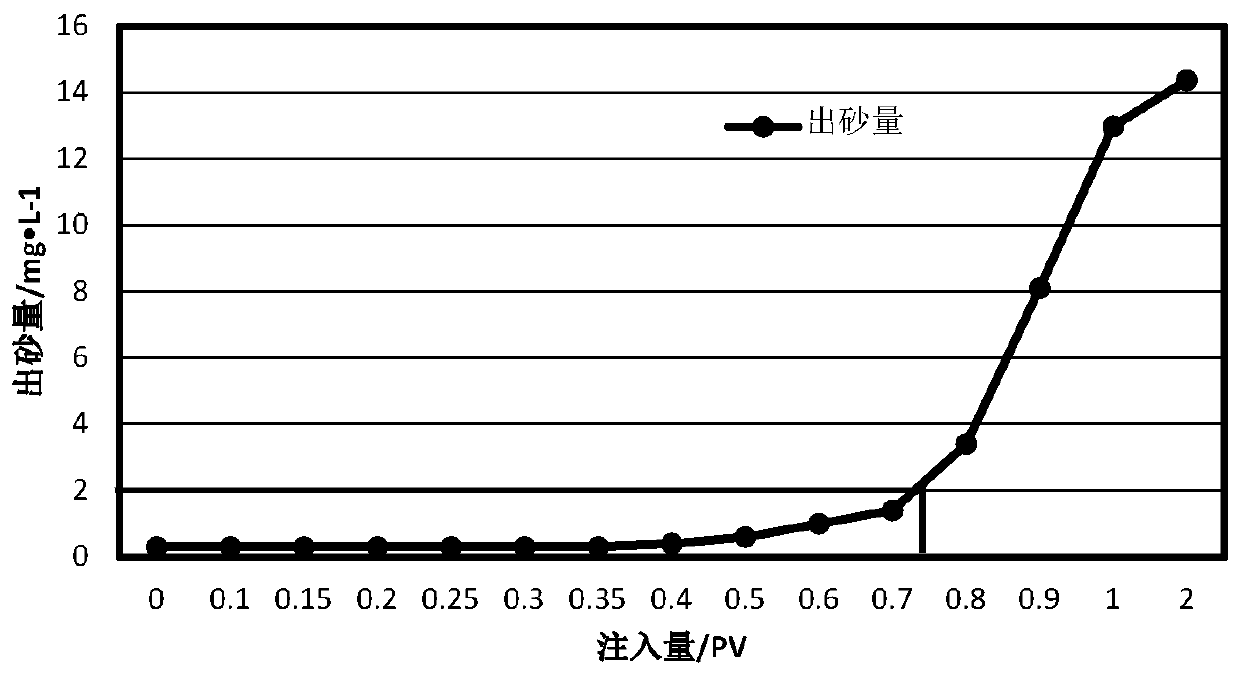

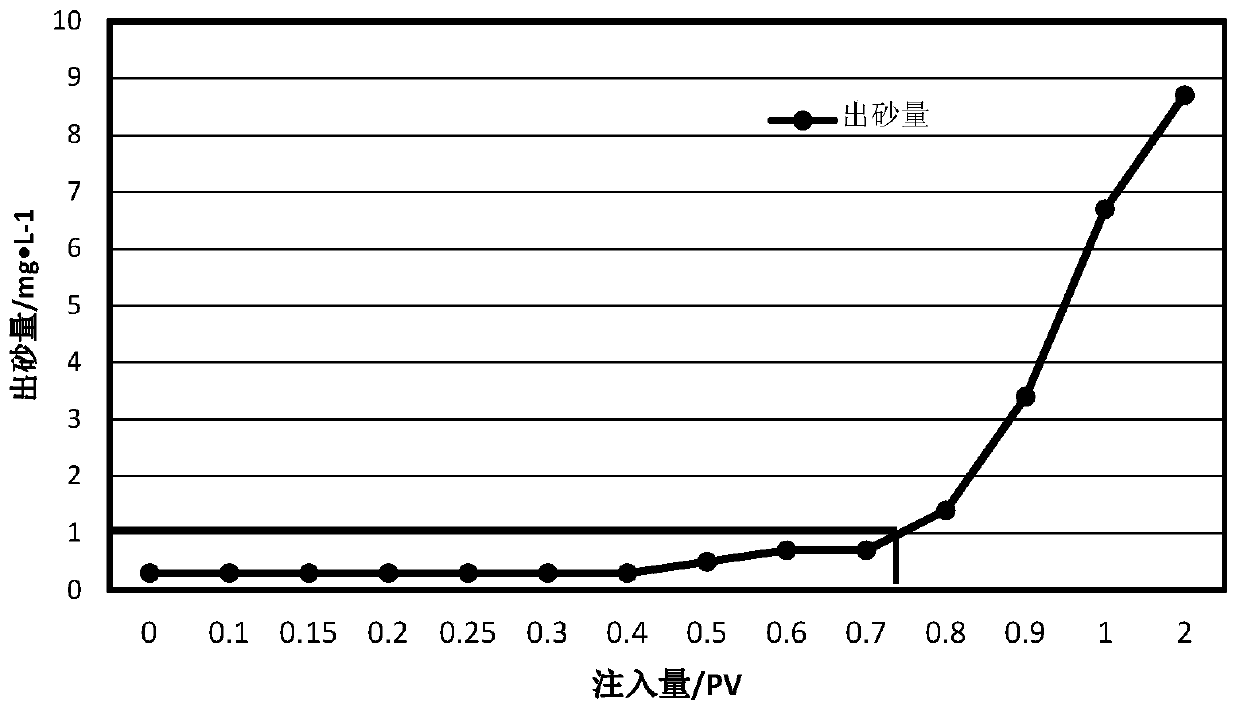

Microbial in-situ sand consolidation method for loose sandstone reservoir

The invention belongs to the technical field of microbial oil recovery, and in particular relates to a microbial in-situ sand consolidation method for a loose sandstone reservoir. The method comprisesthe following steps: screening a test block; preliminarily determining sand consolidation functional microorganisms and nutrients thereof; preliminarily determining sand consolidation functional microorganisms and nutrients thereof; preliminarily determining sand consolidation functional microorganisms and the injection amount of nutrients thereof; determining sand consolidation functional microorganisms and the injection amount of nutrients thereof; determining sand consolidation functional microorganisms and the injection rate of nutrients thereof; and carrying out on-site implementation and effect evaluation. The microbial in-situ sand consolidation method has the advantages of being reasonable, simple in process, easy to operate, safe and reliable, few in input and low in cost. Meanwhile, the sand production rate of the loose sandstone reservoir can be reduced effectively, the period of validity is prolonged and the liquid production capacity is improved, the sand production rateof an oil well is reduced by over 95%, the period of validity is over 3 years, and meanwhile, the liquid production capacity of the block is improved by over 100%. Therefore, the microbial in-situ sand consolidation method has a wide on-site application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

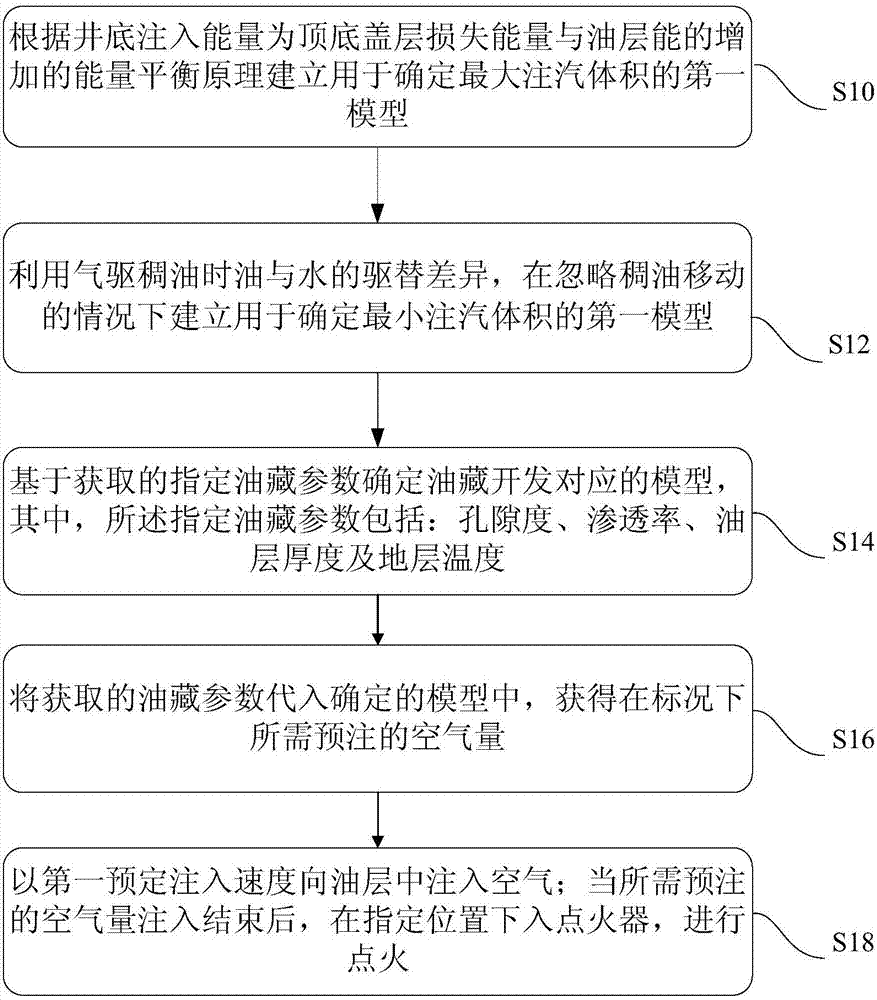

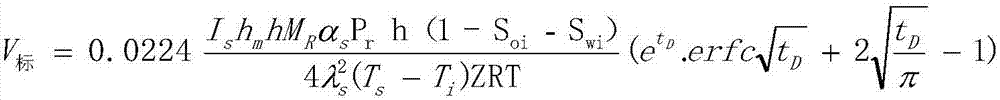

Oil extracting method adopting air pre-injecting

ActiveCN106869886AEnhanced convective heat transferEfficient developmentFluid removalPorosityEnergy balancing

The invention discloses an oil extracting method adopting air pre-injecting. The method comprises the following steps that a first model used for determining the largest steam-injection volume is built according to the energy balance principle that down hole injected energy is the sum of top-bottom cap rock lost energy and increased energy of an oil layer; a second model used for determining the minimum steam-injection volume is built through the displacement difference between oil and water when thickened oil is flooded by the air under the condition that thickened oil movement is ignored; the model corresponding to oil reservoir exploitation is determined on the basis of obtained designated oil reservoir parameters which comprise the porosity, the permeability, the oil layer thickness and the formation temperature; the obtained oil reservoir parameters are substituted into the determined model, and the needed air pre-injecting quantity is obtained under the standard condition; air is injected into the oil layer at a first preset speed; and after the needed air pre-injecting quantity is achieved, an igniter is dropped to a designated position to conduct igniting. According to the oil extracting method adopting air injecting, fireflood exploiting can be effectively applied to the field of thickened oil reservoirs, so that a thickened oil reservoir, in a water logging state, of a main oil-producing layer is effectively exploited.

Owner:PETROCHINA CO LTD

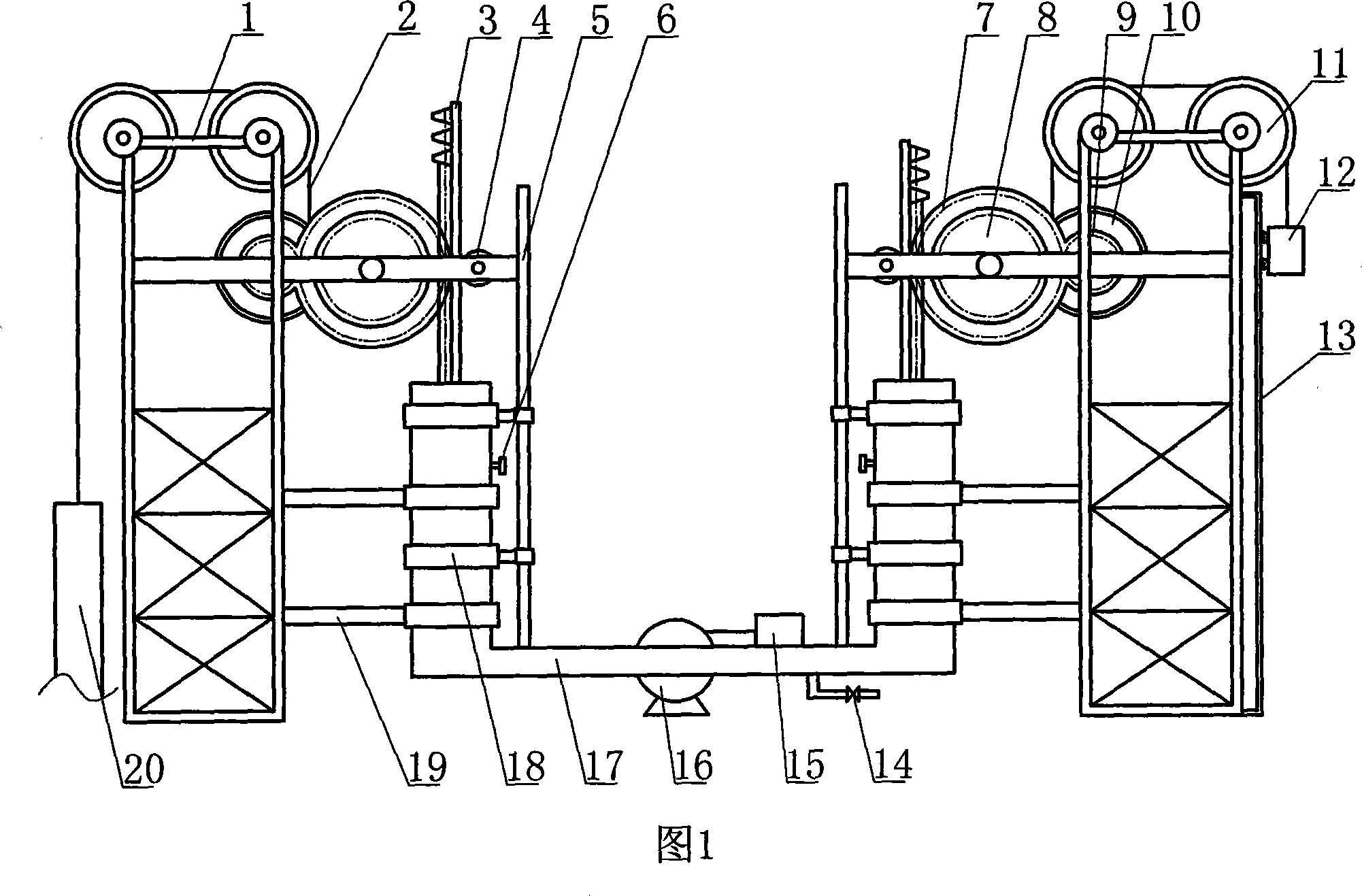

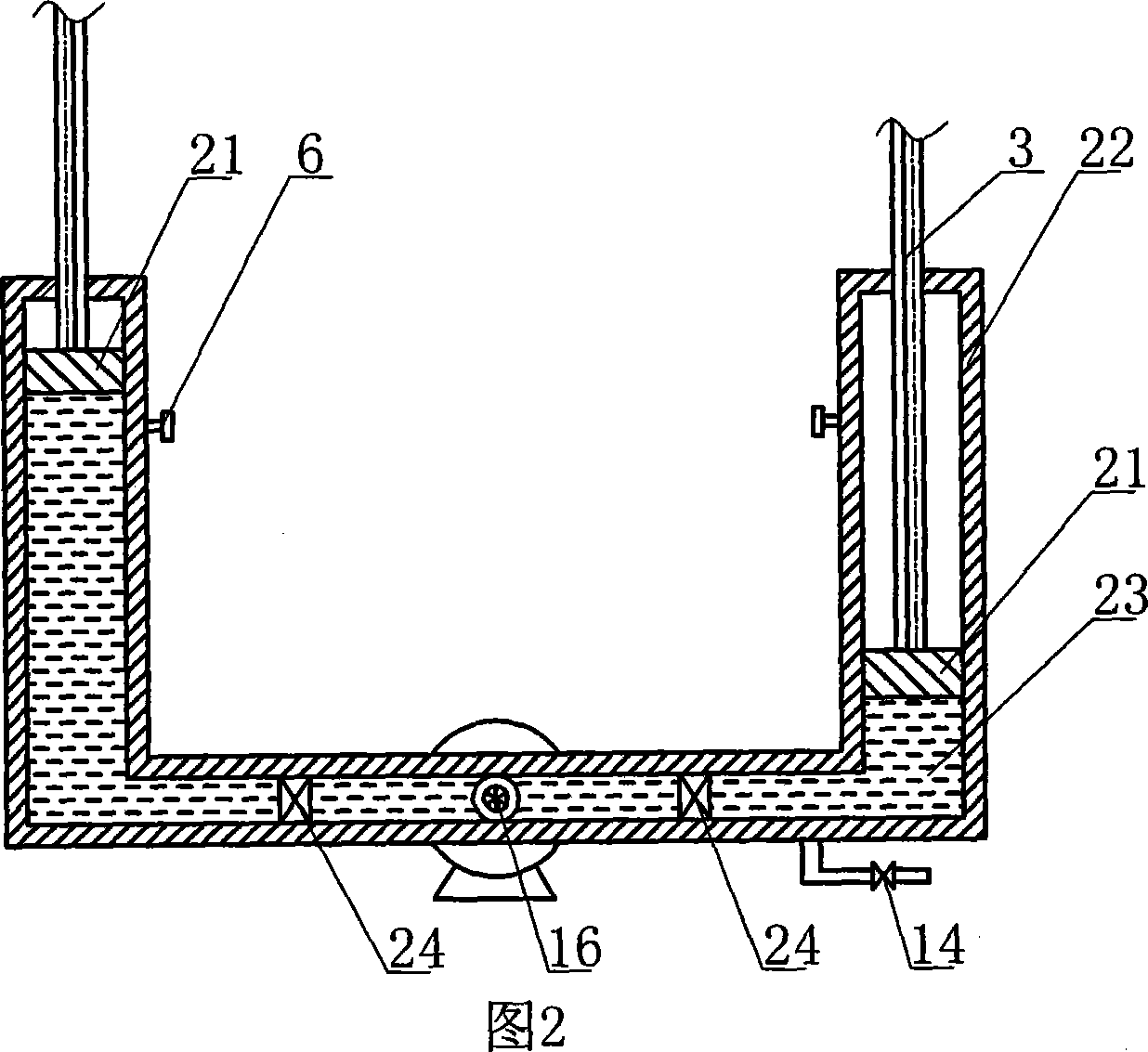

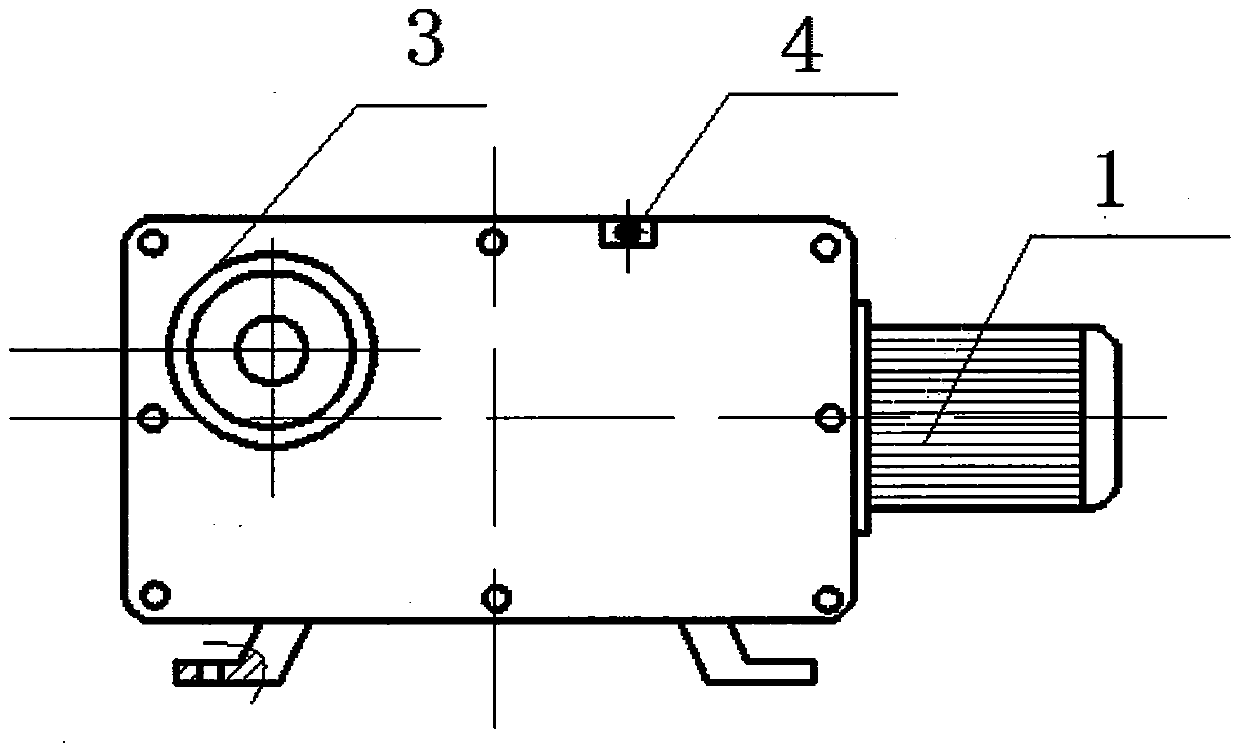

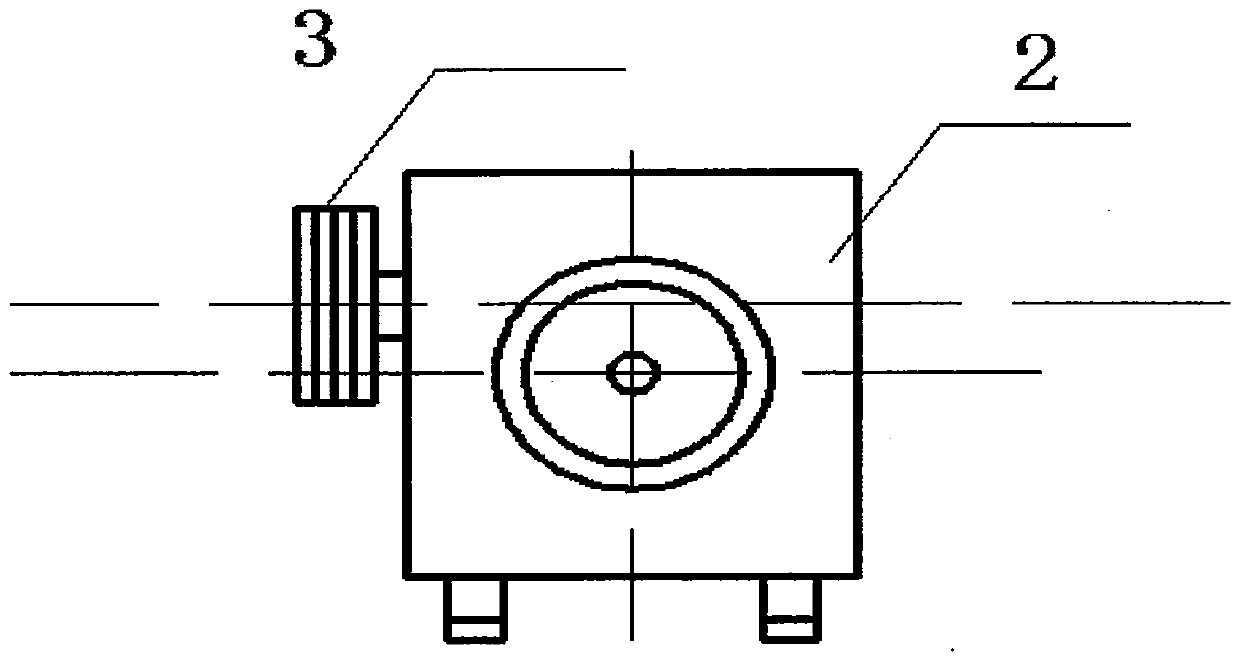

Stroke adjustable energy-saving hydraulic pumping unit

InactiveCN101078340AAdjustable strokeAdjustable stroke timesFluid removalFluid gearingsPunchingHydraulic pump

The invention relates to an energy-saving hydraulic oil pumping unit with adjustable stroke used in oil field, comprising frame, gear group, hydraulic transmission mechanism, rack, head sheave, suspended-weight rope and oil pumping bar. Two frames are set at two sides of hydraulic transmission mechanism symmetrically. A gear group and two head sheaves are set on each frame. Two gear groups are mated with racks set at two ends of hydraulic transmission mechanism respectively. The gear group draws the oil pumping bar through the suspended-weight rope and the head sheave. Thereinto, the hydraulic transmission mechanism comprises communicating vessel, piston and hydraulic pump. A hydraulic pump is fixed in the communicating vessel and two pistons are set in cavities at two ends of communicating vessel respectively. Driving liquid is poured between two pistons in cavities of communicating vessel. The invention is provided with simple structure, scientific and reasonable design, adjustable stroke and punching time, convenient maintenance, dismounting and use, safe operation, high liquid production volume, little energy consumption and low operating cost. It is also provided with higher innovation.

Owner:丁长良

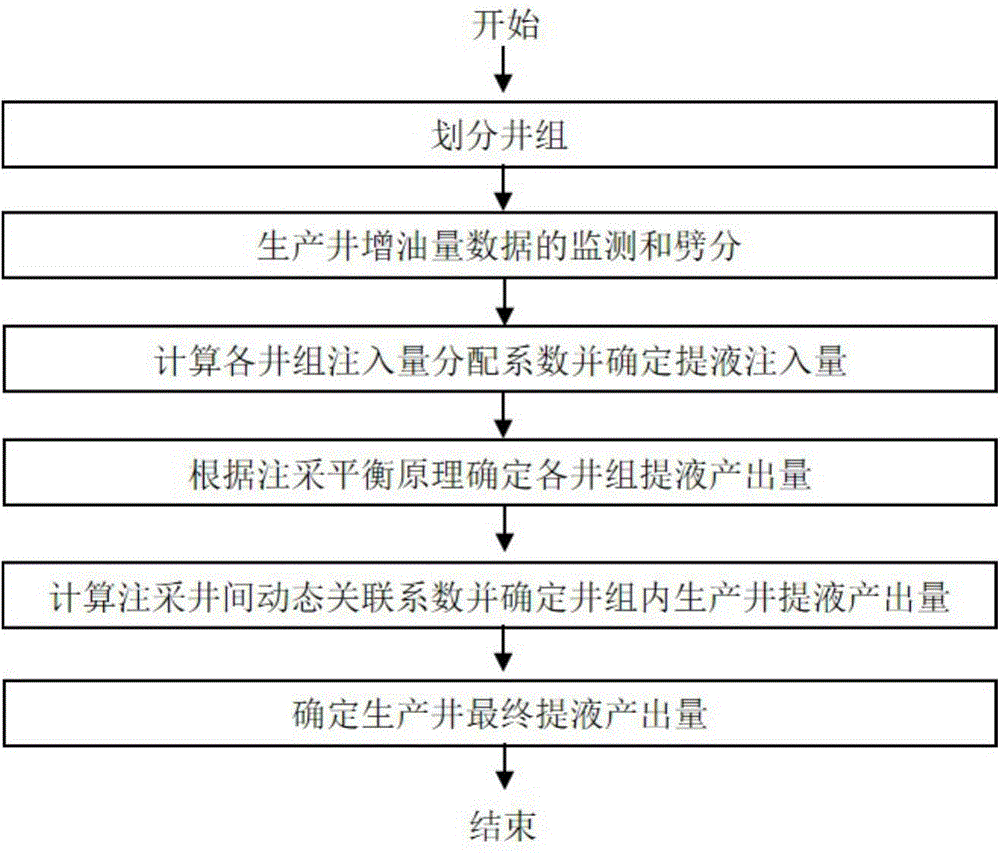

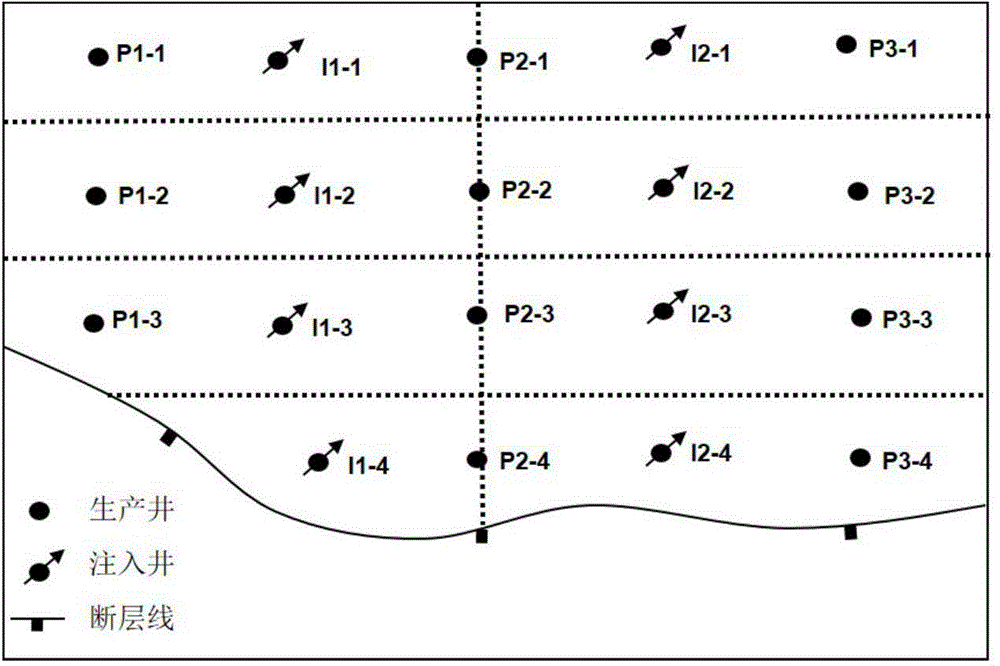

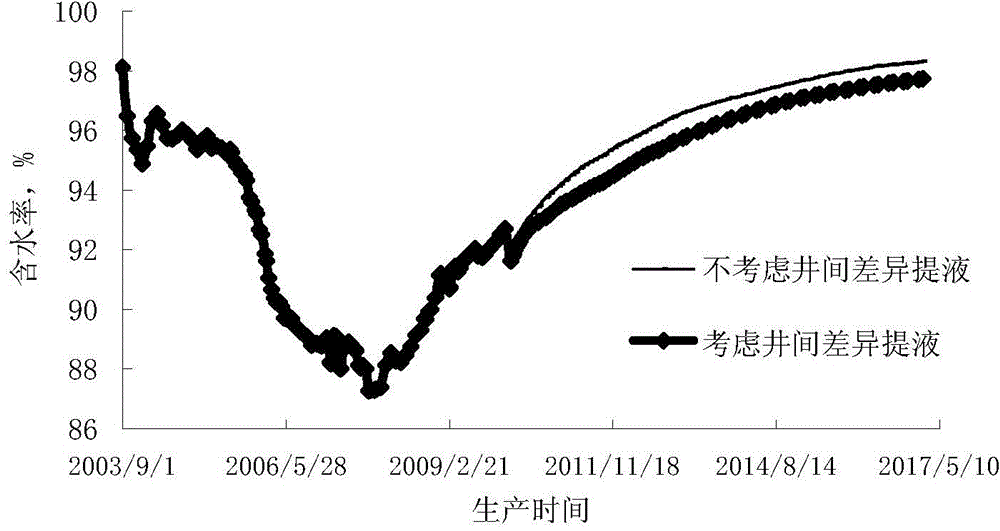

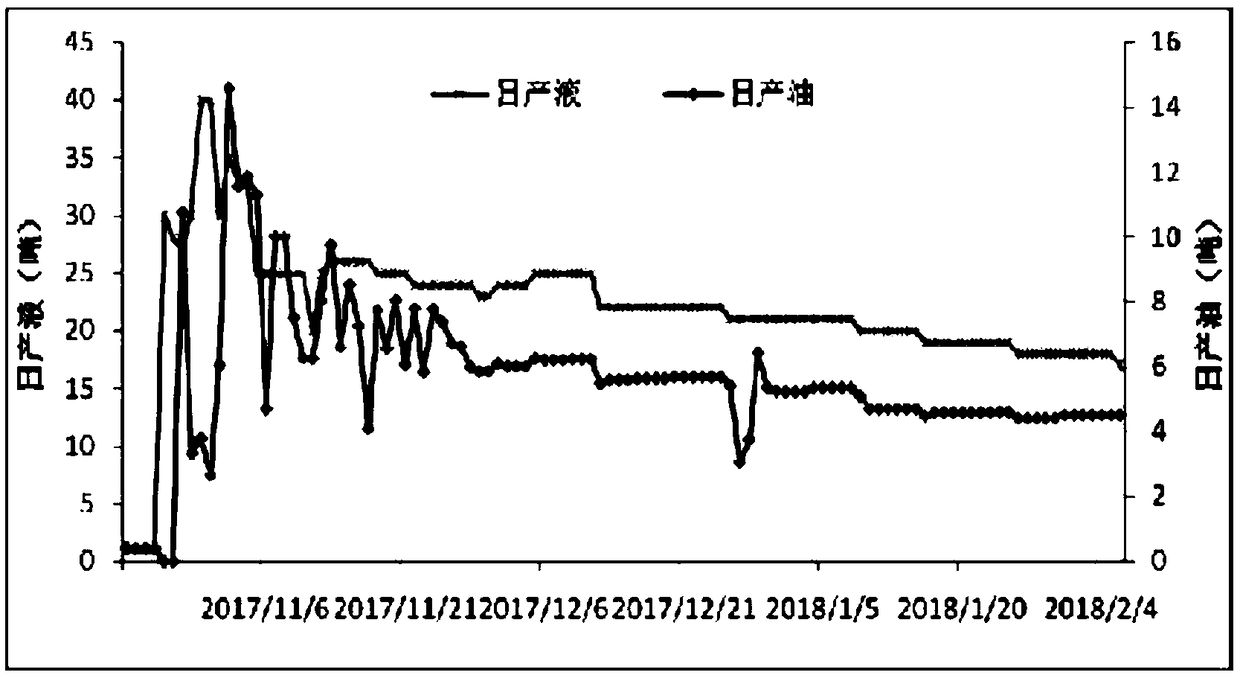

Liquid extraction method for binary compound flooding subsequent water flooding stage considering inter-well difference

ActiveCN104632160AIncrease fluid productionEasy to operateSurveyFluid removalWater floodingBinary compound

Disclosed is a liquid extraction method for a binary compound flooding subsequent water flooding stage considering inter-well difference. The liquid extraction injection quantity of each single well is optimized according to oil increment after chemical agent injection, and the liquid extraction yield of each single well is optimized according to dynamic relevancy between an injector and a producer. The effective liquid extraction is based on the difference between the oil increasing effect after binary injection and the dynamic relevancy between the injector and the producer, the liquid extraction injection quantity is distributed according to the oil increasing effect of each well group after binary injection, larger liquid extraction injection quantity is distributed for the well with better oil increasing effect of the chemical agent injection stage, single well liquid production capacity is distributed according to the inter-well dynamic relevancy in the well group based on the principle of well group injection and production balance, small liquid production capacity is distributed for a production well with high dynamic relevancy to an injection well, and conversely, large liquid production capacity is distributed for a production well with low dynamic relevancy to the injection well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

With-production without-injection-type isolated well point potential tapping and effect raising method

The invention relates to a with-production without-injection-type isolated well point potential tapping and effect raising method, which mainly solves the problem of poor developing and potential tapping effects as the existing with-production without-injection-type isolated well point is imperfect in production and injection and has no external energy source. The method is characterized by comprising the following steps: (1) a target well is optimally selected: based on the position of the isolated well point and in combination of cementing quality, perforation interpretation data, fine reservoir description results, fine residual oil research results, reservoir use condition evaluation data and the like, a target well is selected comprehensively and optimally; (2) the potential tapping time for the target well is determined: according to the dynamic development trend of the target well, a decline rule and the current production condition, the potential tapping time is determined, andpotential tapping is selected to be developed at the time when the fluid volume declines quickly and the fluid supply drops near shortage; (3) section optimization is carried out on the target well;(4) a potential tapping scheme is determined; and (5) field construction is carried out. The method can solve the problem that the isolated well is short of energy, and can thus realize the purpose ofimproving the remaining reserve recovery degree of the isolated well.

Owner:DAQING OILFIELD CO LTD +1

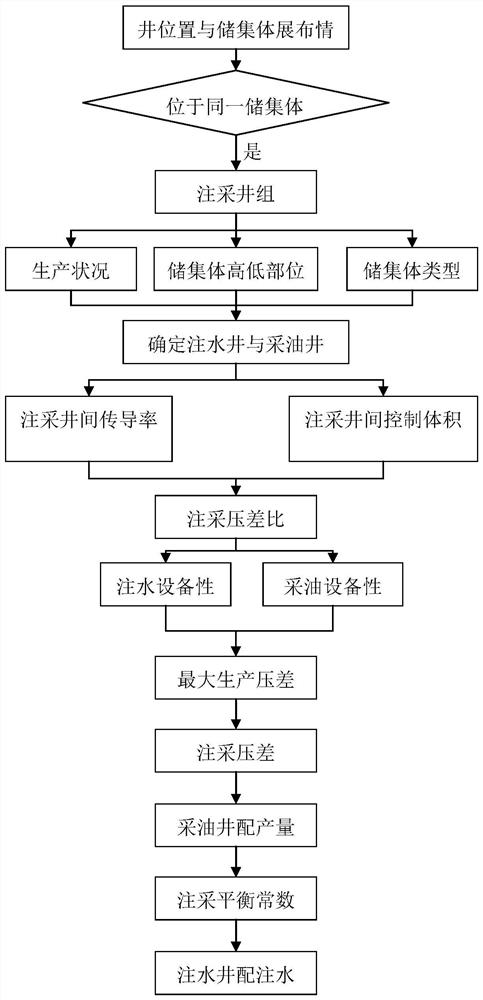

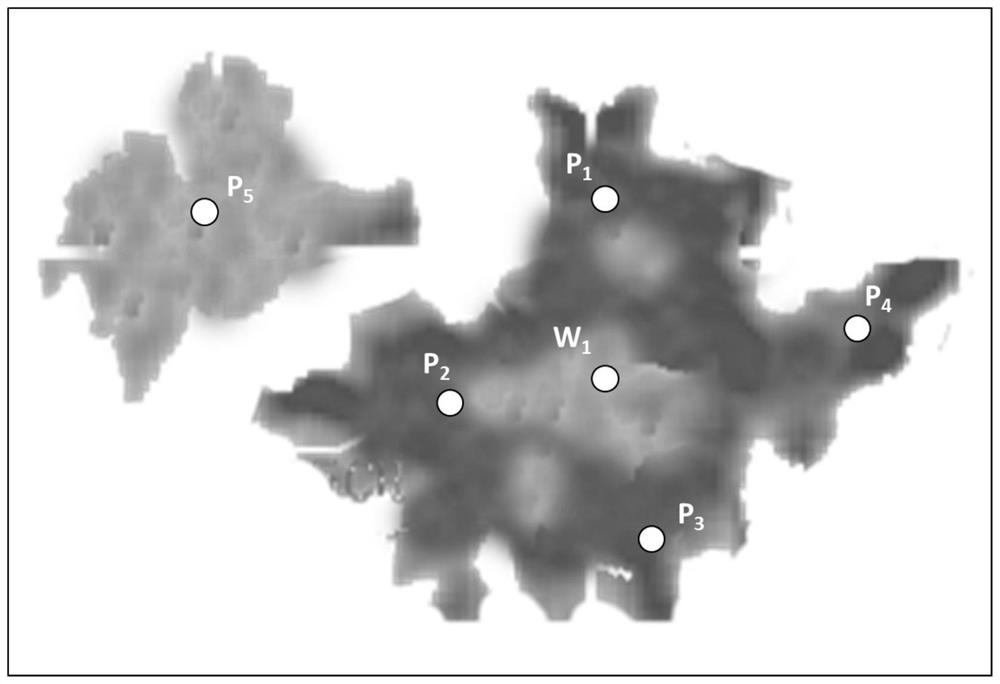

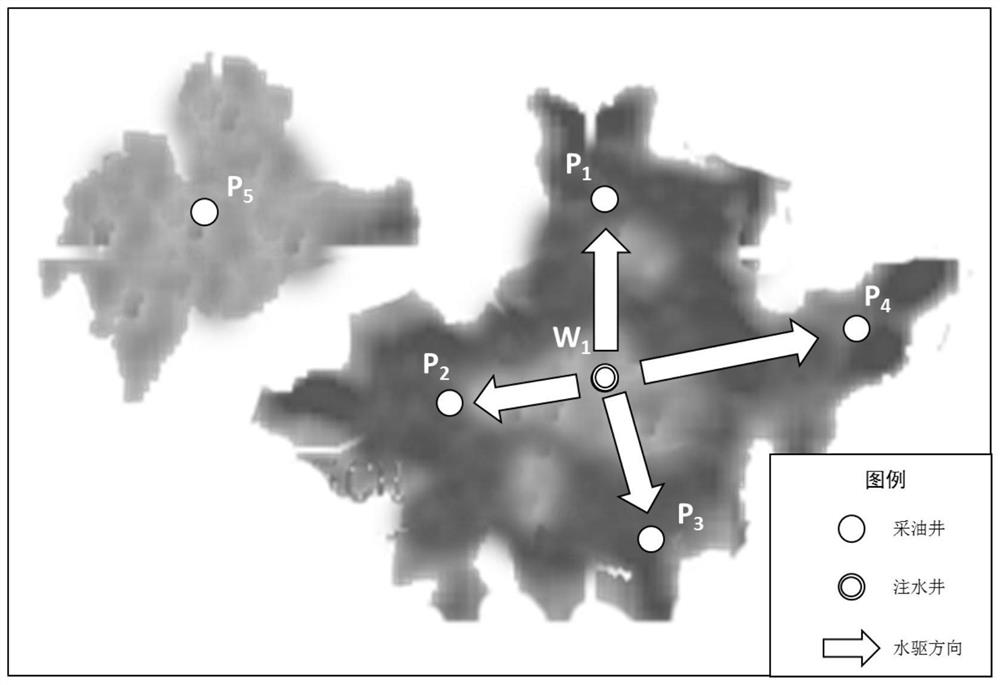

Targeted water flooding design method for fracture-vug carbonate oil reservoir

ActiveCN111663926AImprove conductivityIncrease fluid productionFluid removalThermodynamicsSoil science

The invention discloses a targeted water flooding design method for a fracture-vug carbonate oil reservoir. The method comprises the following steps that S1, an injection-production well group is determined; S2, a water injection well and oil production wells are determined; S3, the control volume and conductivity between the injection well and each production well are determined; S4, the maximumproduction pressure difference between the injection well and the production wells is determined; S5, a production pressure difference ratio between the injection well and each production well is determined; S6, a production pressure difference between the injection well and each production well is determined; S7, the liquid yield of each oil production well is determined; and S8, the maximum daily water injection amount of the water injection well is determined. According to the design method, the injection-production amount is determined according to the controlled reserves and conductivityamong the injection and production wells, the problem of unidirectional efficiency caused by water channeling of injection water along a dominant channel is avoided, and the water injection sweep efficiency and the water injection utilization rate are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

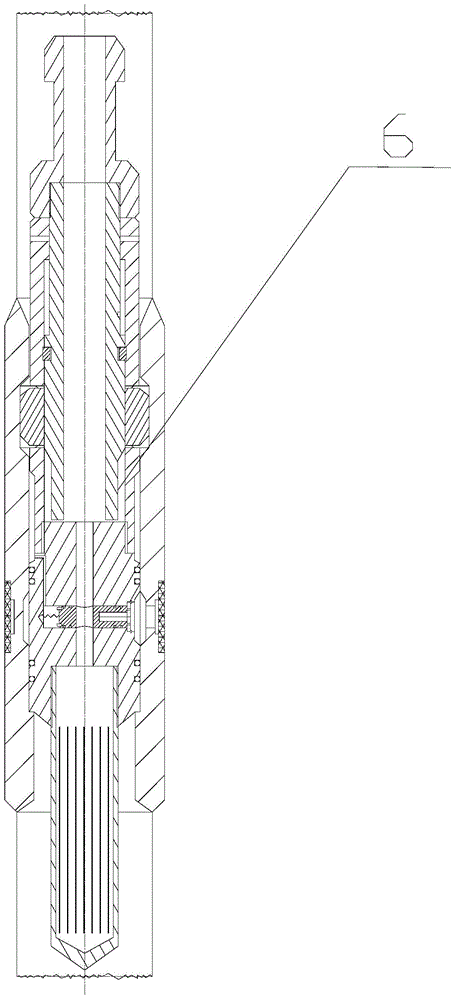

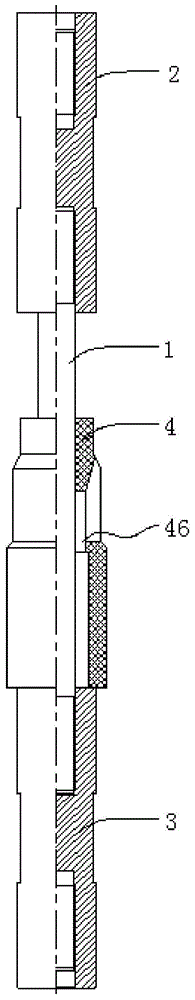

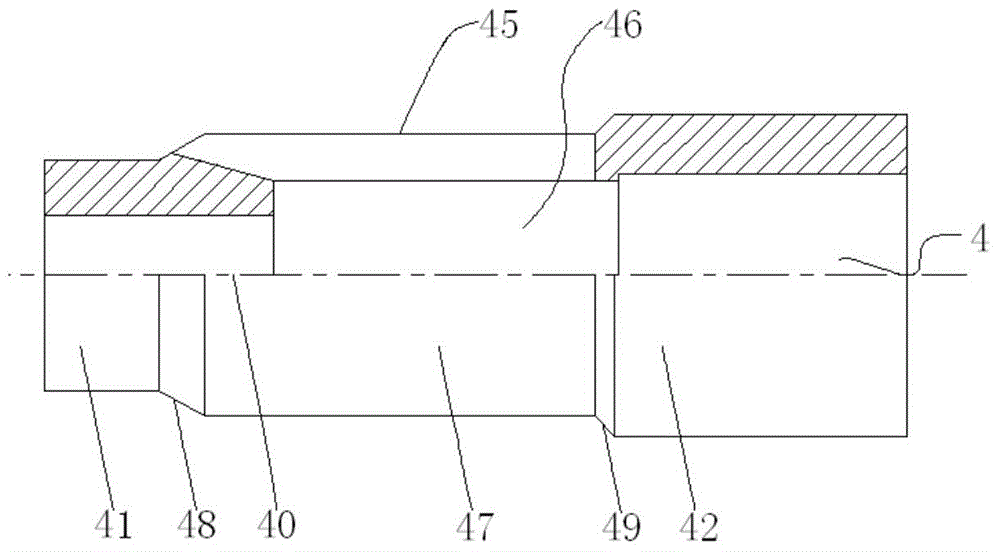

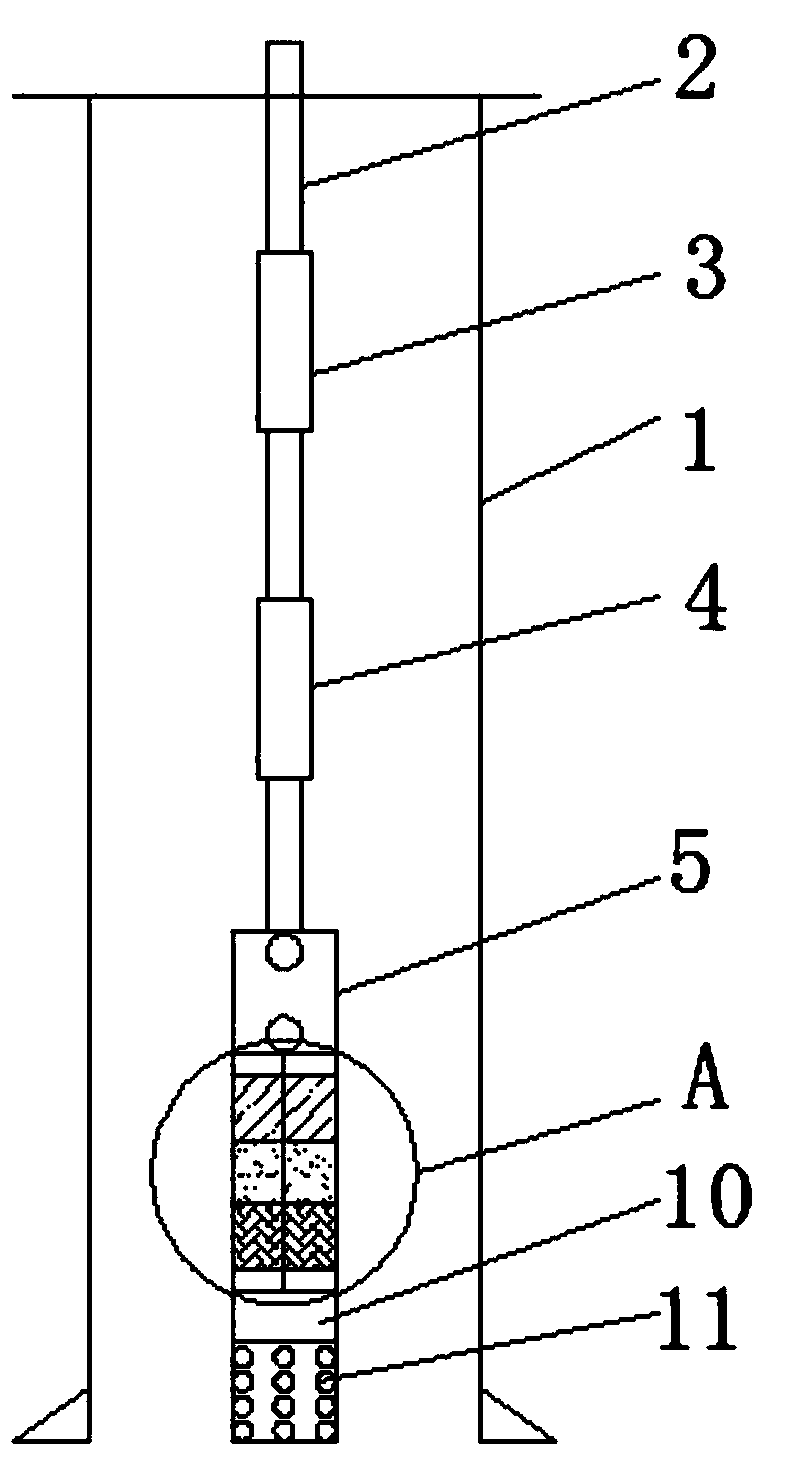

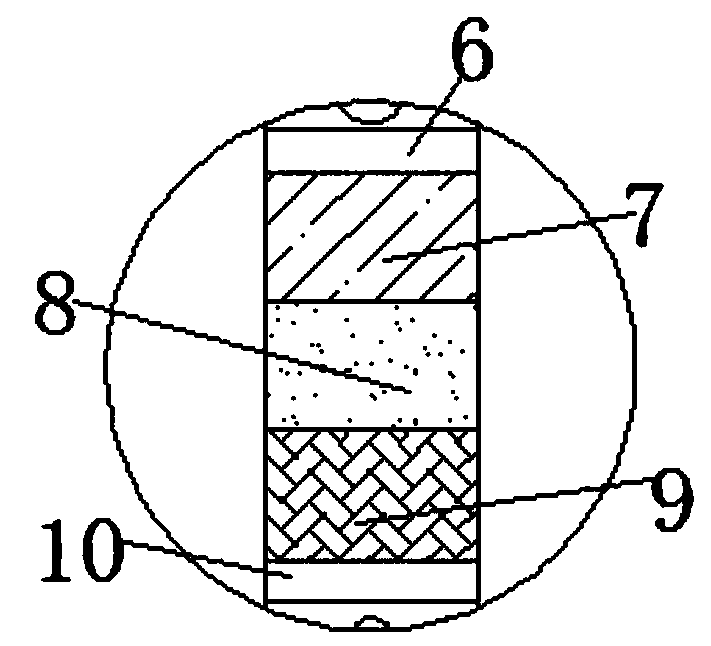

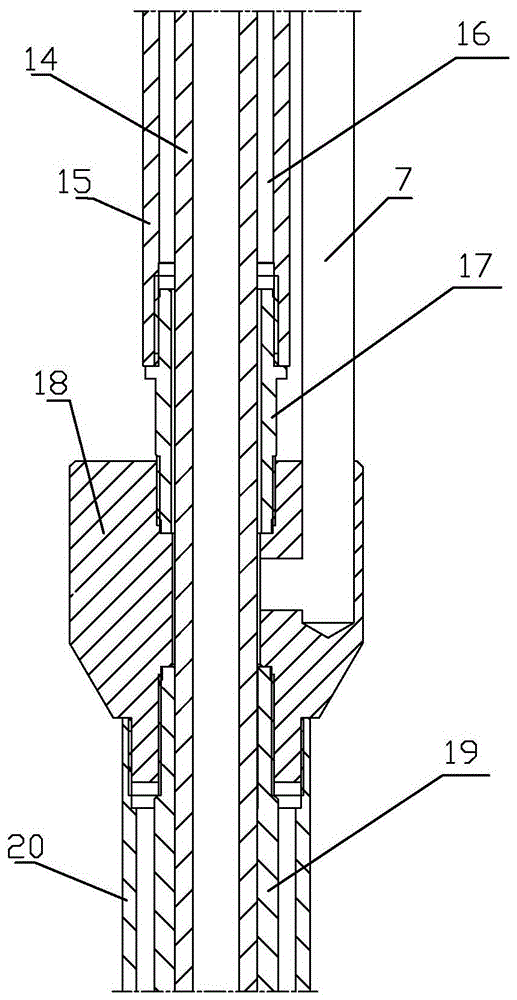

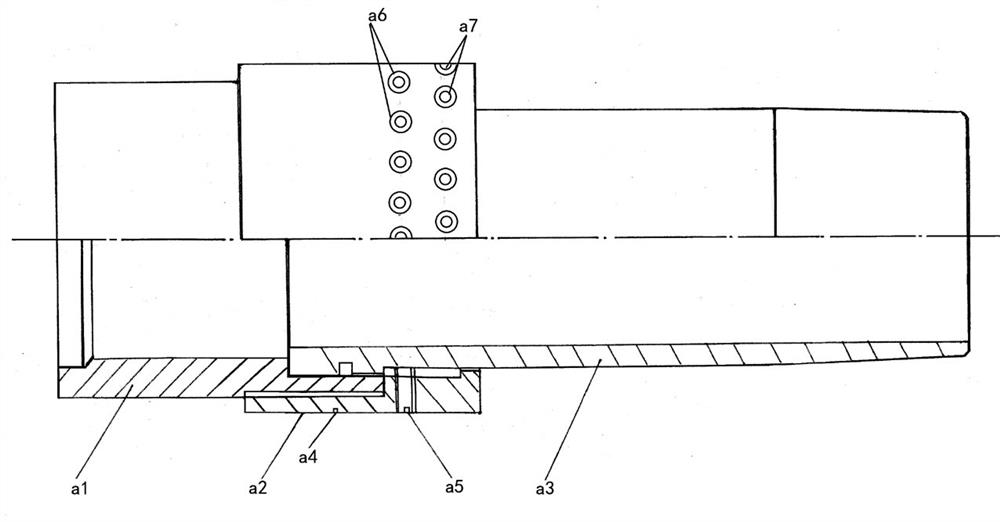

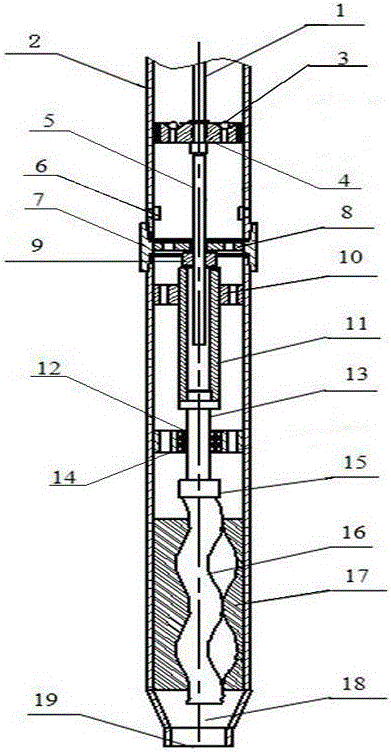

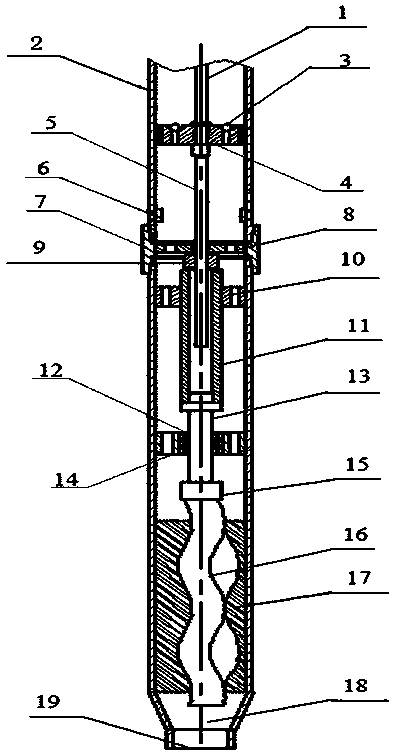

Pumping-aiding device of oil pumping rod and sand blocking oil outlet sliding sleeve thereof

The invention discloses a pumping-aiding device of an oil pumping rod and a sand blocking oil outlet sliding sleeve thereof. The pumping-aiding device of the oil pumping rod comprises a core rod, wherein the upper end of the core rod is connected with an upper connecting hoop; the lower end of the core rod is connected with a lower connecting hoop; the sand blocking oil outlet sliding sleeve can glidingly sleeve the middle part of the core rod and is a hollow step shaft; the hollow part is a step through hole; a first shaft section and a second shaft section are at least formed on the step shaft from top to bottom; the outer diameters of the first shaft section and the second shaft section are sequentially increased; a transition surface is formed between the first shaft section and the second shaft section; a lateral opening is axially and downwards formed in the place which contains the transition surface and is communicated with the step through hole to form an oil passage; the maximum inner diameter of the sand blocking oil outlet sliding sleeve is smaller than the outer diameter of the lower connecting hoop. According to the pumping-aiding device of the oil pumping rod and the sand blocking oil outlet sliding sleeve provided by the invention, pumping-aiding, sand-blocking and righting functions can be simultaneously realized, and the pumping-aiding device and the sand blocking oil outlet sliding sleeve are simple in structure.

Owner:PETROCHINA CO LTD

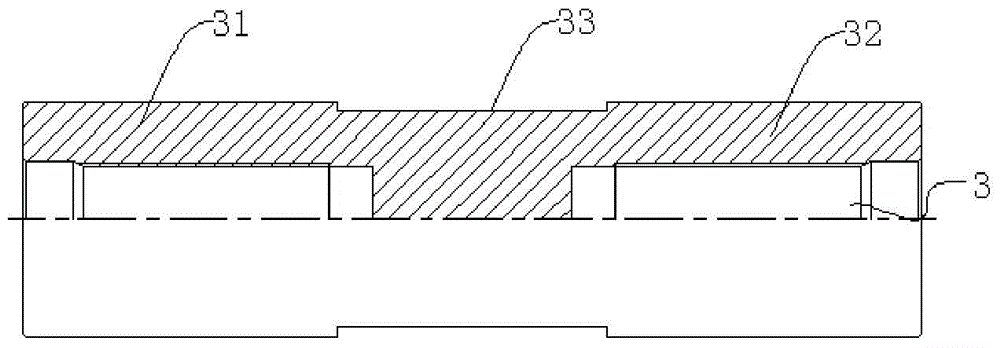

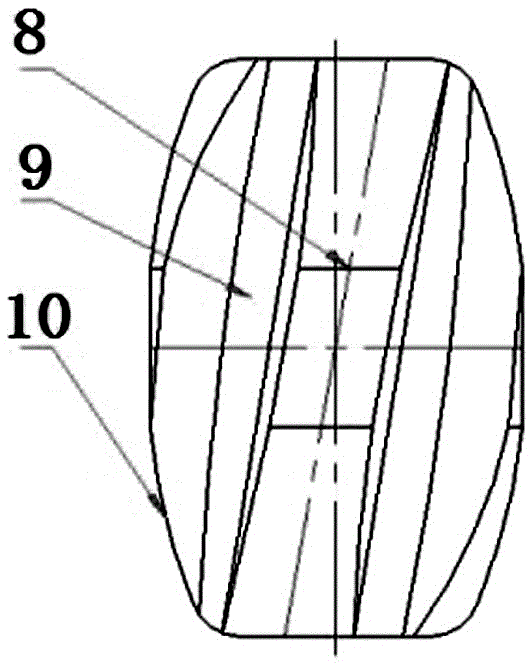

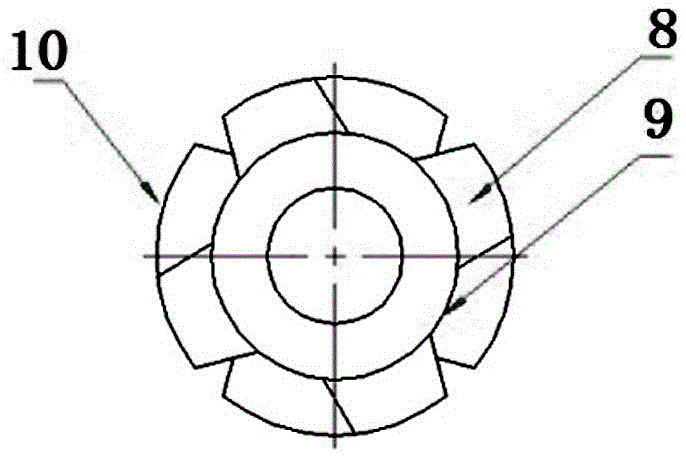

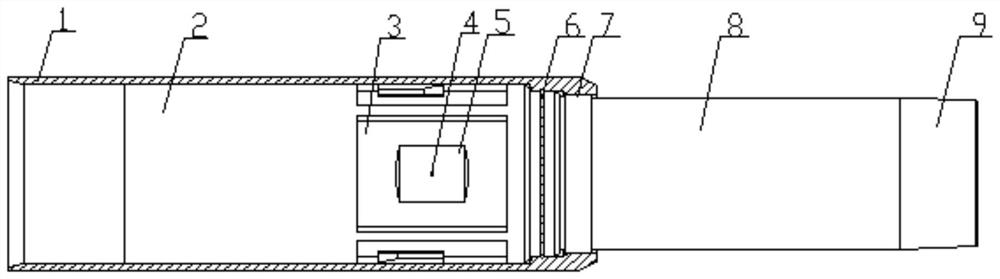

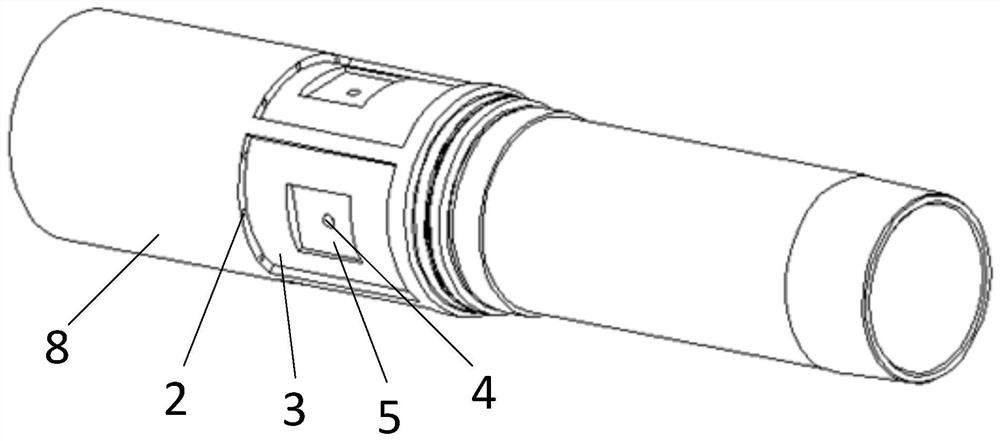

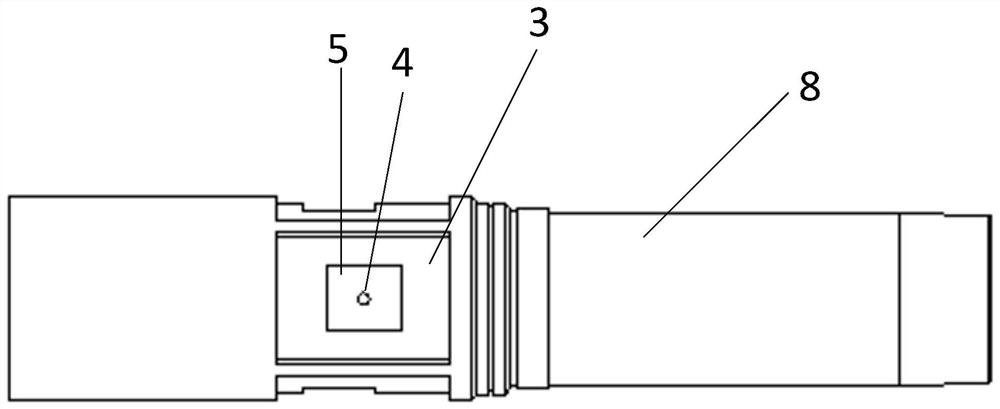

Oil well sand control screen pipe and preparation method

ActiveCN112682009AIncrease fluid productionImprove diversion capacityLiquid surface applicatorsFluid removalPhysical chemistryPolymer

The invention discloses an oil well sand control screen pipe and a preparation method. The sand control screen pipe comprises a pipe body and a coating, wherein the coating is prepared by soaking, brushing or spraying a coating treatment solution on the pipe body; the coating treatment solution is prepared from an organosilicon compound, a silane coupling agent, a cosolvent and a solvent; and based on the weight of the solvent being 100%, the content of the organosilicon compound is 0.1-50%, the content of the silane coupling agent is 0.1-30%, and the content of the cosolvent is 0.1-10%. The sand control screen pipe can reduce adsorption of substances such as polymers, crude oil and clay on the surface of the screen pipe, improves the flow conductivity of the screen pipe, and is simple in formula, low in field application condition, low in construction cost and long in lasting effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil pumping unit well group flexible drive control system

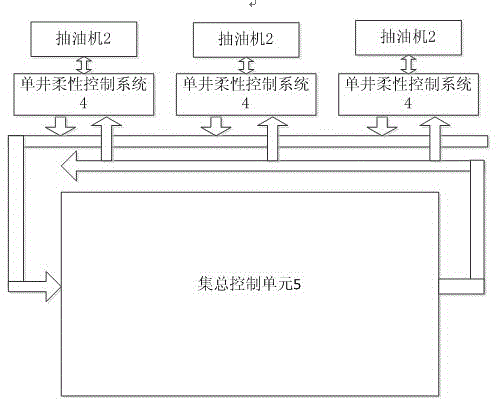

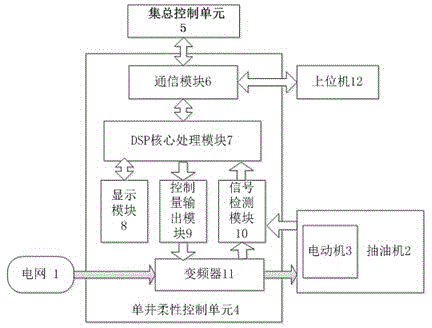

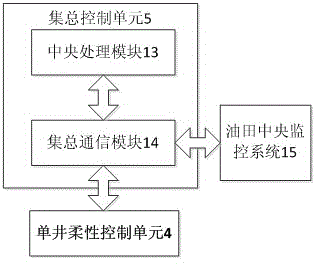

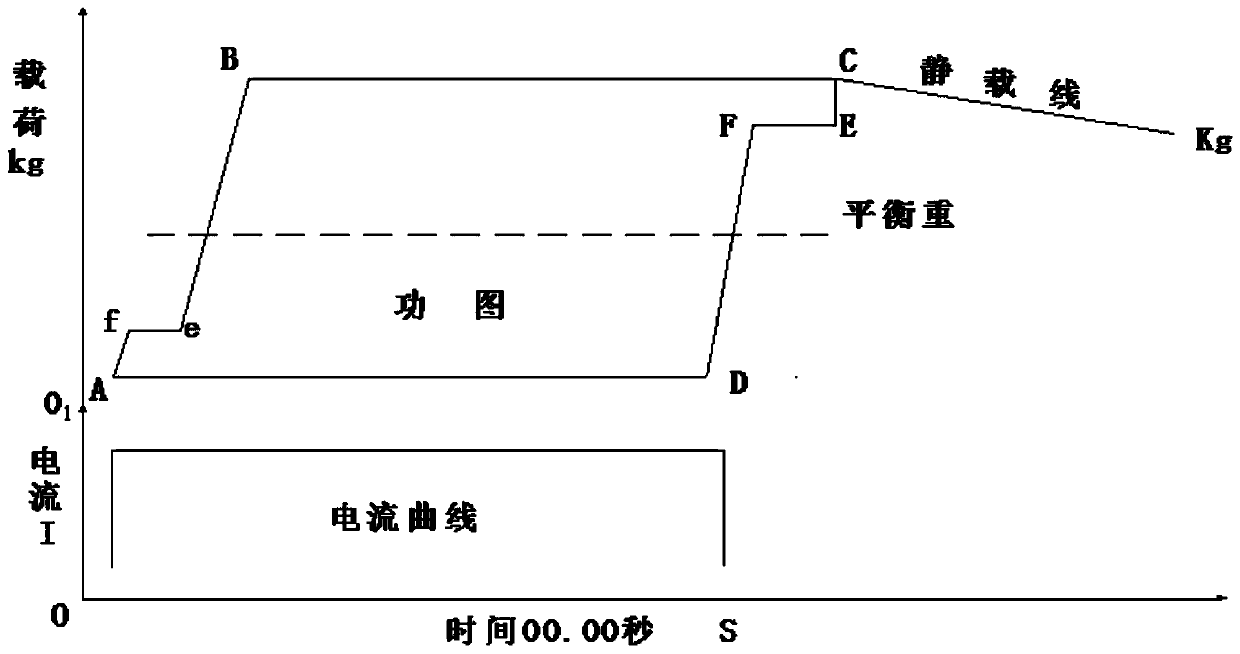

InactiveCN106292569ACentralized parameter tuning is easy to implementIncrease fluid productionEnergy industryTotal factory controlTime conditionControl system

The invention provides an oil pumping unit well group flexible drive control system. The oil pumping well group flexible drive control system comprises a plurality of single well flexible control units and a lumped control unit; each single well control unit is correspondingly connected to one oil pumping unit; each single well flexible control unit transmits a single well production parameter and a real time condition to a lumped control unit; the lumped control unit collects data information of all single wells in the well group to perform fusion, analyzes and calculation to output various control parameters corresponding to all single wells and transmits the various control parameters to the flexible control unit of each single well; after each single well flexible control unit receives the control parameters, the single well flexible control unit regulates the operation mode and operates according to the received parameters. The oil pumping unit well group flexible drive control system realizes well group optimization regulation and control by the means of the single well flexible control, improves integral energy efficiency level of the well group, changes a traditional optimization control mode which focus on the single well and achieves system comprehensive energy saving.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of synchronous numerical control oil pumping according to stroke frequency for oil well testing and operation after filling of pump

Owner:DALIAN HONGQIAO TECH

High-efficiency wax-proof, scale-proof and liquid-increasing device

InactiveCN109339739AReduce the number of well washesExtended well cleaning cycleCleaning apparatusFluid removalSolubilityPetroleum

The invention relates to the technical field of petroleum exploitation, and discloses a high-efficient wax-proof, scale-proof and liquid-increasing device. The high-efficient wax-proof, scale-proof and liquid-increasing device comprises a deep well, wherein an oil sucker rod is arranged in the deep well in a penetrating mode, a seven-split rod oil sucker rod wax-proof device is fixedly connected to the bottom end of the oil sucker rod, and a six-split rod oil sucker rod wax-proof device is fixedly connected to the bottom end of the seven-split rod oil sucker rod wax-proof device. Through the integration of high intensity magnetic, acoustic wave and eddy current technology, the high-efficiency wax-proof, scale-proof liquid-increasing device can perform the before pump and after pump treatment on well water-bearing crude oil. The unique design structure of the device can enable the flow rate, flow pattern, temperature, pressure, viscosity, the solubility of gas-liquid phase, the mixing degree of solid-liquid phase, the environment of crystal adsorption and growth, the microstructure of hydrocarbon components and so on of the produced liquid to produce a series of physical changes, the produced liquid is highly melted, so that the amount of wax is greatly reduced, the washing cycle is prolonged, and remarkable effects of wax-proof, scaling-proof, viscosity-proof and oil-increasingare achieved. A good wax-proof and scale-proof method is achieved.

Owner:WUHAN FUSHIDA ENERGY TECH CO LTD

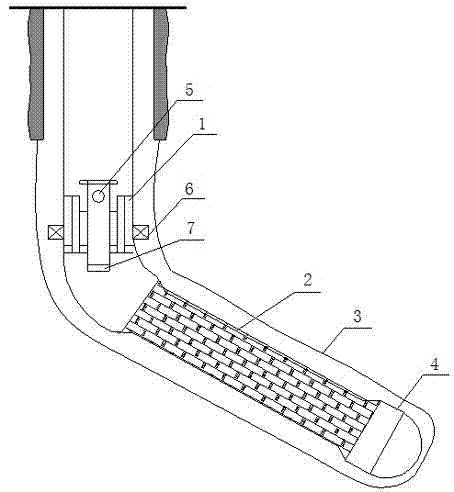

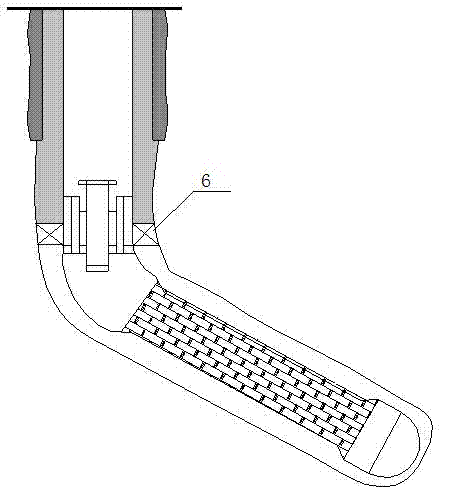

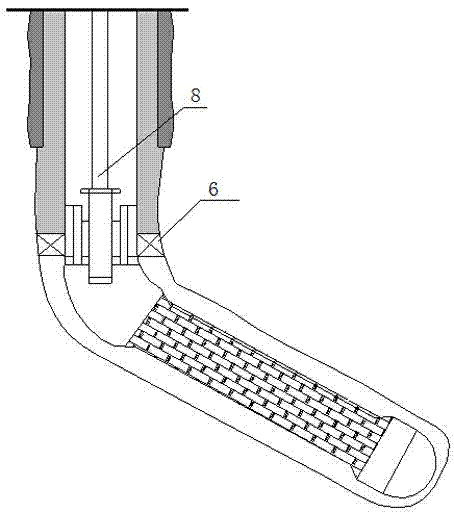

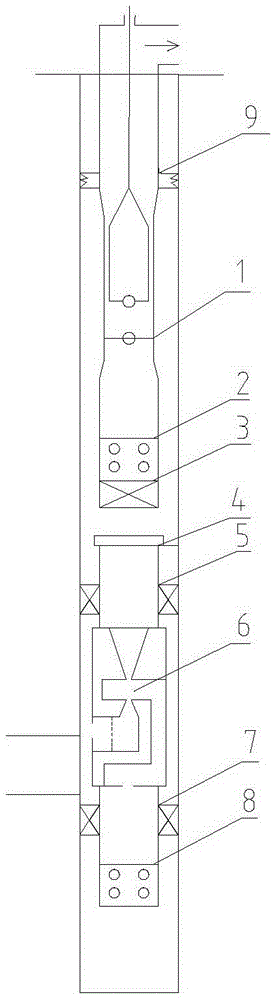

Oil well gas prevention system

InactiveCN106567695AControl gas productionIncrease fluid productionFluid removalCarrying capacitySpray nozzle

The invention discloses an oil well gas prevention system and a using method. The oil well gas prevention system comprises an oil well casing and a gas prevention pump. The lower end of the gas prevention pump 1 is sequentially connected with an upper filter screen pipe and an upper screwed plug. A release sub located below the gas prevention pump 1 is arranged in the oil well casing. The release sub is located in the oil well casing through an upper packer arranged on the periphery of the release sub. The lower end of the release sub is connected with a gas prevention lifting pump. The gas prevention lifting pump is located and installed in the oil well casing through a lower packer. The lower end of the gas prevention lifting pump is connected with a lower filter screen pipe. A lower oil layer liquid inlet is formed below the gas prevention lifting pump. An upper oil layer liquid inlet is formed in one side of the gas prevention lifting pump. The oil well gas prevention system has the following advantages that the production pressure difference of the low-pressure oil layer is increased, the liquid production amoung of the low-pressure layer is increased, interlayer interference is avoided, the function of changing the motion direction of liquid and the acceleration function are achieved, the liquid carrying capacity of gas is improved, and the liquid production capacity of the low-pressure layer is improved; and secondary filter of well liquid is achieved, and a spray nozzle is effectively prevented from being blocked.

Owner:CHINA PETROLEUM & CHEM CORP

Curved limited movement type anti-wear sucker rod and manufacturing method thereof

The invention discloses an arc-shaped surface limited movement type anti-wear sucker rod and a manufacturing method thereof. The limited movement type anti-wear sucker rod is formed by additionally arranging a plurality of limiters and strengthening bodies on a sucker rod body. The limiters are firmly connected onto the sucker rod body through casting and a strengthening body is arranged between every two adjacent limiters; a plurality of spiral lug bosses and spiral grooves are arranged on the circumferential side of each strengthening body; the spiral groove between every two spiral lug bosses is used as an oil flowing channel; and the outer circle of the strengthening body is of an arc-shaped surface shape. Compared with the prior art, the arc-shaped surface limited movement type anti-wear sucker rod can prevent a connecting hoop of the sucker rod from eccentric wear and a rod body of the sucker rod from the eccentric wear, and can also prevent the sucker rod from being broken and falling off, so that the strengthening bodies can move when necessary; and meanwhile, the served limited movement type anti-wear sucker rod can also be used for scraping wax and the sucker rod can be prevented from releasing.

Owner:程佑富

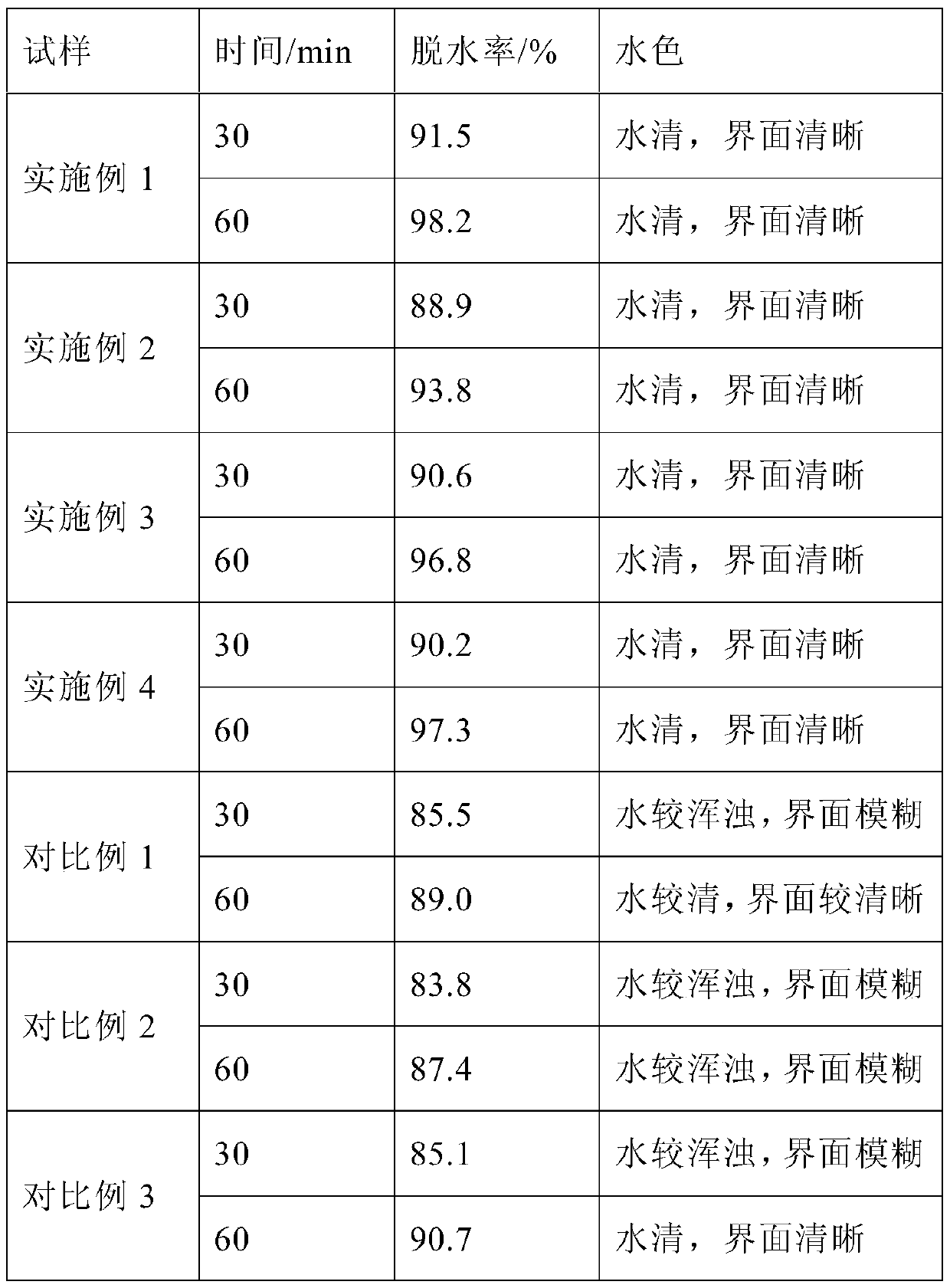

Preparation method and use of emulsion inhibitor for fracturing acidizing in oilfield

ActiveCN110437820ABig potential application prospectImprove wettabilityDrilling compositionEmulsionPolymer science

The invention relates to the technical field of oil exploitation, and more particularly to a preparation method and use of an emulsion inhibitor for fracturing acidizing in an oilfield. The preparation method of the emulsion inhibitor comprises the following steps: preparing a component A, preparing a component B, and uniformly mixing the component A and the component B. The use comprises inhibiting emulsification in fracturing acidizing operation in an oilfield and serving as an oil displacement agent in ternary combinational flooding or binary combinational flooding operation in an oilfield.According to the invention, the component A and the component B are combined, so that the dehydration rate can be above 90%, and therefore, the emulsion inhibitor is very suitable for use in oilfieldacidizing operation as an emulsion inhibitor. The emulsion inhibitor prepared by the preparation method disclosed in the invention can create extremely low interfacial tension (which can reach 10<-4>mN / m) on the phase surface of crude oil, and thus can be used in ternary combinational flooding or binary combinational flooding operation in an oilfield as an oil displacement agent.

Owner:山东滨州昱诚化工科技有限公司

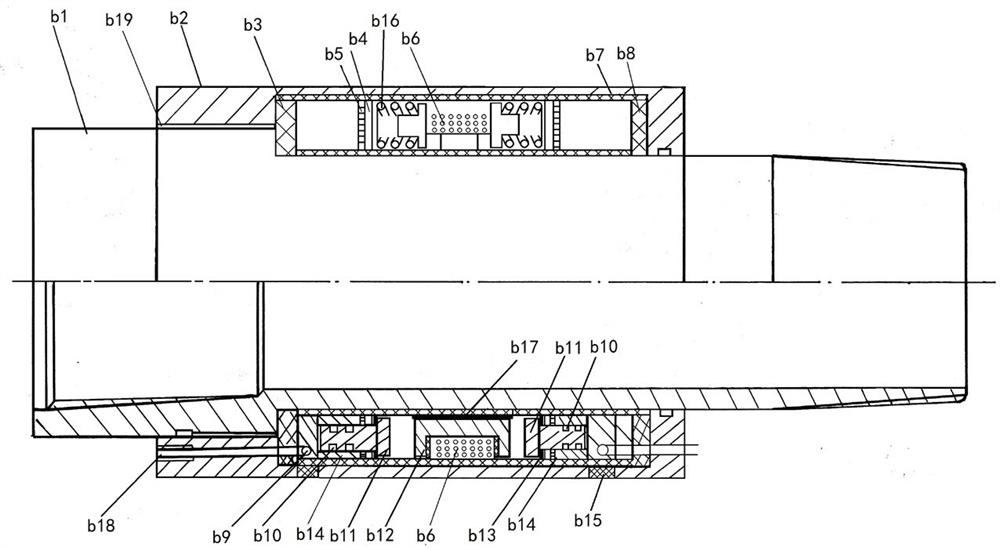

Double-action oil well pump used for rodless oil extraction

ActiveCN105673464AIncrease fluid productionIncrease displacementPositive displacement pump componentsFlexible member pumpsCouplingHigh pressure

The invention discloses a double-action oil well pump used for rodless oil extraction. The double-action oil well pump comprises an upper coupling, a long pump cylinder, a long plunger, a lower pump coupling, a short pump cylinder and a lower coupling. The double-action oil well pump is characterized in that an upper pump oil outlet valve is arranged at the upper end of the long pump cylinder; a liquid inlet is formed in a side wall of the long pump cylinder; a movable joint seat is arranged at the lower end of a short plunger; an end cap is arranged at the upper end of the short plunger; the lower end of a movable joint penetrates through the movable joint seat at the lower end of the short plunger and is connected and fixed with the upper end of the long plunger; a flow converter is arranged at the lower end of the upper coupling; a middle flow channel and a side flow channel are formed in the flow converter; a lower end opening of the side flow channel is fixedly connected with an outlet of the upper pump oil outlet valve; an upper end opening of the side flow channel is communicated with an inner cavity of the upper coupling; a lower end opening of the middle flow channel is communicated with an oil outlet of the lower pump coupling through a high-pressure oil pipe; an upper end opening of the middle flow channel is connected and fixed with the lower pump oil outlet valve; and the oil outlet of the lower pump coupling is communicated with the bottom of a lower pump cavity. According to the double-action oil well pump, twice liquid feeding and twice liquid discharging are finished by one stroke, so that the liquid production capacity of a single well is increased.

Owner:SHANDONG WEIMA PUMPS MFG

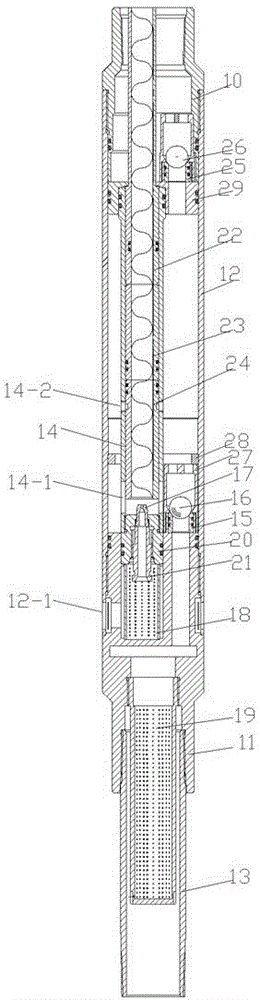

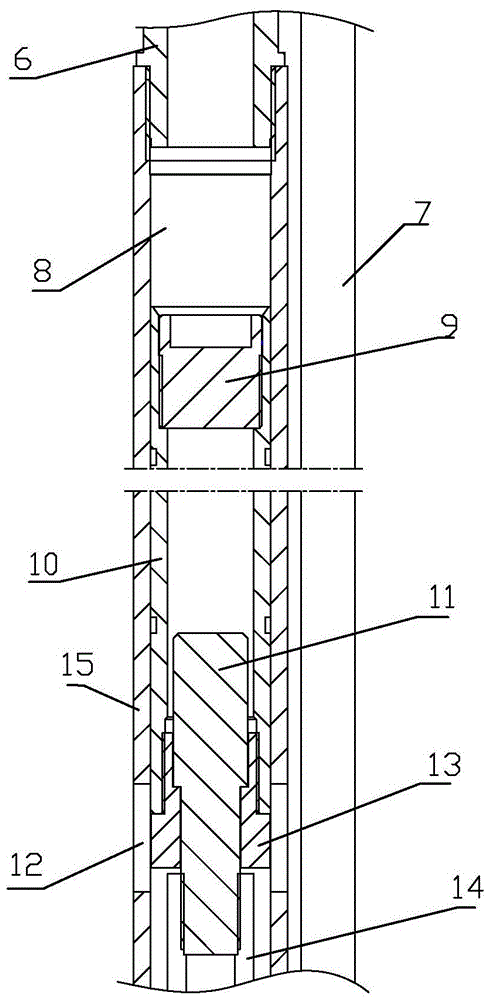

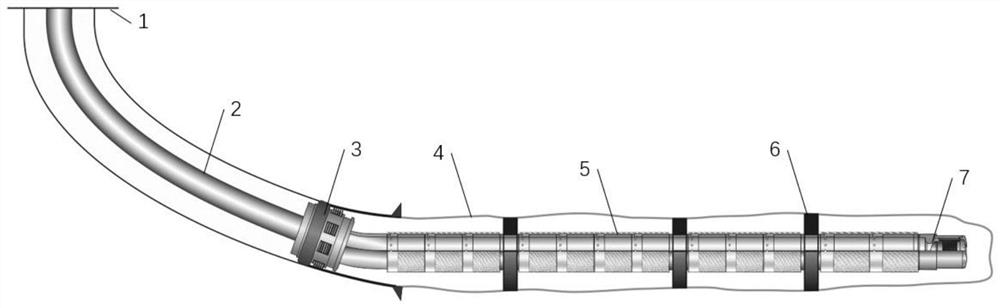

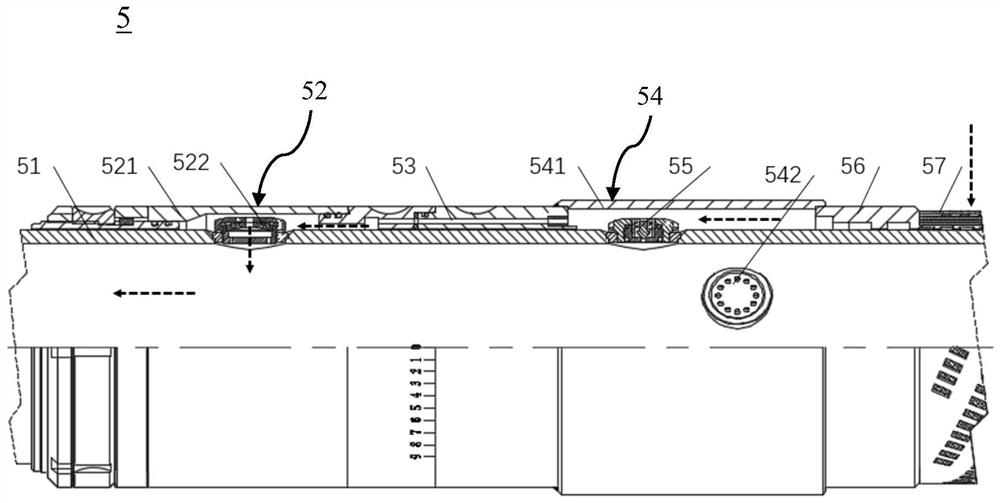

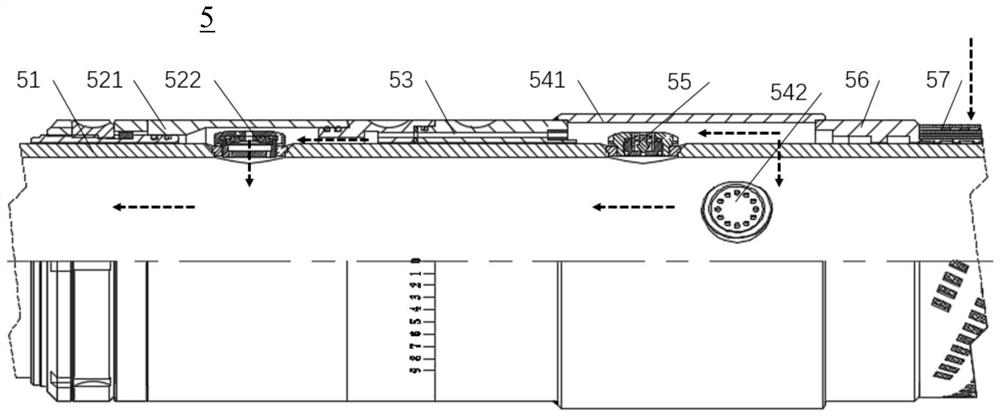

Self-adaptive flow regulating and water controlling device for oil-gas well

The invention discloses a self-adaptive flow regulating and water controlling device for an oil-gas well. The self-adaptive flow regulating and water controlling device comprises an outer sleeve, anda base pipe arranged in the outer sleeve in a sleeved mode; the outer wall of the base pipe is provided with a flow adjusting and water controlling controller located in the outer sleeve, and the flowadjusting and water controlling controller comprises a long inlet flow channel, a short inlet flow channel, a fluid flow dividing channel and a rotational flow disc cavity; the long inlet flow channel and the short inlet flow channel extend along a straight line, the flow channel areas are constant, the length of the long inlet flow channel is greater than that of the short inlet flow channel, and the long inlet flow channel and the short inlet flow channel communicate with an inlet of the fluid flow dividing channel; and an outlet of the fluid flow dividing channel communicates with the rotational flow disc cavity and is arranged to output fluid to the rotational flow disc cavity in a rotational flow mode, the channel area of the fluid flow dividing channel is gradually reduced from theinlet to the outlet, the fluid flow dividing channel surrounds the outer side of the rotational flow disc cavity, and a throttling channel is arranged between the fluid flow dividing channel and the rotational flow disc cavity.

Owner:北京合力奇点科技有限公司

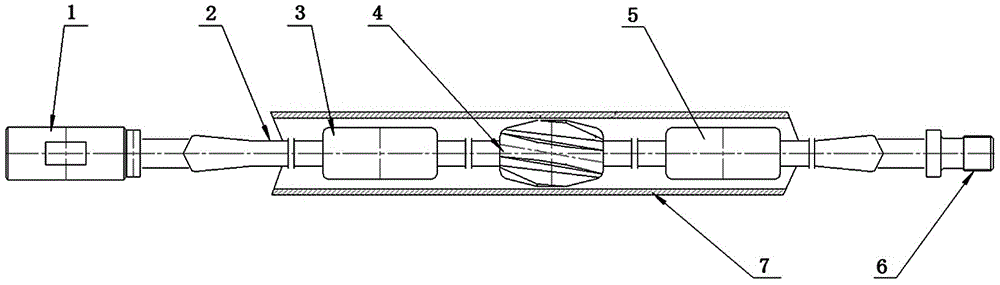

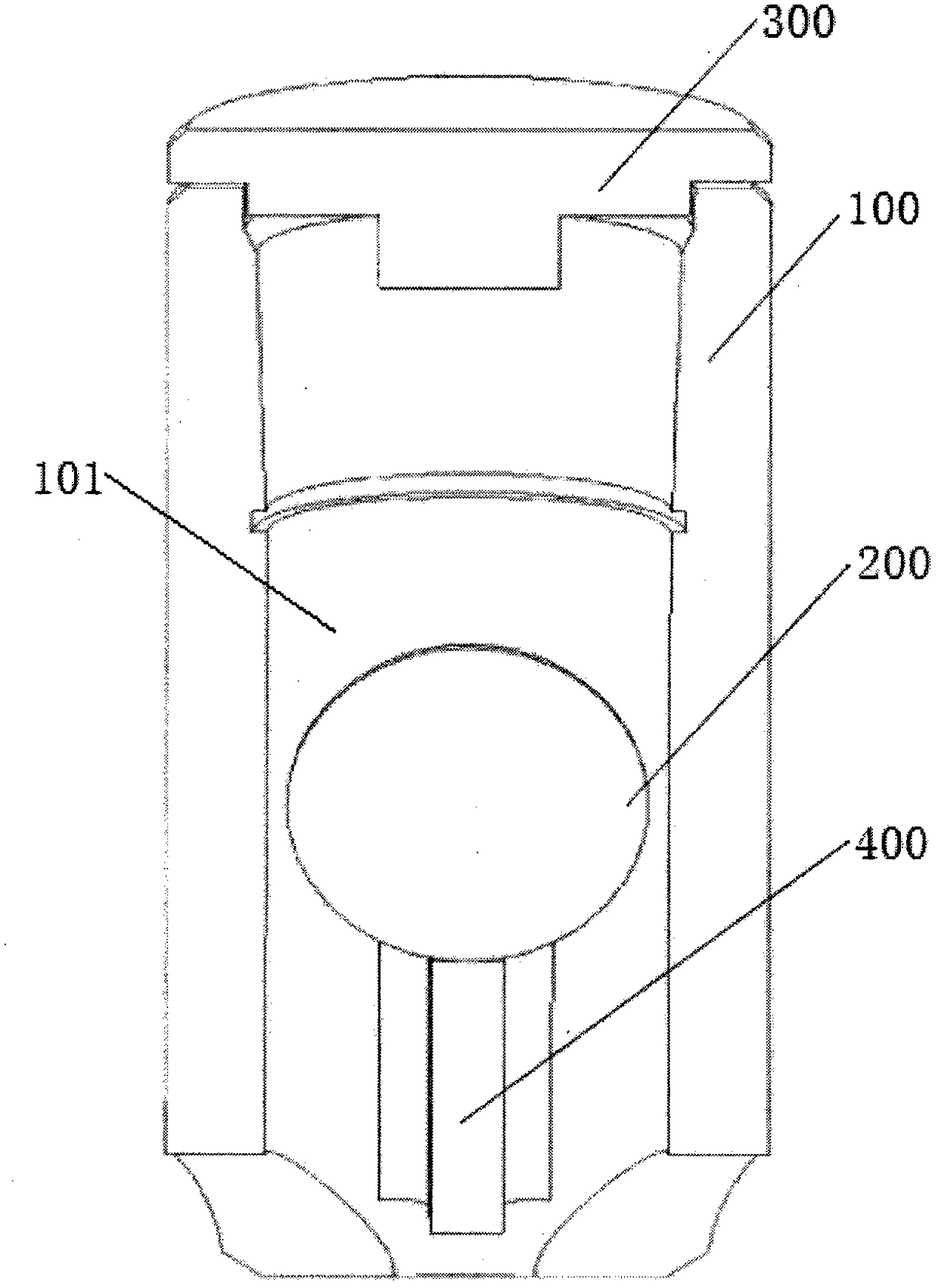

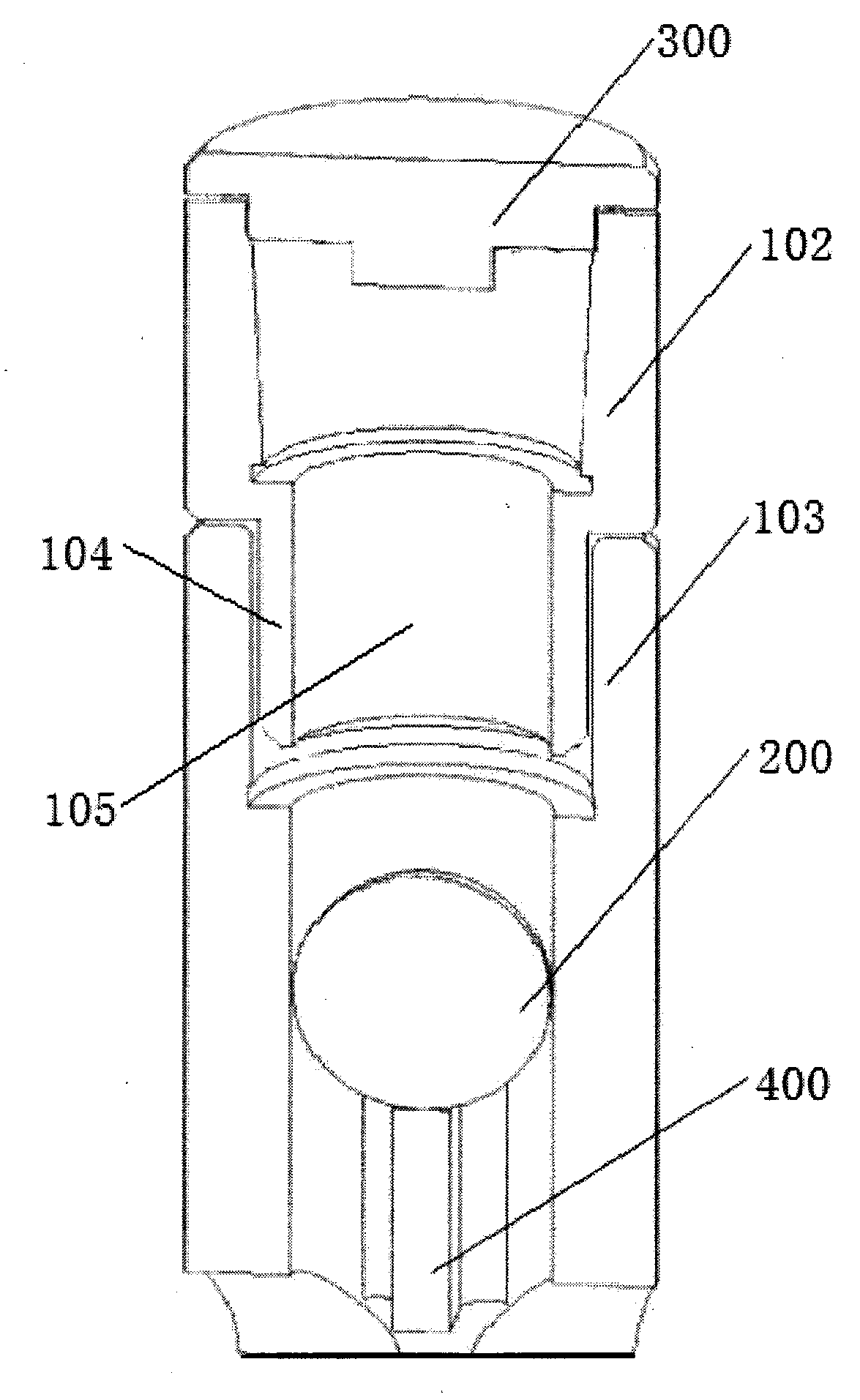

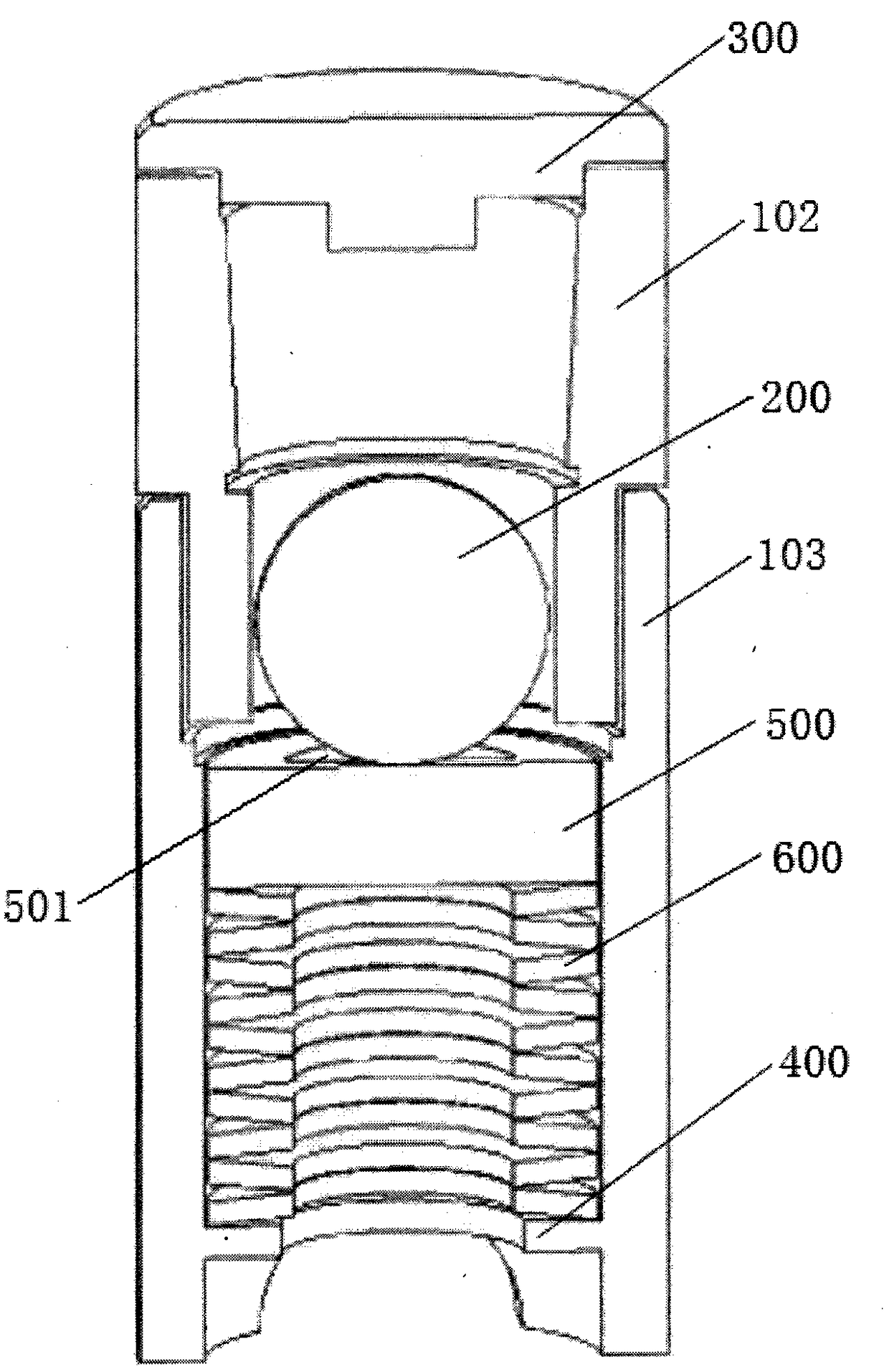

Fluid dynamic annular space cavitation device

InactiveCN108166957AIncrease water injectionIncrease fluid productionFluid removalComing outCavitation

The invention relates to a fluid dynamic annular space cavitation device. The fluid dynamic annular space cavitation device comprises a cylindrical shell body, a spherical dynamic body, a stop plate and a bracket; the cylindrical shell body is internally provided with a working area, and the spherical dynamic body is disposed in the working area in the cylindrical shell body; a channel for fluid flowing is formed between the outer wall of the spherical dynamic body and the inner wall of the cylindrical shell body, and fluid flowing through the channel is subjected to cavitation; the stop plateis disposed on the top of the cylindrical shell body and used for preventing the spherical dynamic body from escaping from the upper part of the cylindrical shell body, so that the spherical dynamicbody is operated within the working area in the cylindrical shell body; and the bracket is disposed at the inner bottom of the cylindrical shell body for preventing the spherical dynamic body from coming out of the lower portion of the cylindrical shell body. The fluid dynamic annular space cavitation device has the beneficial effects of small volume, wide application range and safety and reliability.

Owner:北京漫海能源科技有限公司

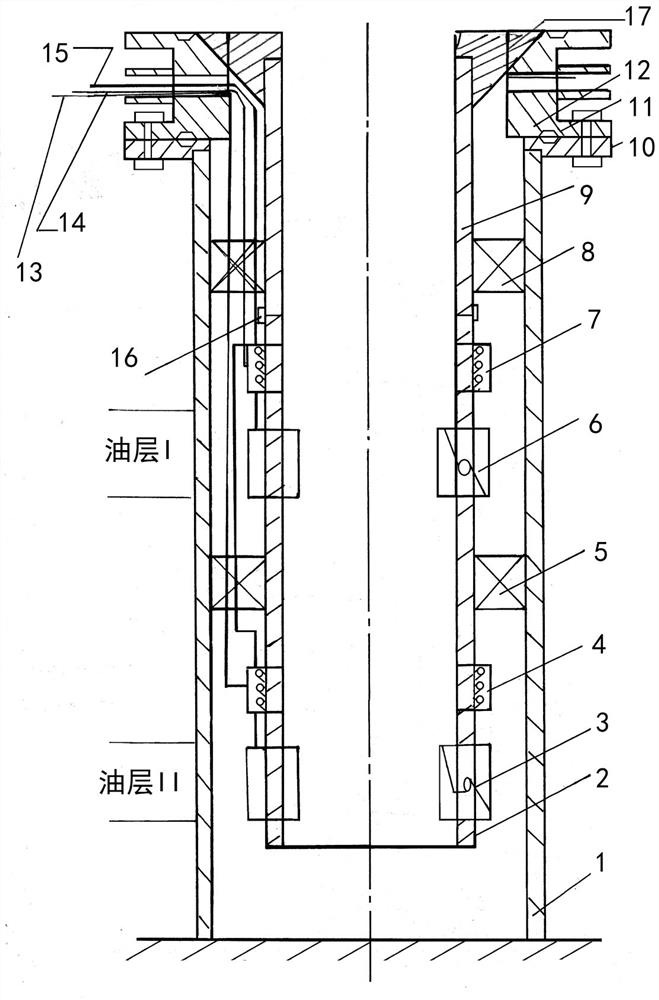

Layered oil production device with double electric submersible pumps sharing power line

InactiveCN112253061AIncrease fluid productionImprove the effect of increasing productionFluid removalPower cableElectric control

The invention relates to a layered oil production device with double electric submersible pumps sharing a power line. According to the technical scheme, a lower-layer starting switch and a lower-layerelectric submersible pump are arranged below a lower-layer cable passing packer, and an upper-layer electric submersible pump, an upper-layer starting switch and a phase compensator are arranged between the lower-layer cable passing packer and an upper-layer cable passing packer; and a second power cable of the lower-layer electric submersible pump is upwards connected to a first power cable of the upper-layer electric submersible pump in parallel along the lower-layer cable passing packer, and a lower-layer starting switch control line of the lower-layer electric submersible pump moves alongthe lower-layer cable passing packer, the upper-layer cable passing packer, and penetrates through a threading hole of a large four-way joint of a wellhead with an upper-layer starting switch controlline. The layered oil production device with the double electric submersible pumps sharing the power line has the advantages that the structure of an underground power cable is simplified, the problem that a cable passing packer with an eccentric structure cannot penetrate into two sets of power cables is solved, the purpose that the two electric submersible pumps are used for underground layeredoil production is achieved, oil production layers are clearer, production allocation is achieved through electric control, and efficient oil production is achieved.

Owner:陈海荣

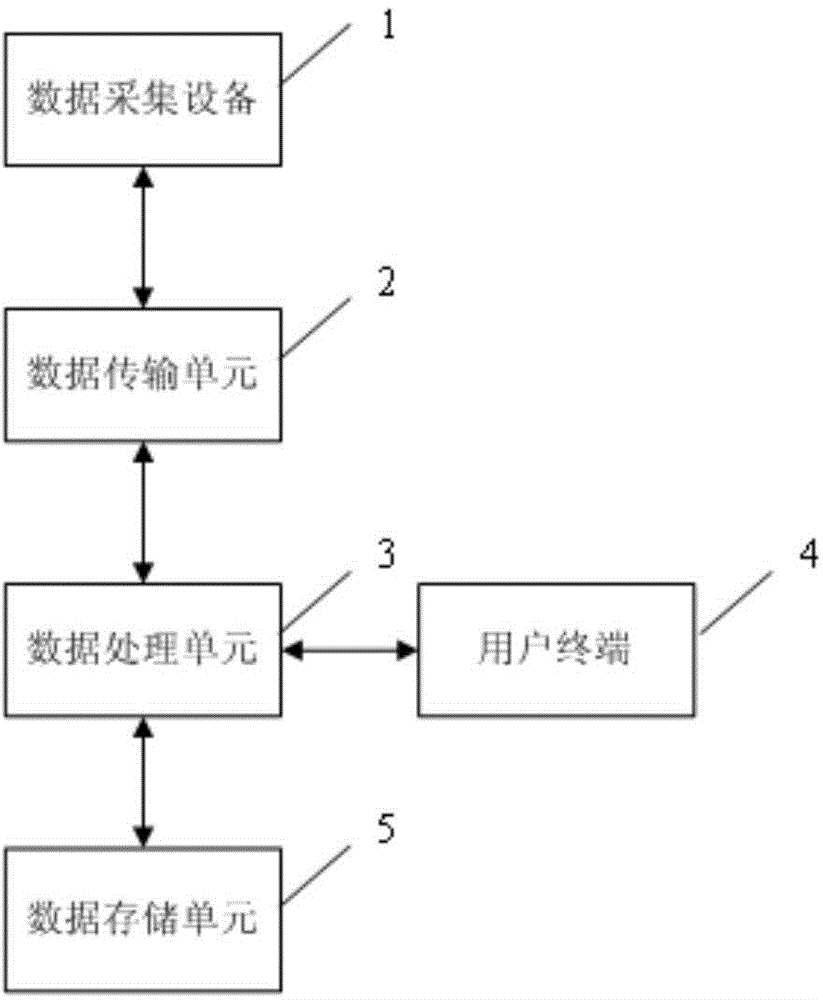

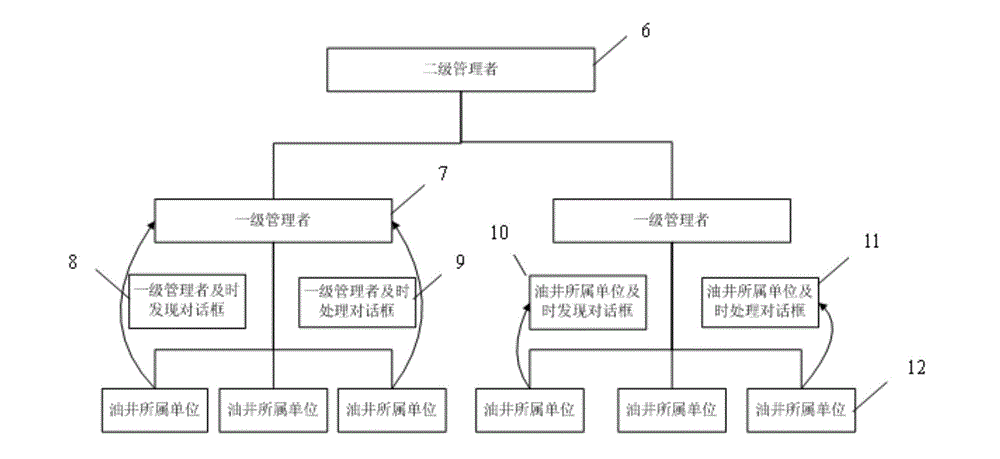

Oil well operation abnormity alarming treatment method

InactiveCN104564012AShorten fault discovery timeIncrease effective uptimeSurveyAlarmsAlarm messageData acquisition

The invention provides an oil well operation abnormity alarming treatment method. On the basis of data acquisition equipment, a data transmission unit, a data processing unit, a data storage unit and a user terminal, the data processing unit acquires working condition data of an oil well and analyzes and treats the working condition data; if the acquired working condition data is out of a change range which is set by taking oil well basic data as standards, alarming information is generated, and an oil well affiliated unit is informed of performing treatment on the alarming information in a mode of discovering a dialog in time and treating the dialog in time; a primary manager audits a measure taken by the oil well affiliated unit; a secondary manager performs statistic assessment on abnormity alarming treatment conditions, and a tertiary manager and managers of high levels can browse and inquire any oil well operation abnormity alarming event and treatment conditions. When the oil well generates the alarming information, the oil well affiliated unit is reminded of checking oil production operation conditions and solving problems by going to a well site in time according to the method, and top-to-bottom production pressure pass is realized and the oil field management level is improved.

Owner:SHANDONG TIANGONG PETROLEUM EQUIP

Combined type double-acting rod type oil well pump and oil extraction method thereof

InactiveCN106014910ALarge displacementIncrease fluid productionPositive displacement pump componentsConstructionsDrive shaftCoupling

The invention relates to a combined type double-acting rod type oil well pump and an oil extraction method thereof. The combined type double-acting rod type oil well pump comprises a sucker rod, a beam type oil well pump, a screw pump driving device and a screw pump, wherein a piston is arranged in a pump barrel of the beam type oil well pump; the upper end of the piston is connected with the sucker rod; a walking valve is arranged at an upper port of a vertical through hole of the piston; the lower end of the piston is connected with a lead screw of the screw pump driving device; side suction valves are arranged on the pump barrel; the pump barrel is connected with an outer barrel of the screw pump through a coupling; a pump transmission shaft of the screw pump driving device is connected with a screw; a nut baffle is arranged below the side suction valves; the lead screw penetrates through the center of the nut baffle and is inserted in a torque barrel; a self-locking-free nut is fixed on the lead screw and is positioned between the nut baffle and the torque barrel; a pump transmission shaft is fixed at the lower end of the torque barrel; and the lower end of the pump transmission shaft is connected with the screw. Two-time oil suction and two-time oil drainage are finished in an up-down stroke, the liquid production capacity of a single well is greatly increased, and the displacement of the pump is also increased.

Owner:NORTHEAST GASOLINEEUM UNIV

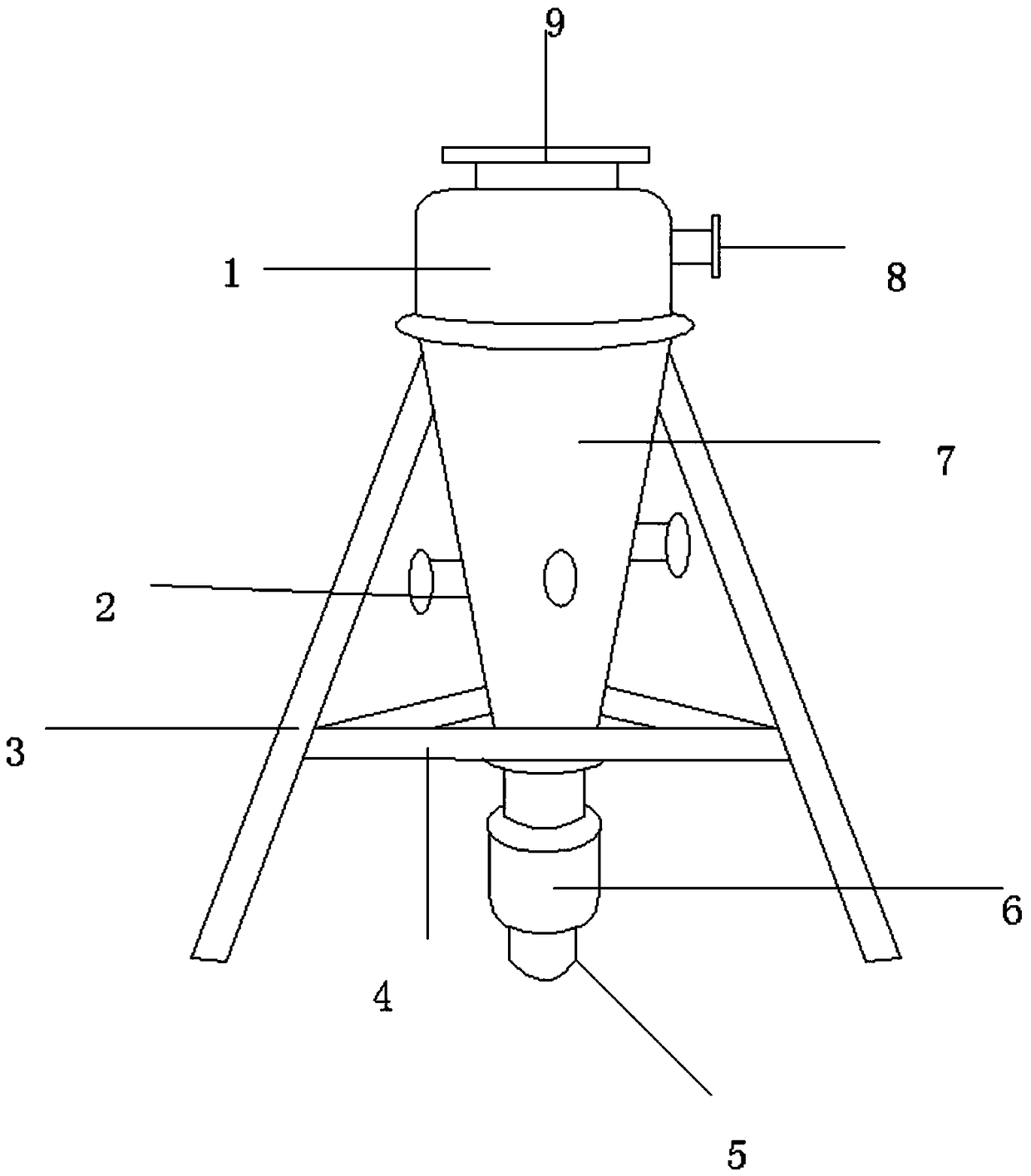

Swirling flow sand remover

InactiveCN108905316AImprove sand removal efficiencyIncrease fluid productionCentrifugal force sediment separationFiltration circuitsEngineeringPrecipitation

The invention discloses a swirling flow sand remover. The structure of the swirling flow sand remover comprises a swirling flow chamber, clustering swirling flow tube cylinders, a sand discharging port, a sand storage chamber and a sand precipitation chamber, wherein the swirling flow chamber is connected to a water outlet and a water inlet, a preliminary filtering device is arranged inside the swirling flow chamber, the swirling flow chamber is connected to the sand precipitation chamber, the sand precipitation chamber is provided with the three clustering swirling flow tube cylinders, an efficient sand removing device is arranged in the sand precipitation chamber, the clustering swirling flow tube cylinders are connected to the sand storage chamber, and the lower end of the sand storagechamber is provided with the sand discharging port. According to the present invention, a complete set of the sand removing equipment is provided, the sand removing efficiency is high, and the liquidoutput of the sand remover to the oil field is improved.

Owner:施英

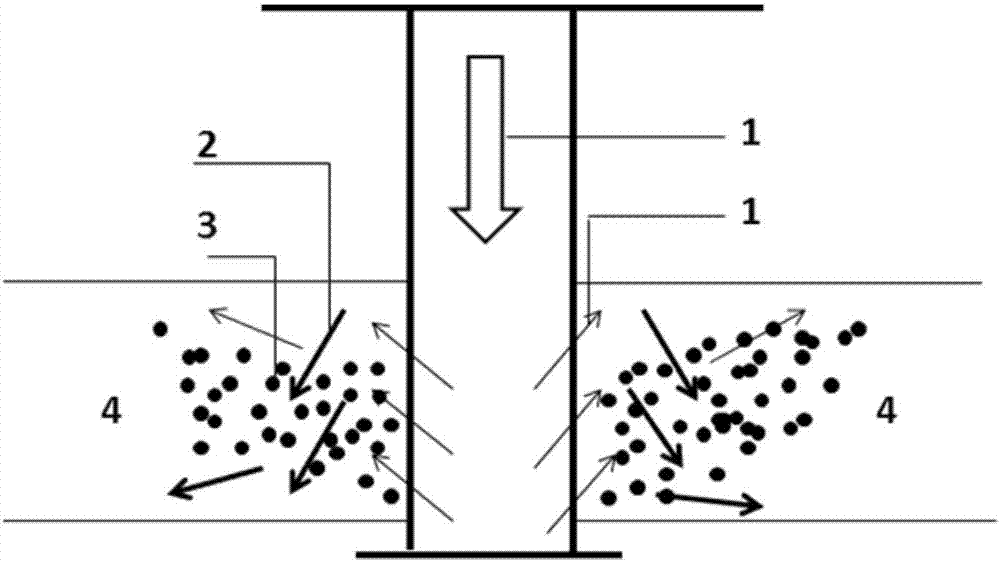

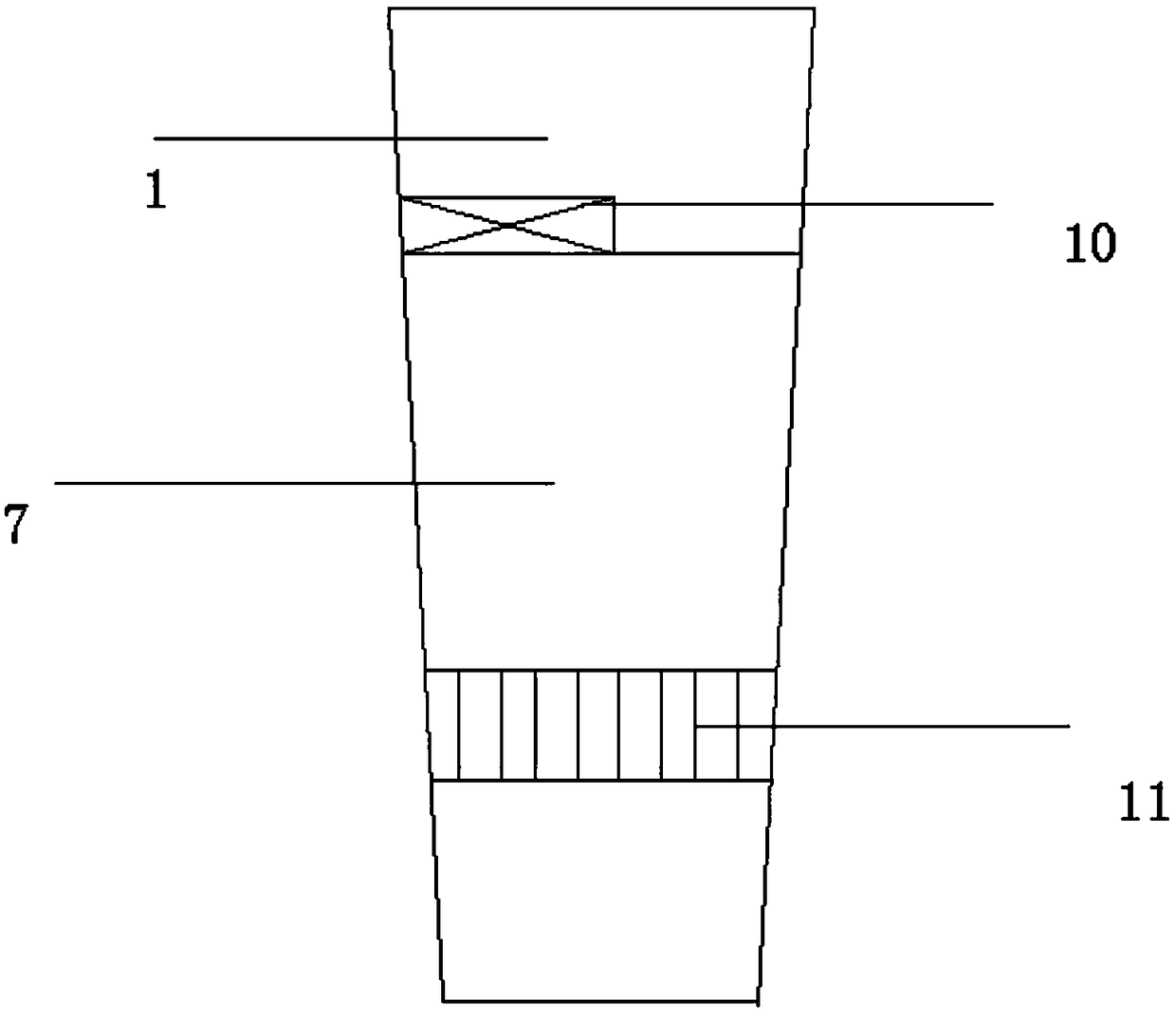

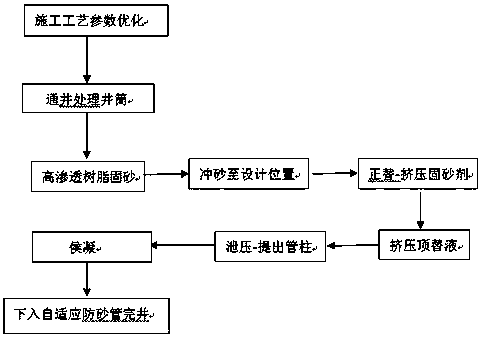

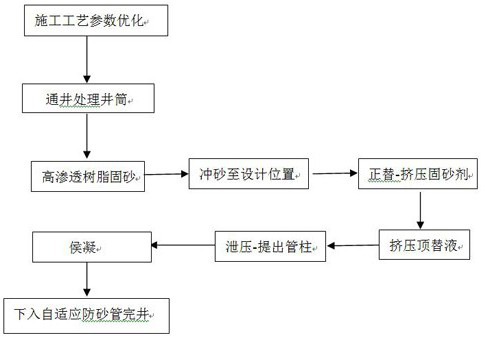

Non-filling self-adapting sand prevention technology method

ActiveCN111577217AIncrease fluid productionReduce mixFluid removalFlushingMining engineeringWellbore

The invention provides a non-filling self-adapting sand prevention technology method. The non-filling self-adapting sand prevention technology method comprises the following steps of step1 according to data including oil reservoir physical properties, geological structures, reservoir sand granularmetric analysis, numerical simulation and the like, performing technology parameter optimizing; step 2, processing a wellhole for drafting; step 3, performing sand fixing with high-infiltration resins: firstly, washing the sand to a position according to design requirements, arranging a construction pipe column according to design requirements, performing preprocessing on the oil layer, then selecting a high-infiltration resin type sand fixing dose, extruding the resin type sand fixing dose and replacement liquid, after pressure is naturally proliferated, slowly raising the construction pipe column for coagulation; and step 4, arranging a self-adapting sand prevention inflation sand preventionpipe column. The non-filling self-adapting sand prevention technology method disclosed by the invention has the main advantages that a filling operation is not needed, so that the construction technology is simplified, the cost is low, and no risk is generated; the quick sand is fixed by the high-infiltration resins, and the fluid naturally passes, so that sand is prevented, and oil is not prevented; and self-adapting classified expanding materials allow sand of which the diameter is less than 40 microns to pass, and preferable sand prevention is really performed through sand passing.

Owner:CHINA PETROCHEMICAL CORP +3

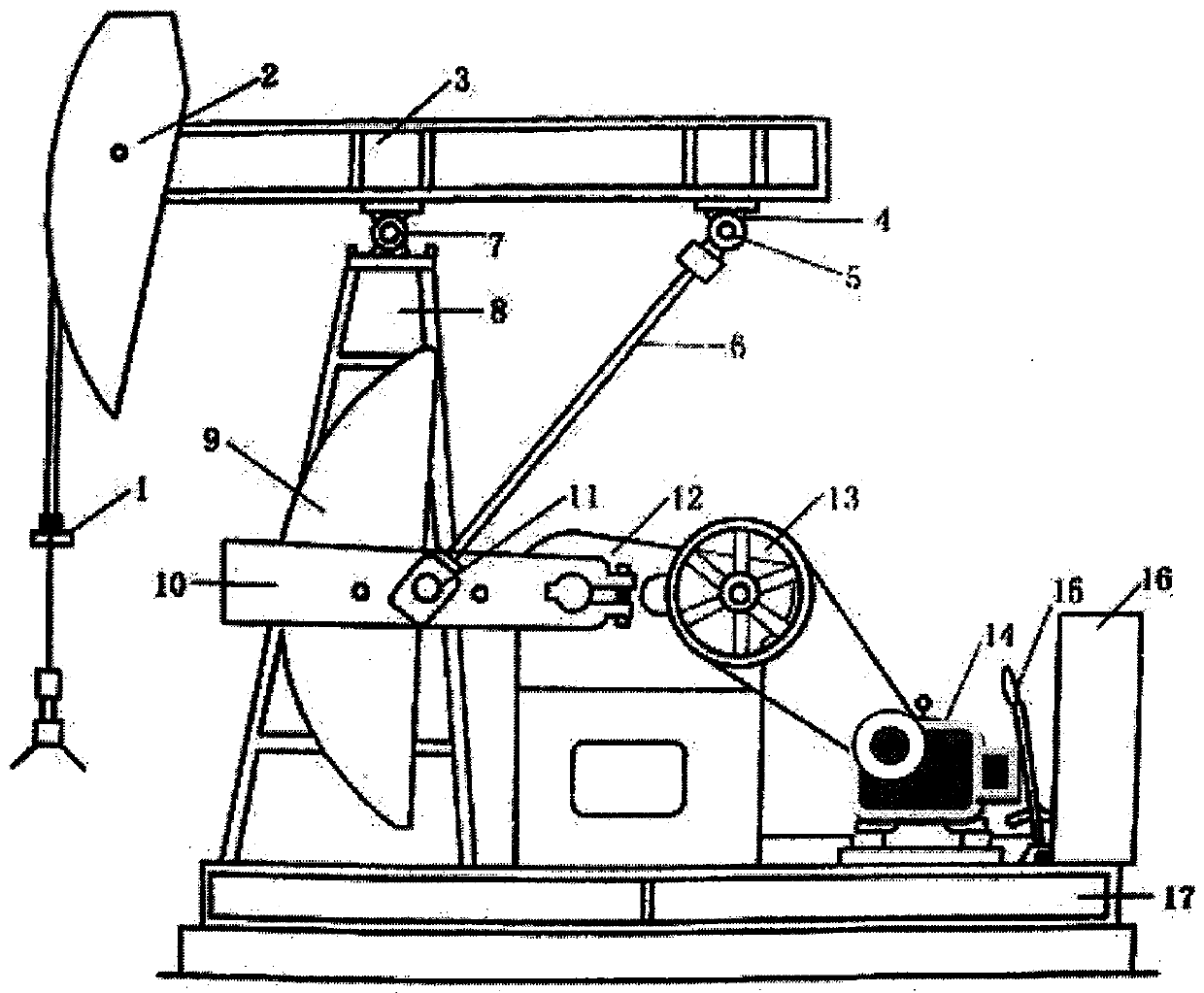

Oil pumping unit integrating linear speed regulation and ultralow stroke frequency of motor

InactiveCN110905451ASave design spaceSave tedious debuggingConstructionsFluid removalCrankTransmission belt

The invention provides an oil pumping unit integrating linear speed regulation and ultralow stroke frequency of a motor. According to the oil pumping unit, an integrally manufactured walking beam is adopted, one end of the walking beam is connected with a mounting horse head, and the other end of the walking beam is connected with one end of a connecting rod through the connecting rod and a walking beam connecting bearing; the other end of the connecting rod is connected with the middle part of a crank, one end of the crank is connected to a speed output shaft of a reduction gearbox, and an input shaft of the reduction gearbox is connected with a large belt pulley; the large belt pulley is connected to an output shaft of a linear speed regulation device through a belt; and the walking beamis connected to a bracket through a central bearing assembly, and the walking beam and the bracket are integrally assembled, so that the oil pumping unit is formed. The oil pumping unit is driven towork through a transmission belt; the linear speed regulation device adopts a non-clutch design, is integrated and replaces an original power motor; and the stroke frequency of the oil pumping unit iscontrolled through a linear gear shift regulator, and reaches 0.2-8 times / minute or a lower stroke frequency.

Owner:孙志健 +2

A filling-free self-adaptive sand control method

ActiveCN111577217BIncrease fluid productionReduce mixFluid removalFlushingSelf adaptiveParticle Size Analyzer

Owner:CHINA PETROCHEMICAL CORP +3

Compound double-acting rod oil well pump and oil production method thereof

InactiveCN106014910BLarge displacementIncrease fluid productionConstructionsPositive displacement pump componentsDrive shaftCoupling

The present invention relates to a composite double-acting rod oil well pump and an oil production method thereof, wherein the compound double-acting rod oil well pump comprises a sucker rod, a beam type oil well pump, a screw pump driving device, a screw pump, a beam type There is a piston in the pump barrel of the oil well pump, the upper end of the piston is connected with the sucker rod, the upper port of the vertical through hole of the piston is provided with a floating valve, the lower end of the piston is connected with the lead screw of the screw pump driving device, and the pump barrel is provided with a side suction valve. ;The pump cylinder and the outer cylinder of the screw pump are connected by a collar, and the pump drive shaft of the screw pump driving device is connected to the screw; the nut baffle is arranged under the side suction valve, and the lead screw passes through the center of the nut baffle and is inserted into the torque cylinder , no self-locking nut is fixed on the lead screw and is located between the nut baffle and the torque cylinder, the lower end of the torque cylinder is fixed to the pump transmission shaft, and the lower end of the pump transmission shaft is connected to the screw rod. The invention completes two times of oil drawing and two times of oil discharge within the up and down strokes, which greatly improves the liquid production rate of a single well and increases the displacement of the pump.

Owner:NORTHEAST GASOLINEEUM UNIV

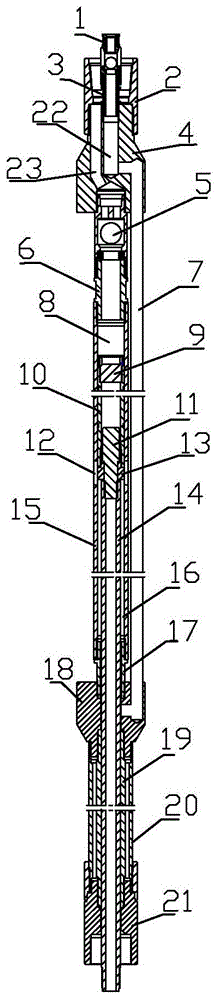

Automatic inflow water control device and water control method thereof

PendingCN113756745ASimple active water controlSimple productivityFluid removalWell/borehole valve arrangementsFluid viscosityStream flow

The invention discloses an automatic inflow water control device and a water control method thereof. The automatic inflow water control device comprises a base pipe, a self-adaptive internal flow control mechanism, an inflow control mechanism, a yield increasing inflow control mechanism and a fluid injection one-way flowing device; the self-adaptive internal flow control mechanism is installed on the base pipe and comprises a self-adaptive internal flow controller and a self-adaptive outer sleeve, the self-adaptive internal flow controller is provided with a channel used for communicating the inside and the outside of the base pipe, and the opening degree of the channel is adjusted to automatically limit the flow according to different viscosities of fluid flowing through the self-adaptive internal flow controller; the inflow control mechanism is arranged on the base pipe in a sleeve manner and is connected to the self-adaptive outer sleeve; the yield increasing inflow control mechanism is installed on the base pipe and comprises a yield increasing sleeve and a yield increasing inflow controller, the yield increasing inflow controller is provided with a yield increasing channel used for communicating the interior and the exterior of the base pipe, and the yield increasing channel is controlled to be opened or closed according to the production pressure difference or the set designated opening pressure difference; and the fluid injection one-way flowing device is used for ensuring that the liquid injected from a wellhead can only flow into a stratum from the base pipe in a single direction. The invention further provides a water control method of the water control device.

Owner:STARSE ENERGY & TECH GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com