Oil pumping unit well group flexible drive control system

A technology for drive control and pumping unit wells, applied in general control system, control/regulation system, program control, etc., can solve the problem of inability to reverse the recovery and utilization of electric energy, unfavorable energy saving and efficiency of pumping unit groups, and limited range of motor slip and other problems to achieve the effect of eliminating the phenomenon of reverse power generation, reducing installed capacity, and achieving energy efficiency levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

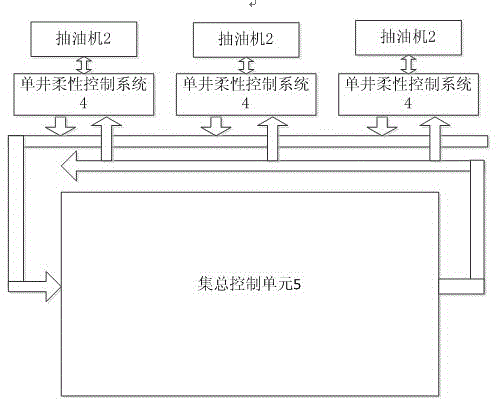

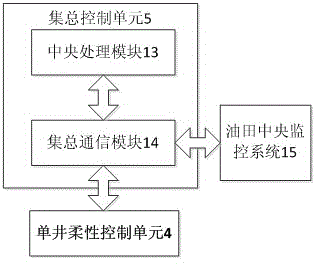

[0022] Such as figure 1 as shown, figure 1 It is a structural diagram of the pumping unit group flexible drive control system of the present invention. The flexible driving control system of the well group of pumping units is composed of a plurality of single well flexible control units 4 and a lumped control unit 5 .

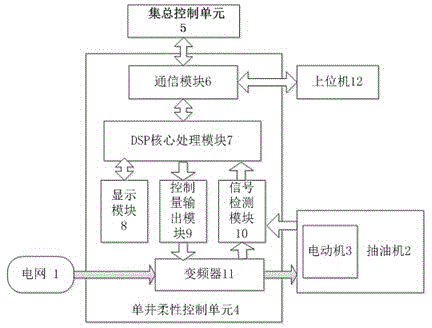

[0023] Each single-well flexible control unit 4 is correspondingly connected to one pumping unit 2, and the single-well flexible control unit 4 uses a DSP processor TMS320F28335 with 32-bit floating-point processing capability to detect the operating status of the pumping unit 2 in real time and output control quantities to change The output voltage and frequency of the frequency converter 11 in the single well flexible control unit 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com