Oil pumping unit integrating linear speed regulation and ultralow stroke frequency of motor

A pumping unit, linear technology, applied in the fields of shale gas recovery and oil field exploitation, can solve problems such as high power consumption, polluted power supply, large-scale power outages in oil production plants, etc., to improve service life, increase installed capacity, The effect of line loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner will be described in detail below.

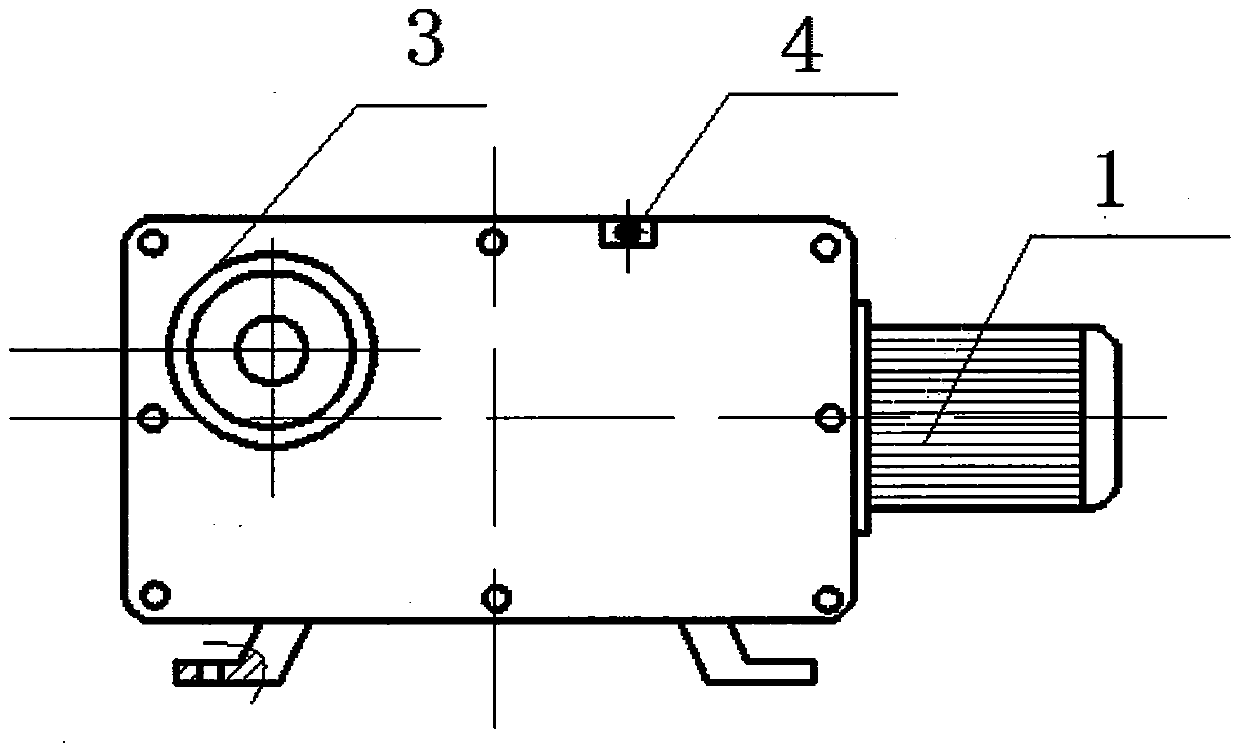

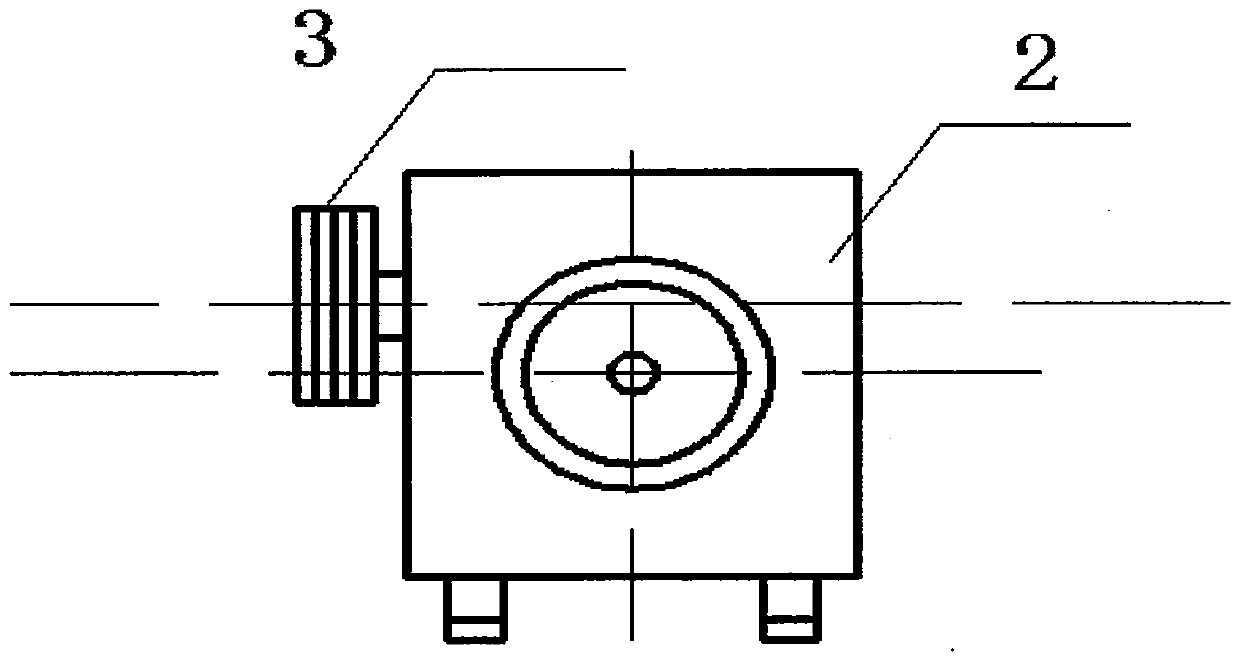

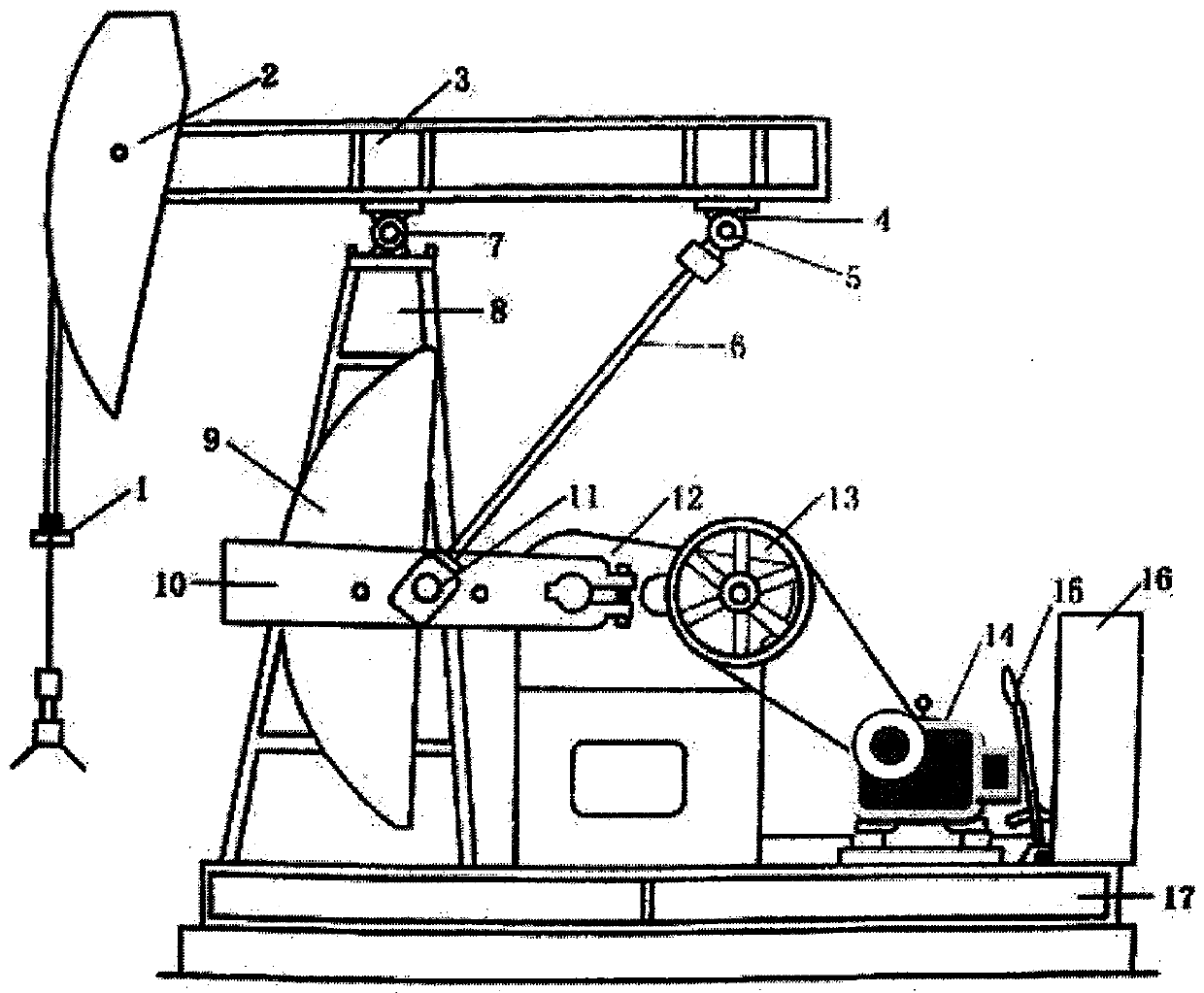

[0038] The following description takes the linear speed controller as an example: figure 1 , figure 2 It is a schematic diagram of the structure of the linear speed regulating device.

[0039] The linear speed regulating device 14 includes: a motor 1 ; a linear speed governor 2 ; an output shaft 3 of the speed governor;

[0040] The linear speed regulator 14; the motor 1 is directly connected to the linear speed regulator 2, and the motor 1 and the linear speed regulator 2 are an integral body; it is directly installed on the pumping unit.

[0041] The linear speed regulating device 14 body is designed with its own linear shift regulator 4 . Realize automatic control; achieve the purpose of linear speed regulation.

[0042] The linear speed regulating device 14 drives the pumping unit to work through the transmission belt of the speed governor output shaft 3 .

[0043] The above implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com