Micro actuator for oil filler cap and charging cap

A technology of actuators and small doors, applied in the field of micro actuators, can solve the problems of large space occupation, inconvenient use, and loose closing, etc., and achieve the effects of convenient operation, simple and compact structure, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

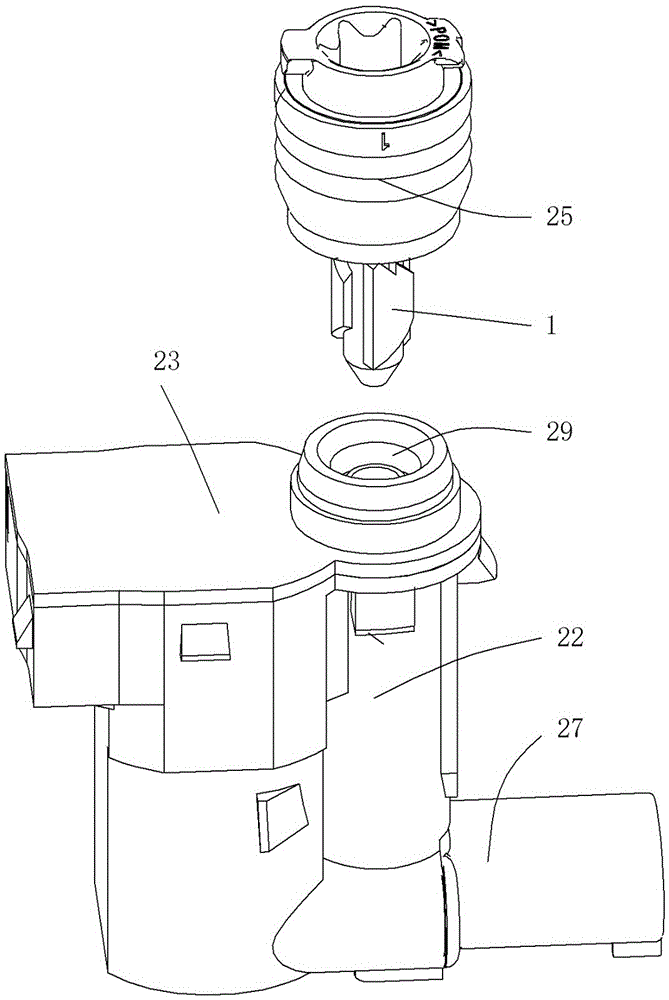

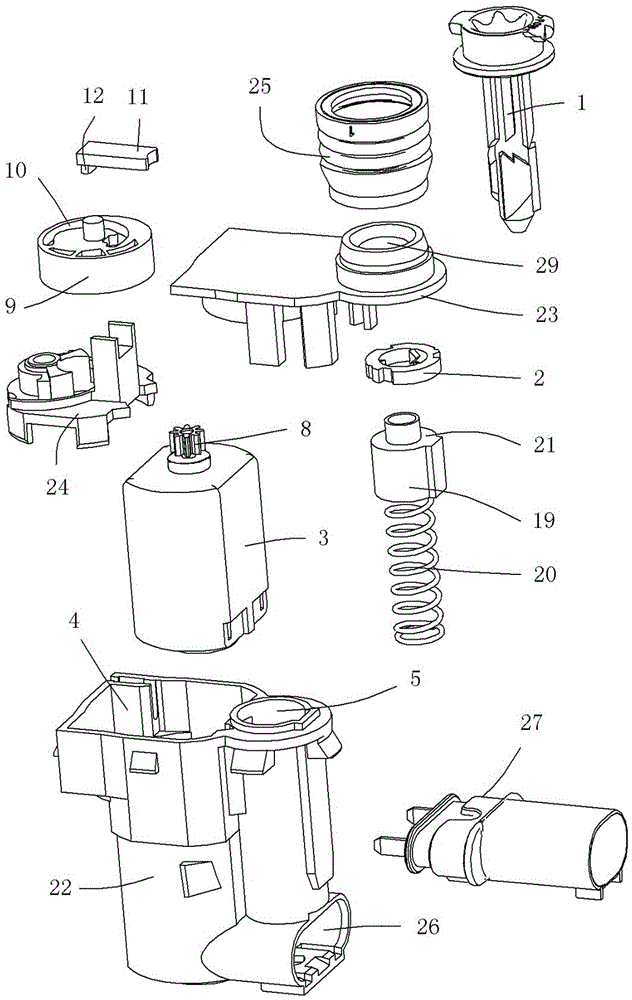

[0025] refer to Figure 1~Figure 7 , a micro-actuator for refueling small doors and charging small doors, including a lock seat assembly and a lock rod 1, the lock seat assembly includes a base, a lock piece 2 and a motor 3, and the base is equipped with There is a closed motor cavity 4 and a locking cavity 5 with one end open;

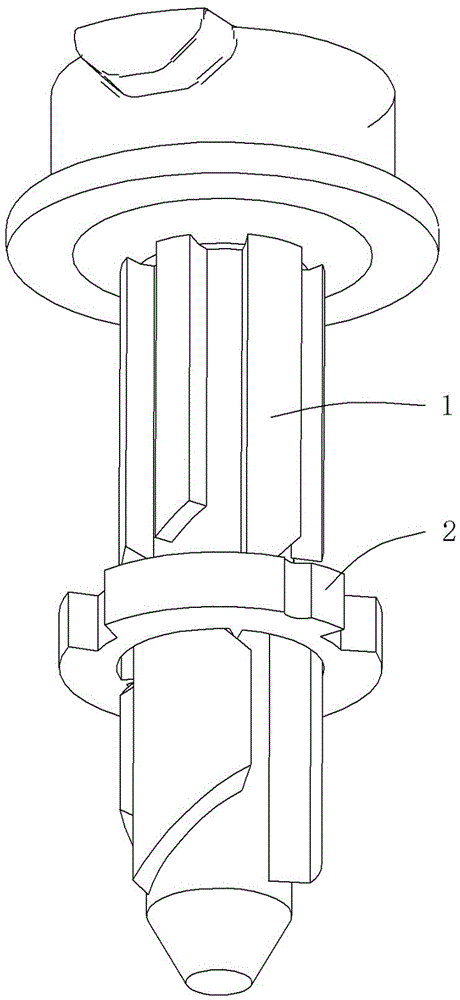

[0026] The locking piece 2 is rotatably installed in the locking cavity 5, and the center of the locking piece is provided with a locking hole 6, and at least one locking protrusion 7 is protruded on the inner wall of the locking hole, and in the locking cavity There is a reset piece under the locking piece;

[0027] The motor 3 is installed in the motor chamber 4, the output shaft of the motor is provided with a gear 8, and the gear is provided with a toothed sleeve 9 meshing with the gear, and the end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com