Non-filling self-adapting sand prevention technology method

A process method and self-adaptive technology, applied in chemical instruments and methods, earth-moving drilling, and fluid production, etc., can solve the problems of small construction displacement, aggravated oil well sand production, increased viscosity and sand-carrying capacity, etc., reducing equipment The effect of covering area, preventing formation sand migration, and improving completion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

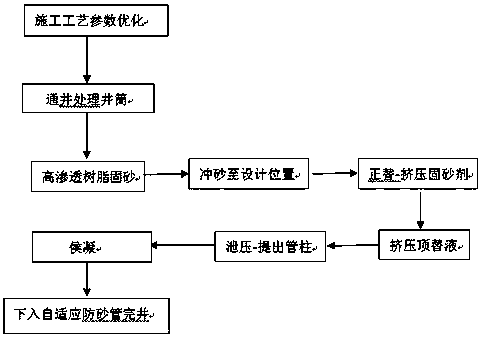

[0040] A filling-free self-adaptive sand control process method, comprising the following steps:

[0041] Step 1. Determine the structural size of the three-stage expansion sand control net of the self-adaptive expansion sand control string according to the analysis of reservoir physical properties, geological structure, and reservoir sand particle size, that is, the mesh size of the expansion sand control net in the sand retaining layer is the formation sand grain size The value is 3 to 4 times; in the stable sand layer, the mesh size of the expansion sand control net is 4 to 5 times the median value of the formation sand grain size; The value is 5 to 6 times.

[0042] Step 2, use pre-fluid to treat the wellbore, and use the well drilling standard to carry out the well drilling operation;

[0043] Step 3: wash the sand first, then lower the construction pipe string, use organic solvent to wash the heavy organic precipitate precipitated in the formation, use surfactant to red...

Embodiment 2

[0046] The step 3 in the above-mentioned embodiment 1 further includes:

[0047] 1) Select a sand producing well with good liquid supply capacity and permeability, and flush the sand to the position required by the design;

[0048] 2) Lower the construction string according to the design requirements;

[0049] 3. For sand production wells with crude oil viscosity > 1500mPa.s, water content < 80% or long-term polymer injection, the oil layer must be pretreated before sand control, including using organic solvents to wash the heavy organic precipitates precipitated in the formation, and using surfactants to reduce Oil-water interfacial tension, adding penetrant to enhance the permeability of the reservoir;

[0050] 4) For resin-type sand consolidation agents, the squeeze pressure should be lower than the fracture pressure of the formation, and if the oil layer is blocked, it must be unblocked first;

[0051] 5) Squeeze the resin-type sand-consolidating agent to make the low-mo...

Embodiment 3

[0057] The sand control process method includes:

[0058] Step 1: Determine the structural size of the three-stage expansion sand control net of the self-adaptive expansion sand control string according to the analysis of reservoir physical properties, geological structure, and reservoir sand particle size. times, this layer is the sand-retaining layer; in the middle layer, the sand-retaining transition layer, the mesh size of the expansion sand control net is 4 to 5 times the median value of the formation sand, which is the sand stabilization layer; the inner layer is the expansion control layer in the annulus of the screen casing. The mesh size of the sand mesh is 5 to 6 times the median value of the sand grain size of the formation, that is, the sand discharge layer.

[0059] In step 2, the wellbore is treated with prefluid, and the drilling operation is carried out according to the drilling specification.

[0060] Step 3: wash the sand first, and then lower the constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com