Swirling flow sand remover

A swirl sand removal and swirl tube technology, which is applied to chemical instruments and methods, filtration separation, sediment separation by centrifugal force, etc., can solve the problem of low sand removal efficiency, imperfect sand removal equipment, and the impact of sand removers on oilfield production. Eliminate problems such as low liquid volume, and achieve the effect of increasing liquid production and high sand removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

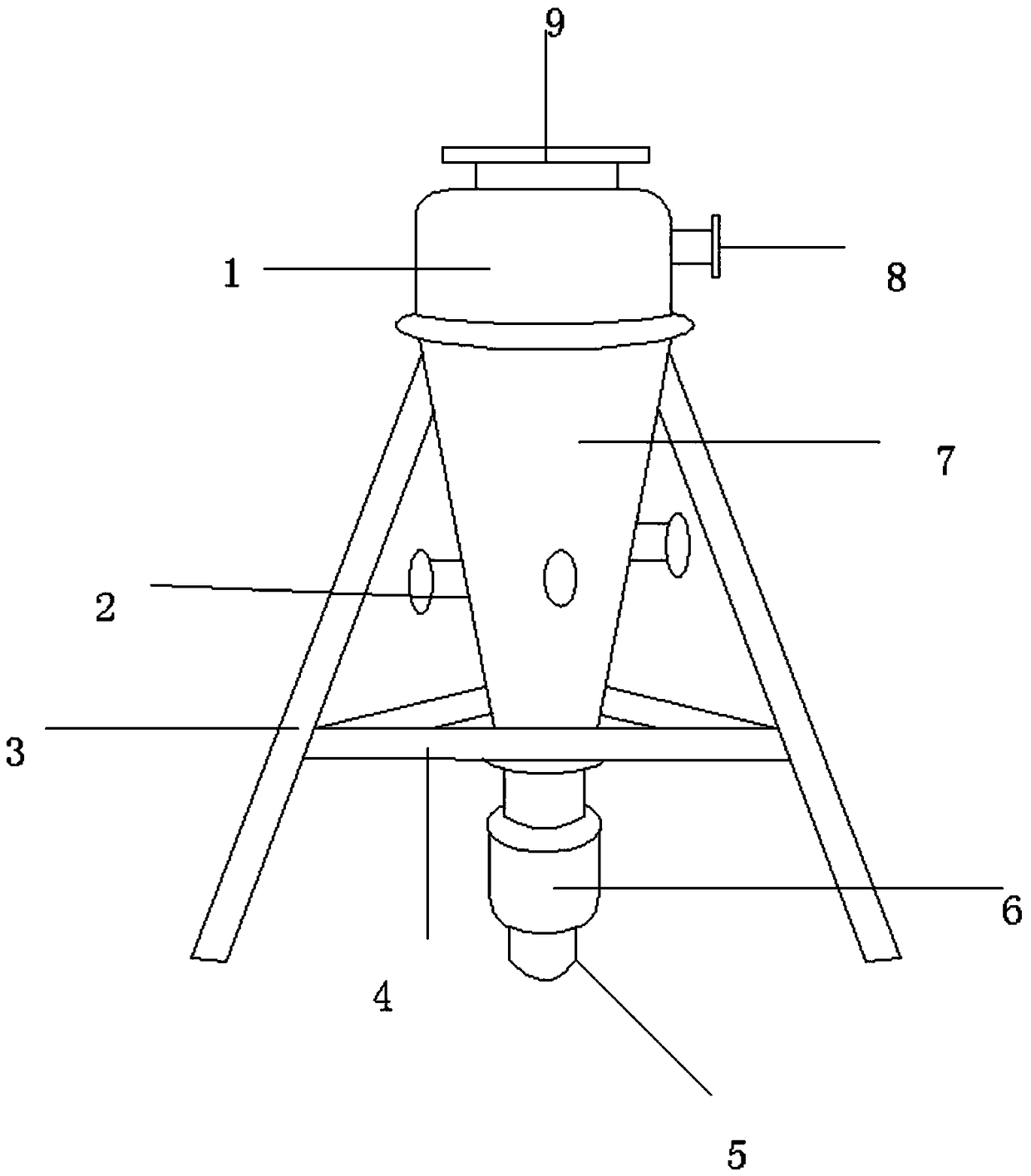

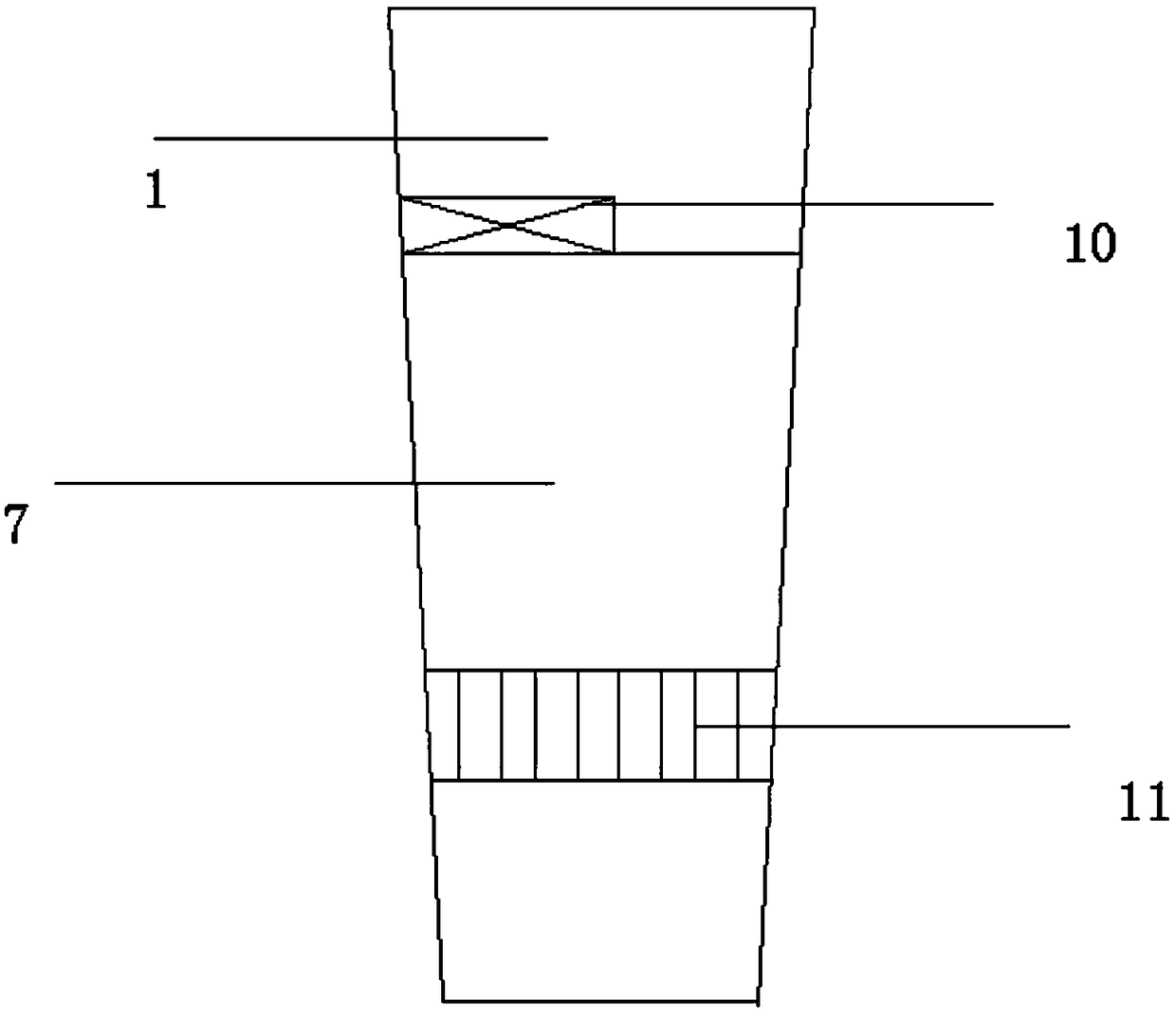

[0012] refer to figure 1 and figure 2 , a cyclone desander, its structure includes a cyclone chamber 1, a clustered cyclone tube 2, a sand discharge port 5, a sand storage chamber 6, and a sand chamber 7, and the cyclone chamber 1 is connected to a water outlet 9 and water inlet 8, the inside of the cyclone chamber 1 is provided with a preliminary filter device 10, the cyclone chamber 1 is connected to the grit chamber 7, and the grit chamber 7 is provided with three clustered cyclone tubes The sand chamber 7 is equipped with a high-efficiency sand removal device 11, the cluster swirl tube 2 is connected to the sand storage chamber 6, and the sand discharge port 5 is provided at the lower end of the sand chamber 6 , the grit chamber 7 is connected to the bracket 3, the bracket 3 is connected to the triangular bracket 4, and the connection between the swirl chamber 1 and the grit chamber 7 is provided with screws. The product of the invention provides a complete set of desan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com