Sand removing process and system of waste glue

A technology of glue and process, which is applied in the field of sand removal process and system of waste glue, can solve the problems of frequent maintenance of butterfly separator, unfavorable reuse, and large content of dilute glue, so as to improve the quality of viscose, reduce impurities, and optimize diluent The effect of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

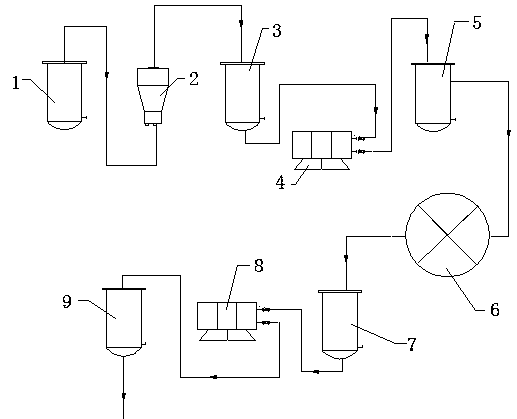

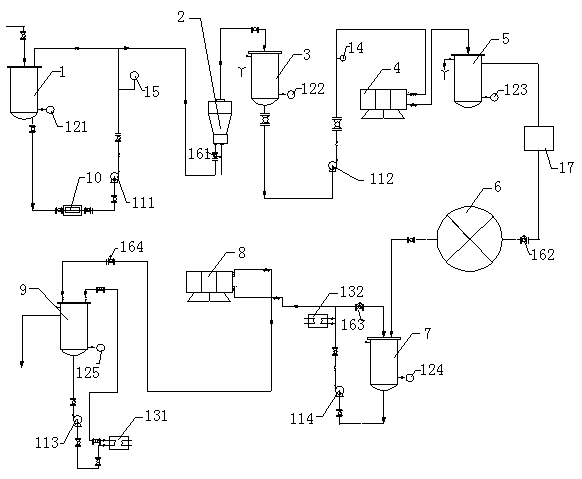

Method used

Image

Examples

Embodiment 1

[0047] A process for removing sand from waste glue belongs to the technical field of viscose production in the textile industry. The specific steps are:

[0048] a. Add the waste glue solution and the dissolved alkali into the collection barrel I according to a volume ratio of 1:6 to form a mixed solution, the dissolved alkali is an alkali solution commonly used in the viscose production industry;

[0049] b. The mixed liquid prepared in step a is delivered to the cyclone desander 2 through a booster pump. The feed pressure of the cyclone desander 2 is 3MPa, and the mixture is separated in the cyclone desander 2 to obtain the separated liquid I and waste residue; separation liquid I is discharged from a pipe with a discharge pressure of 1.5MPa, and waste residue is discharged every 30 minutes;

[0050] c. Transport the separated liquid processed in step b to a plate and frame filter I with a precision of 120 mesh for filtration to obtain filtrate I;

[0051] d. The filtrate processed ...

Embodiment 2

[0064] A waste glue removal process, the specific steps are:

[0065] a. Add the waste glue liquid and the dissolved alkali into the collection tank I in a volume ratio of 1:8 to form a mixed liquid;

[0066] b. The mixed liquid prepared in step a is delivered to the cyclone tube of the cyclone desander 2 through a booster pump, and the feed pressure is 4 MPa, and the mixture is separated in the cyclone desander 2 to obtain separated liquid I and waste residue ; The separation liquid I is discharged from the pipeline with a discharge pressure of 2.5MPa, and the waste residue is discharged every 40 minutes;

[0067] c. Transport the separated liquid after processing in step b to a metal mesh plate and frame filter with a precision of 120 mesh for filtration;

[0068] d. The filtrate processed in step c is sent to the iron separator 17 for filtration, and then sent to the butterfly separator 6 with a rotation speed of 7500r / min for separation;

[0069] e. Transport the separated liquid t...

Embodiment 3

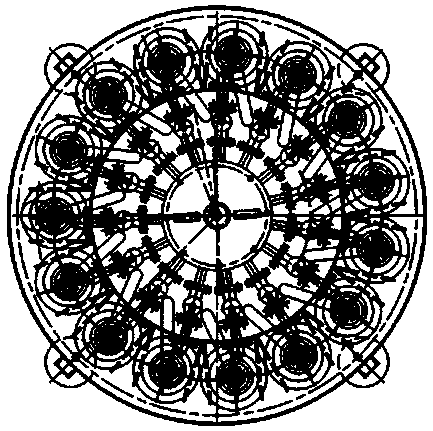

[0079] Compared with Examples 1 and 2, the difference feature is that the cyclone desander 2 is an 8-core cyclone desander 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com