Automatic inflow water control device and water control method thereof

A technology of water control device and inflow control, which is applied in wellbore/well valve device, production fluid, earth-moving drilling, etc. The effect of liquid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing, structure principle and working principle of the present invention are described in detail:

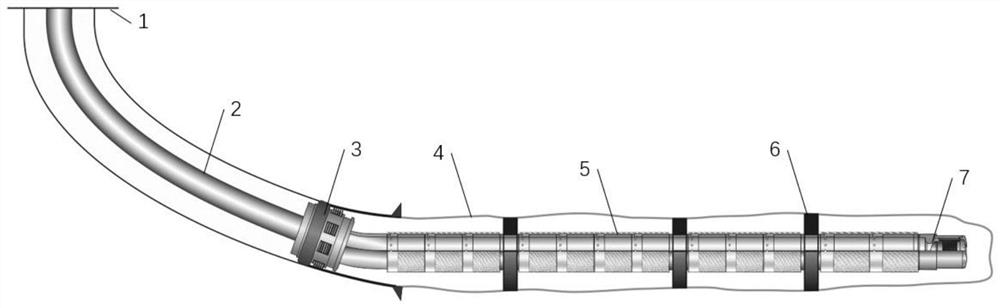

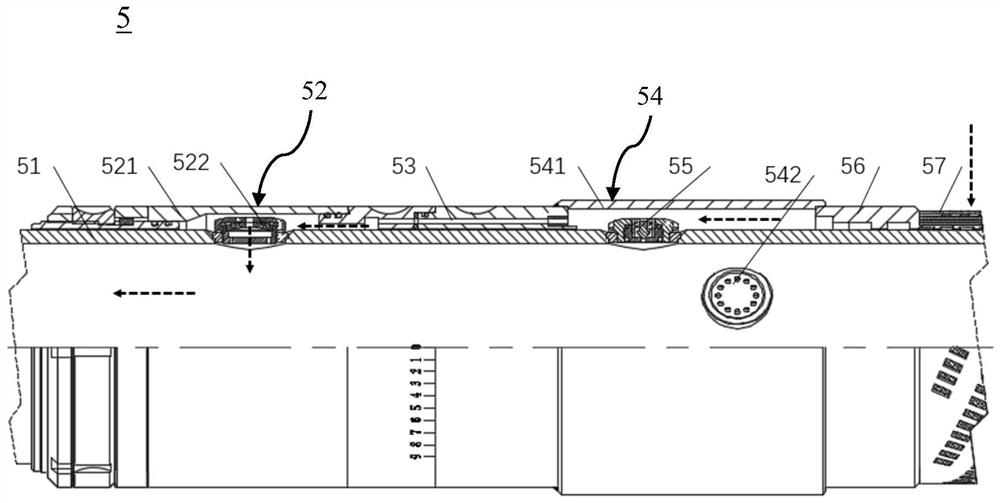

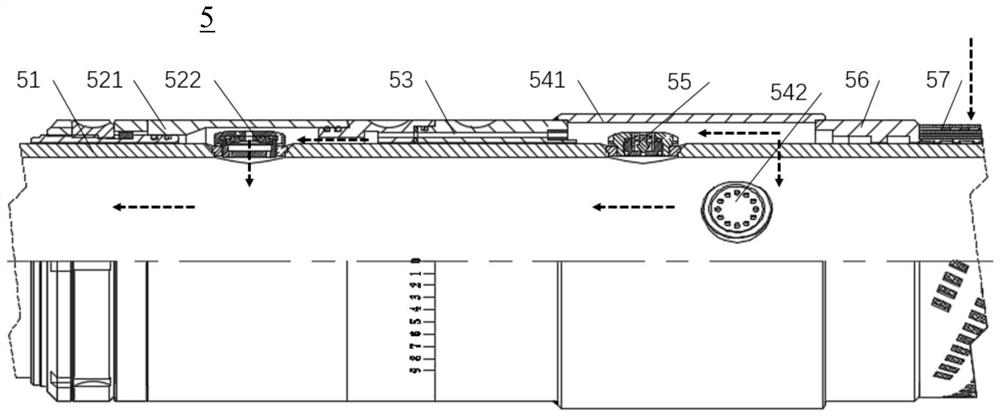

[0058] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the arrangement of the downhole pipe string according to an embodiment of the present invention, figure 2It is a schematic structural diagram of the automatic inflow water control device 5 according to an embodiment of the present invention (conventional current-limiting state). The automatic inflow water control device 5 of the present invention can increase production and can inject liquid, and it is a plurality of connected together, combined into the well, the whole pipe string is communicated with the ground 1 through the oil pipe 2, the top packer 3 and the middle packer 6 (such as an open hole packer or a continuous packer) according to the well condition, the wellbore 4 is divided into multiple sections, and the guide shoe 7 guides the pipe strin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com