Conducting loop structure of low-voltage circuit breaker

A low-voltage circuit breaker and conductive circuit technology, which is applied to circuit breaker parts, circuit breaker contacts, circuits, etc., can solve the problems that static contacts cannot use conductors, affect product temperature rise and performance, and product quality is unstable , to achieve the effect of reducing switch cost and temperature rise, simplifying the production and installation process, and improving dynamic and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

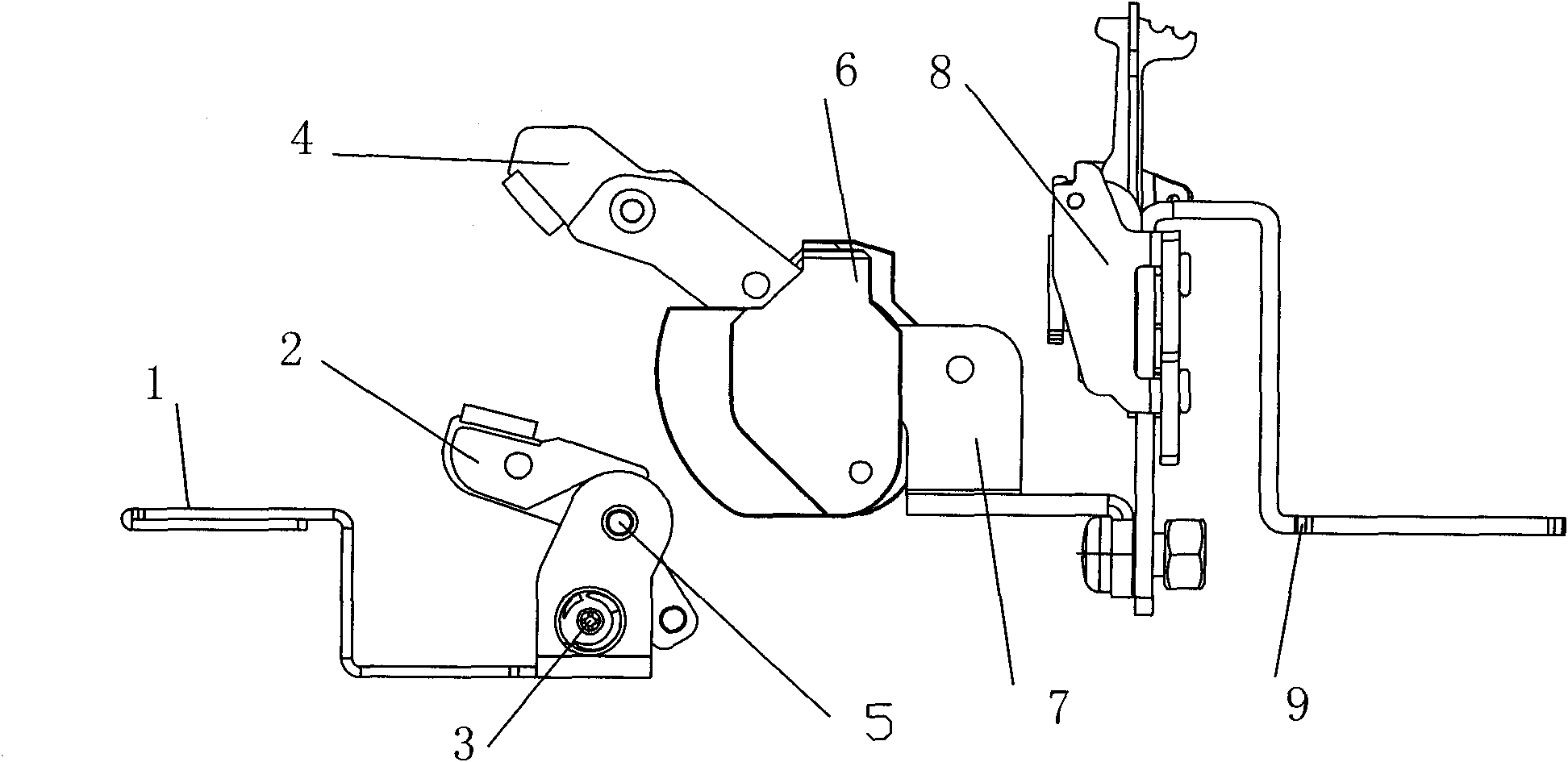

[0018] See figure 1 , The conductive circuit structure of the low-voltage circuit breaker includes the static contact 2, the moving contact 4, the rotating shaft 6, the tripping system 8 and the thermal element 9 on the tripping system 8. The static contact 2 and the movable contact 4 are in contact at the position of the rotating shaft 6 . Wherein, the static contact 2 is connected to the static contact holder 1 .

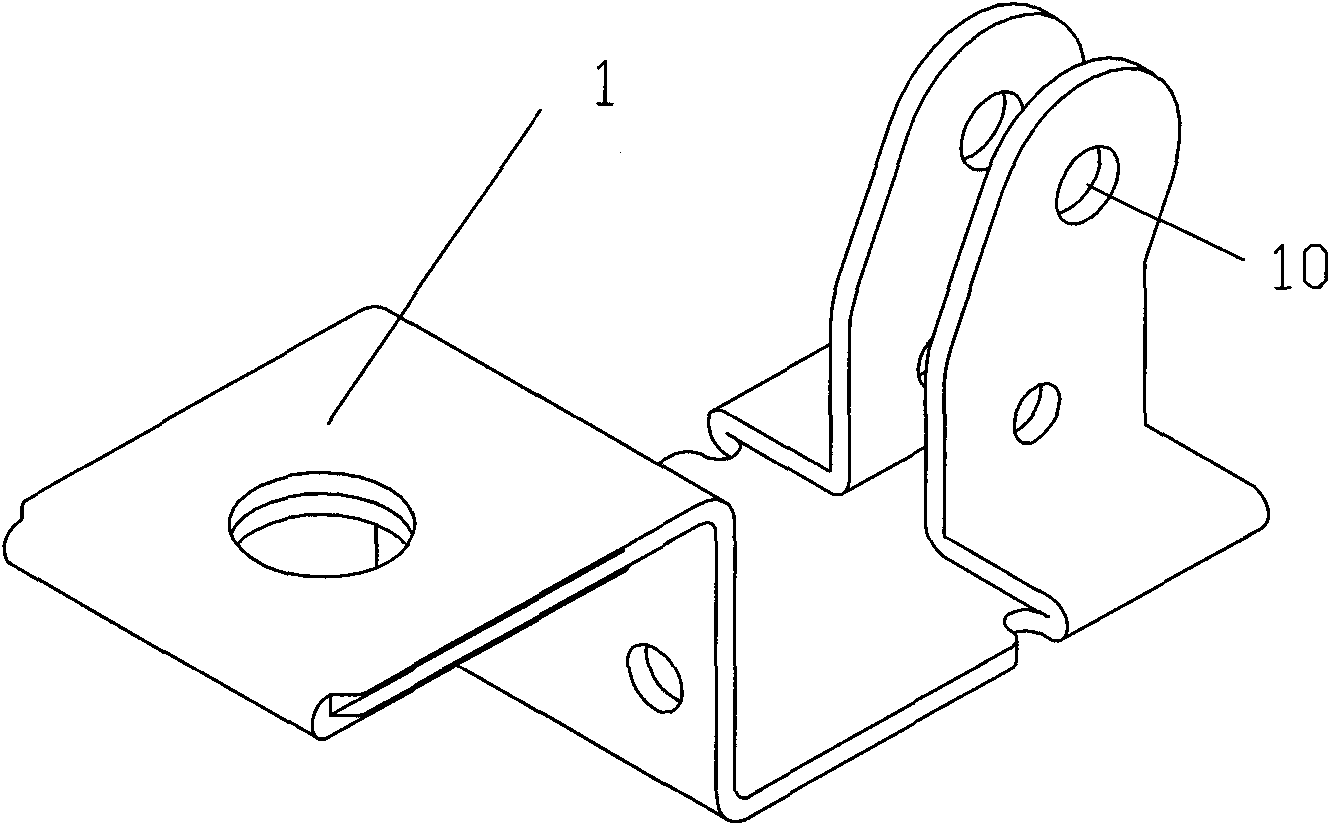

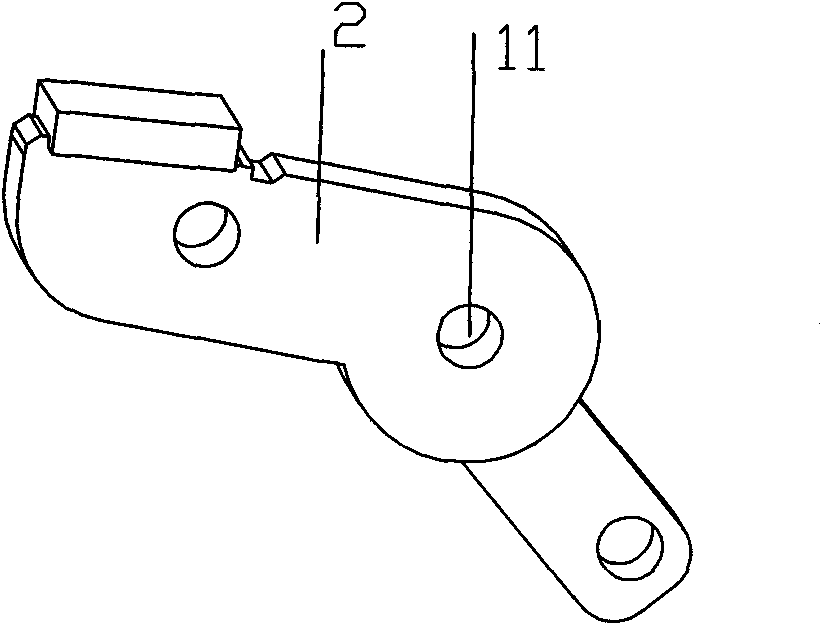

[0019] Such as Figure 2-4 , the static contact holder 1 is made of non-ferromagnetic material and consists of three continuous parts, the left part is a square structure with a hole, through which the incoming busbar and the static contact holder 1 are connected by screws Together, the right part is a double-piece clamping structure supported relative to the middle part. The static contact 2 is rotatably arranged between the double-piece clamping structures. A first hole 10 is provided on the double-piece clamping structure. The first hole 10 It is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com