Double-action oil well pump used for rodless oil extraction

A rodless oil extraction, double-acting technology, applied in the components of pumping devices for elastic fluids, pumps with flexible working elements, pumps, etc., can solve the problem of increasing energy consumption and oil production costs, short service life, and failure rate High problems, to achieve the effect of increasing single well fluid production, saving oil production costs, and increasing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

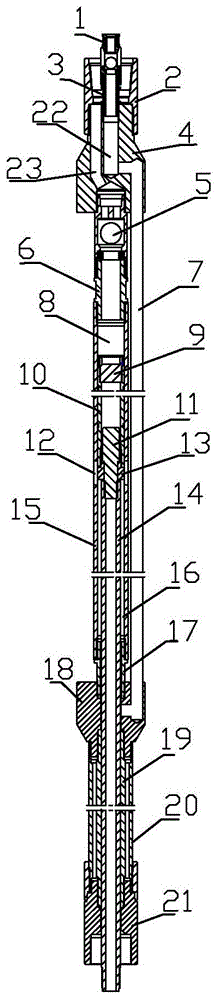

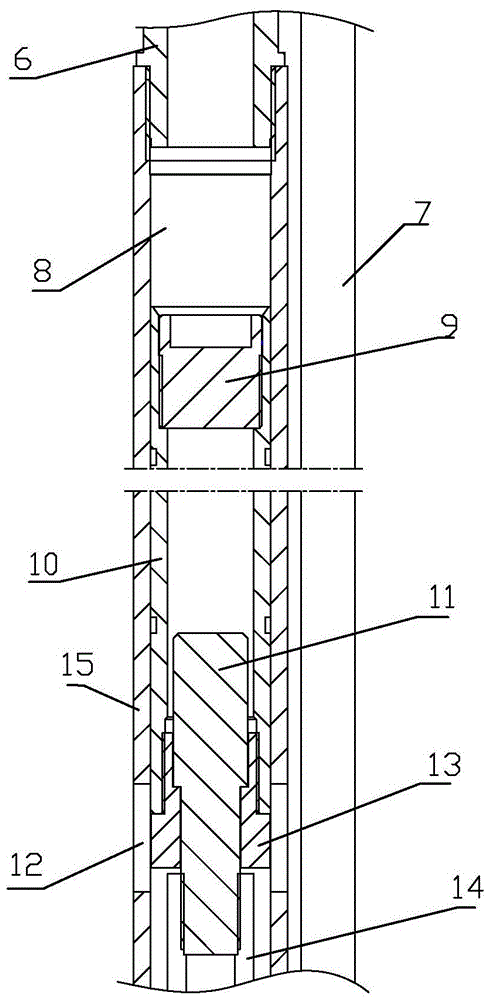

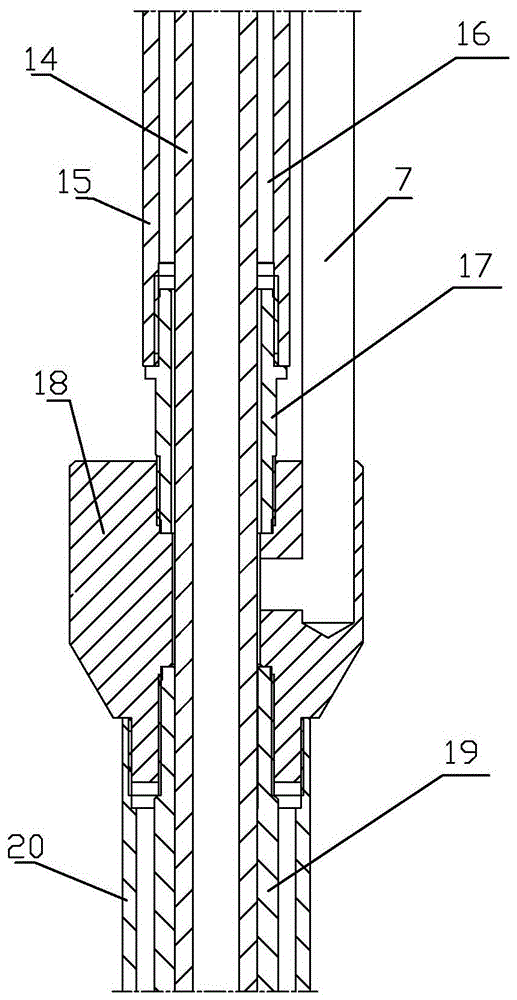

[0012] refer to figure 1 , figure 2 , image 3 Make the invention. The double-acting oil well pump used in rodless oil production includes an upper coupling 2, a long pump barrel 15, a long plunger 14, a lower pump coupling 18, a short pump barrel 19 and a lower coupling 21, and the upper end of the upper coupling 2 is fixed Connect the oil pipe, the lower end of the lower collar 21 is connected to the outer wall of the linear motor, the upper end of the short pump barrel 19 is fixedly connected with the lower end of the lower pump collar 18, the lower end of the short pump barrel 19 is fixedly connected with the upper end of the lower collar 21, and the long plunger 14 The lower part of the pump is sleeved in the cavity of the short pump barrel 19, the long plunger 14 slides without clearance in the cavity of the short pump barrel 19, and the lower end of the long plunger 14 is connected and fixed with the drive shaft of the linear motor, so that the drive shaft of the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com