Oil well gas prevention system

An oil well and gas prevention technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems that cannot meet the needs of production, the overall structure design is not reasonable, and the liquid carrying capacity is poor, etc. Achieve the effects of avoiding conflicts between layers, improving liquid carrying capacity, and improving liquid production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

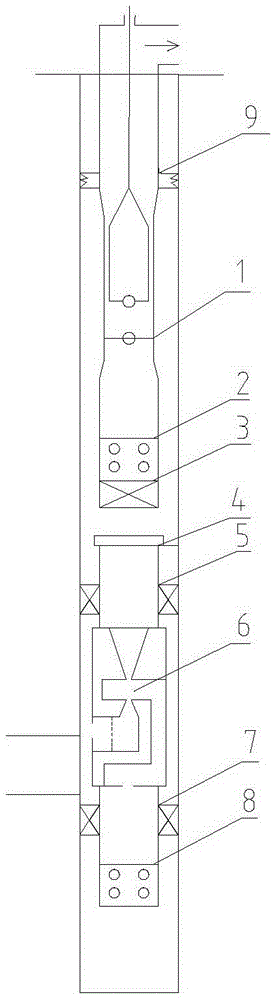

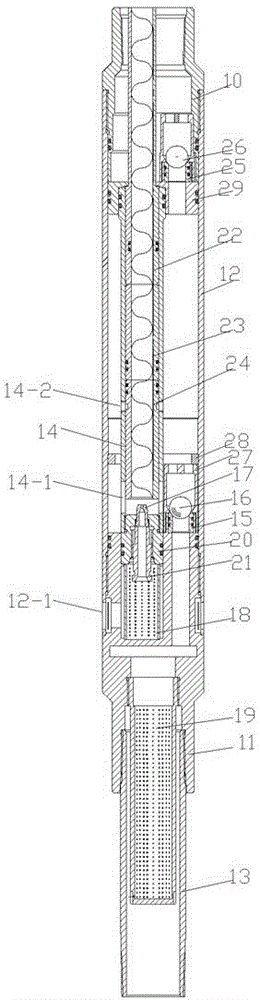

[0021] The oil well gas prevention system and usage method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0022] As shown in the figure, the oil well gas prevention system of the present invention is applied to the occasion where the upper layer is a high pressure gas production layer and the lower layer is a low pressure production layer. The oil pipe is positioned in the oil well casing through the anchor 9, the lower end of the anti-air pump 1 is connected with the upper filter screen 2 and the upper plug 3 in turn, and the oil well casing is also provided with a hand-off joint 4 located below the upper anti-air pump 1, The hand-off joint 4 is positioned in the oil well casing through the upper packer 5 arranged around it, and the lower end of the hand-off joint 4 is connected to an anti-gas lift pump 6, and the anti-gas lift pump 6 is positioned and installed through a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com