Gas-containing milk beverage and preparation method thereof

A technology for milk beverages and preparation steps, which is applied in the field of gas-containing milk beverages and its preparation, and can solve problems such as insufficient gas production, fried bottles, and no obvious taste of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025]

[0026] One embodiment of the present invention provides a preparation method of a carbonated milk beverage, comprising the following steps:

[0027] Preparation of fermented base material: after mixing raw milk, white sugar and stabilizer evenly, adjust the acidity to pH 4.30-4.40, and after constant volume with water, homogenize and sterilize;

[0028] Add strain: cool down to 30-37℃, inoculate Kluyveromyces marxianus with the addition amount of 2-8U / ton, and stir evenly;

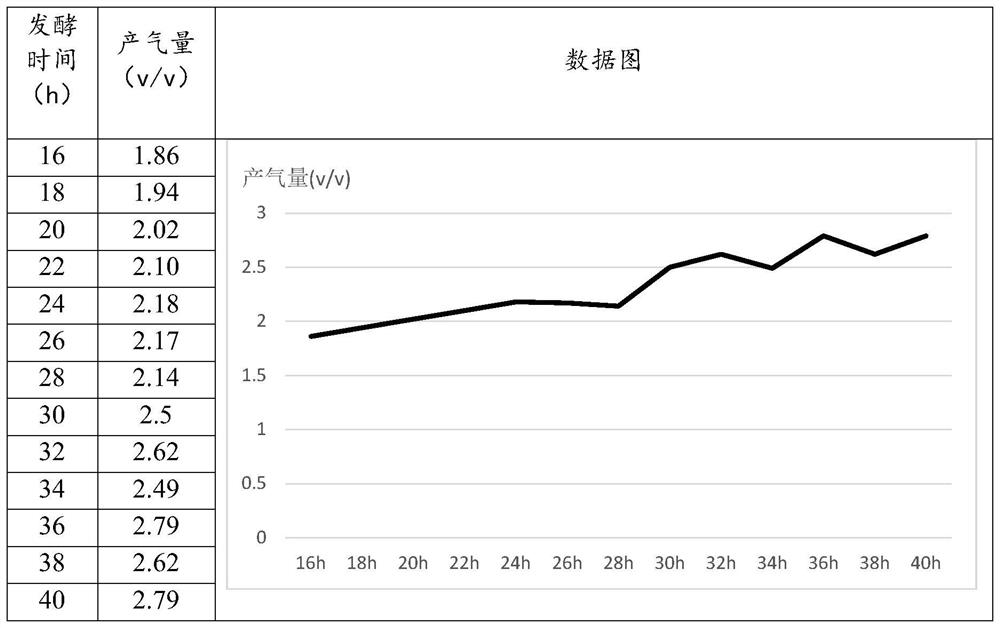

[0029] Fermentation: Fermentation at 30-37℃ for 20-30h;

[0030] Sterilization: Sterilize after fermentation.

[0031] In the above preparation method, the fermentation base material provides the material basis for fermentation, which is the basis for the bacterial species to carry out fermentation activities. If the base material is not well prepared, if the sterilization is not complete, it will affect the fermentation, thereby affecting the gas production. The amount of bacteria added affec...

Embodiment 1

[0058] The carbonated milk beverage was prepared by the following preparation method according to the following composition.

[0059]Raw material composition (total 1000kg): 155kg milk, 5.5kg whey protein powder WPC35, 80kg white sugar, 3kg soluble soybean polysaccharide, 3kg propylene glycol alginate, 0.2kg diacetyl tartaric acid monoglyceride, 0.1kg beer essence, 1.2kg Pineapple essence, water balance.

[0060] Preparation:

[0061] 1. Preparation of fermented base material: Heat the milk and whey protein powder WPC35 to 60°C, add white sugar and stabilizer, mix well, then make the material and stir for 15 minutes. The acid was adjusted to pH 4.30, and the volume was adjusted with water. After adding the essence, the mixture was heated to 60°C for homogenization, and the homogenization pressure was 50 / 250 bar. Sterilize after homogenization, the sterilization temperature is 85℃, and the sterilization time is 10min.

[0062] 2. Adding strains: After sterilization, cool dow...

Embodiment 2

[0068] The carbonated milk beverage was prepared by the following preparation method according to the following composition.

[0069] Composition of raw materials (total 1000kg): 155kg milk, 5.5kg whey protein powder WPC35, 80kg white sugar, 3kg soluble soybean polysaccharide, 3kg propylene glycol alginate, 0.2kg diacetyl tartaric acid monoglyceride, 65kg Alphonso mango pulp, water balance.

[0070] Preparation:

[0071] 1. Preparation of fermented base material: Heat the milk and whey protein powder WPC35 to 65°C, add white sugar and stabilizer, and mix them evenly. Adjust the acid to pH 4.40, and make up the volume with water. After adding the juice, the mixture is heated to 65°C for homogenization, and the homogenization pressure is 50 / 300 bar. Sterilize after homogenization, the sterilization temperature is 95℃, and the sterilization time is 15min.

[0072] 2. Adding strains: after sterilization, cool down to 37°C, inoculate and ferment, and add 8U / ton of strains.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com