Non-aqueous electrolyte with high temperature characteristics and low impedance, its application and lithium-ion battery

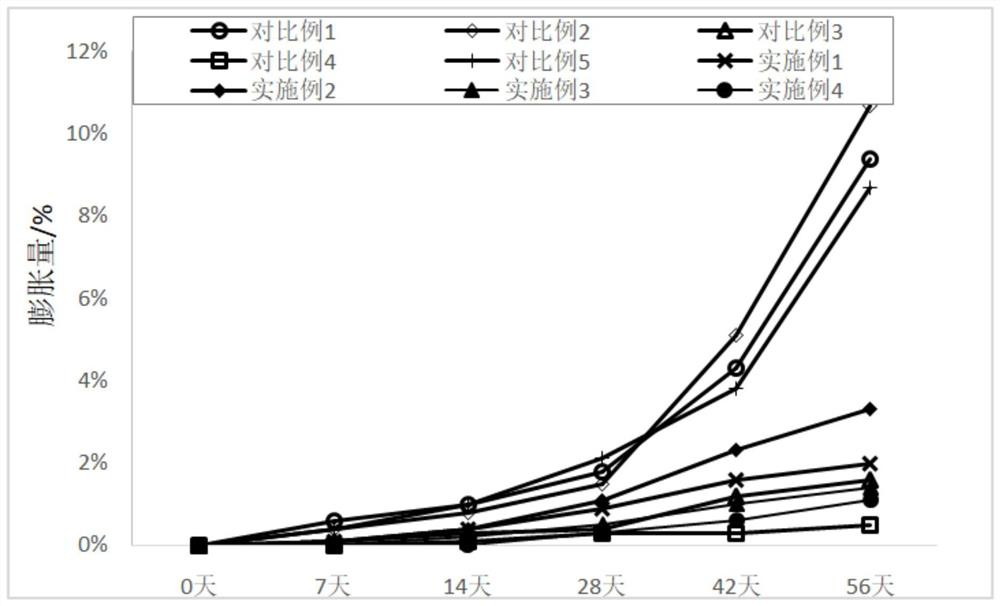

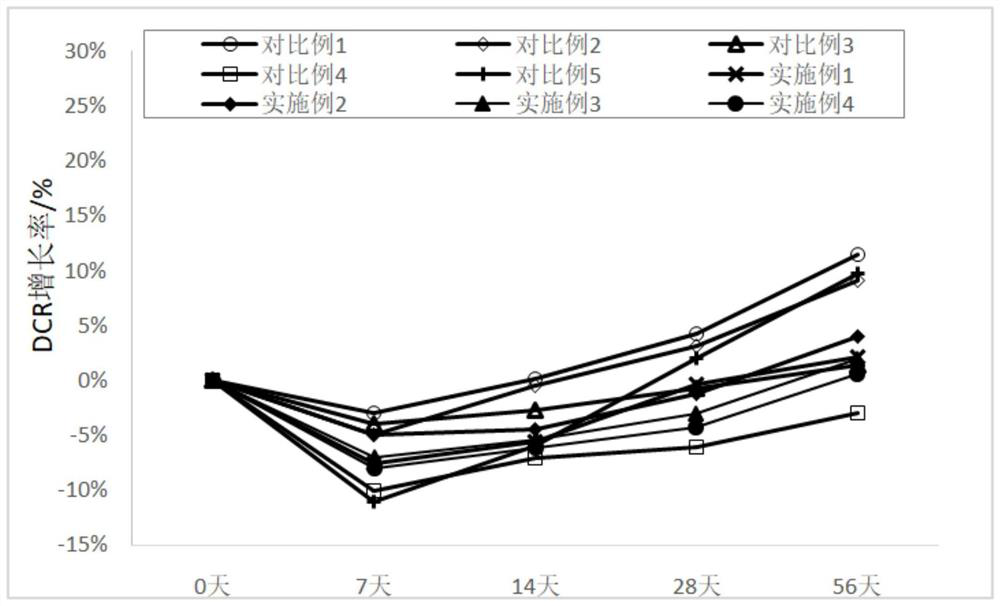

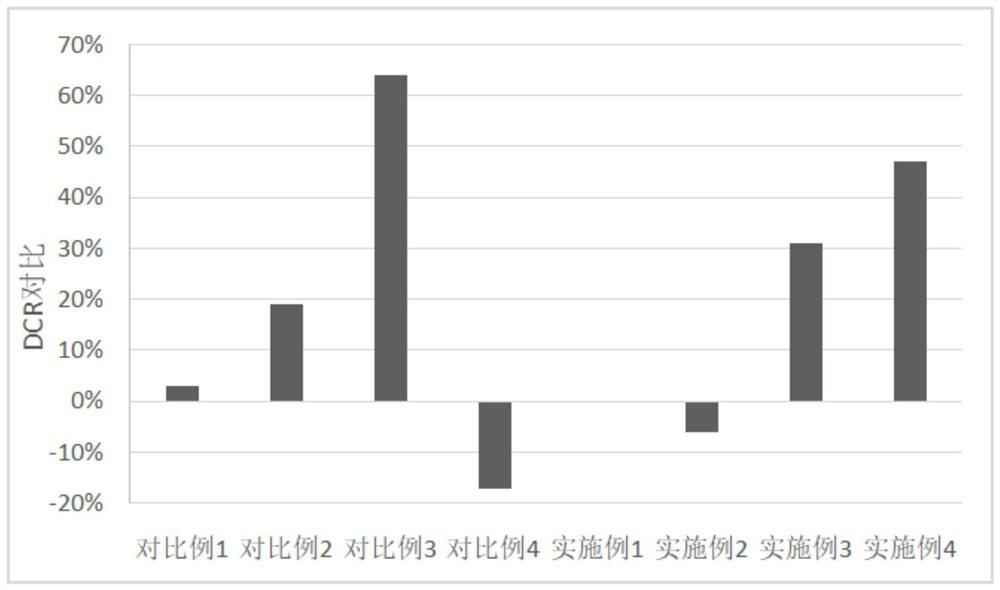

A non-aqueous electrolyte, lithium-ion battery technology, applied in the field of non-aqueous electrolyte and lithium-ion batteries, can solve the problems of large storage DCR growth, high temperature gas production, poor high temperature characteristics, etc., and achieves both rate and high temperature storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Preparation of non-aqueous electrolyte:

[0040] Mix EC / EMC / DEC into a non-aqueous organic solvent in a mass ratio of about 3:5:2, and mix the non-aqueous organic solvent with 14wt% LiPF 6 After the aqueous solution is mixed, and relative to 100 parts by weight of the non-aqueous electrolyte, add 1wt% lithium difluorophosphate, 1wt% LiFSi, 1wt% DTD, 1wt% PS, 0.2wt% VC, 0.2wt% TVS, 0.5wtTMSP , so as to obtain a non-aqueous electrolyte. In the obtained non-aqueous electrolyte, the mass fraction of non-aqueous organic solvent is 81.1%, LiPF 6 The mass fraction is 14%.

[0041] 2. Preparation of lithium secondary battery:

[0042]Based on the total weight of the positive electrode material, 97wt% NCM (LiNi x co y mn 1-x-y o 2 , x≥0.3, y≤0.3, 1-x-y≤0.5), 2wt% carbon black as a conductive agent, and 1wt% PVDF as a binder were added to the solvent NMP to make a positive electrode mixture slurry. The positive electrode mixture slurry is coated on the positive electro...

Embodiment 2

[0064] A lithium secondary battery was prepared in the same manner as in Example 1, except that the content of TVS in the non-aqueous electrolyte solution was 0.1 wt%, and the content of TMSP was 0.3 wt%. Specifically, based on the total weight of the non-aqueous electrolyte, the non-aqueous electrolyte is composed of the following mass fraction components:

[0065] Non-aqueous organic solvent 81.4wt% (EC / EMC / DEC is about 3:5:2 by mass ratio), LiPF 6 14wt%, 1wt% lithium difluorophosphate, 1wt% LiFSi, 1wt% DTD, 1wt% PS, 0.2wt% VC, TVS 0.1wt%, TMSP 0.3wt%.

Embodiment 3

[0067] A kind of nonaqueous electrolytic solution is based on its gross weight, and is made up of the component of following mass fraction:

[0068] Non-aqueous organic solvent 89.5wt% (EC / EMC / DEC is about 3:5:2 by mass ratio), LiPF 6 8.7wt%, 0.1wt% lithium difluorophosphate, 0.6wt% LiFSi, 0.3wt% PS, 0.5wt% TVS, 0.3wt% TMSP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com