Layered oil production device with double electric submersible pumps sharing power line

A technology of layered oil production and electric submersible pump, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problem that the size of the cable packer cannot be enlarged, and multiple power cables can not be crossed side by side. Problems such as high cable cost, to achieve the effect of easy installation of power cables, simple commissioning and production, and good production increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

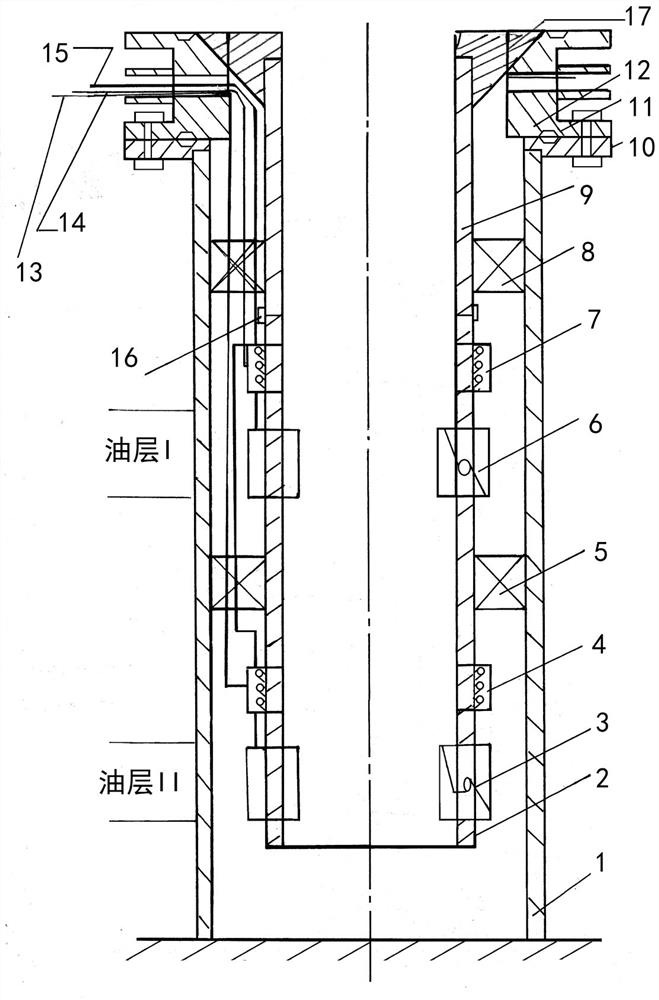

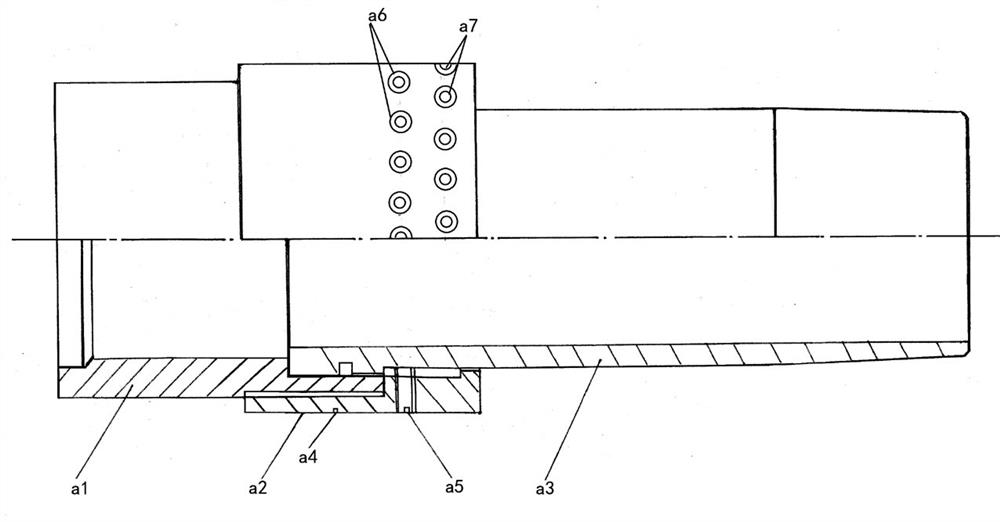

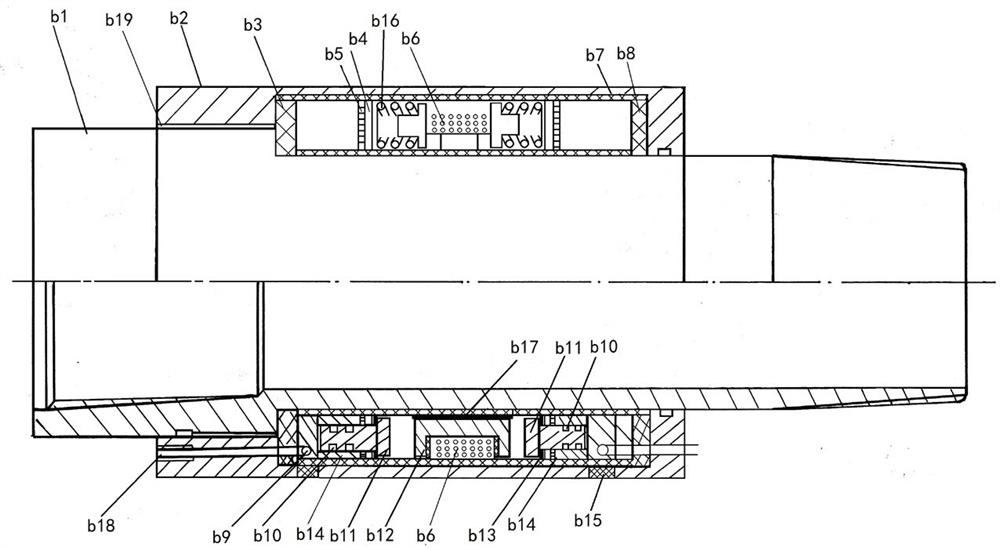

[0036] Embodiment 1, with reference to figure 1 , a layered oil recovery device with dual electric submersible pumps sharing a power line mentioned in the present invention, including a casing 1, a liner 2, a production string 9, a wellhead flange 10, a large cross 12, a hanger 17, a large The spool 12 is installed above the wellhead flange 10, and the production string 9, the electric submersible pump and the liner 2 are lowered into the casing 1 through the hanger 17. It is characterized in that: the electric submersible pump adopts the lower electric submersible pump The submersible pump 6 also includes a lower start switch 4, a lower pass cable packer 5, an upper start switch 7, an upper pass cable packer 8, a lower start switch control line 13, an upper start switch control line 14, and a three-phase power line 15 and phase compensator 16 are connected to the lower ESP 3, the lower start switch 4, the lower pass cable packer 5, the upper ESP 6, the upper start switch 7, t...

Embodiment 2

[0062] Embodiment 2, a layered oil recovery device with dual electric submersible pumps sharing power lines mentioned in the present invention, including casing 1, liner 2, production string 9, wellhead flange 10, large cross 12, hanger 17. The large cross 12 is installed above the wellhead flange 10, and the production string 9, the electric submersible pump and the liner 2 are lowered into the casing 1 through the hanger 17, and the feature is that the electric submersible pump adopts the lower electric submersible pump 3 and the upper electric submersible pump 6, and also includes a lower start switch 4, a lower pass cable packer 5, an upper start switch 7, an upper pass cable packer 8, a lower start switch control line 13, an upper start switch control line 14, three The phase power line 15 and the phase compensator 16 are connected to the lower electric submersible pump 3, the lower start switch 4, the lower pass cable packer 5, the upper electric submersible pump 6, the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com