Liquid extraction method for binary compound flooding subsequent water flooding stage considering inter-well difference

A binary compound flooding and follow-up technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of not considering the difference in dynamic correlation of oil increment, limited development effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

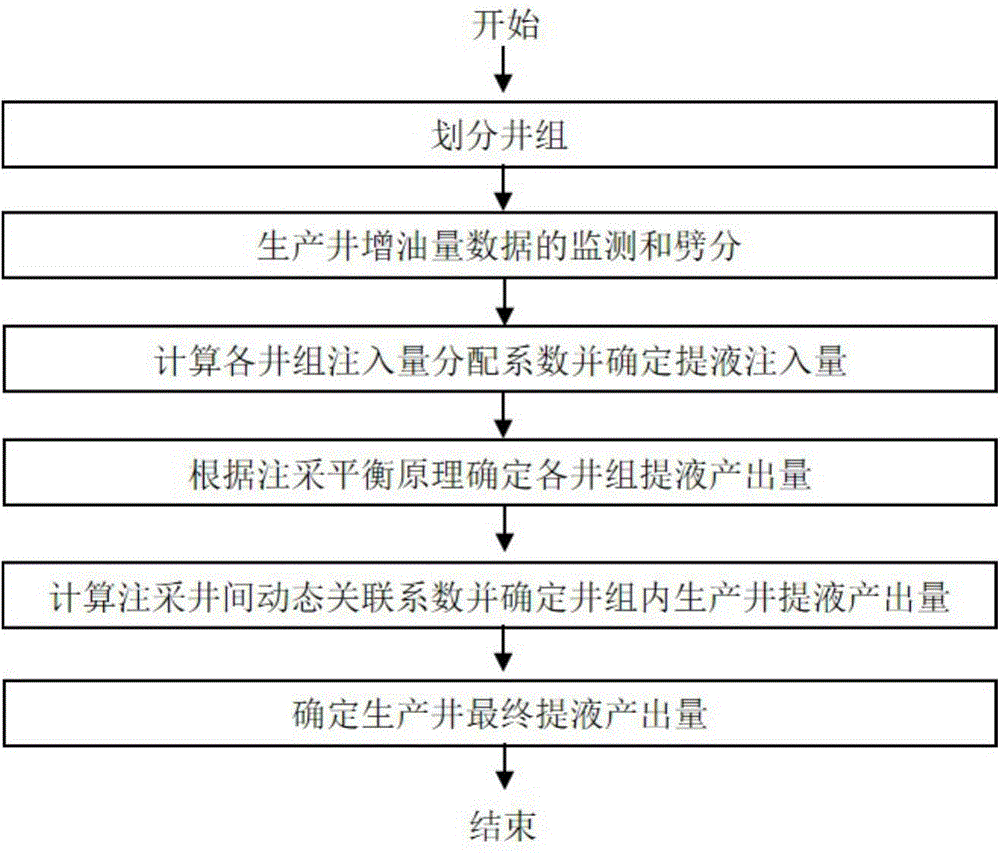

Method used

Image

Examples

Embodiment 1

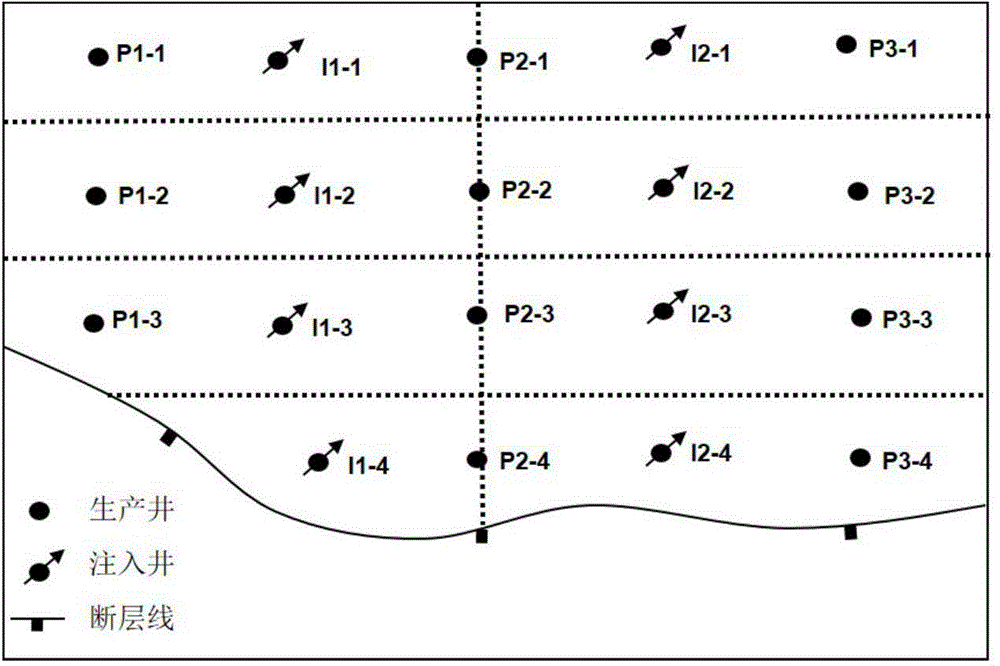

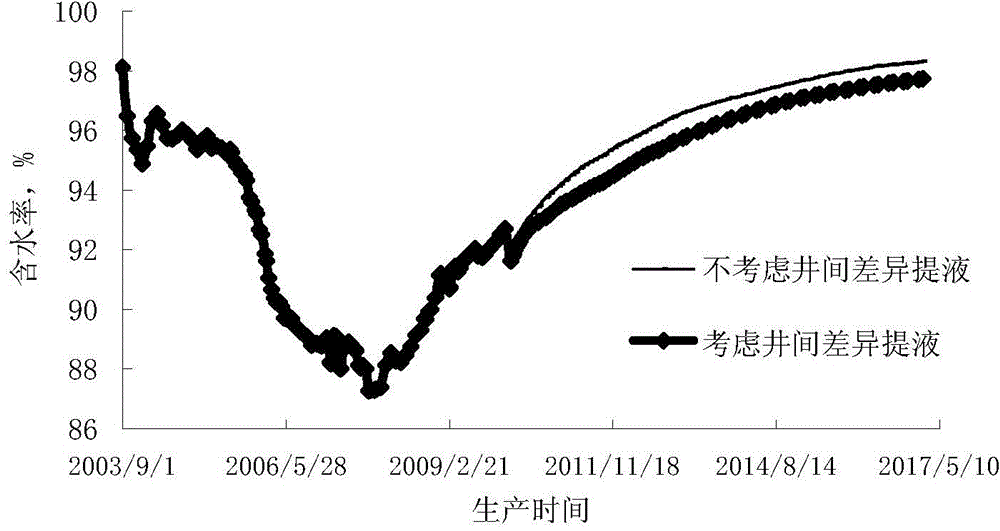

[0041] In a binary compound flooding pilot area, 19 wells are designed, see figure 2 , among them, 11 production wells and 8 injection wells, using the positive row injection-production well pattern, began to inject polymer pre-slug in September 2003, injecting 0.078 times the pore volume; began to inject polymer in June 2004 The binary main slug of material and surfactant injected 0.49 times the pore volume; in January 2010, it was transferred to follow-up water flooding. In order to ensure the development effect of subsequent water flooding, the liquid extraction measures were adjusted. This measure increases the injection and production volume of each single well at the end of chemical agent injection, and the average liquid extraction rate in the whole area is determined to be 20% after optimization, that is, the injection and production volume of 8 injection wells and 11 production wells are all increased from 960m 3 / d increased to 1152m 3 / d. The following takes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com