With-production without-injection-type isolated well point potential tapping and effect raising method

A technology of isolated well point and injection type, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., and can solve problems such as imperfect injection and production, lack of energy, and poor development potential tapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention will be further described in conjunction with Daqingtai 10-18 well.

[0033] (1) Optimizing the target well:

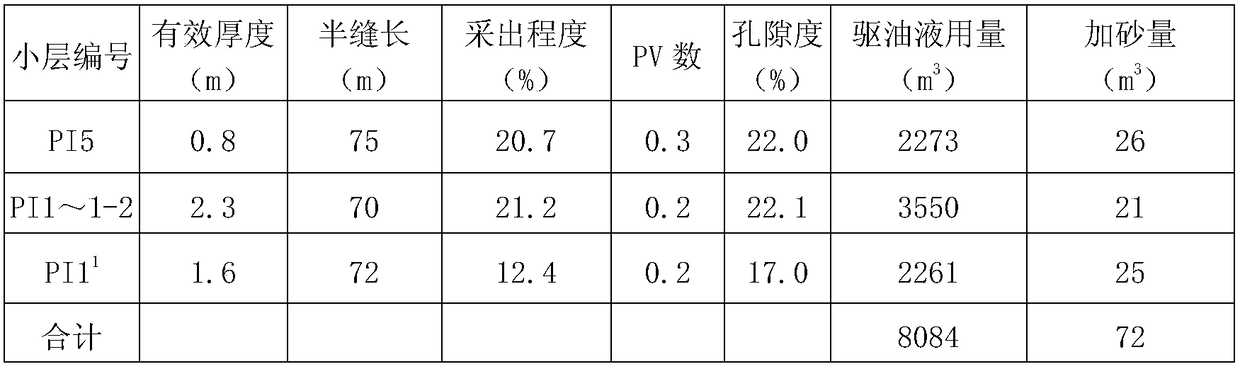

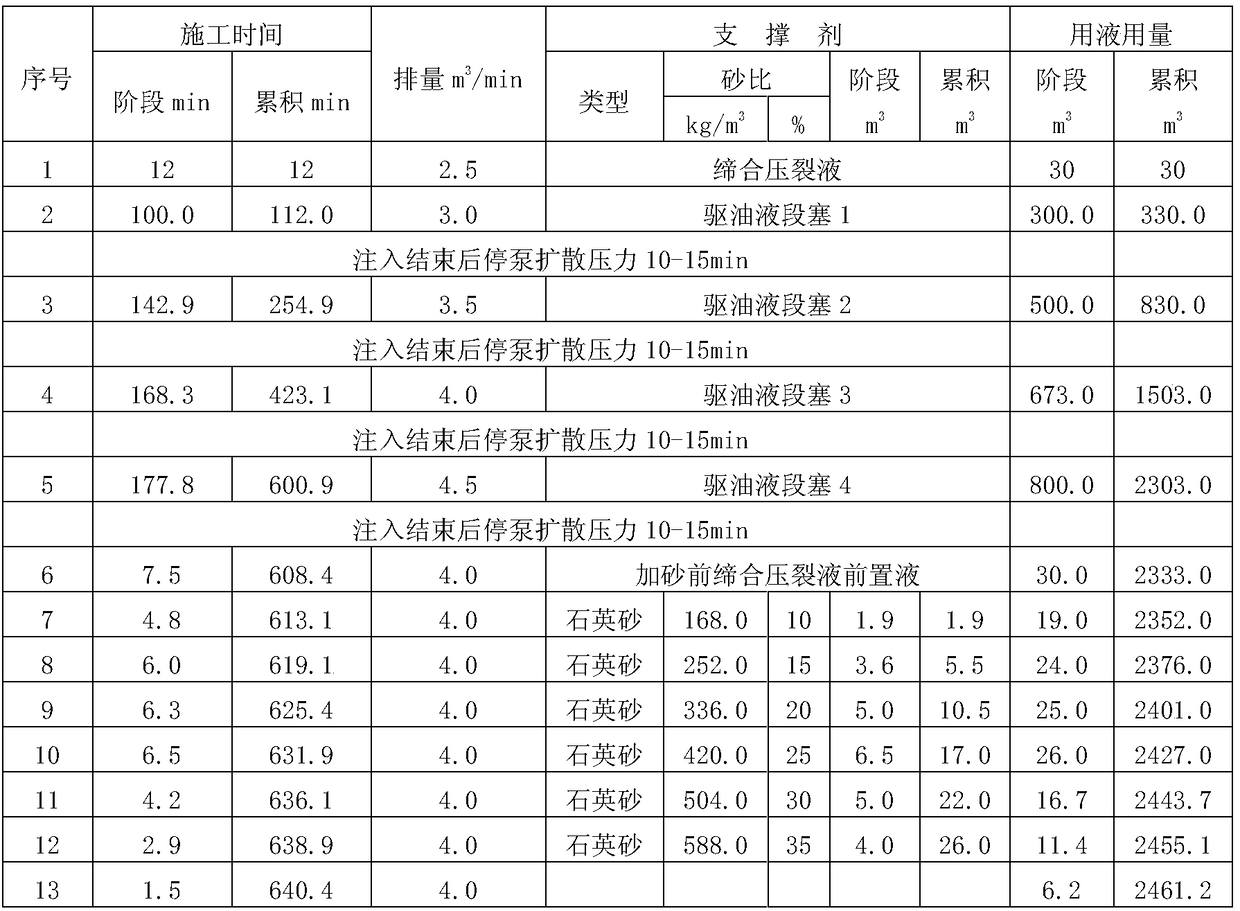

[0034] Well Tai 10-18 is located in the fault trap area and is an isolated production well with production and no injection. Drilling time was completed on June 30, 2009. The depth of the perforated section is 1111.6-1138.9m, and a total of 4 sublayers of Pu I1-5 have been perforated. According to the location of the isolated well point, combined with cementing quality, perforation interpretation data, fine reservoir description results, fine remaining oil research results, reservoir production status evaluation data and other comprehensive evaluations, it has the potential to tap potential, and is selected as the target well.

[0035] (2) Determine the timing of tapping the potential of the target well:

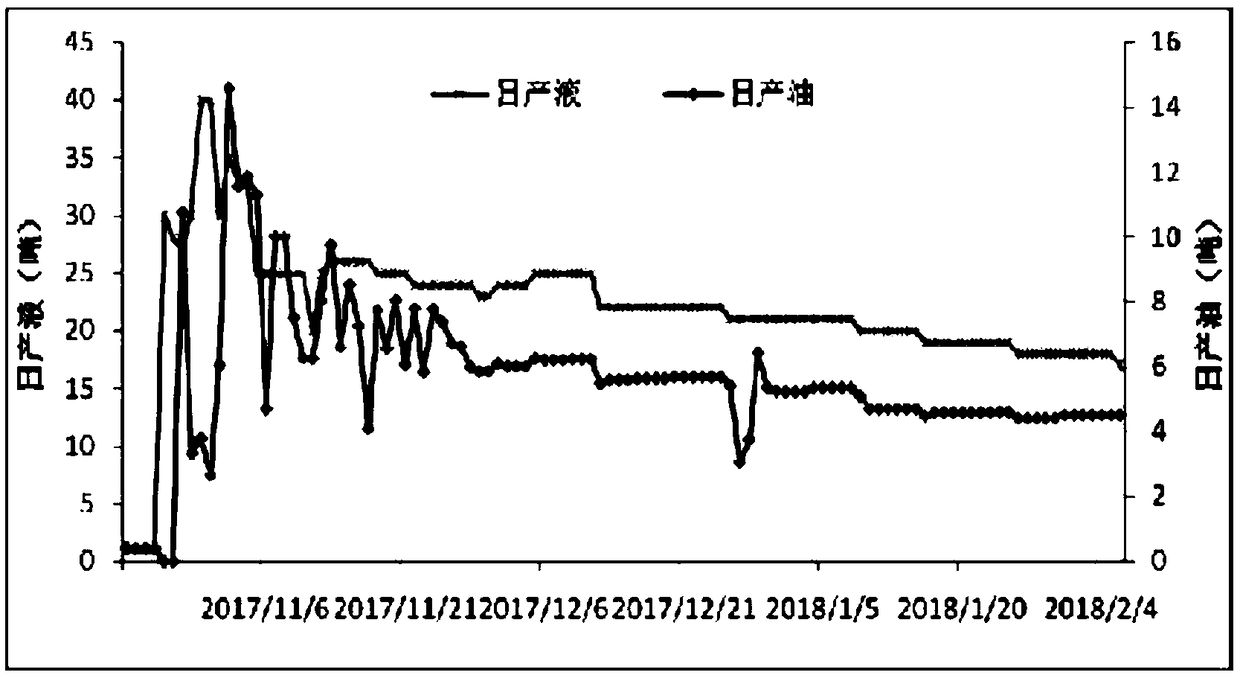

[0036] The well was put into production with ordinary perforation in December 2009. Initially, the daily fluid production was 3.0t, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com