Method for completing well by cementing top of expandable screen

A technology of cementing and screen pipe, which is applied in earth-moving drilling, wellbore/well components, production fluid, etc., can solve problems such as screen pipe damage and screen pipe collapse, avoid repeated operation, prevent well wall collapse, The effect of increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

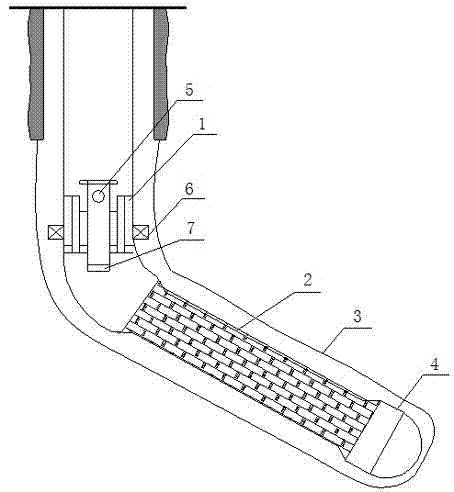

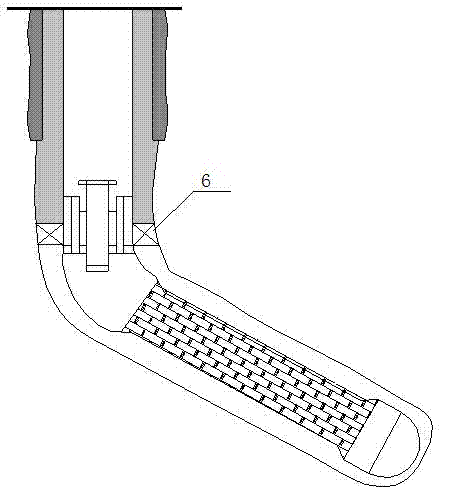

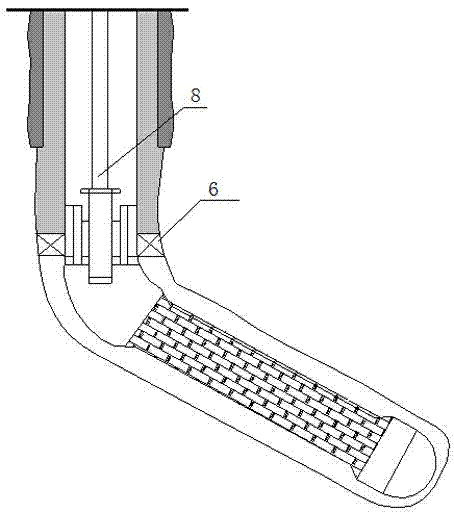

[0018] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0019] Such as Figure 1~Figure 5 As shown, the completion liner of the expansion screen top cementing completion method is mainly the ordinary casing and the expansion screen 2, and the plug-free system 1 is added between the casing and the expansion screen 2. For the expandable screen 2, please refer to the patent No. ZL200820018905.1 (an expandable sand control screen). The cementing hole 5 is processed on the plug-free system 1, which can provide a passage from the casing to the annulus during the cementing process. After the cementing is completed, the cementing hole can be closed by itself, and the plug-free system 1 is processed with a sealant The barrel 6 is used to isolate the annular space between the casing and the expandable screen 2 during the cementing process, so that the cement slurry will not sink into the annular space between the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com