Method of synchronous numerical control oil pumping according to stroke frequency for oil well testing and operation after filling of pump

An oil-pumping and oil-well technology, which is applied in the field of pump-filled synchronous numerical control oil-pumping method according to the strokes, can solve the problems of unsatisfactory pump filling, no calculation and management method, large error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

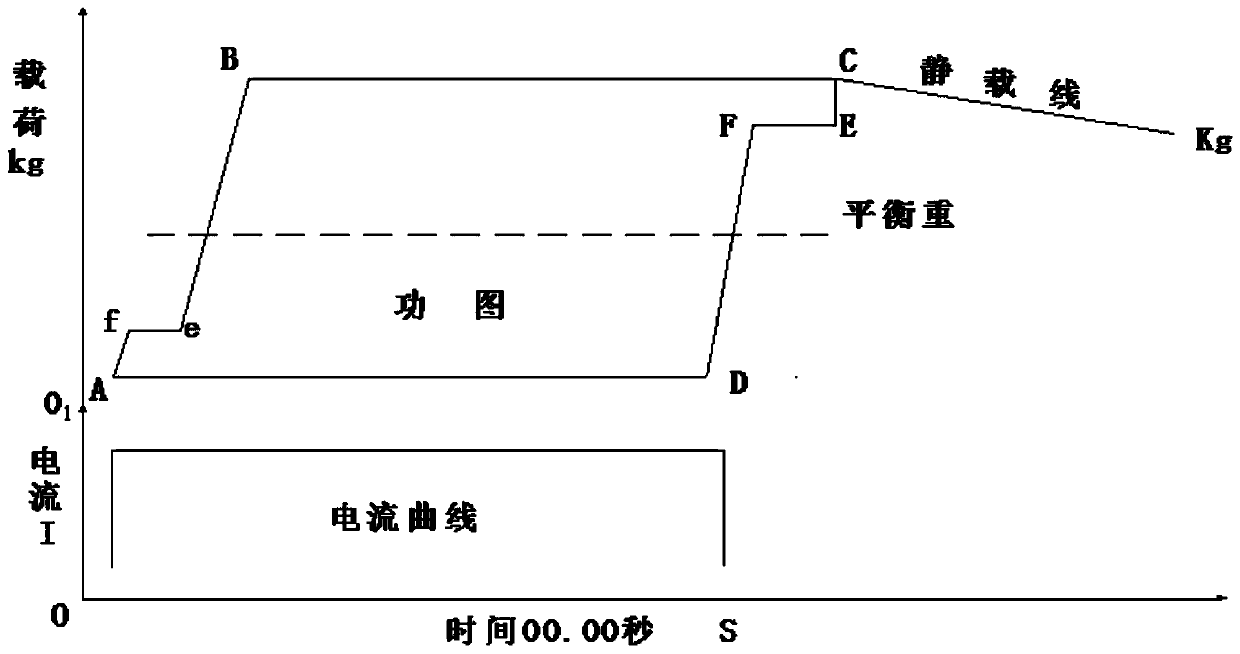

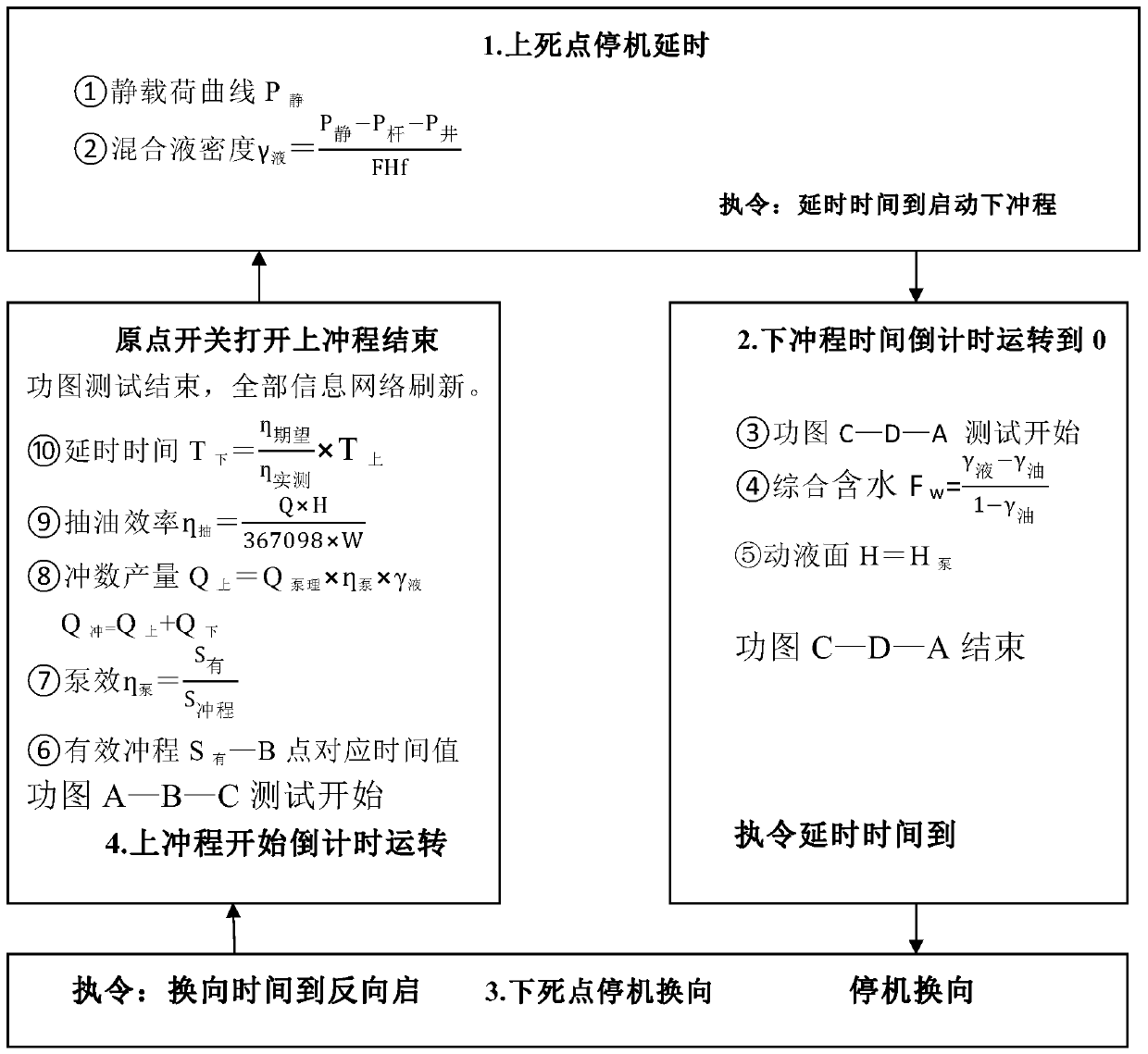

[0114] Such as figure 1 As shown, the present invention provides a kind of oil well test and waits for the pump to be full and presses the synchronous numerical control oil pumping method; When the plunger of the pump moves upwards and touches the liquid surface, the pipe rod is elastically deformed before the oil outlet valve is opened, and the load rises from a straight line to the maximum value of B, and the inflection point begins to stabilize. Point B is the effective value, and the length to C is the effective stroke of the upstroke. There is no f-e line segment for double-acting pumps, point B is only the maximum load point, and C is the top dead point of pumping. The beam machine must immediately switch to the downward direction, while the smart machine must stop and delay the changeover. When the lower pump is full, it must wait for oil storage The device is fully filled to ensure that the upper pump is fully charged when going down. At the bottom dead point, there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com