Optimum stroke process suitable for super-low permeability reservoir digital oil pumping unit

A technology of optimal stroke times and process methods, applied in earthwork drilling, self-adaptive control, mining fluids, etc., can solve problems such as high risk of electrokinetics, heavy installation workload, hot fire on site in oil fields, etc., and achieve extended inspection Pump cycle, low maintenance cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

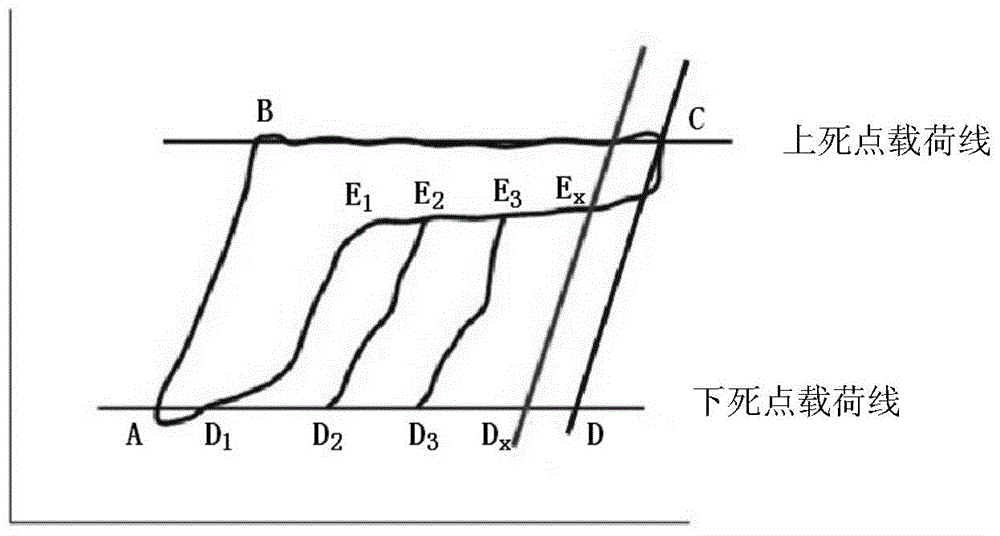

[0049] Embodiment 1: as figure 1 , figure 2 , image 3 as shown,

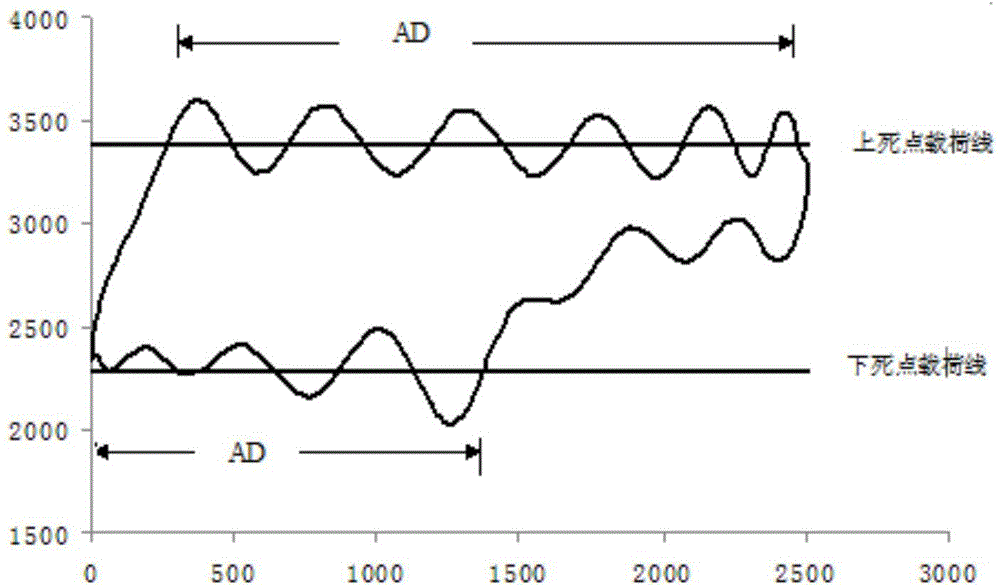

[0050] In practical applications, it is difficult for the wellhead RTU to obtain the theoretical pump power diagram, so the surface power diagram is used to approximate the pump fullness. An example of calculating the pump fullness from the actual work diagram is as follows:

[0051] by figure 2 Take the dynamometer diagram as an example. Through approximate calculation, the load value of the load line at the top dead point is 33.83kN, and the load value of the load line at the bottom dead point is 22.82kN. The effective stroke, The approximate effective stroke during the downstroke is:

[0052] AD=2.507-2.53=2.254; ADx=1.357-0=1.357;

[0053] The approximate value of pump fullness calculated from this is: b=ADx / AD=1.357 / 2.254=60%;

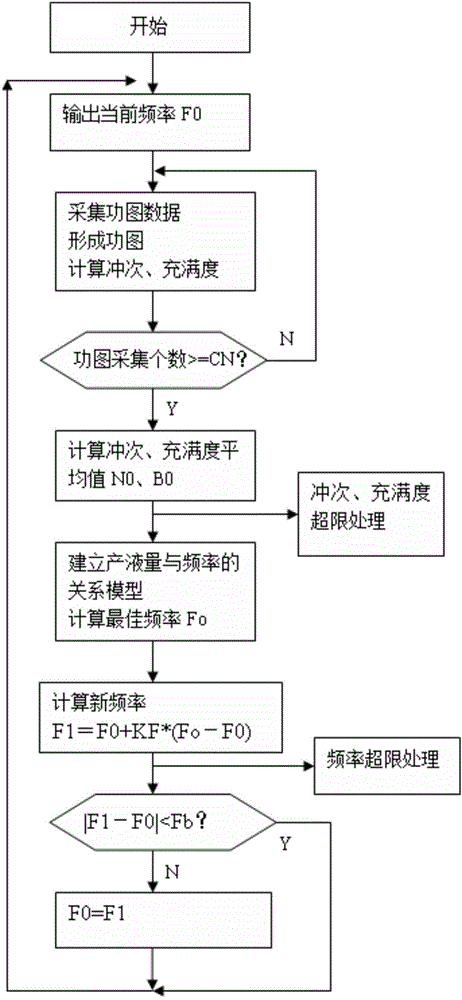

[0054] 3. Flow chart of stroke frequency adjustment;

[0055] The flow chart is attached image 3 .

[0056] Setting parameters:

[0057] Fmin, Fmax—minimum and maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com