Fluid dynamic annular space cavitation device

A fluid power and cavitation technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems that affect the full production of crude oil, limited operation effect, corrosion of construction equipment and pipe strings, etc., and achieve the goal of overcoming cavitation The effect of cavitation is not good or even cavitation is not good, the effect lasts for a long time, and the radiation range expands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

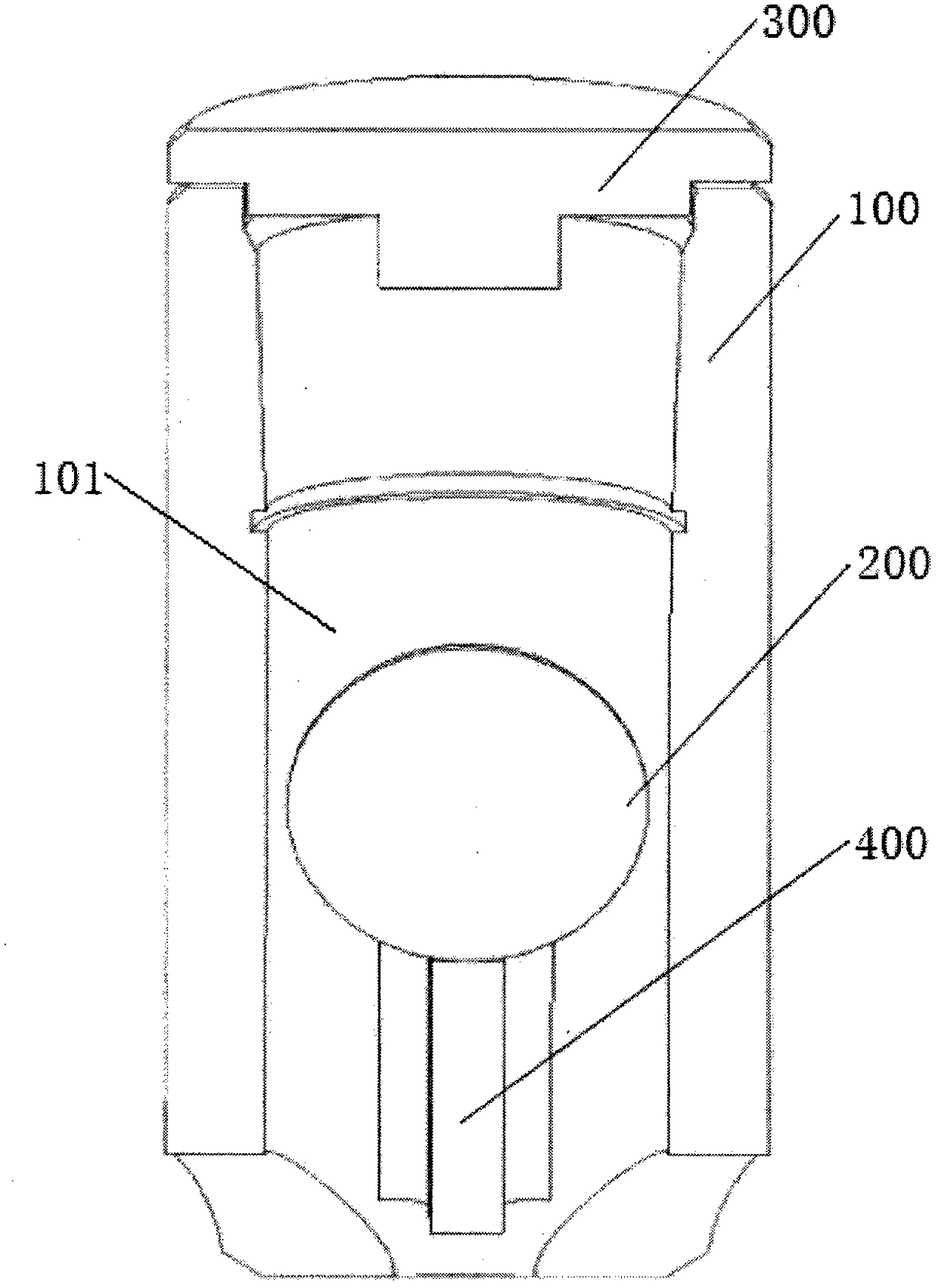

[0034] Such as figure 1 As shown: the hydrodynamic annular space cavitation device provided by Embodiment 1 of the present invention includes a cylindrical shell 100, a spherical dynamic body 200, a stop plate 300 and a bracket 400, and a working area is set inside the cylindrical shell 100 101, the spherical power body 200 is set in the working area 101 in the cylindrical housing 100, and a fluid (water) circulation is formed between the outer wall of the spherical power body 200 and the inner wall of the cylindrical housing 100 channel (not shown in the figure), and cavitate the fluid flowing through the channel, the stop plate 300 is arranged on the top of the cylindrical housing 100, and is used to prevent the spherical power body 200 from The upper part of the cylindrical housing 100 is protruded, so that the spherical power body 200 works in the working area 101 in the cylindrical housing 100, and the stop plate 300 is provided with a water hole, and the bracket 400 It ...

Embodiment 2

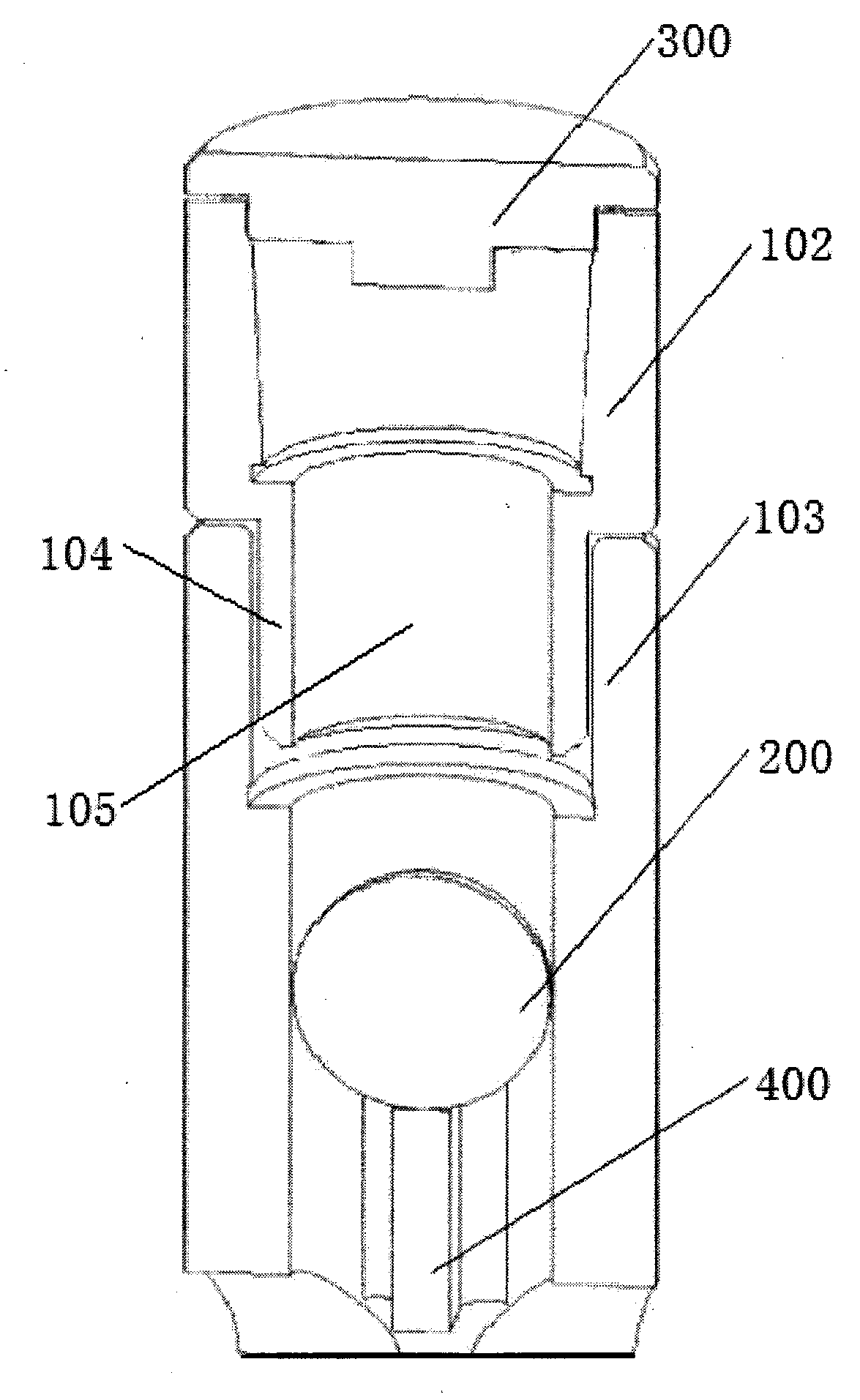

[0037] Such as figure 2 As shown, the difference between the hydrodynamic annulus cavitation device provided by Embodiment 2 of the present invention and Embodiment 1 is that: the cylindrical casing 100 includes an upper cylindrical casing 102 and a lower cylindrical casing 103, and the upper cylindrical casing 100 The lower end of the cylindrical housing 102 is arranged inside the upper end of the lower cylindrical housing 103, and the lower end of the upper cylindrical housing 102 is screwed to the upper end of the lower cylindrical housing 103 to form a tight fit; in order to meet different situations It is manufactured according to the oil well depth and reservoir structure, and can be adjusted according to different construction conditions.

[0038] The lower end of the upper cylindrical housing 102 is provided with an extension 104 extending downwards, the shape of the extension 104 is cylindrical, and the inside of the extension 104 is provided with a first through hol...

Embodiment 3

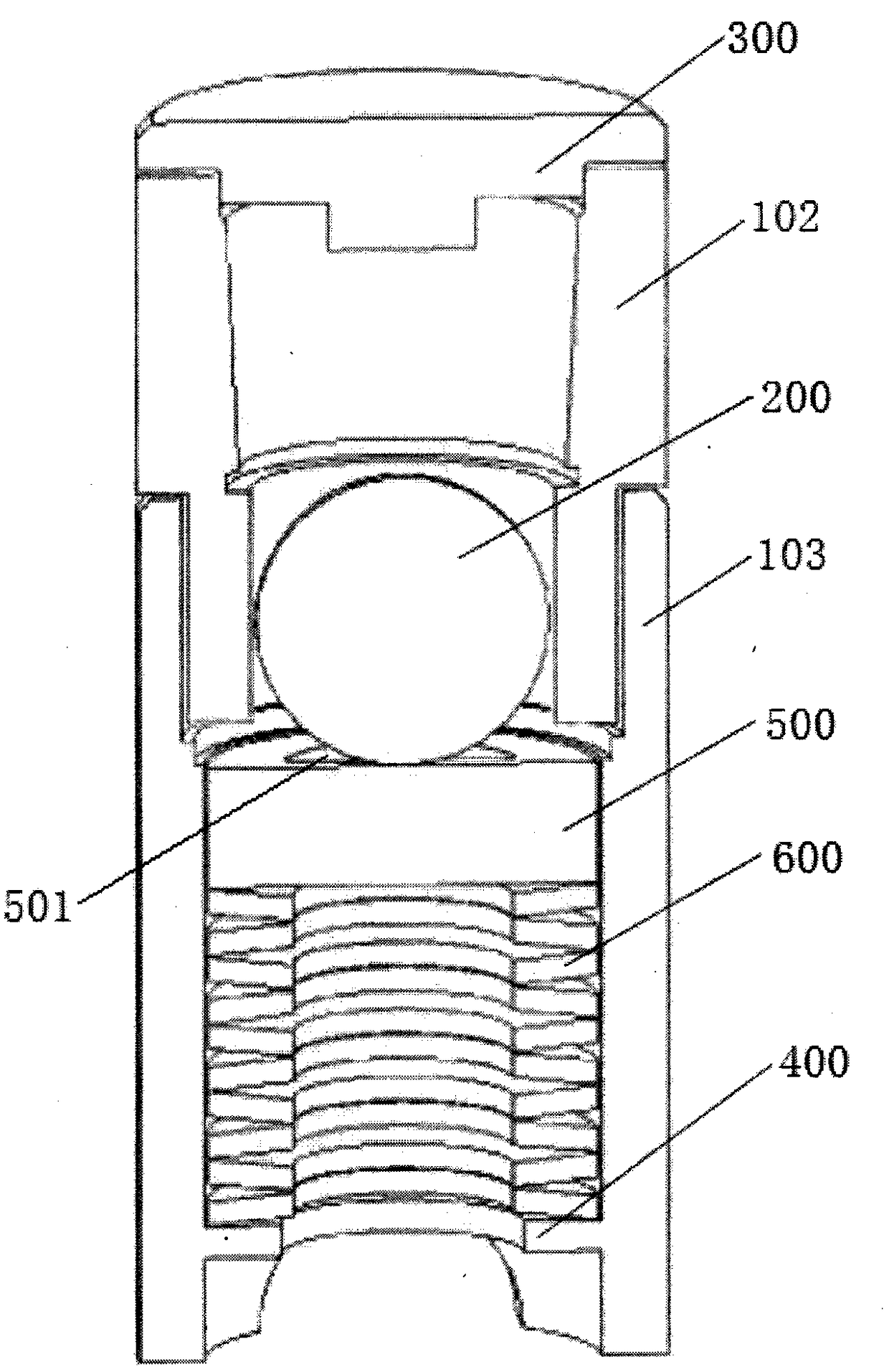

[0041] The difference between the hydrodynamic annulus cavitation device provided by Embodiment 3 of the present invention and Embodiment 2 is that the body dynamic annular cavitation device of the present invention further includes a backing plate 500 and a plurality of disc springs 600, and the backing plate 500 The shape is cylindrical, the backing plate 500 is arranged in the lower cylindrical housing 103, the spherical power body 200 is arranged on the backing plate 500, and the backing plate 500 is provided with a first passage for fluid to pass through. Two through holes 501 , and the inner diameter of the second through hole 501 provided on the backing plate 500 is smaller than the outer diameter of the spherical power body 200 .

[0042] A plurality of disc springs 600 are disposed below the backing plate 500 and above the bracket 400 . The setting of the backing plate 500 and multiple disc springs 600 above can play a buffering role, reduce the wear on the spherical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com