Oil-resistant mineralization-degree-resistant solid foam-scrubbing agent and preparation method thereof

A technology of salinity resistance and foam discharge agent, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as inconvenience in carrying, and achieve the effects of convenient carrying, long performance time and new ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

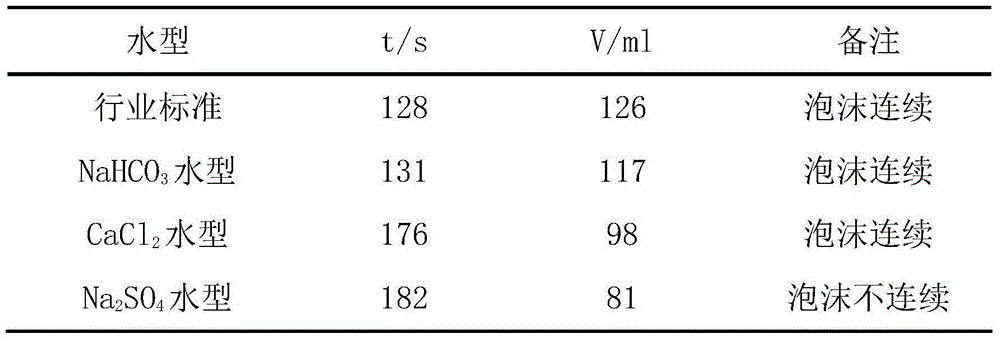

Image

Examples

Embodiment 1

[0020] The solid foaming agent of the present invention is composed of the following raw materials in mass percentage: 30% of AES, 10% of OP-10, 0.2% of polyacrylamide, 10% of thiourea and 49.8% of paraffin.

[0021] The preparation method of the solid foaming agent of the present invention comprises the following steps: (1) adding AES and OP-10 in a beaker, stirring evenly, adding polyacrylamide and paraffin, stirring again; (2) stirring the above Put the raw material solution into a water bath, heat it at 70°C for 3 hours, take it out, and stir it while cooling; (3) When the raw material solution is cooled to room temperature and becomes powdery, pour it into a mold and extrude it to obtain oil-resistant and resistant The finished product of salinity solid foaming agent.

[0022] Preparation of mineralized water with a certain concentration: weigh 12.5gNaCl and 2.5gCaCl 2 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqu...

Embodiment 2

[0026] The solid foaming agent of the present invention is composed of the following raw materials in mass percentage: 30% of AES, 10% of OP-10, 0.2% of polyacrylamide, 10% of thiourea and 49.8% of paraffin.

[0027] The preparation method of the solid foaming agent of the present invention comprises the following steps: (1) adding AES and OP-10 in a beaker, stirring evenly, adding polyacrylamide and paraffin, stirring again; (2) stirring the above Put the raw material solution in a water bath, heat it at 70°C for 3 hours, take it out, and stir it while cooling; (3) When the raw material solution is cooled to room temperature and becomes powdery, pour it into a tablet machine and extrude it to obtain Finished product of oil-resistant and salinity-resistant solid foaming agent.

[0028] Preparation of mineralized water with a certain concentration: weigh 1.25g NaHCO 3 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqueous so...

Embodiment 3

[0032] The solid foaming agent of the present invention is composed of the following raw materials in mass percentage: 30% of AES, 10% of OP-1, 0.2% of polyacrylamide, 10% of thiourea and 49.8% of paraffin.

[0033] The preparation method of the solid foaming agent of the present invention comprises the following steps: (1) adding AES and OP-10 in a beaker, stirring evenly, adding polyacrylamide and paraffin, stirring again; (2) stirring the above Put the raw material solution into an oven, heat it at 70°C for 3 hours, take it out, and stir it while cooling; (3) When the raw material solution is cooled to room temperature and becomes powdery, pour it into a mold and extrude it to obtain oil-resistant and resistant The finished product of salinity solid foaming agent.

[0034] Preparation of mineralized water with a certain concentration: weigh 15gNaCl and 27.5gCaCl 2 Dissolve it in a clean small beaker, then pour it into a 250ml volumetric flask and make it into an aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com