Salt-resistant acid-resistant drainage foam discharge agent composition for gas recovery and its preparation method and application

A technology of water drainage and gas recovery and foaming agent, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of gas well production reduction, excessive fluid accumulation in gas wells, stop spraying, etc., and achieve increased viscosity and good technical effects , enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of composition XN-1, preparation steps:

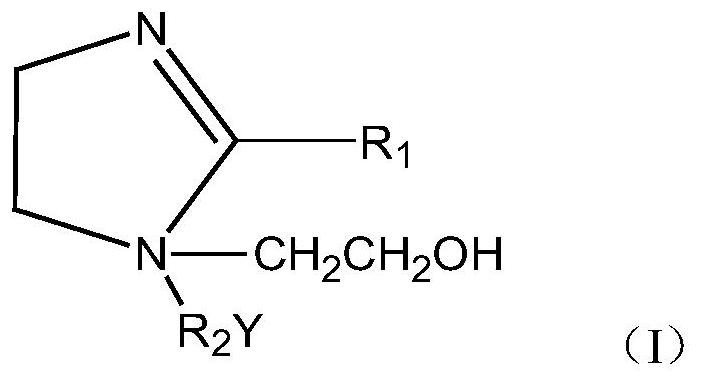

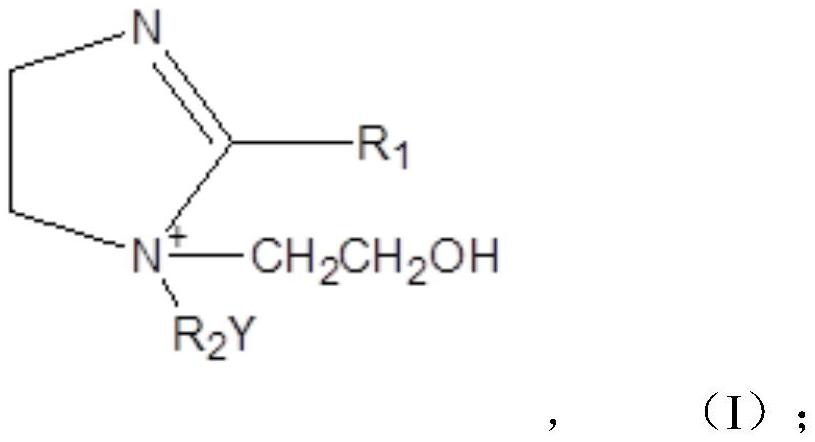

[0038] (1) Synthesis of imidazoline type amphoteric surfactant

[0039] a. Add 25 grams of C to the reactor 12 h 25 COOH and 10 grams of hydroxyethylethylenediamine were heated up to 100°C, and the vacuum degree of the reactor was adjusted to a water outlet state, and then the temperature was continued to rise to 200°C, and the reaction was carried out for 6 hours, and the reaction was stopped to obtain an imidazoline intermediate;

[0040]B, the imidazoline intermediate obtained by 15 grams of reaction and 7.5 grams of sodium chloroacetate were added in the reactor, and reacted for 5 hours at 80° C. to obtain the described imidazoline type amphoteric surfactant;

[0041] (2) Preparation of foam discharge agent composition

[0042] The imidazoline type amphoteric surfactant, AOS 14-16 and silicon dioxide in a mass ratio of 1:1:1 in water with a salinity of 50,000mg / L and a pH value of 7, mix well, and prepare...

Embodiment 2

[0044] The preparation of composition XN-2, preparation steps:

[0045] (1) Synthesis of imidazoline type amphoteric surfactant

[0046] a. Add 23 grams of C to the reactor 14 h 27 COOH and 10 grams of hydroxyethylethylenediamine were heated up to 100°C, and the vacuum degree of the reactor was adjusted to a water outlet state, and then the temperature was continued to rise to 200°C, and the reaction was carried out for 6 hours, and the reaction was stopped to obtain an imidazoline intermediate;

[0047] B, 15 grams of imidazoline intermediates obtained by the reaction and 10 grams of sodium chloropropylsulfonate were added to the reactor, and reacted for 6 hours at 80° C. to obtain the described imidazoline type amphoteric surfactant;

[0048] (2) Preparation of foam discharge agent composition

[0049] The imidazoline type amphoteric surfactant, AOS 14-18 Dissolve silicon dioxide and silicon dioxide in water with a salinity of 150,000mg / L and a pH value of 3 at a mass ra...

Embodiment 3

[0051] Preparation of composition XN-3, preparation steps:

[0052] (1) Synthesis of imidazoline type amphoteric surfactant

[0053] a. Add 18 grams of C to the reactor 10 h 21 COOH and 10 grams of hydroxyethylethylenediamine were heated up to 100°C, and the vacuum degree of the reactor was adjusted to a water outlet state, and then the temperature was continued to rise to 200°C, and the reaction was carried out for 6 hours, and the reaction was stopped to obtain an imidazoline intermediate;

[0054] B, 15 grams of the imidazoline intermediate obtained by the reaction and 8.5 grams of sodium chloropropionate were added to the reactor, and reacted for 3 hours at 100° C. to obtain the described imidazoline type amphoteric surfactant;

[0055] (2) Preparation of foam discharge agent composition

[0056] The imidazoline type amphoteric surfactant, AOS 16-18 and silicon dioxide in a mass ratio of 1:2:3 in water with a salinity of 80,000mg / L and a pH value of 5, mix well, and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com