Foaming agent for highly mineralized water containing barium-strontium ions and gas condensate and preparation method thereof

A technology with high salinity and strontium ions, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of foaming agents such as poor anti-condensate oil, clogging, and precipitation, and achieve excellent foaming performance and the effect of liquid-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

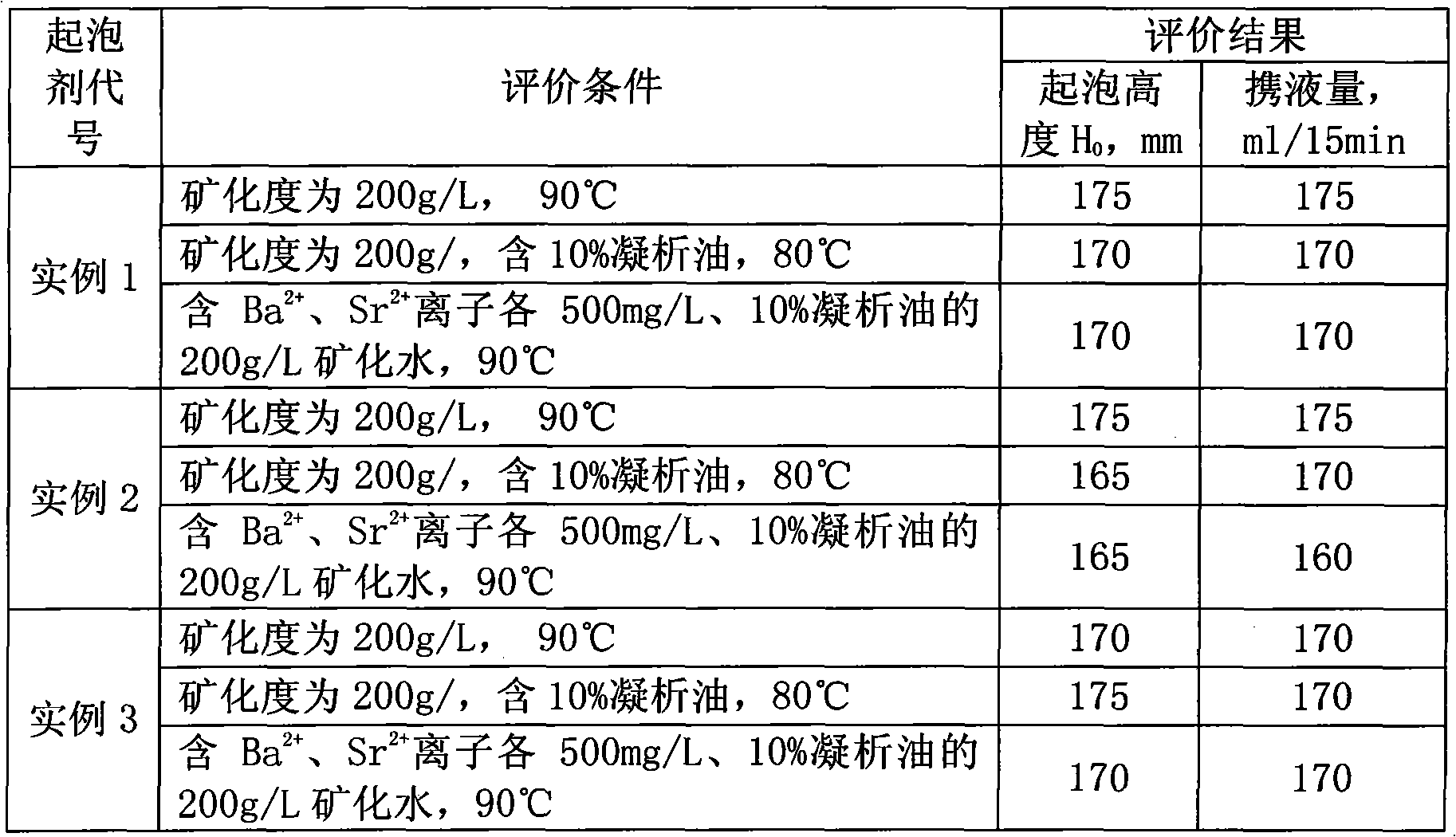

Examples

Embodiment 1

[0032] The formula is: 500kg zwitterionic surfactant; 200kg nonionic surfactant; 100kg barium strontium ion inhibitor; 50kg pH regulator; 150kg solvent. Wherein, zwitterionic surfactant refers to alkyl amidopropyl betaine, and general chemical formula is: R 1 CONH(CH 2 ) 3 N + (CH 3 ) 2 CH 2 COONa, where R 1 It is an alkyl group containing 12-14 carbons. Nonionic surfactants are alkylphenol polyoxyethylene ethers whose general chemical formula is R 2 C 6 h 4 O(CH 2 CH 2 O)nH, wherein, R 2 It is an alkyl group containing 9-12 carbons, n=4-6. The barium strontium ion inhibitor refers to polyaspartic acid. The pH adjuster refers to triethanolamine. The solvent is soft water.

[0033] The preparation process is as follows: according to the formula ratio, add 500kg of zwitterionic surfactant and 200kg of nonionic surfactant into a stainless steel reaction kettle, heat to about 50°C, stir for 20min to 25min, then add 150kg of solvent, stir for 20min to 30min, and fin...

Embodiment 2

[0035] The formula is: 400kg zwitterionic surfactant; 100kg nonionic surfactant; 50kg barium strontium ion inhibitor; 30kg pH regulator; 420kg solvent. Wherein, zwitterionic surfactant refers to alkyl amidopropyl betaine, and general chemical formula is: R 1 CONH(CH 2 ) 3 N + (CH 3 ) 2 CH 2 COONa, where R 1 It is an alkyl group containing 12-14 carbons. Nonionic surfactants are alkylphenol polyoxyethylene ethers whose general chemical formula is R 2 C 6 h 4 O(CH 2 CH 2 O)nH, wherein, R 2 It is an alkyl group containing 9-12 carbons, n=4-6. The barium strontium ion inhibitor refers to polyaspartic acid. The pH adjuster refers to triethanolamine. The solvent is soft water.

[0036]The preparation process is as follows: according to the formula ratio, add 400kg of zwitterionic surfactant and 100kg of nonionic surfactant into a stainless steel reaction kettle, heat to about 60°C, stir for 20min-25min, then add 420kg of solvent, stir for 20min-30min, and finally Ad...

Embodiment 3

[0038] The formula is: 450kg zwitterionic surfactant; 150kg nonionic surfactant; 70kg barium strontium ion inhibitor; 40kg pH regulator; 290kg solvent. Wherein, zwitterionic surfactant refers to alkyl amidopropyl betaine, and general chemical formula is: R 1 CONH(CH 2 ) 3 N + (CH 3 ) 2 CH 2 COONa, where R 1 It is an alkyl group containing 12-14 carbons. Nonionic surfactants are alkylphenol polyoxyethylene ethers whose general chemical formula is R 2 C 6 h 4 O(CH 2 CH 2 O)nH, wherein, R 2 It is an alkyl group containing 9-12 carbons, n=4-6. The barium strontium ion inhibitor refers to polyaspartic acid. The pH adjuster refers to triethanolamine. The solvent is soft water.

[0039] The preparation process is as follows: according to the formula ratio, add 450kg of zwitterionic surfactant and 150kg of nonionic surfactant into a stainless steel reaction kettle, heat to about 55°C, stir for 20min to 25min, then add 290kg of solvent, stir for 20min to 30min, and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com