Foam atomizer and wellbore structure for bubble exhaust and gas production of natural gas well and gas production method

An atomizer and natural gas technology, applied in the field of multiphase flow, can solve the problems of high price of electric submersible pump drainage system, short life of unit equipment, increase of back pressure at the bottom of the well, etc., to achieve improved atomization efficiency, simple structure, The effect of deep drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

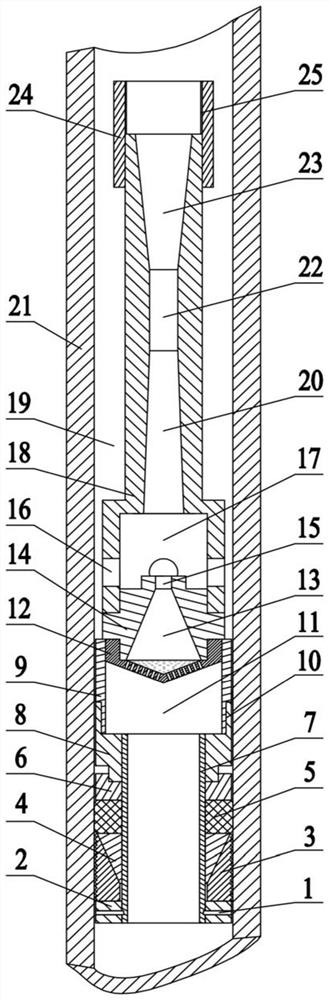

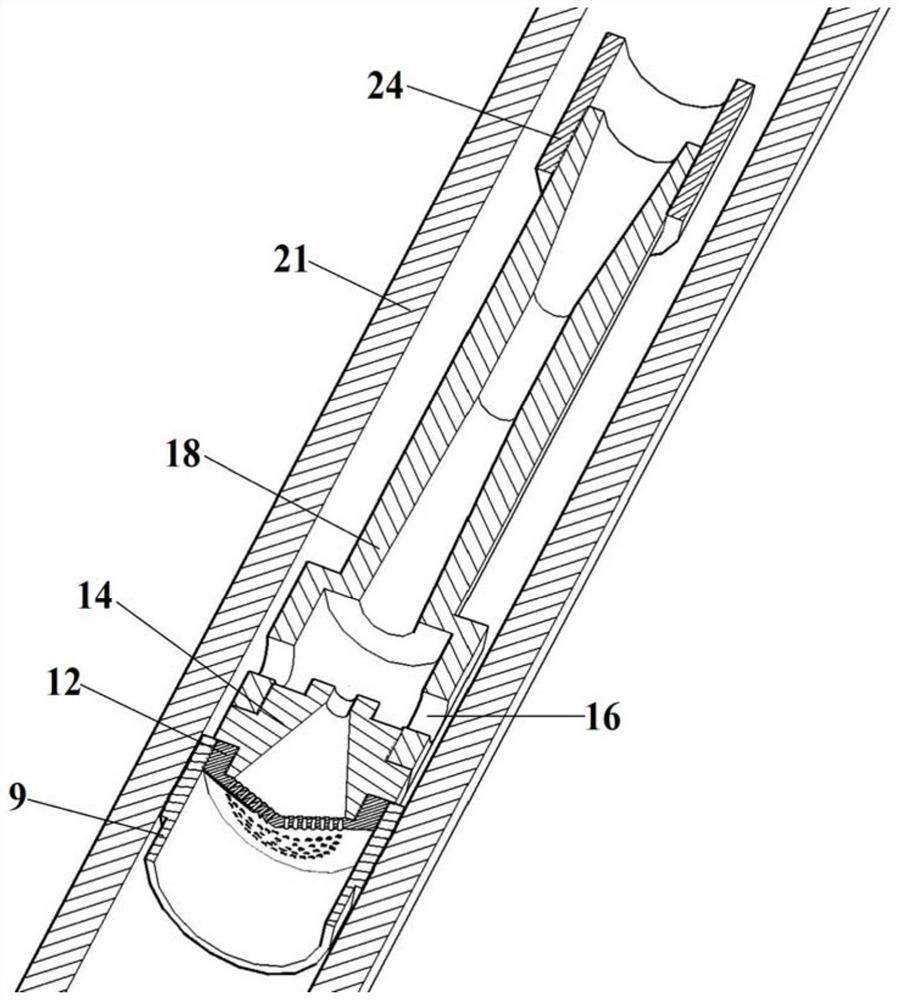

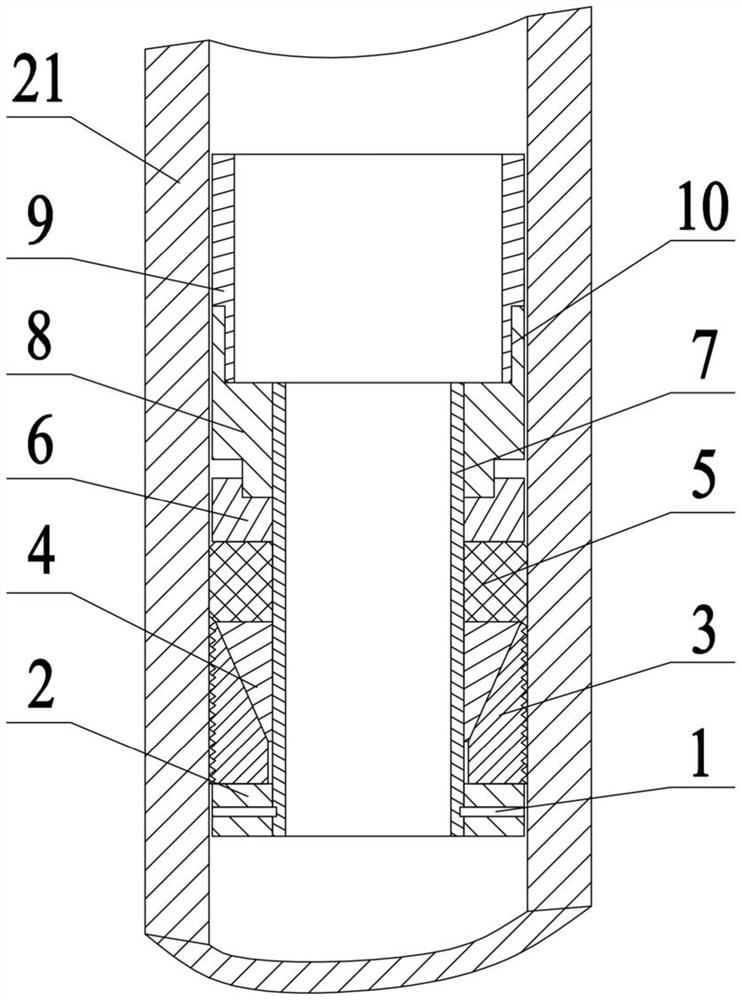

[0039] see figure 1 with figure 2 , the present embodiment is used for the foam atomizer of natural gas well bubble row gas recovery, mainly by atomizer inlet section barrel 9, porous cone plate 12, nozzle barrel 14 and atomizer vortex section barrel 18 composition; The structure of the foam atomizer includes an atomizer inlet 11, a porous cone plate 12, a nozzle inlet 13, a nozzle throat 15, a swirl hole 16, a nozzle rear cavity 17, a receiving chamber 20, and a mixing chamber from bottom to top. 22. The diffusion chamber 23 and the connecting section 24 between the atomizer and the downhole operation tool; the outer wall of the cylinder body 9 of the inlet section of the atomizer is provided with the connecting thread 10 between the atomizer and the packer; the porous cone plate 12 is distributed with The metal cone plate with thin round holes, the thin round holes are atomization holes, used for preliminary atomization, the plane of the cone plate is perpendicular to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com