Gas atomization nozzle for preparing superfine metal powder

A gas atomization nozzle and metal powder technology, applied in the field of atomization nozzles, can solve the problems of unfavorable atomization efficiency, reduced size of atomization nozzle, coarse powder particle size, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

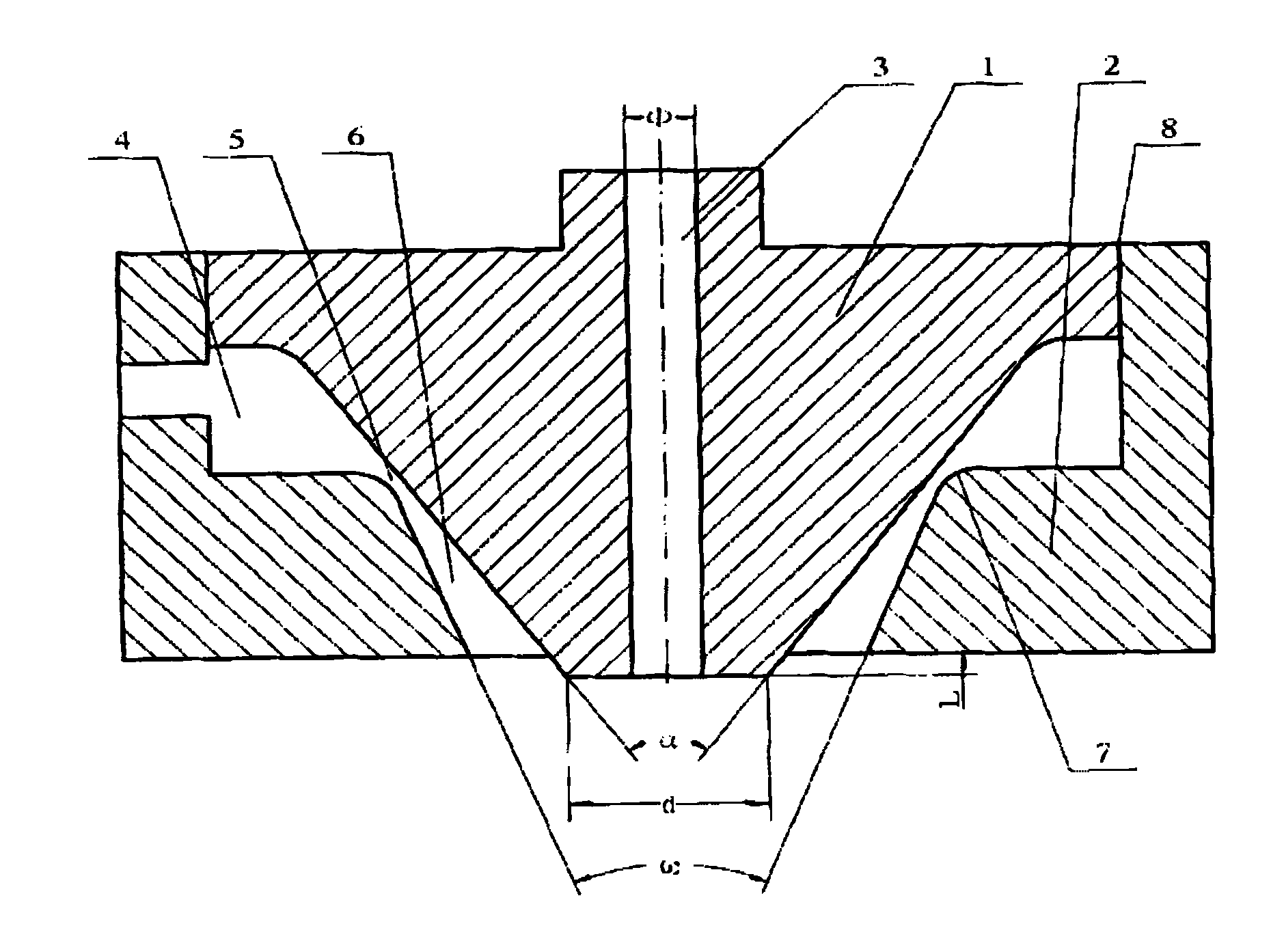

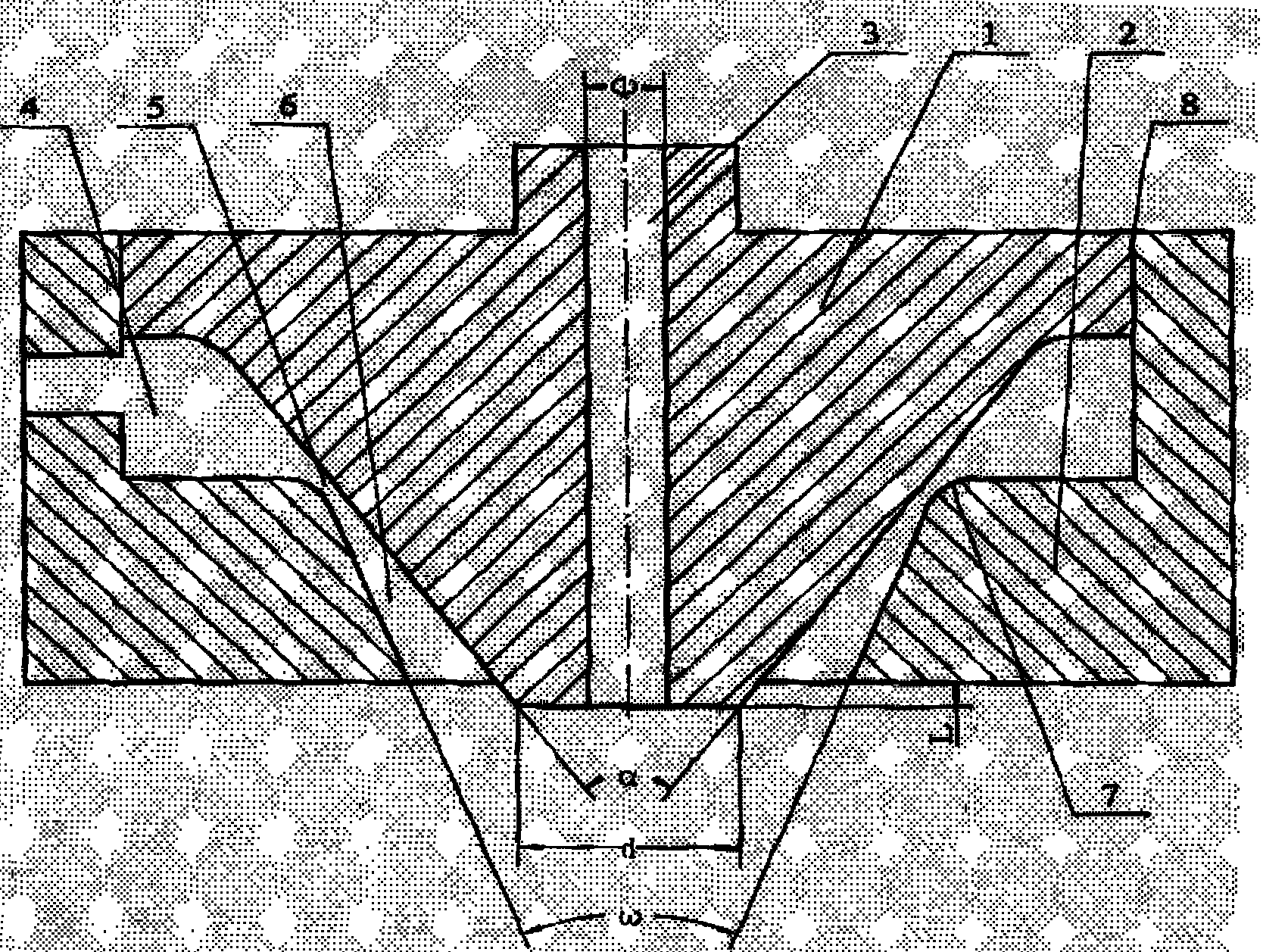

[0024] use figure 1 For the nozzle structure shown, the maximum operating pressure of the nozzle is 3.0MPa, and the gas flow rate is 6Nm 3 / min (nitrogen), the cone angle of the upper part of the nozzle is 65°, the cone angle of the lower inner cone is 50°, the outer diameter of the outlet of the upper nozzle is 10mm, the diameter of the central through hole is 3.5mm, and the hole extending out of the lower nozzle Air outlet end 4.5mm. The upper nozzle is made of boron nitride ceramics. The atomization test of the powder was carried out with Fe-5.4wt%Si-9.6wt%Al iron alloy as the atomization object. The test alloy was 25kg, the atomization temperature was 1500°C, and the atomization pressure was 3.0MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. In the atomized powder, the proportion of powder with a particle size smaller than 150 μm (-100 mesh) is 96.3%, and the proportion of powder with a particle size smaller than 45 μm (...

Embodiment 2

[0026] use figure 1 For the nozzle structure shown, the maximum operating pressure of the nozzle is 3.0MPa, and the gas flow rate is 5Nm 3 / min (nitrogen), the cone angle of the upper part of the nozzle is 65°, the cone angle of the lower inner cone is 50°, the outer diameter of the outlet of the upper nozzle is 8mm, the diameter of the central through hole is 3.0mm, and the hole extending out of the lower nozzle Air outlet end 4.5mm. The upper nozzle is made of boron nitride ceramics. Ni-14wt%Cr-10wt%P alloy was used as the atomization object to carry out the atomization test of the powder, the test alloy was 20kg, the atomization temperature was 1250°C, and the atomization pressure was 2.5MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. Among the atomized powder, the proportion of powder with a particle size smaller than 75 μm (-200 mesh) is 85%, and the proportion of powder with a particle size smaller than 45 μm (-320 me...

Embodiment 3

[0028] use figure 1 For the nozzle structure shown, the maximum operating pressure of the nozzle is 3.0MPa, and the gas flow rate is 4Nm 3 / min (nitrogen), the cone angle of the upper part of the nozzle is 55°, the cone angle of the lower inner cone is 40°, the outer diameter of the outlet of the upper nozzle is 8mm, and the diameter of the central through hole is 2.5mm, extending out of the lower nozzle Air outlet end 4.5mm. The upper nozzle is made of boron nitride ceramics. The atomization test of powder was carried out with pure aluminum as the object of atomization, the test alloy was 10kg, the atomization temperature was 800°C, and the atomization pressure was 2.5MPa. After atomization, use a standard analytical sieve to measure the particle size of the powder. Among the atomized powder, the proportion of powder with a particle size smaller than 150 μm (-100 mesh) is 95.5%, and the proportion of powder with a particle size smaller than 45 μm (-320 mesh) is 70.1%. , th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com