Plug-in coiled tubing induced-spraying device

A plug-in, tubing technology, applied in wellbore/well components, production fluid, sealing/isolation, etc., can solve problems such as unsatisfactory liquid-carrying effect of large-diameter tubing strings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

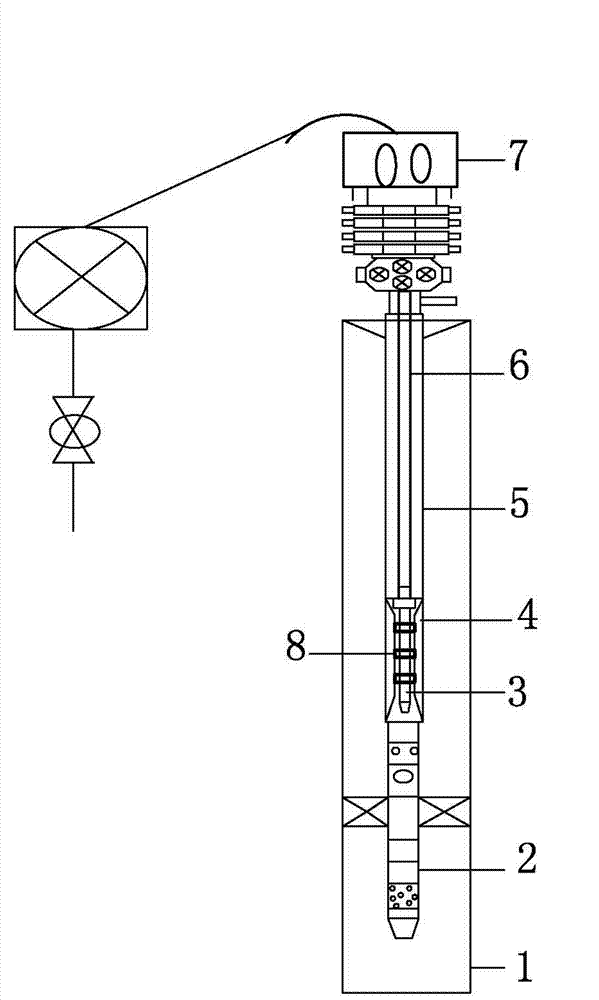

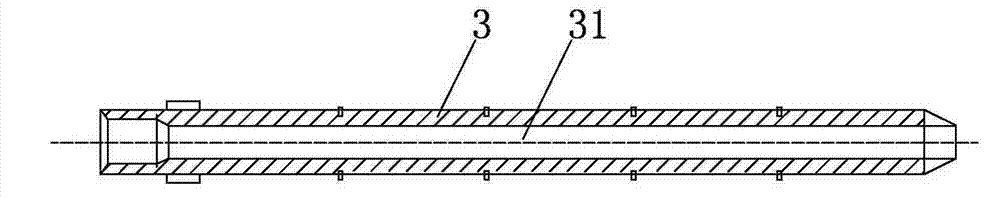

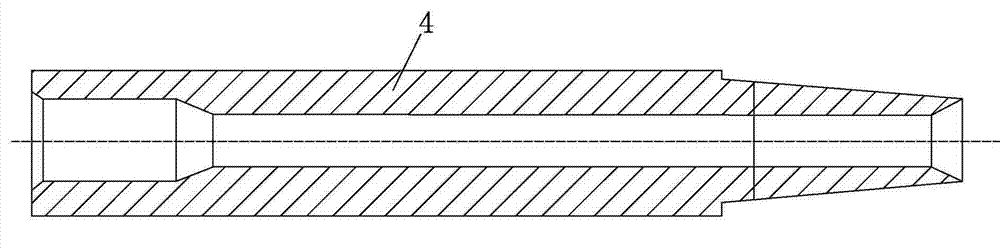

[0022] Such as Figure 1 to Figure 3 As shown, the plug-in coiled tubing injection device of the present invention includes an outer string 5, a coiled tubing 6, and a coiled tubing injector 7. For conventional oil and gas well testing, the outer string 5 can be a drill pipe or an oil pipe, and the outer string 5 is lowered into the oil and gas well 1 , and the lower end of the outer string 5 is also provided with a drill pipe test string assembly 2 . The coiled tubing 6 is sent into the outer tubing string 5 through a coiled tubing injector 7 . The outer pipe string 5 is provided with a positioning and sealing working cylinder 4, and the outer peripher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com