Solid material fermentation device

A fermentation device and solid material technology, applied in the field of solid material fermentation devices, can solve problems such as unfavorable fermentation, insufficient stirring, and reduced performance, so as to improve work efficiency and performance, mix quickly and evenly, and mix materials quickly and evenly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

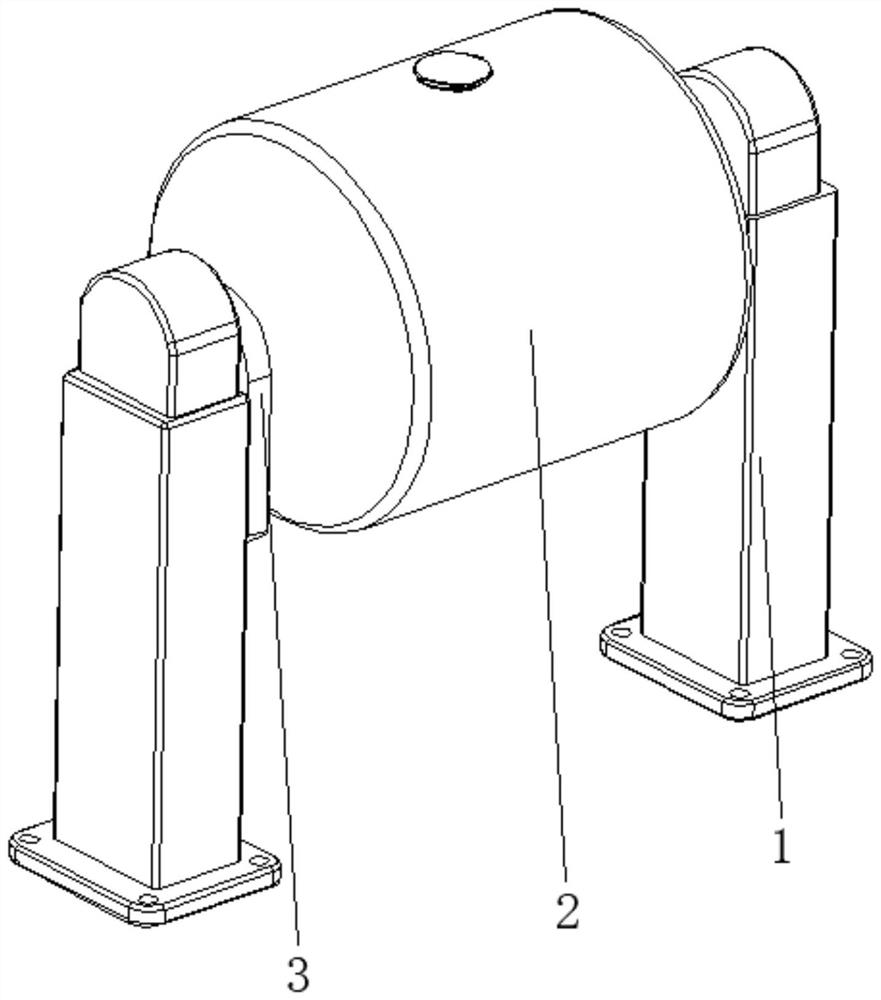

[0030] see Figure 1-6 , the present invention provides a technical solution: a solid material fermentation device, comprising a support column 1, a fermentation device 2, and a drive mechanism 3, the fermentation device 2 is arranged on the top of the support column 1, and the drive mechanism 3 is arranged on the surface of the support column 1 The top is connected with the fermenting device 2;

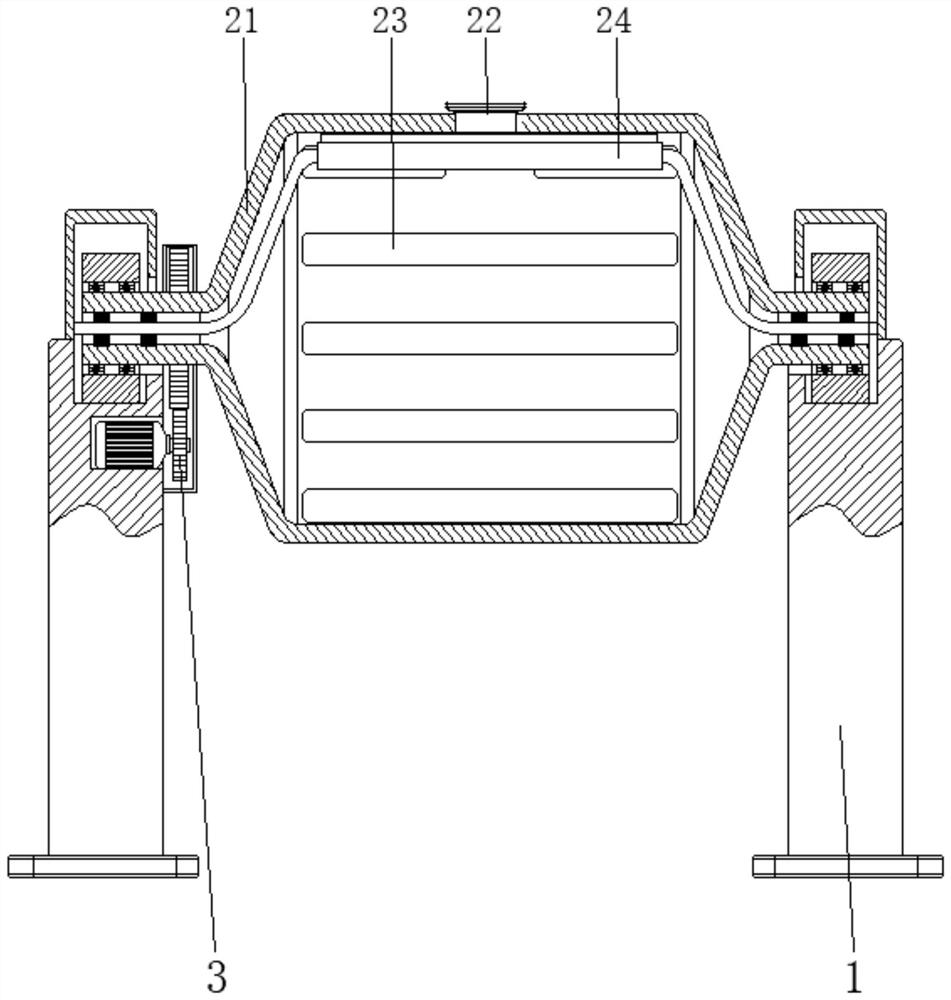

[0031] The interior of the fermentation device 2 is provided with a tank body 21, a feed port 22, a stirring device 23, and a cleaning device 24. The end of the tank body 21 is connected with the top of the support column 1 through a bearing seat, and the feed port 22 is arranged on the top of the tank body 21. In the central position of the surface, the stirring device 23 is arranged on the inner wall of the tank body 21, the stirring device 23 is evenly distributed on the inner wall of the tank body 21, the cleaning device 24 is arranged inside the tank body 21, and the end of the ...

Embodiment example 2

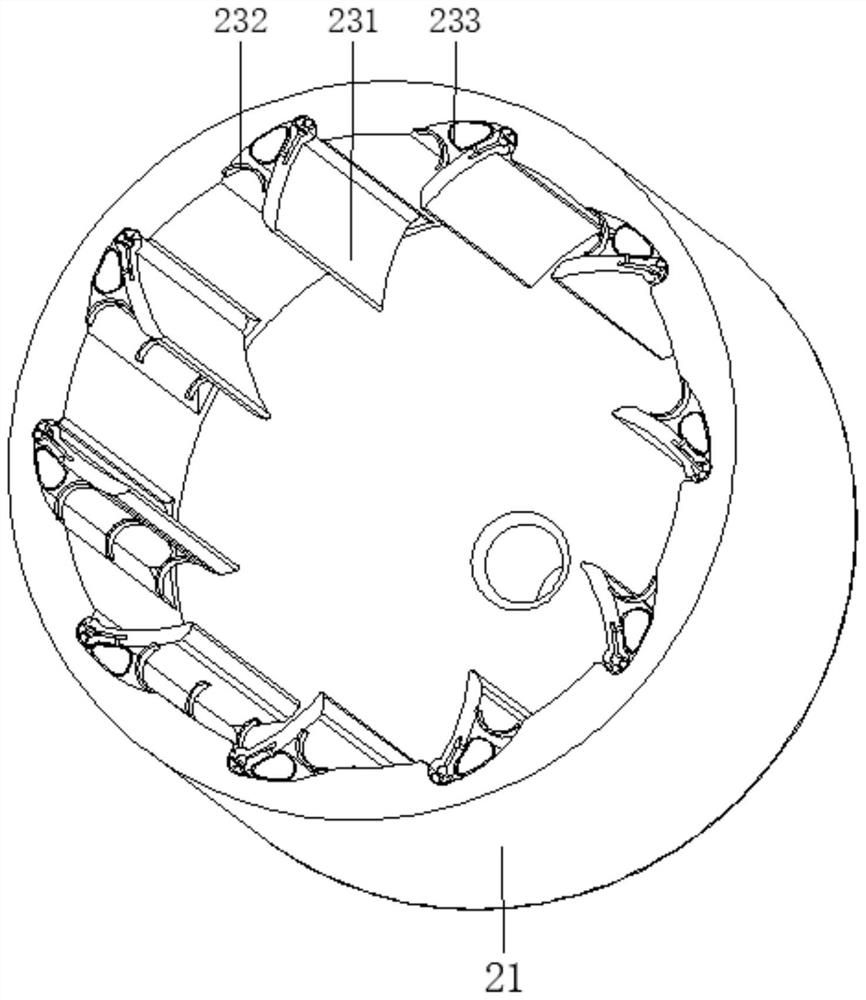

[0033]The stirring device 23 is provided with an arc-shaped rake device 231, an arc-shaped shrapnel 232, and an elastic bar-shaped bag 233. One end of the arc-shaped rake device 231 is rotatably connected to the inner wall of the tank body 21, and the arc-shaped shrapnel 232 is fixed on the arc-shaped rake. Between the two sides corresponding to the surface of the device 231 and the inner wall of the tank body 21 , the elastic strip-shaped bag 233 is arranged between the two sides corresponding to the surface of the curved surface rake device 231 and the inner wall of the tank body 21 and close to the arc-shaped shrapnel 232 , when the curved surface rake device 231 rotates with the tank body 21, the raw materials accumulated at the bottom can be turned over, and there will be no dead angle of mixing, so that the mixture can be mixed quickly and evenly. At the same time, with the continuous rotation, the curved surface rake device When 231 meets the wall scraping device 243, th...

Embodiment example 3

[0036] The cleaning device 24 is provided with a Z-shaped connecting rod 241, a sealing ring 242, and a wall scraping device 243. The Z-shaped connecting rod 241 is arranged on the inside of the tank body 21 and is positioned at an end position. The top is fixedly connected, the sealing ring 242 is arranged at the end of the Z-shaped connecting rod 241 and the surface of the sealing ring 242 is attached to the end of the inner wall of the tank body 21, and the wall scraping device 243 is arranged inside the tank body 21 and connected with the Z-shaped The end of the rod 241 is fixedly connected. When the arc-shaped rake device 231 rotates to the position of the scraper device 243, it is affected by the pressure, combined with the action force and reaction. At this time, the elastic force of the arc-shaped shrapnel 232 is used to make the scraper The surface of the device 243 is in close contact with the wall scraping device 243, thereby scraping off the sticky material in time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com