PCSC shear joint structure of plate girder overall assembly type composite beam bridge

A prefabricated and composite beam technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of poor effectiveness of concrete bridge slabs, unable to be implemented at the same time, and difficult to guarantee welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

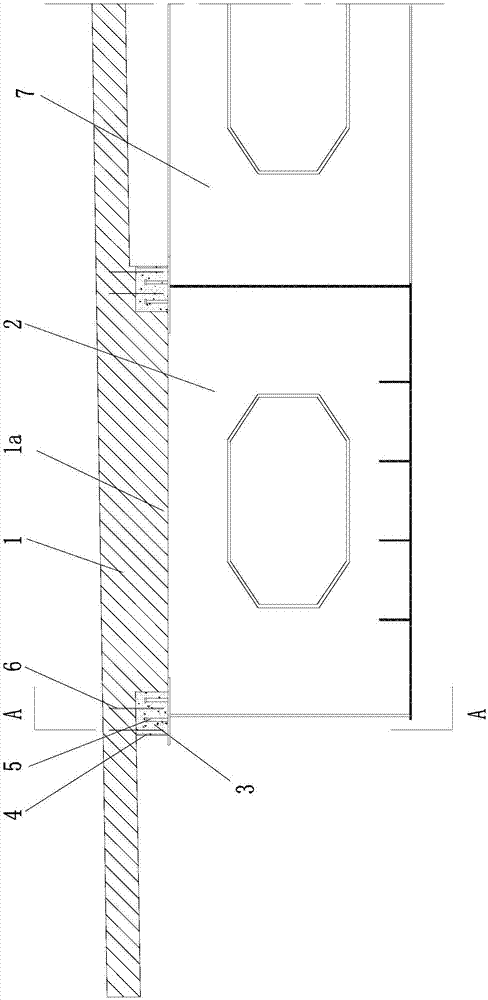

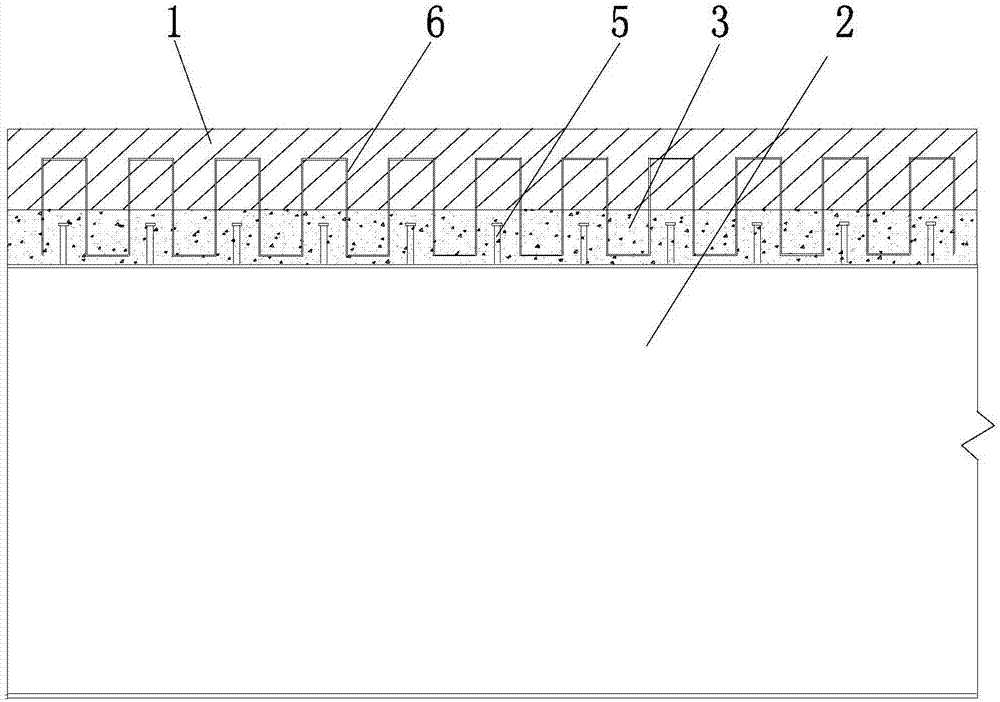

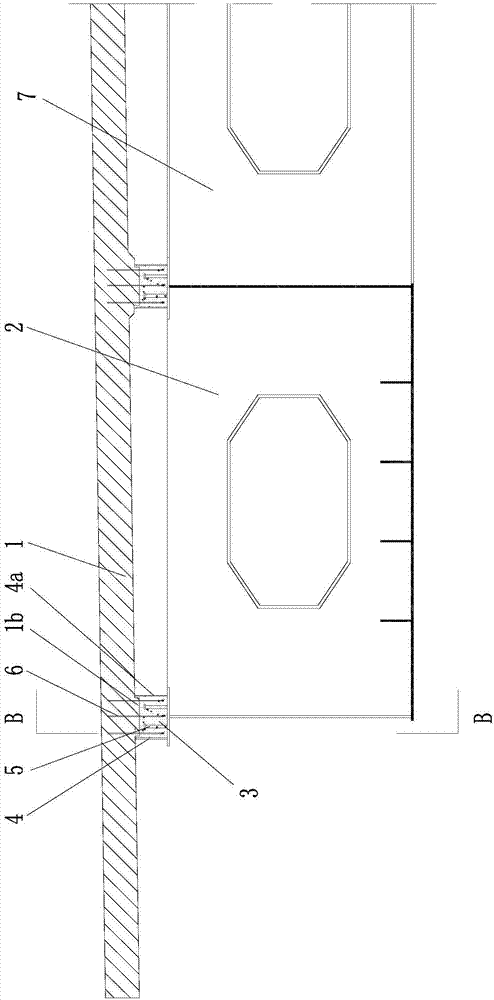

[0025] figure 1 It is a structural schematic diagram of the first embodiment of the present invention, figure 2 for figure 1 Sectional view along A-A direction; this embodiment adopts the composite girder formed by the PCSC shear connection structure of the slab girder integrally assembled composite girder bridge. Bury the shear member Ⅰ (connecting steel bar) protruding from the bottom of the slab below, set the shear member Ⅱ (shear nail) and longitudinal side baffle 4 on the top surface of the steel beam (S) along the longitudinal direction, install the bridge deck on the steel beam Put it in place, make the pre-embedded connecting steel bars of the bridge slab embedded in the longitudinal side baffle 4 on the top surface of the steel beam, and then close the long strip-shaped closed cavity formed by the top surface of the steel beam, the two side baffles and the top surface of the bridge slab. Perform pressure pouring combined with concrete (C) to form a PCSC shear conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com