Liquid dairy product containing vegetable oil and production method thereof

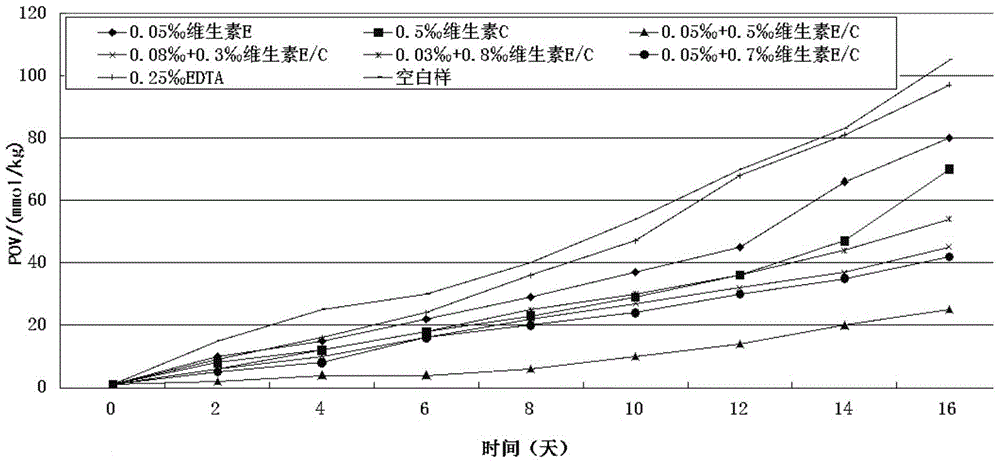

A dairy product and vegetable oil technology, applied in the direction of dairy products, milk preparations, applications, etc., can solve the problem of how to ensure the taste, flavor and stability of the product, oxidation stability, low oxidation stability, affect the taste of the final product and Flavor and other issues, to achieve good taste and stability, good morbidity, product taste improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

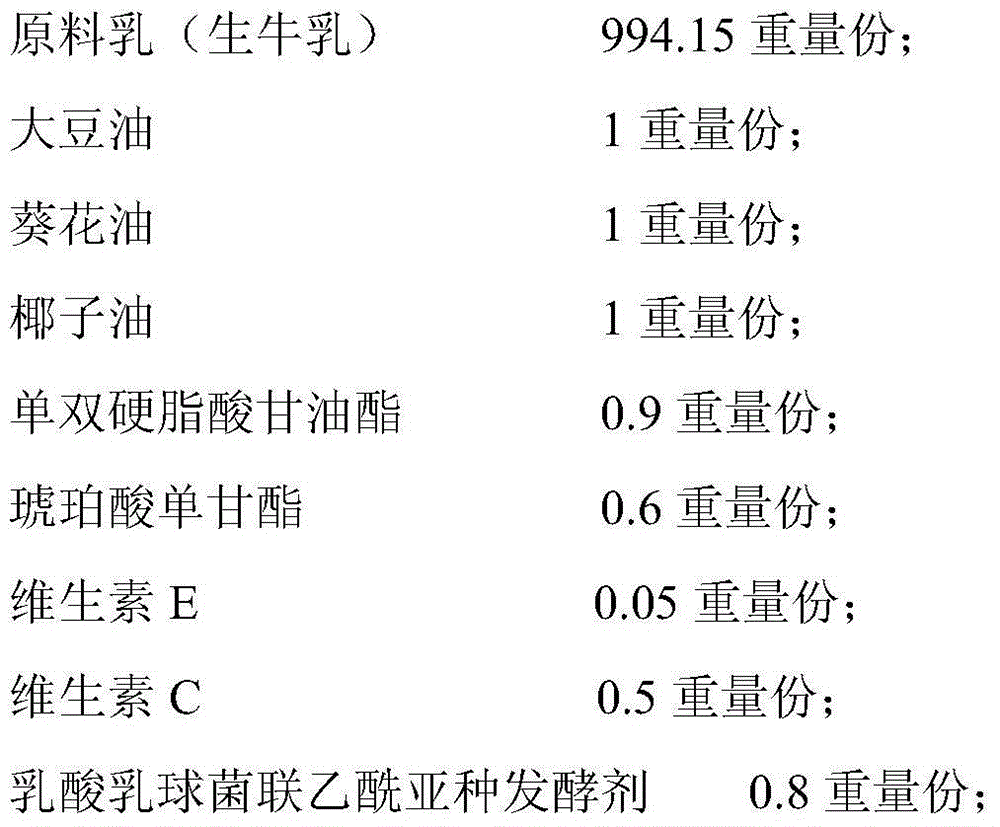

[0035] Embodiment 1, the modulation milk that contains soybean oil, sunflower oil and coconut oil and its production method

[0036] One, the raw material of the modulation milk that contains soybean oil, sunflower oil and coconut oil of the present embodiment comprises:

[0037]

[0038] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0039] Two, the production method of the modulated milk of the present embodiment comprises the following steps successively:

[0040] (1) The raw milk is cleaned and preheated to 40°C, sent to a centrifuge for separation, and skim milk and cream with a fat content of about 35% are obtained;

[0041] (2) The obtained cream was added with Lactococcus biacetyl starter at 40°C, incubated and fermented for about 2.5 hours, and then heated to 65°C for 20 minutes of inactivation; the inactivated fermentation products were used as flavor-adjusting substances to return to Add to the skim milk s...

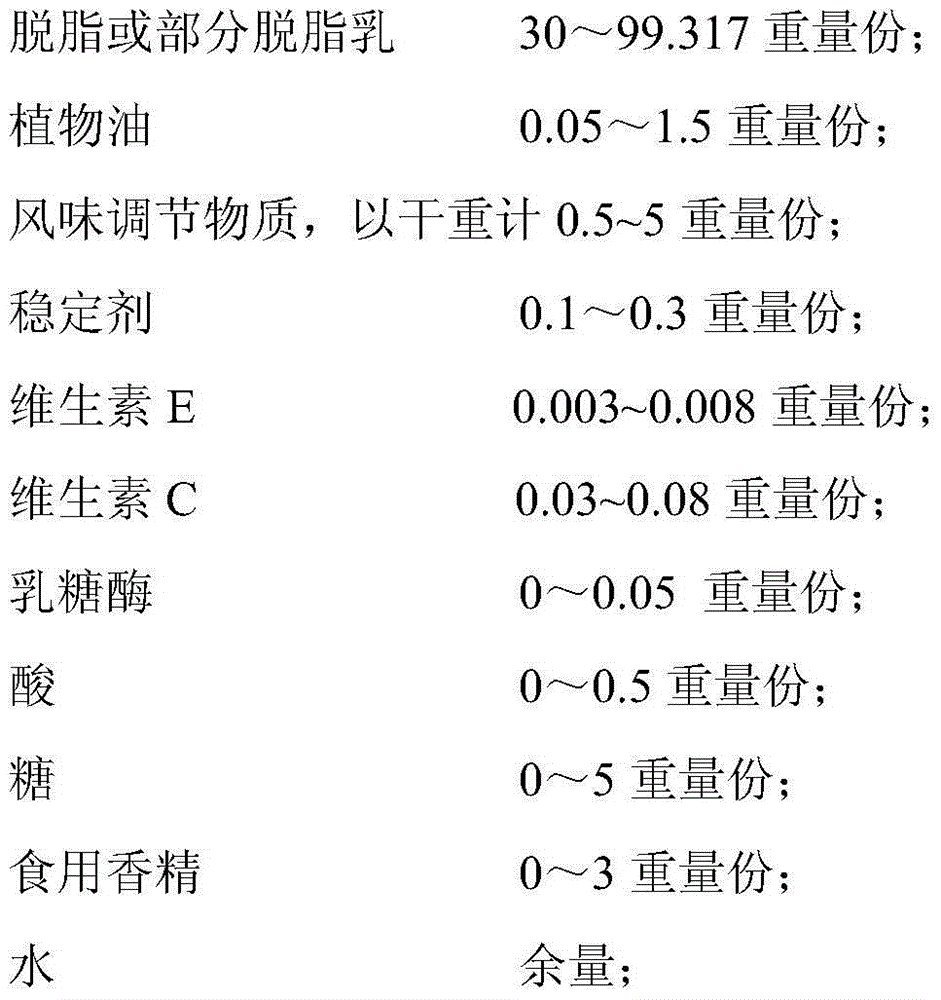

Embodiment 2

[0051] Example 2. Low-lactose milk containing canola oil, corn oil and coconut oil and its preparation method

[0052] One, the raw material of the low-lactose milk containing canola oil, corn oil and coconut oil of the present embodiment comprises:

[0053]

[0054]

[0055] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0056] Two, the production method of the low-lactose milk of the present embodiment comprises the following steps successively:

[0057] (1) The raw milk is cleaned and preheated to 40°C, sent to a centrifuge for separation, and skim milk and cream with a fat content of about 40% are obtained;

[0058] (2) The resulting cream was added with Lactococcus biacetyl starter at 42°C, kept for fermentation for about 2 hours, and then heated to 65°C for 20 minutes of inactivation; the inactivated fermentation products were used as flavor-adjusting substances to return to Add to the skim milk separated in...

Embodiment 3

[0068] Embodiment 3, acidic milk drink containing the oil of rice oil, soybean oil and rapeseed oil and its preparation method

[0069] One, the raw material of the sour milk drink containing rice oil, soybean oil and rapeseed oil of the present embodiment comprises:

[0070]

[0071] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0072] Two, the production method of the sour milk beverage of the present embodiment comprises the following steps successively:

[0073] (1) The raw milk is preheated to 40°C after cleansing, and sent to a centrifuge for separation to obtain skim milk and cream with a fat content of about 30%;

[0074] (2) The resulting cream was added with Lactococcus biacetyl starter at 37°C, kept for fermentation for about 3 hours, and then heated to 60°C for 25 minutes of inactivation; the inactivated fermentation products were used as flavor-adjusting substances to return to Add to the skim milk sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com