High temperature-resistant and solid-free micro-foam drilling fluid or completion fluid

A technology of high temperature resistance and drilling fluid, which is applied in the field of drilling fluid and completion fluid, and can solve the problems of low temperature resistance of solid-free microfoam drilling fluid system, difficulty in protecting and finding oil and gas layers, and poor foam uniformity , to achieve excellent leak prevention and plugging ability, simplify on-site construction technology, and strong rock-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] ⑴ 0.5 part of high temperature resistant tackifier SL-DT, composed of HV-CMC: OCL-PTN=3:5 ratio; ⑵ 0.6 part of high temperature resistant foaming agent SL-DF, which is high temperature resistant modified tea saponin ZY- GW; (3) anti-high temperature protective agent SL-DI 0.2 parts Span 80: Tween 80=1:3 ratio composition; (4) anti-high temperature fluid loss additive SL-JL 2.3 parts, composed of anti-high temperature fluid loss additive OCL-JA : Lignite resin SPNH: sulfomethyl phenolic resin SMP-II=5:3:1.5 ratio; ⑺100 parts of water.

[0055] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperatur...

Embodiment 2

[0058] ⑴ 0.6 parts of high temperature resistant tackifier SL-DT, composed of HV-CMC: OCL-PTN=5:9 ratio; ⑵ 0.8 parts of high temperature resistant foaming agent SL-DF, which is high temperature resistant modified tea saponin ZY- GW; (3) anti-high temperature protective agent SL-DI 0.2 parts Span 80: Tween 80=2:4 ratio composition; (4) anti-high temperature fluid loss additive SL-JL 2.5 parts, composed of anti-high temperature fluid loss additive OCL-JA : lignite resin SPNH: sulfomethyl phenolic resin SMP-II = 6:5:2 ratio; ⑺100 parts of water.

[0059] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperat...

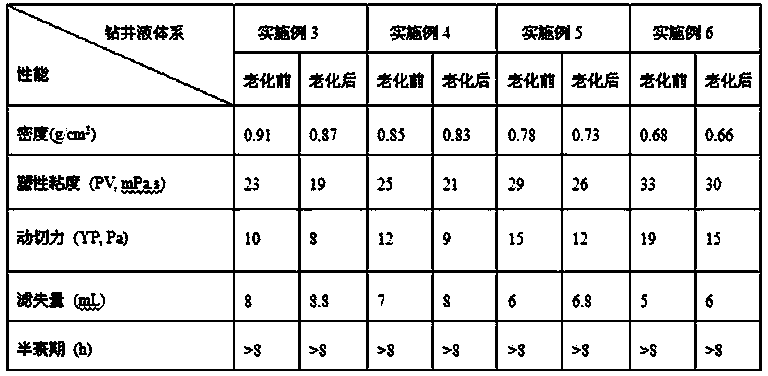

Embodiment 3

[0062] ⑴High temperature resistant tackifier SL-DT, 0.5 parts, composed of HV-CMC:OCL-PTN=2:3 ratio; ⑵High temperature resistant foaming agent, SL-DF 0.5 parts, high temperature resistant modified tea saponin ZY-GW; ⑶ anti-high temperature protective agent, SL-DI 0.2 parts Span 80: Tween 80 = 1:2 ratio; Agent OCL-JA: lignite resin SPNH: sulfomethyl phenolic resin SMP-II = 5:2:1 ratio; 0.2 parts of soda ash; (⑺) 100 parts of water.

[0063] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperature aging tank, aged at 200°C for 16 hours, and then the properties of the microfoam drilling fluid (rheology, flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com