Patents

Literature

57results about How to "Reduce on-site construction procedures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interface waterproofing agent

Owner:厦门防水博士新材料有限公司

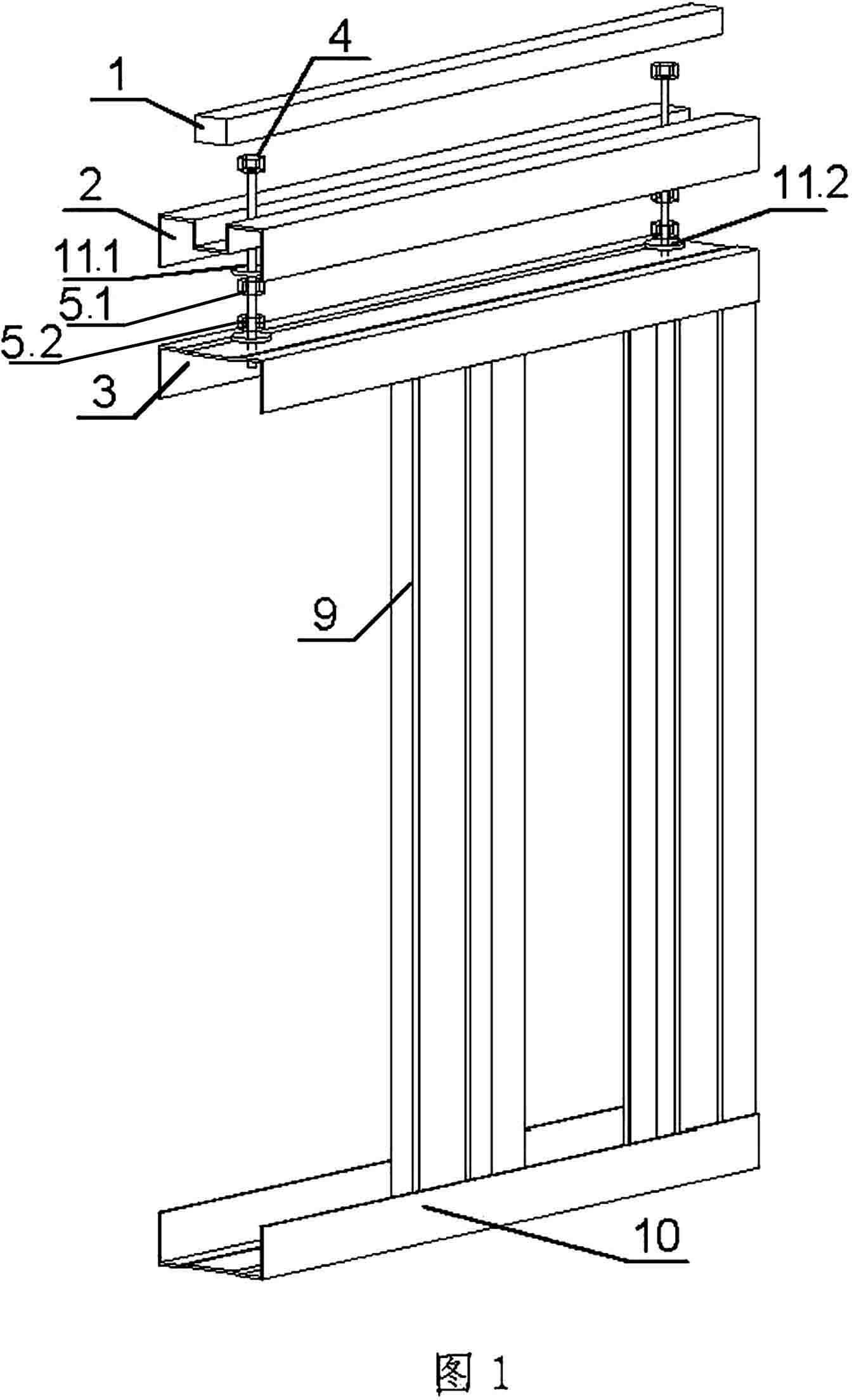

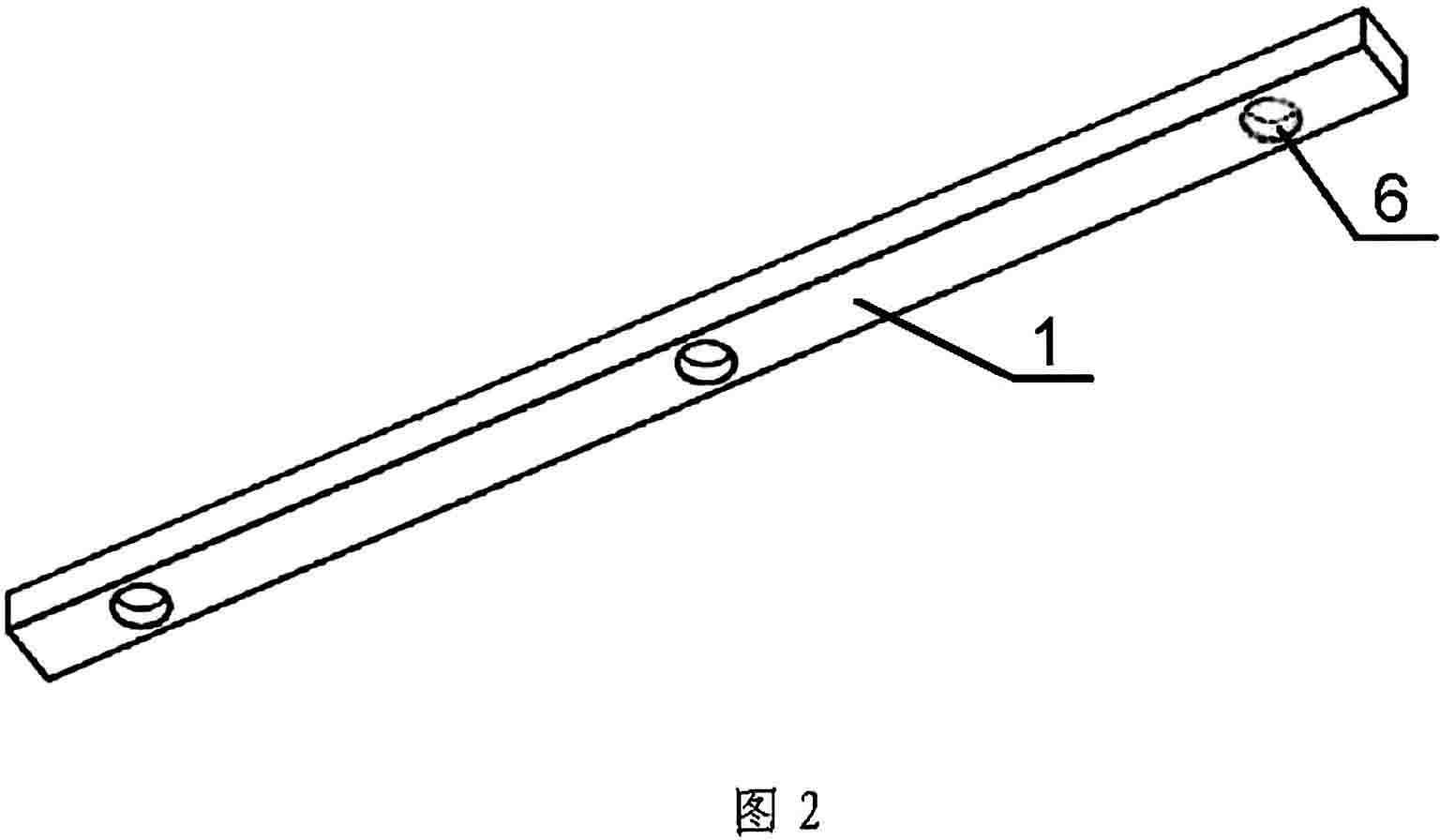

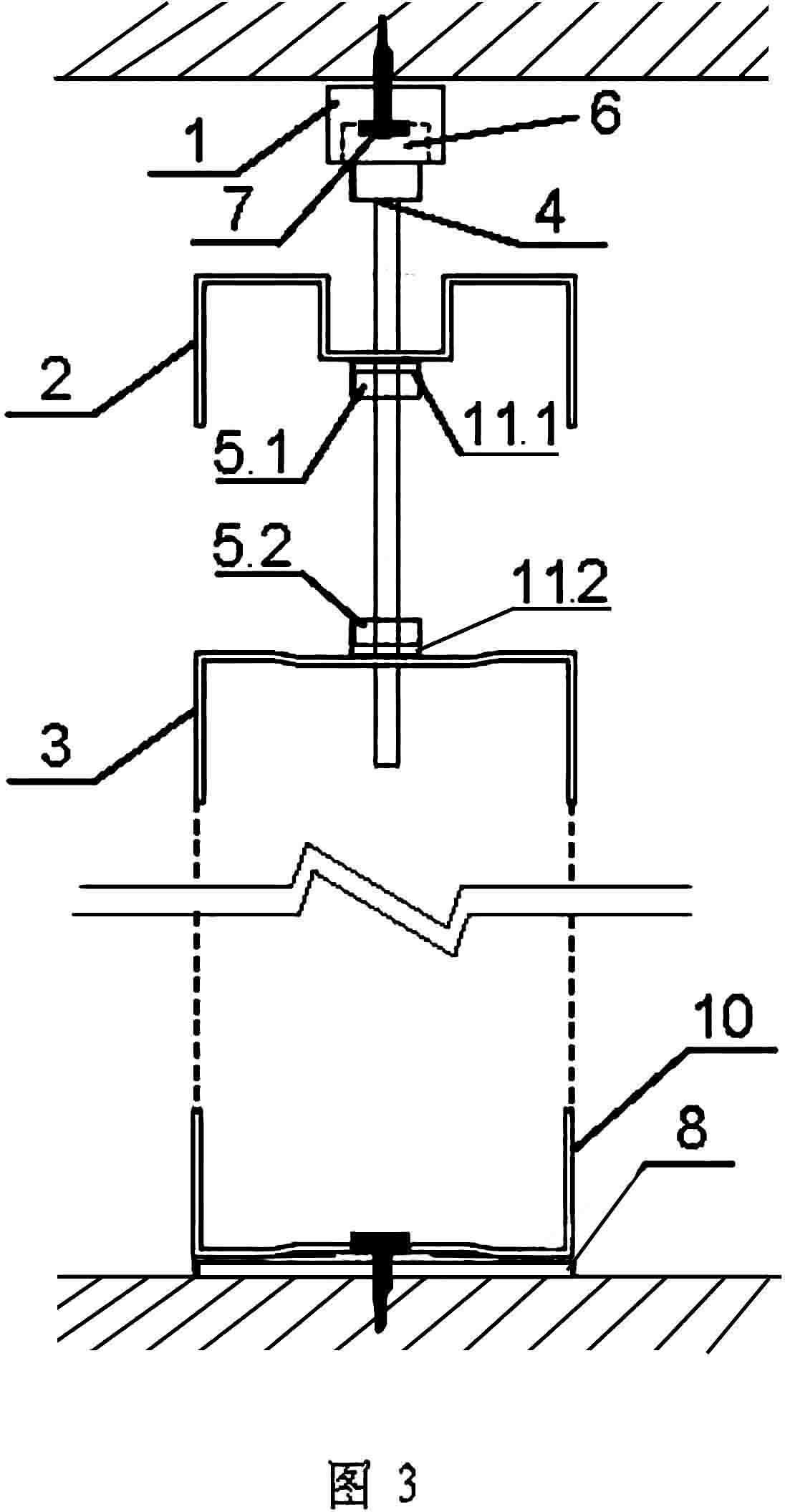

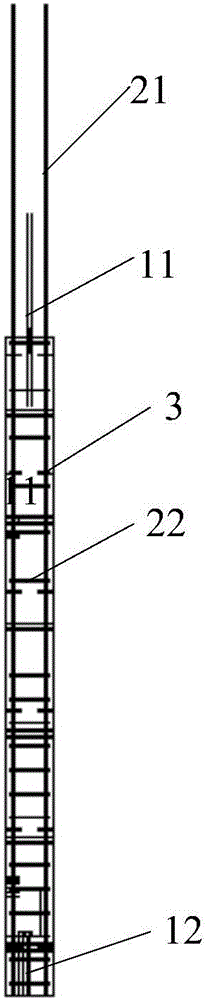

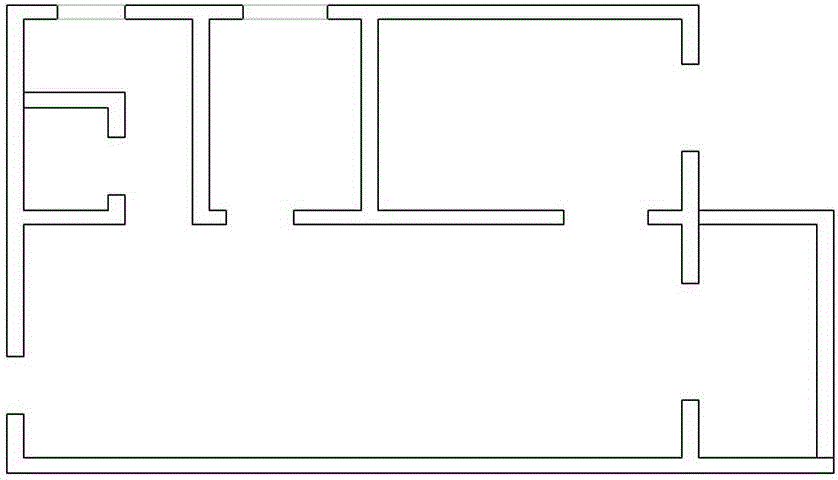

Lightgage steel joist partition wall adaptive to building error of building structural body and construction method thereof

InactiveCN102146706AFlat assemblyNon-destructive disassemblyWallsBuilding material handlingNon destructiveKeel

The invention discloses a lightgage steel joist partition wall adaptive to a building error of a building structural body and a construction method thereof. The partition wall comprises a lightgage steel joist framework and a partition wall plate, wherein the lightgage steel joist framework comprises a ceiling guide rail with a preserved hole, a ceiling keel, a top keel, a vertical keel and a bottom keel from top to bottom; the ceiling guide rail is fixed on the lower part of a ceiling structural body through a fixing element; the ceiling keel and the top keel are provided with upper and lower adjusting screw rod through holes distributed at intervals; the ceiling keel is adjustably fixed below the ceiling guide rail by using the upper and lower adjusting screw rods and a matched upper nut; the upper and lower positions of the top keel on the upper and lower adjusting screw rods are adjusted by using a lower nut; and the two nuts rotate in different directions. By adopting the partition wall, non-destructive detachment can be realized in a building process, a partition wall product is assembled in a modularized way, material waste caused by field cutting in a built-in constructionprocess is avoided, convenience is brought to assembly and disassembly, the consumption of resources used during household building and in the using process is lowered and the service life of households is prolonged. The partition wall can be widely applied to household building construction.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

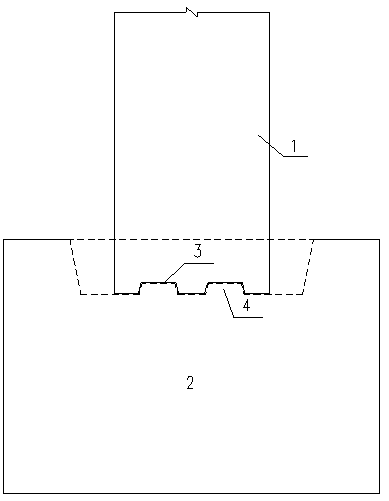

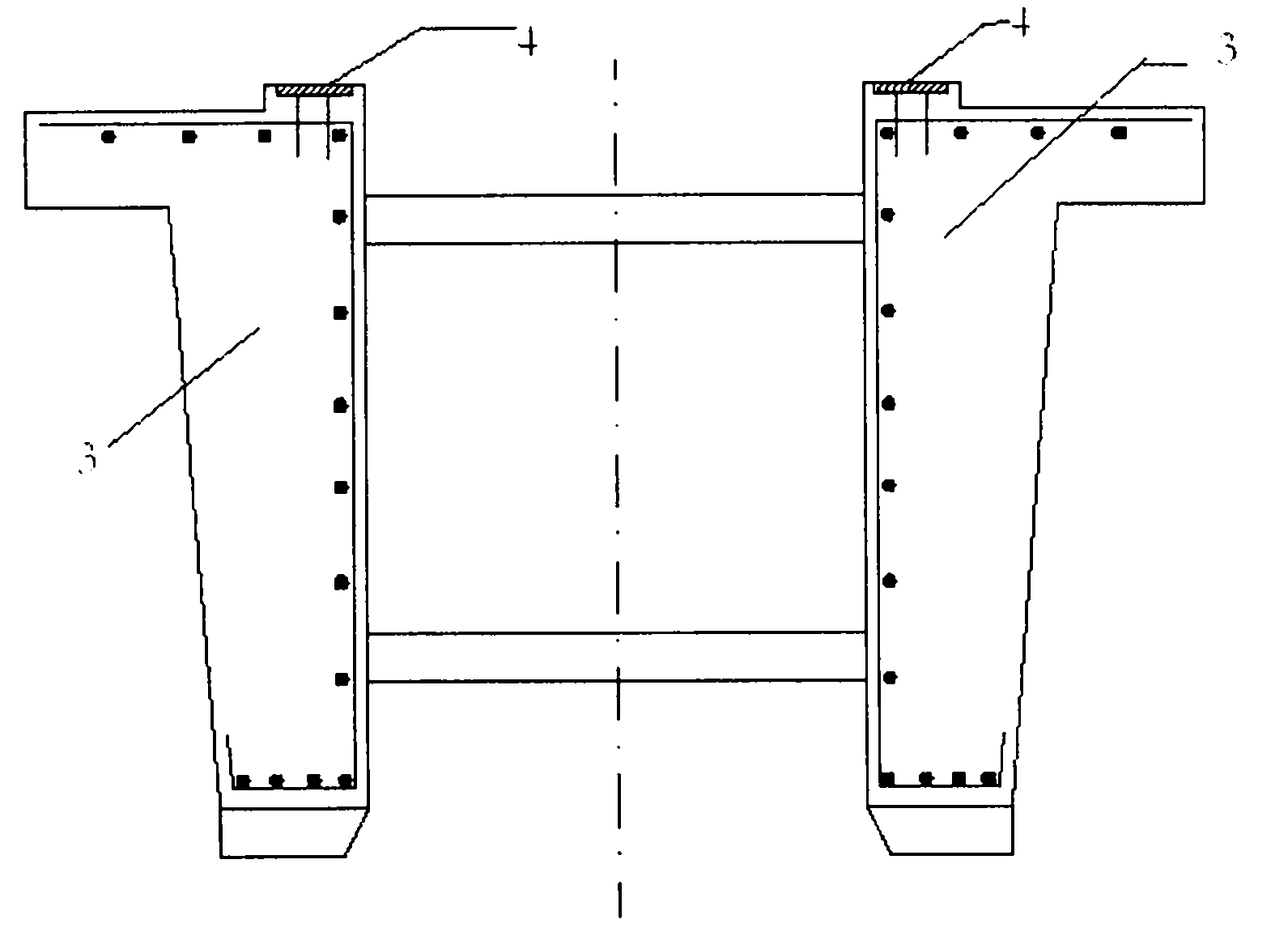

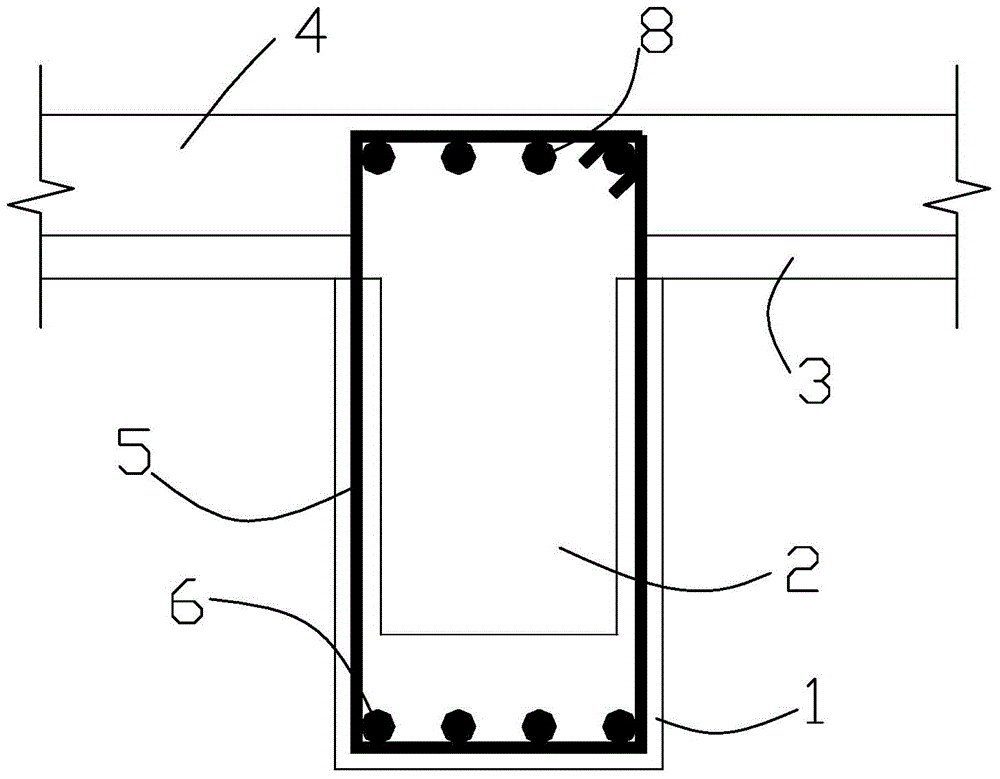

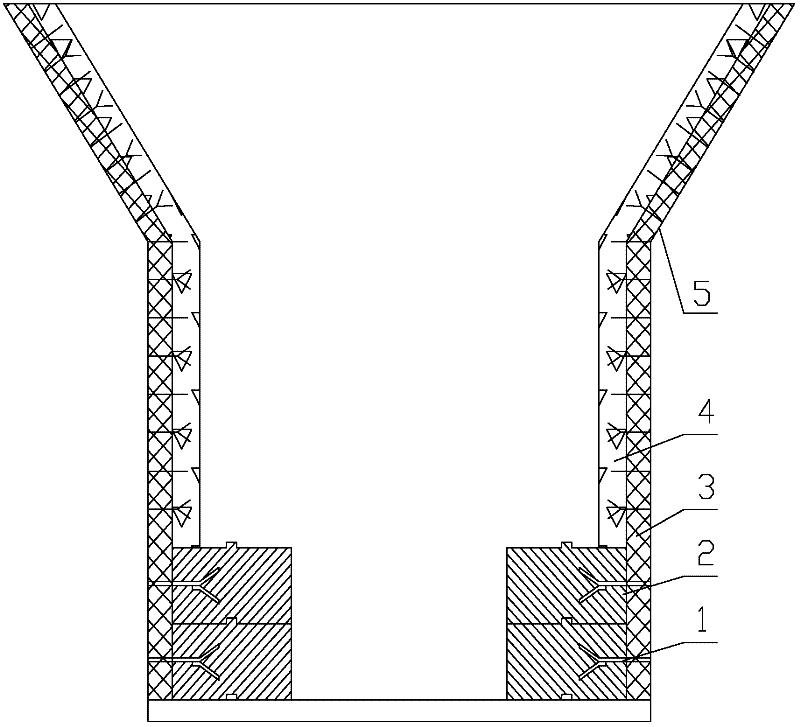

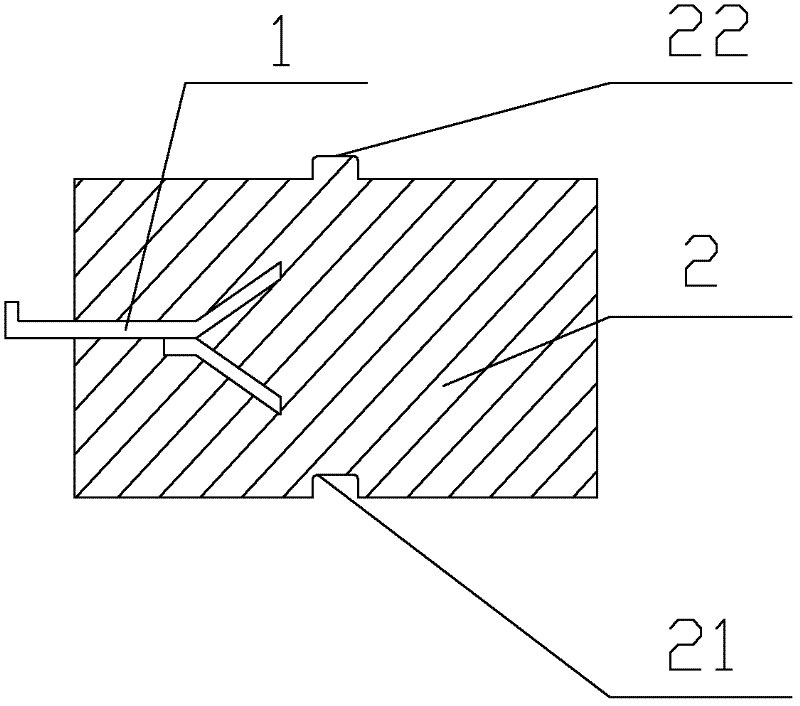

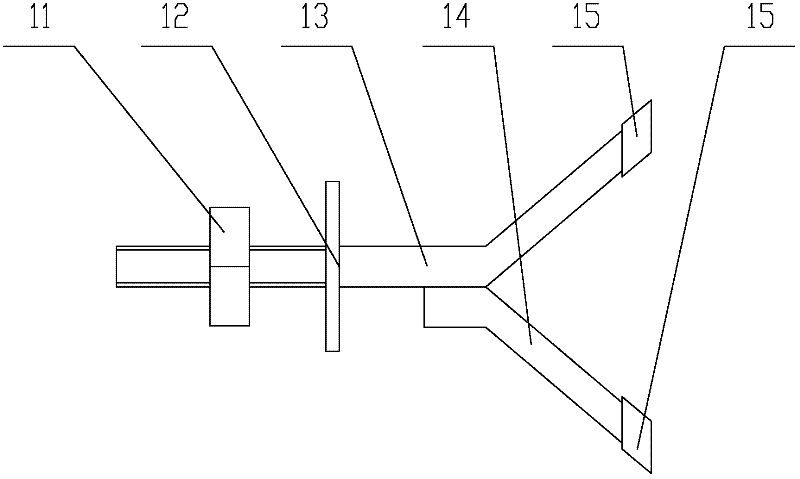

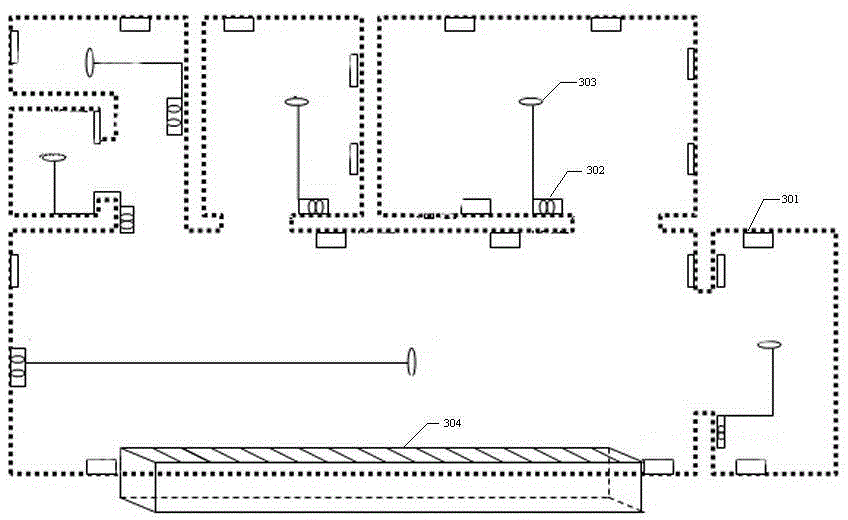

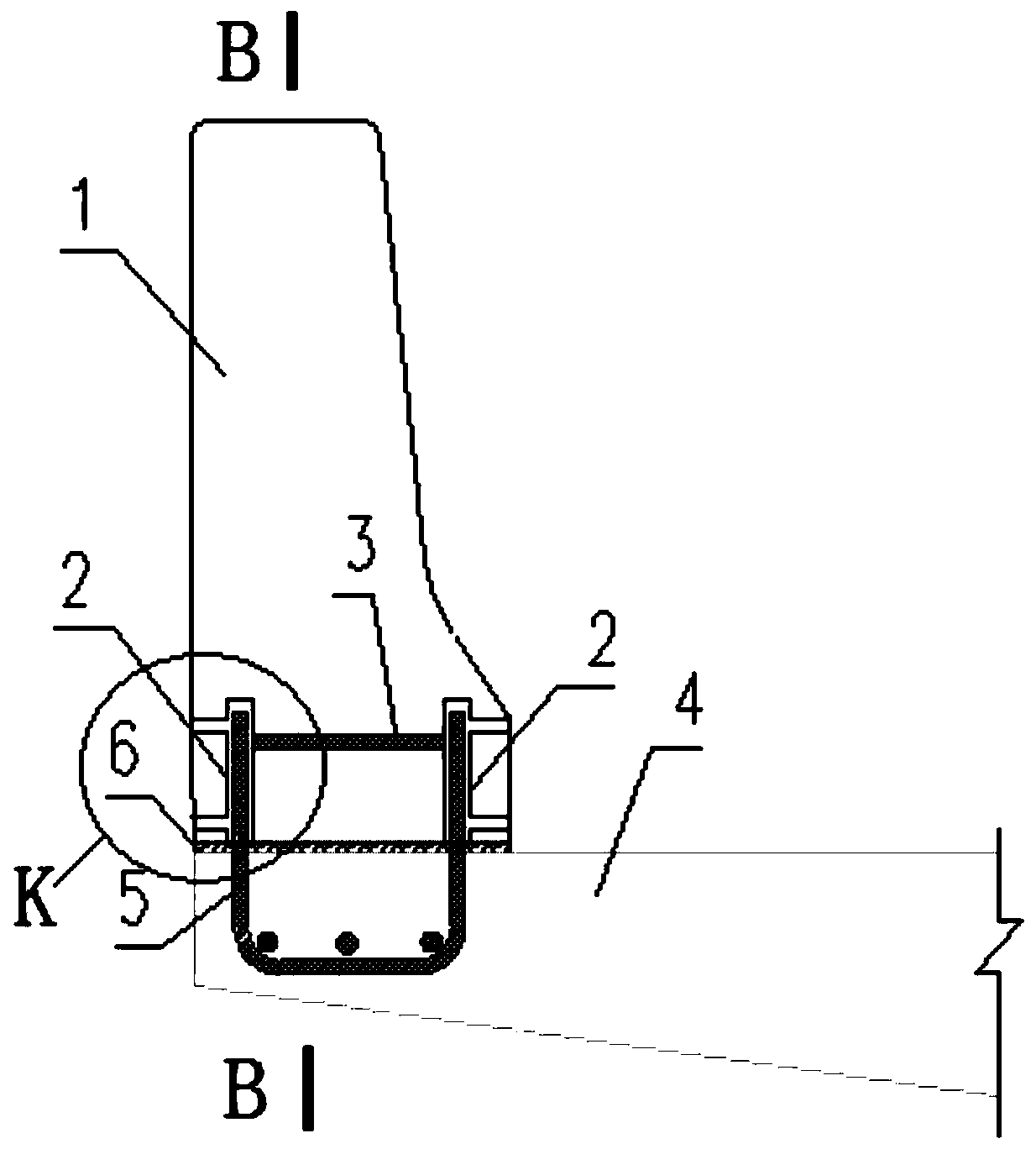

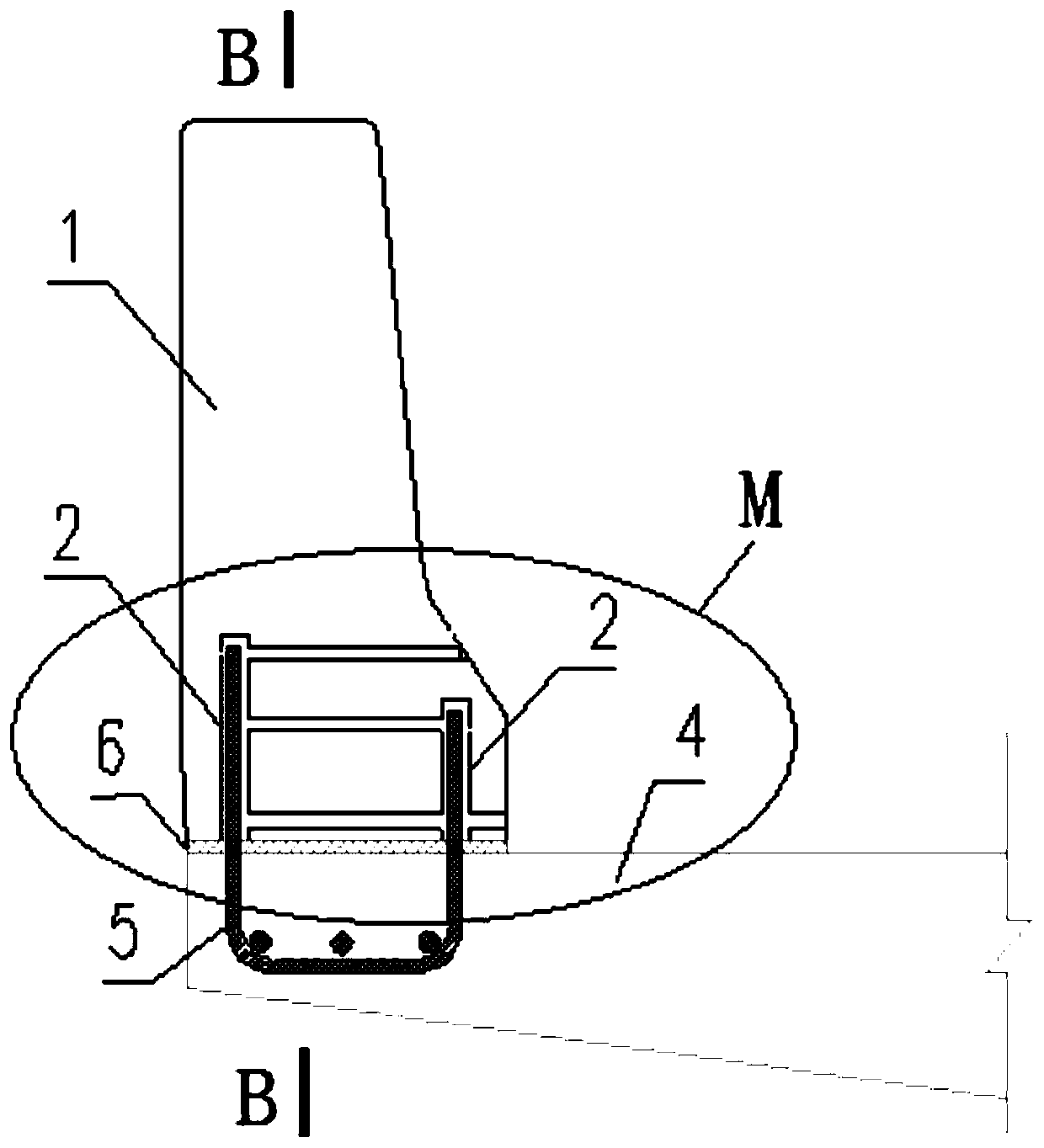

Prefabricated assembling bridge pier connecting device and construction method thereof

InactiveCN107806109AWith anti-collision protection functionSimple construction processFoundation engineeringArchitectural engineeringPier

The invention relates to a prefabricated assembling bridge pier connecting device and a construction method thereof. The prefabricated assembling bridge pier connecting device comprises a pier bottomconnecting device at the bottom of a prefabricated bridge pier and a pile-cap connecting pre-embedded device on the top of a cast-in-place pier cap; and connecting and fixing of the prefabricated bridge pier and the cast-in-place pier cap are achieved through up-down matching and installing of the pier bottom connecting device and the pile-cap connecting pre-embedded device. According to the prefabricated assembling bridge pier connecting device and the construction method thereof, the prefabricated assembling bridge pier with a connecting form of steel plate wrapping and U-shaped ribs and fine-rolling screw-thread steel is adopted, the construction process is simple and convenient; compared with other forms, the site construction process is less, the construction efficiency is greatly improved, and construction quality is ensured most effectively; safety and reliability are high, and the prefabricated assembling bridge pier connecting device and the construction method thereof can beapplied to areas with high seismic intensity; and the connecting structure has a certain anti-collision protection function to a bridge pier main body so that the prefabricated assembling bridge pierconnecting device and the construction method thereof can be widely popularized in city bridges.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

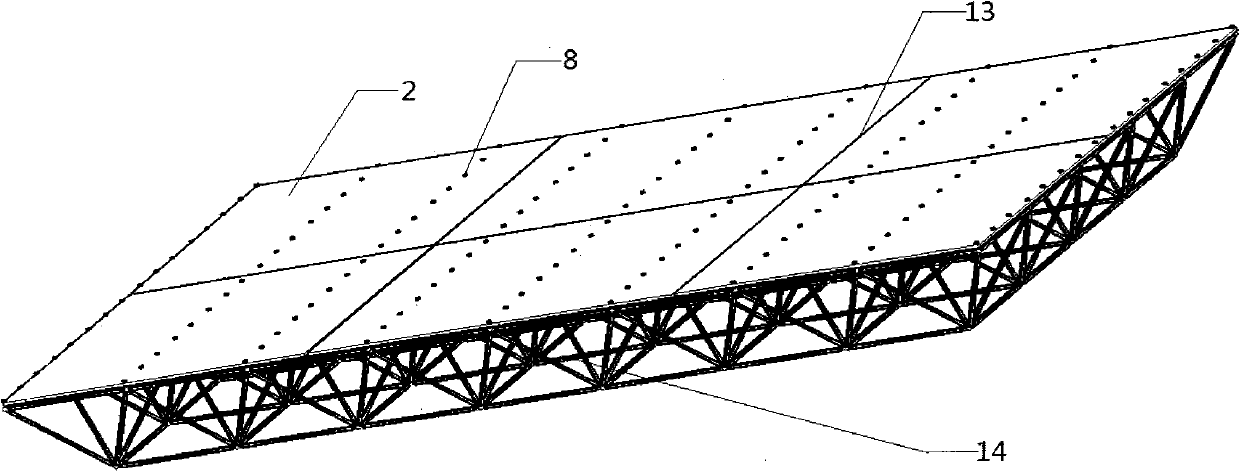

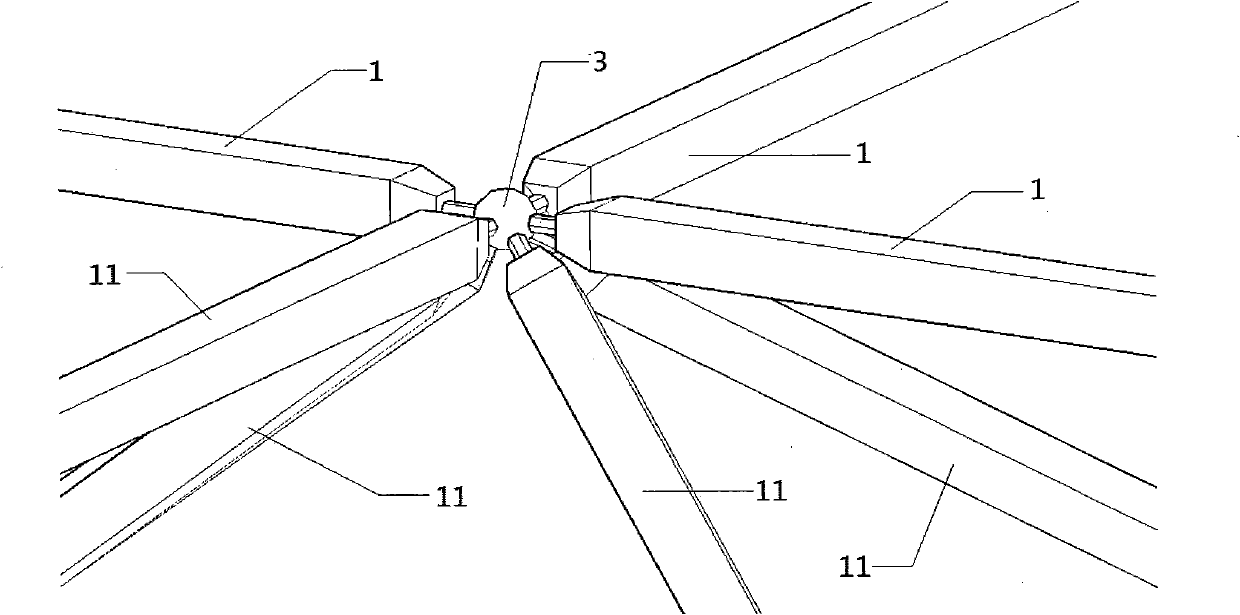

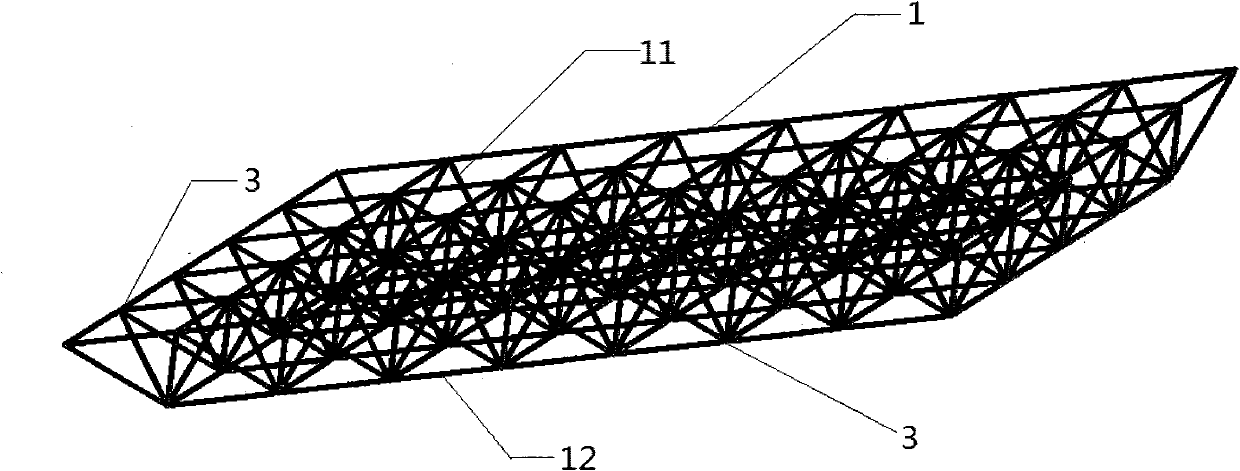

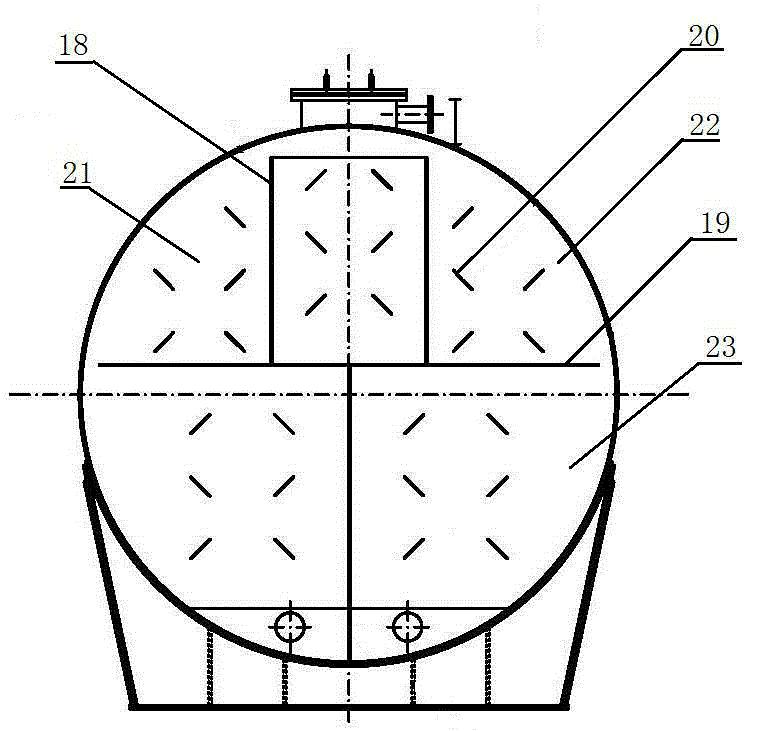

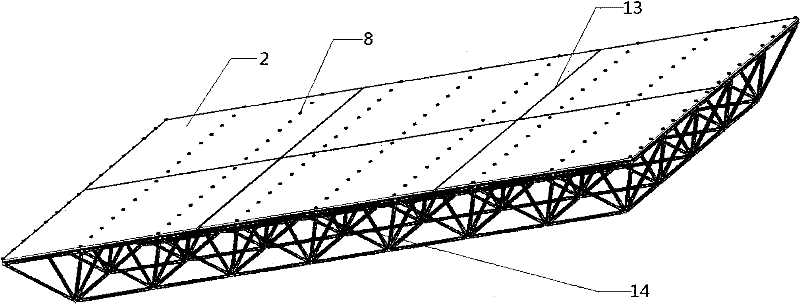

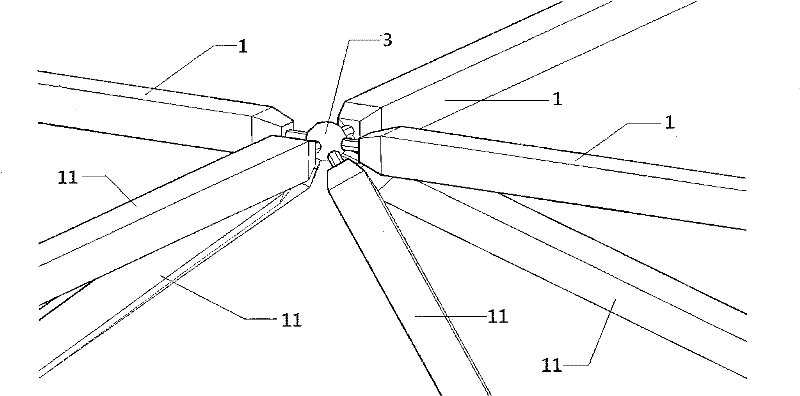

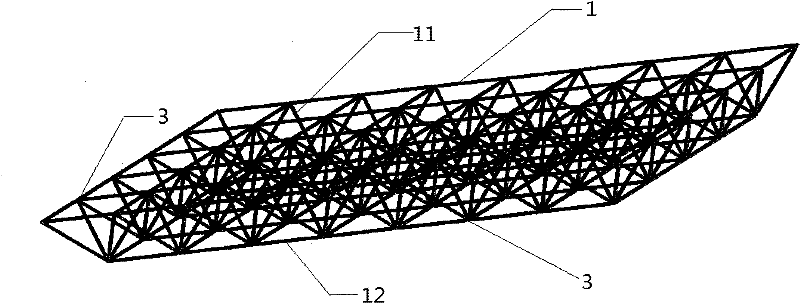

Non-purlin bolt ball node grid structure and manufacturing method thereof

ActiveCN102003028ASave steelReduce on-site construction proceduresRoof covering using slabs/sheetsBuilding roofsPurlinEngineering

The invention relates to a non-purlin bolt ball node grid structure and a manufacturing method thereof. The non-purlin bolt ball node grid structure comprises upper chord members, web members, lower chord members and bolt ball nodes. The bolt ball nodes comprise high-strength bolts, sleeves, solid spheres and pins, the upper chord members, the web members and the lower chord members pass through the solid spheres, the upper chord members adopt square steel tubes or rectangular steel tubes, two sides of the upper chord members are horizontally arranged and two sides are vertically arranged, and the diameter of the bolt ball nodes connecting the upper chord members is no more than the vertical side length of the upper chord members. In the invention, all of the members can realize industrial production and are connected by the bolts on field, field welding is avoided, construction period and construction cost are shortened, purlines are not arranged at the same time, steel products are saved, and construction costs are reduced.

Owner:TIANJIN UNIV

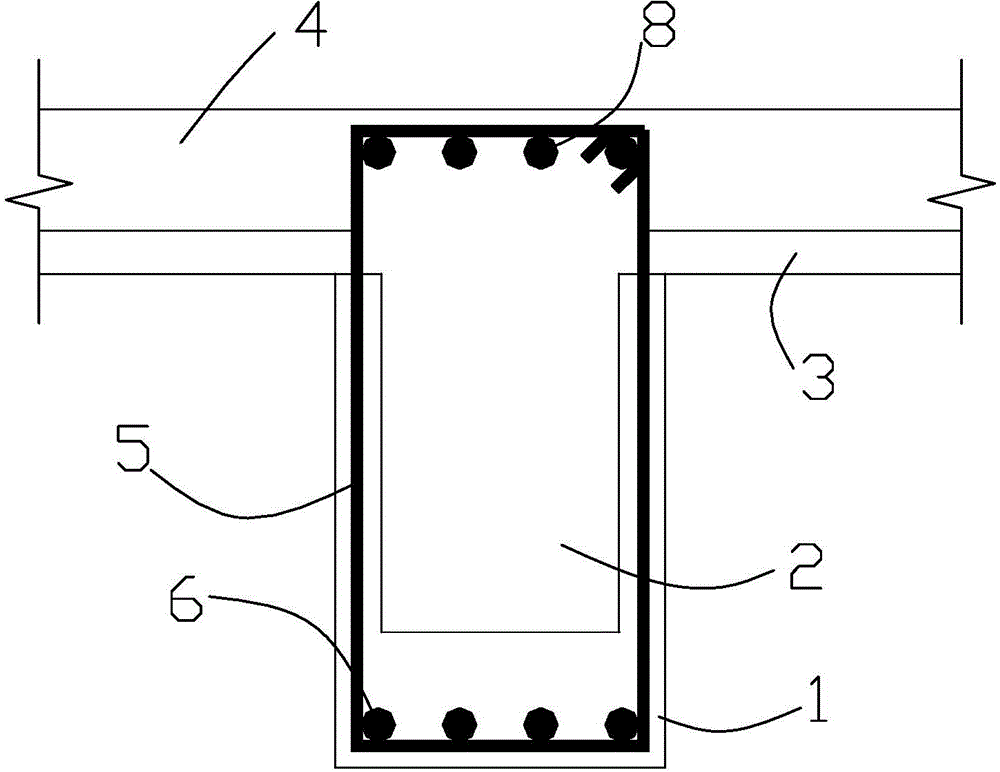

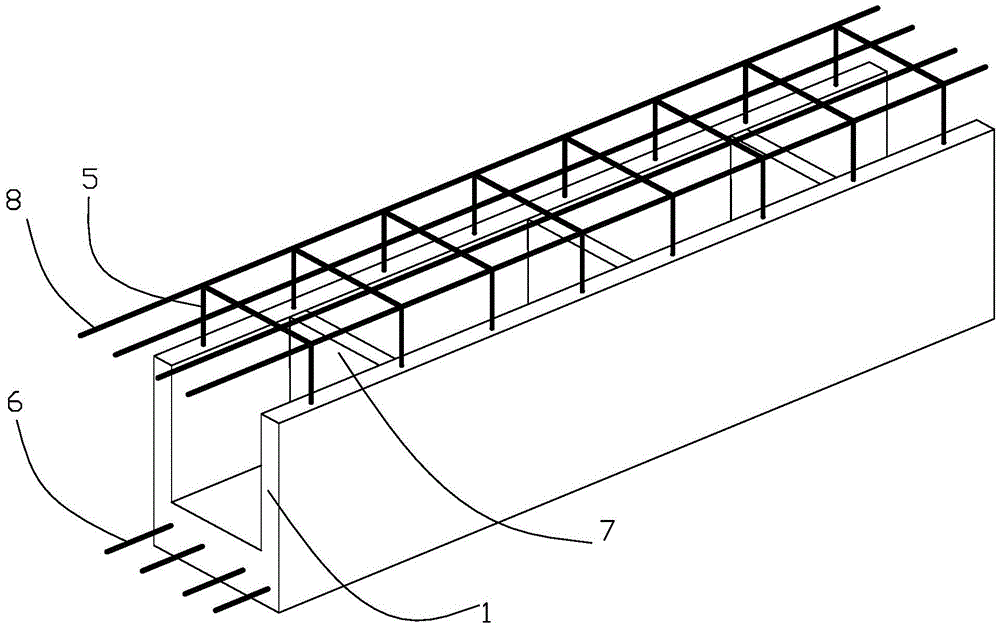

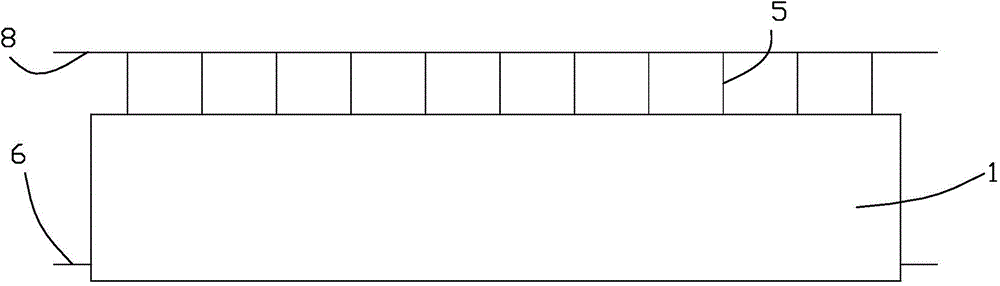

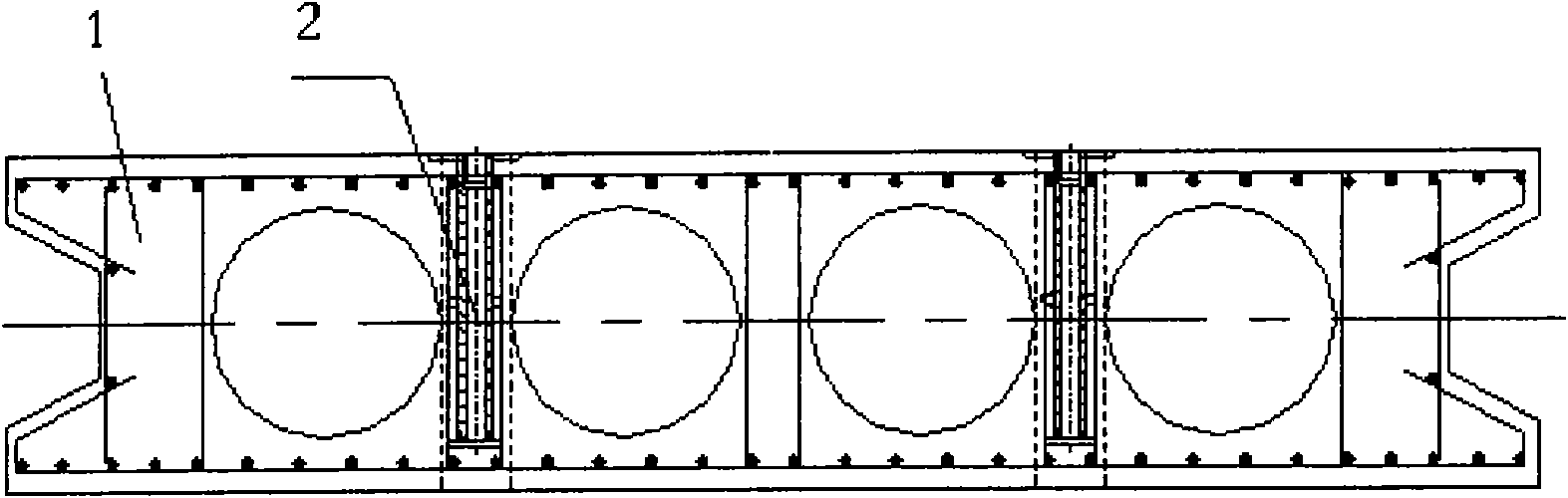

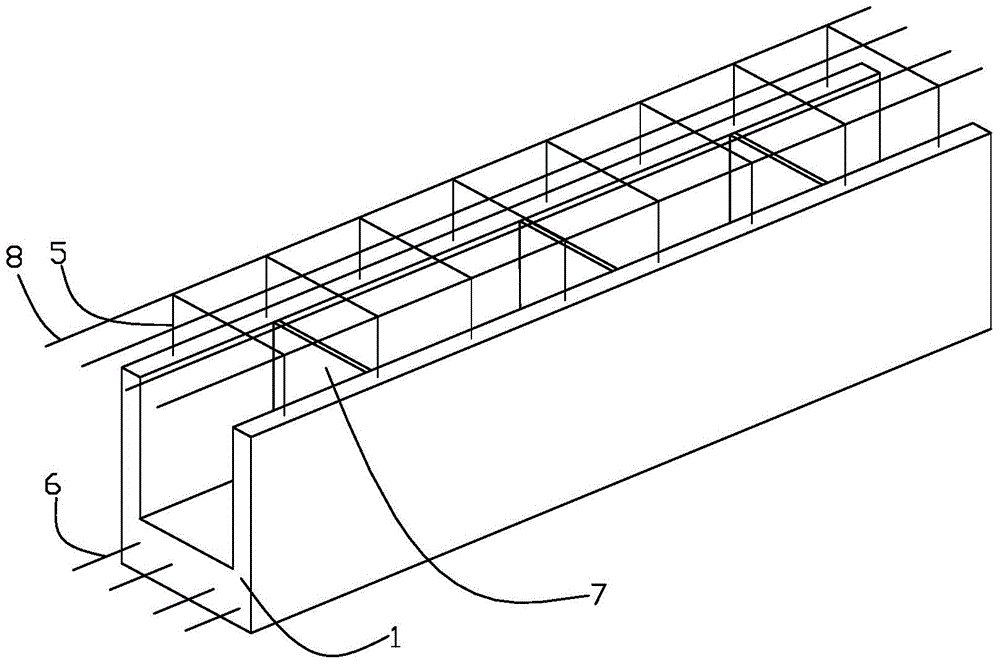

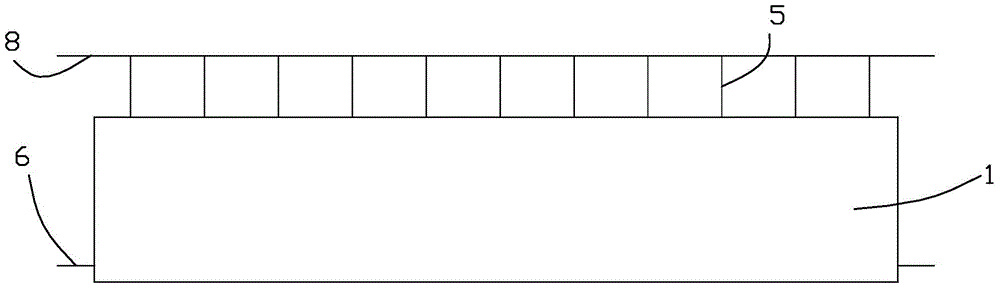

Prefabricated reinforced concrete beam with transverse high-strength concrete separation plate and construction method thereof

InactiveCN104594555AReduce on-site construction proceduresReduce construction materialsGirdersJoistsHigh strength concreteReinforced concrete

A prefabricated reinforced concrete beam with a transverse high-strength concrete separation plate employs an idea of casting a part of a prefabricated part in situ, and is composed of a prefabricated part and a cast-in-situ part, and comprises a prefabricated U-shaped high-strength concrete groove, first in-situ common concrete packed into the prefabricated U-shaped high-strength concrete groove, multiple transverse high-strength concrete separation plates which are arranged in the prefabricated U-shaped high-strength concrete groove and are perpendicular to the groove length direction, multiple closed stirrups which are arranged in the prefabricated U-shaped high-strength concrete groove and are perpendicular to the groove length direction, multiple first longitudinal ribs which are arranged in at the bottom of the prefabricated U-shaped high-strength concrete groove and are parallel to the groove length direction, and a cast-in-situ flange plate arranged at the top of the prefabricated U-shaped high-strength concrete groove. The invention also provides a construction method for the beam. According to the technical scheme, the longitudinal anti-shearing effect between the prefabricated concrete and cast-in-situ concrete is improved, and also lateral destroying is prevented, and the crack resistance, durability and fireproof performance of the beam are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

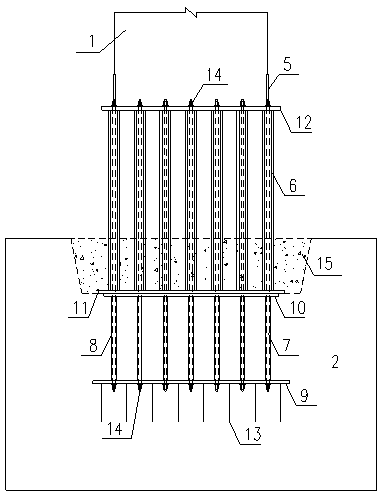

Process for constructing underground structural walls without linings

InactiveCN102116035AImprove bearing capacityBearing capacity recoveryArtificial islandsUnderwater structuresResearch resultUnderground space

The invention relates to a process for constructing underground structural walls without linings. The process is characterized by prefabricating wall panels on the ground, transporting the wall panels, forming slots, hoisting the wall panels into the slots, constructing spliced piles and grouting the toes and sides of the walls. The process has the following advantages: the underground structural wall panels can be fabricated on the ground and then transported to the construction site to hoist and form slots on the underground structural walls and install and splice the wall panels, and the slots can be continuously formed on the underground structural wall panels and the underground structural wall panels can be continuously hoisted, thus improving the construction efficiency; the underground structural walls are unnecessary to serve as lining walls when serving as underground structures combining two walls, thus improving the use ratio of the underground space; the construction technology of the underground structural walls without linings is applied, thus reducing the site construction processes, shortening the construction period and ensuring the quality of the underground structural wall bodies; the process for constructing the foundation pit enclosure structure saves resources, is environment-friendly and further ensures quality; and by using the process, the economic and social benefits are remarkable and the research results have higher application value.

Owner:SHANGHAI MECHANIZED CONSTR GRP

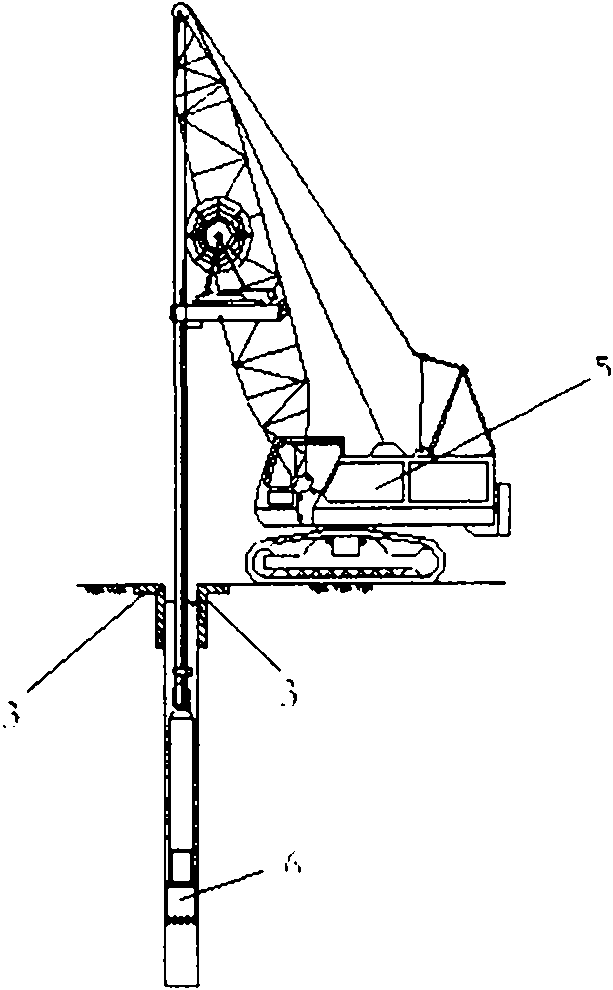

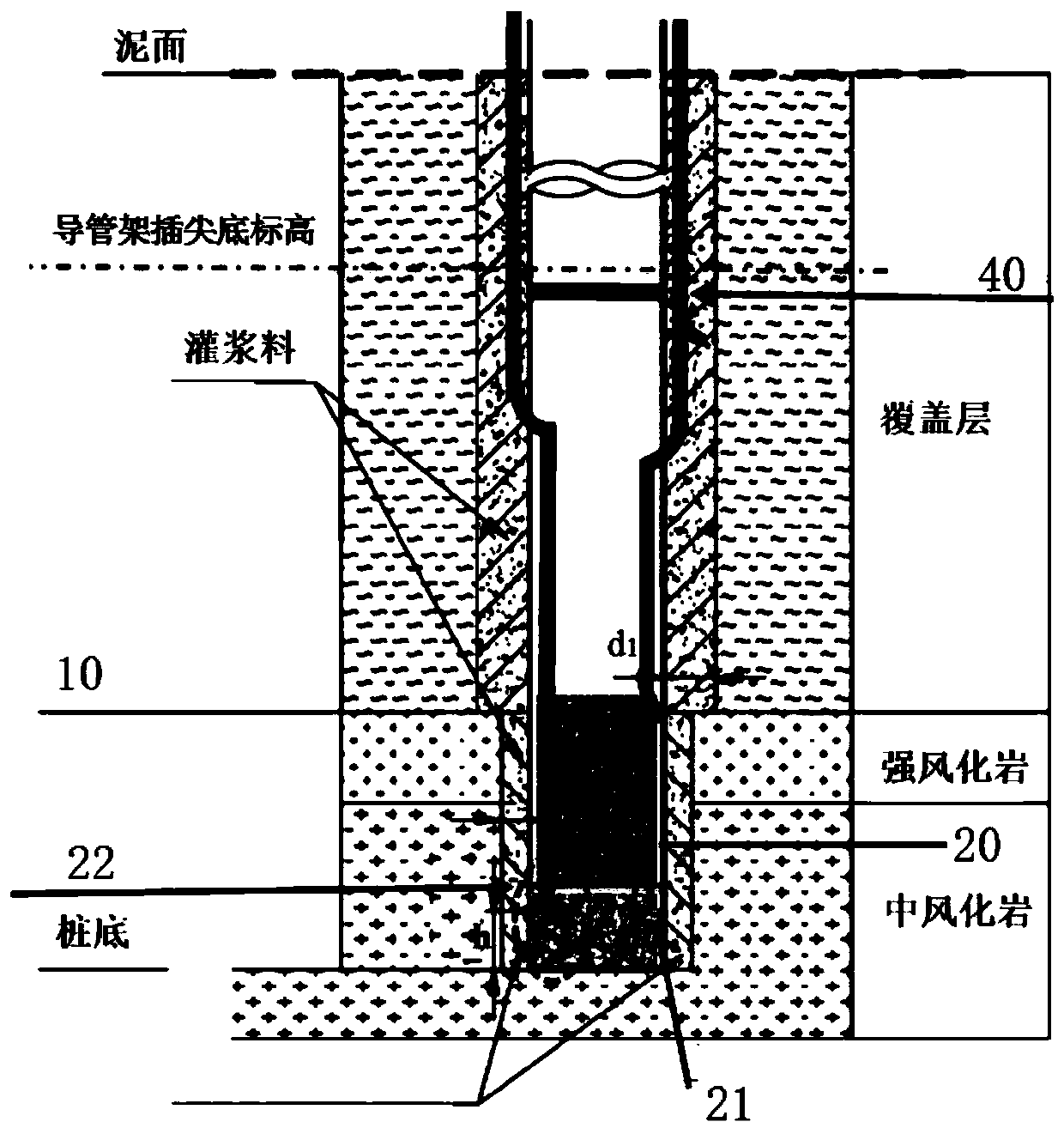

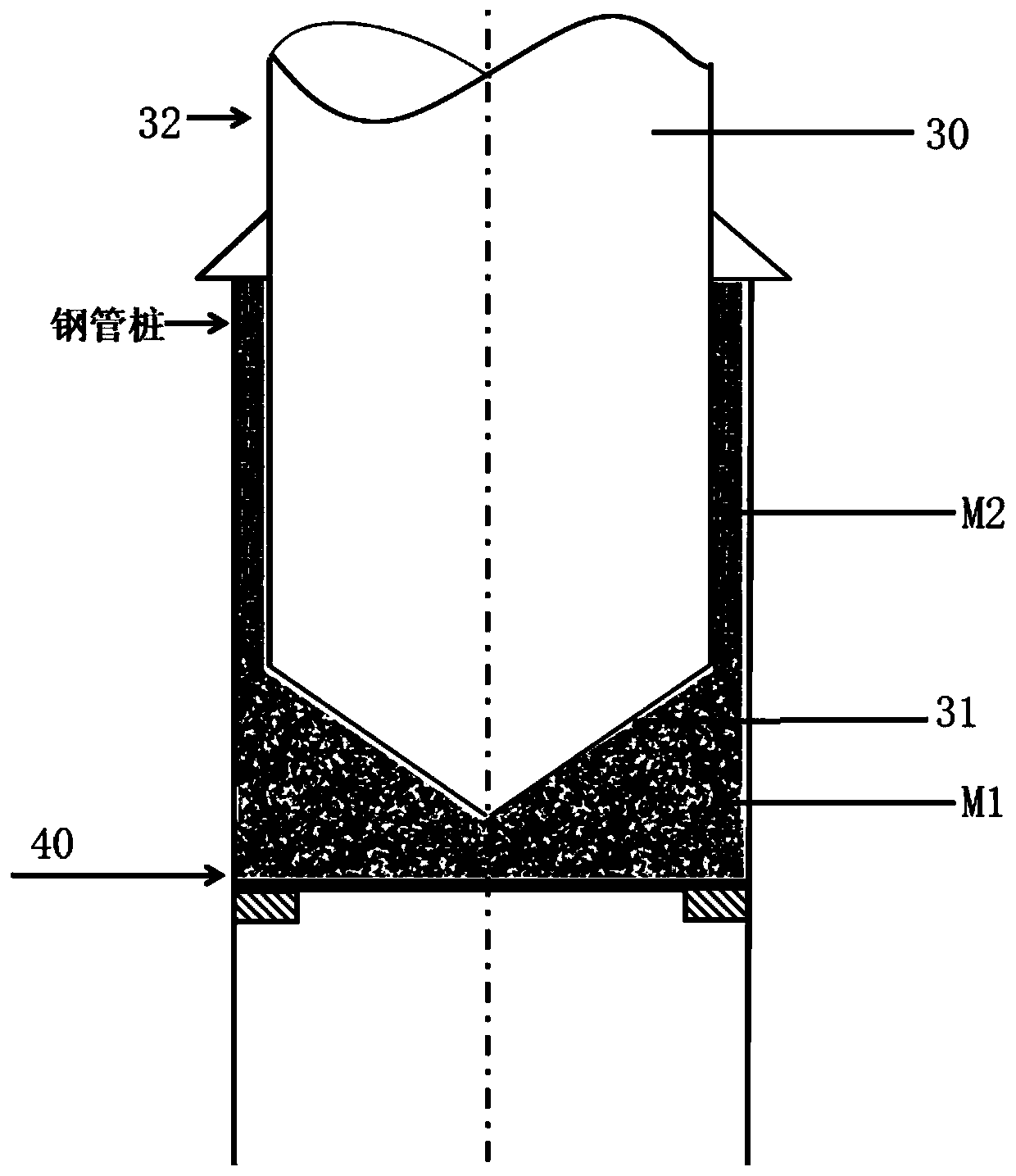

"Pile first method" interpolated jacket foundation construction system for implantable rock-socketed pile

PendingCN111593728AReduce construction riskGuarantee the construction qualityBulkheads/pilesPipeOffshore construction

This application discloses a "pile first method" interpolated jacket foundation construction system for an implantable rock-socketed pile. The construction system comprises a steel pile casing, a steel pipe pile prefabricated with pile core bottom sealing concrete and a jacket; the steel pile casing is sank to a preset position, the steel pipe pile prefabricated with the pile core bottom sealing concrete is implanted in the inner side of the steel pile casting, and a first annular space among the bottom of the steel pipe pile, the steel pipe pile and a rock-socketed hole wall and a second annular space between the steel pipe pile and an overburden layer are both prefabricated with grouting pipelines; and after the first annular space and the second annular space are grouted, the tip part of a pile leg column of the jacket is inserted into the steel pipe pile and fixedly connected with the steel pipe pile, and a third annular space is prefabricated with a grouting pipeline. This systemproposes to pre-pour pile core the concrete to seal the bottom in the pile before the steel pipe pile is shipped, the construction risk is reduced, a offshore construction window is saved, the construction quality of the pile core concrete and the grouting construction quality of a rock-socketed section are ensured, and at the same time, the grouting quality of the rock-socketed section is ensured.

Owner:CCCC THIRD HARBOR ENG +2

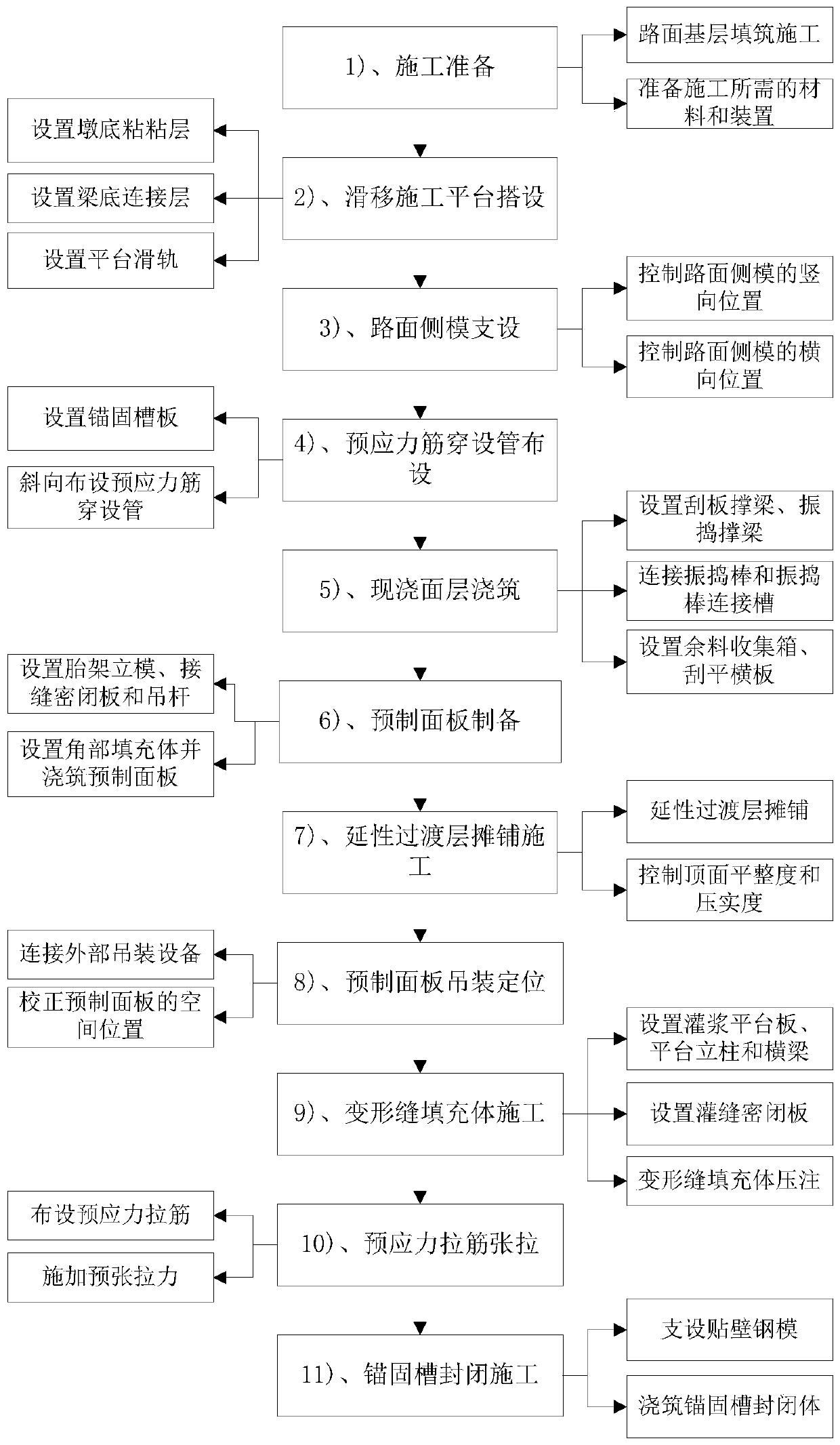

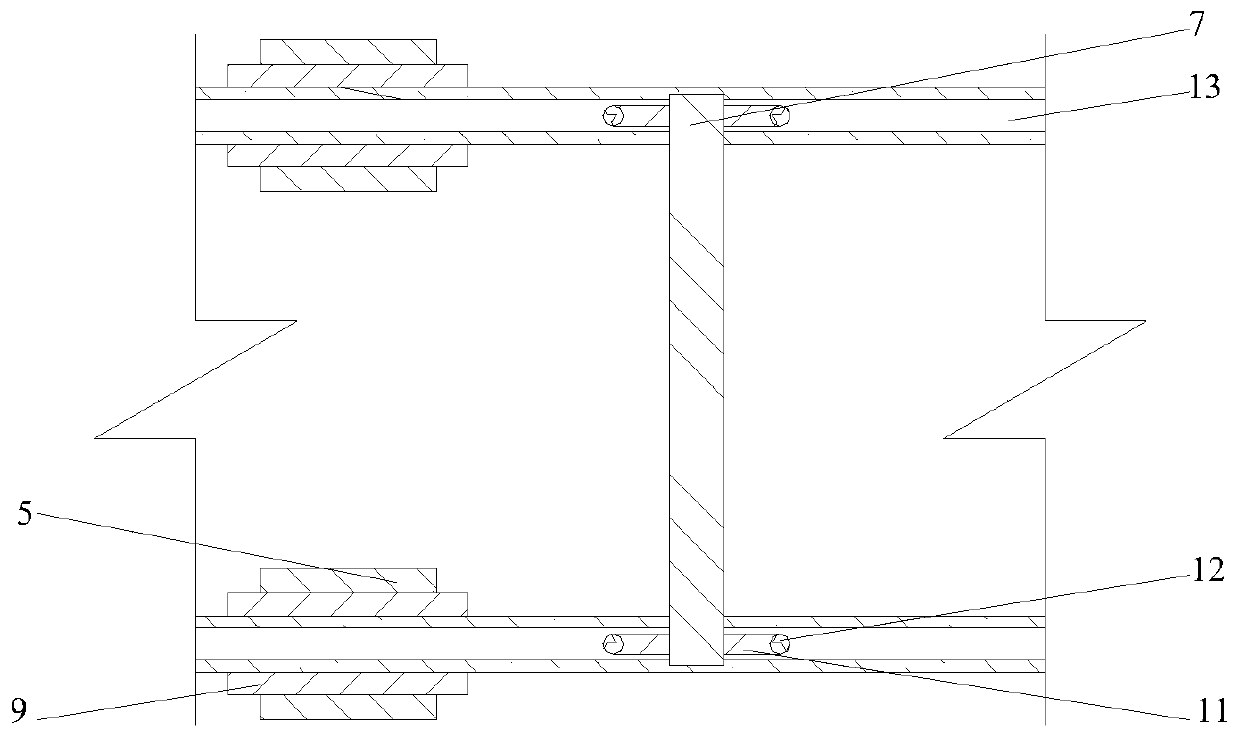

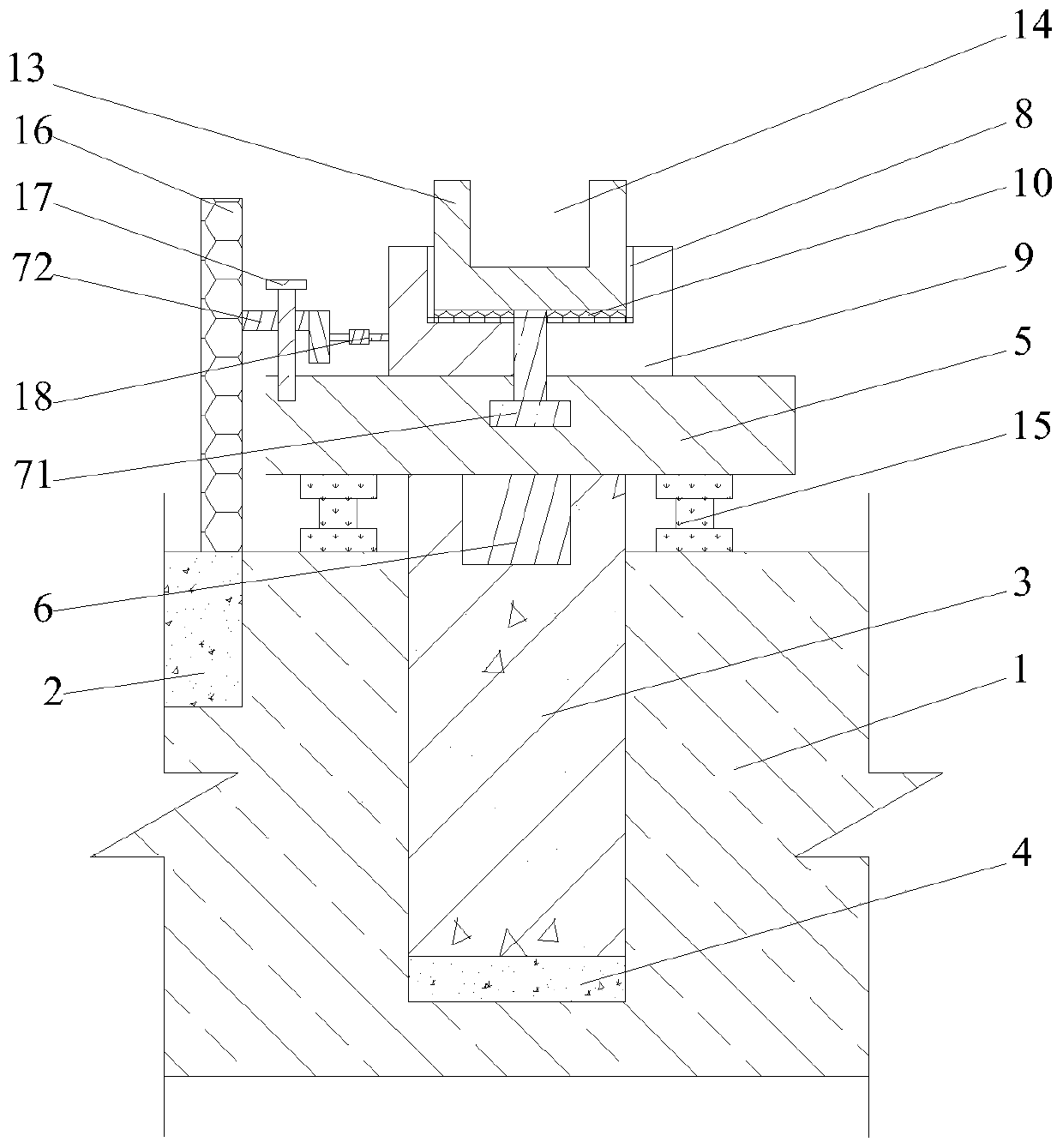

Prefabricated concrete pavement and construction method

ActiveCN110983894AReduce difficultyImprove mechanical performanceIn situ pavingsSingle unit pavingsPre stressArchitectural engineering

The invention provides a prefabricated concrete pavement and a construction method. A prefabricated pier foundation and a pier top positioning plate are adopted to provide support for a platform sliding rail and a pavement side mold, and a platform sliding beam can provide support for a scraper supporting beam and a vibrating supporting beam. Oblique prestress tie bars are adopted. When a cast-in-place surface layer is poured, pouring vibration and surface scraping can be synchronously carried out. An inserting type vibrating rod and a plane vibrator are adopted to cooperatively conduct concrete vibrating construction. A jig frame vertical die is connected with a jig frame bottom plate through a vertical die rotating hinge. A ductile transition layer is arranged between a prefabricated panel and a pavement base layer. Hoisting construction of the prefabricated panel is conducted through combination of rigid suspenders and special-shaped supporting plates. Penetrating positioning ribs are arranged in a prestressed rib penetrating pipe, and the prefabricated panel can be accurately positioned through a position control body transverse support and a position control body vertical support. An anchoring groove sealing body is made of a micro-expansion concrete material. The difficulty of cast-in-place surface layer pouring and prefabricated panel hoisting and positioning construction can be reduced, and the stress performance of the pavement structure is improved.

Owner:德达交通建设发展集团有限公司

Interface waterproofing agent

The invention provides an interface waterproofing agent which comprises a component A and a component B, wherein the component A is liquid, and the component B is powder; the component A and the component B comprise the following components respectively in part by mass: the component A comprises 370 to 450 parts of waterproof glue liquid, 1 to 2 parts of defoaming agent, 1 to 2 part of preservative, 1 to 2 parts of wetting agent and 550 to 630 parts of water; and the component B comprises 800 to 1000 parts of cement, 500 to 600 parts of sand, 500 to 600 parts of ground calcium carbonate and 10 to 20 parts of crylic acid glue powder. The component A and the component B are prepared by mixing the components through the conventional method and are directly brushed on construction parts after being evenly mixed mechanically or manually by the ratio of 1: 2 in use. The interface waterproofing agent synthesizes the water resistance and the interface effect as a whole, so that the scene construction procedures are reduced, the use is convenient, and the manpower and material costs are reduced.

Owner:厦门防水博士新材料有限公司

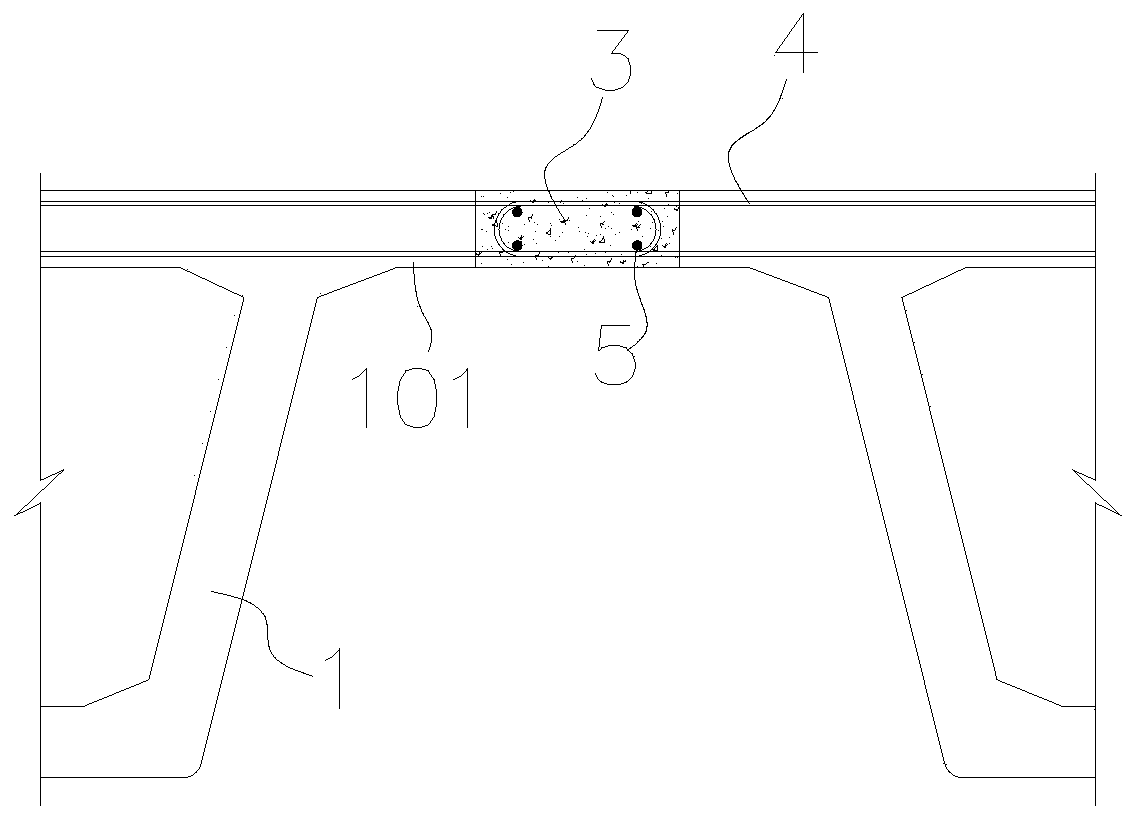

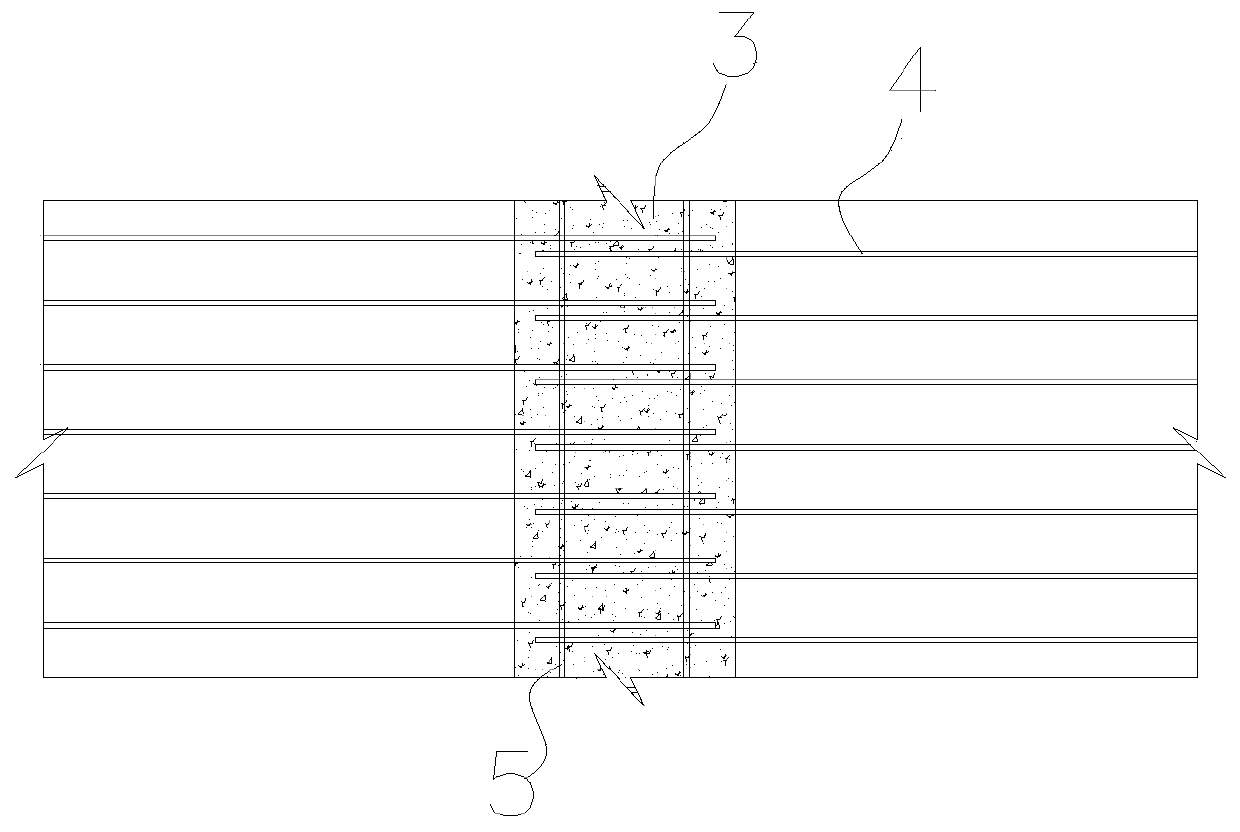

Weldless small box girder wet joint structure and method adopting ultra-high performance concrete

InactiveCN111472250AReduce the impactReduce on-site construction proceduresBridge structural detailsBridge materialsArchitectural engineeringBridge deck

The invention discloses an ultra-high performance concrete wet joint structure with prefabricated small box girders and a construction method of the ultra-high performance concrete wet joint structure. The wet joint structure comprises a plurality of prefabricated small box girders, wherein each prefabricated small box girder is arranged along the bridge direction, and a wet joint along the bridgedirection is formed between two adjacent prefabricated small box girders; a bridge deck slab straight section is arranged at the top of the prefabricated small box girder, a plurality of annular reinforcing steel bars are pre-buried in the bridge deck slab straight section, each annular reinforcing steel bar is arranged in the transverse bridge direction, and the annular ends of the annular reinforcing steel bars extend into the wet joints; a plurality of constructional steel bars are arranged in the wet joint, and each constructional steel bar is arranged in the bridge direction; ultra-high-performance concrete is poured into the wet joints, the constructional steel bars and the annular steel bars extending into the wet joints are wrapped in the ultra-high-performance concrete, and everytwo adjacent small prefabricated box girders are connected into a whole through the ultra-high-performance concrete of the wet joints and the annular steel bars wrapped in the ultra-high-performanceconcrete. According to the invention, the construction procedure can be simplified, the construction efficiency is improved, the manufacturing cost is reduced, and the construction quality is effectively improved.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

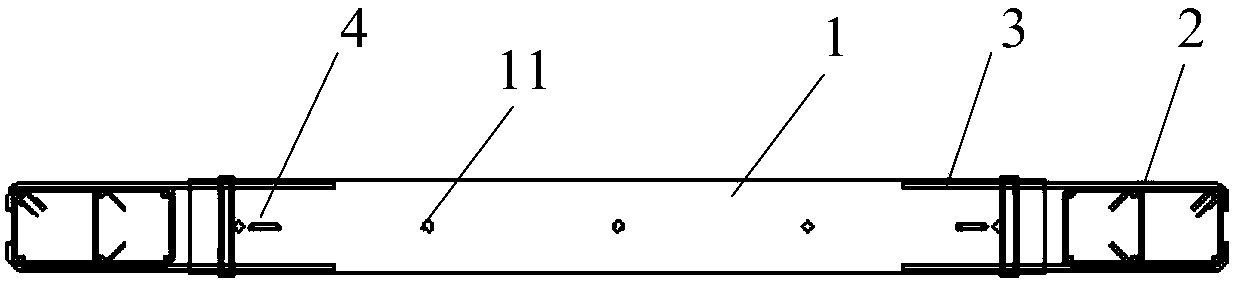

Prefabricated reinforced concrete beam with transverse steel partition boards and construction method

InactiveCN104594557AReduce on-site construction proceduresReduce construction materialsGirdersJoistsHigh strength concreteCrack resistance

The invention relates to a prefabricated reinforced concrete beam with transverse steel partition boards. By adopting the idea of partial prefabrication and partial cast-in-situ, the prefabricated reinforced concrete beam is composed of a prefabrication part and a cast-in-situ part, and specifically includes: a precast U-shaped high-strength concrete groove; cast-in-situ common concrete 1 filling the precast U-shaped high-strength concrete groove; several transverse steel partition boards that are disposed in the precast U-shaped high-strength concrete groove and are perpendicular to the groove length direction; several closed stirrups that are disposed in the precast U-shaped high-strength concrete groove and are perpendicular to the groove length direction; several longitudinal bars 1 that are disposed at the bottom of the precast U-shaped high-strength concrete groove and are parallel to the groove length direction; and a cast-in-situ frange plate disposed at the top of the precast U-shaped high-strength concrete groove. The invention also provides a construction method of the beam. The construction method provided by the invention can improve the longitudinal anti-shearing effect between precast concrete and cast-in-place concrete, at the same time prevents lateral damage, and improves the crack resistance, durability and fire resistance of the beam.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

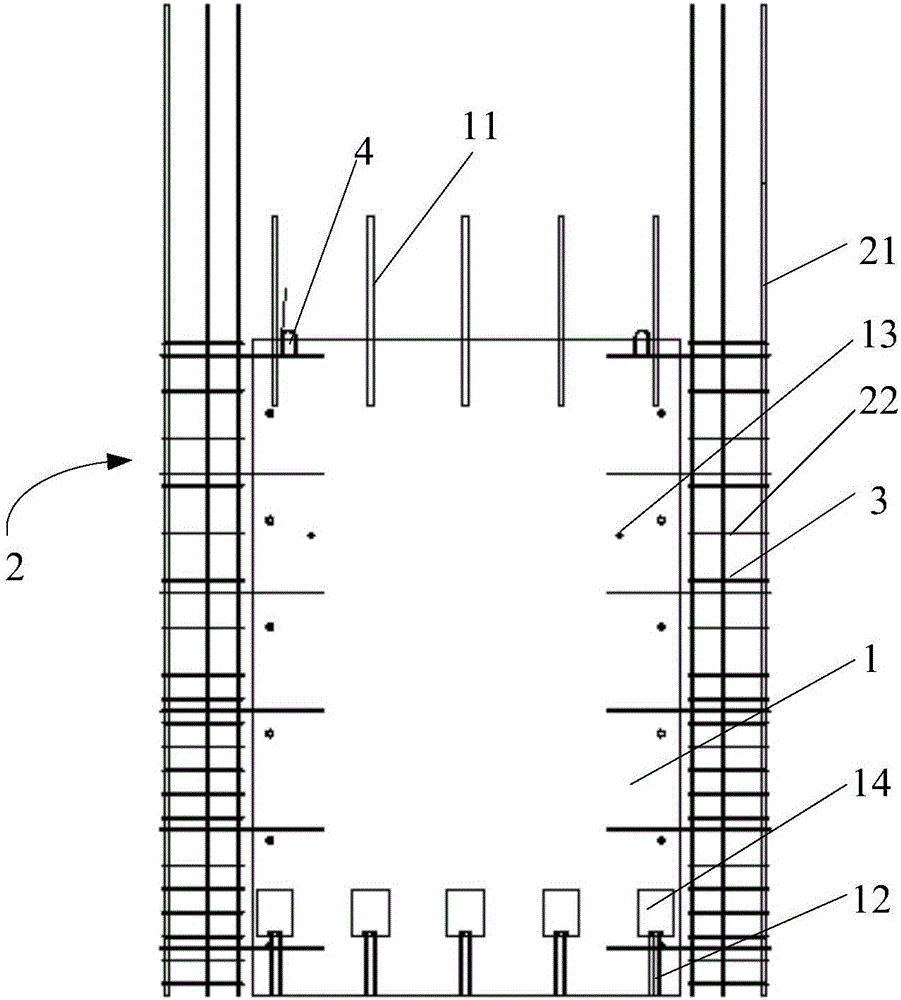

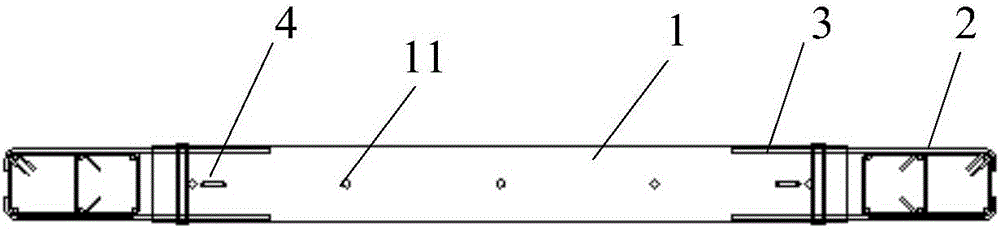

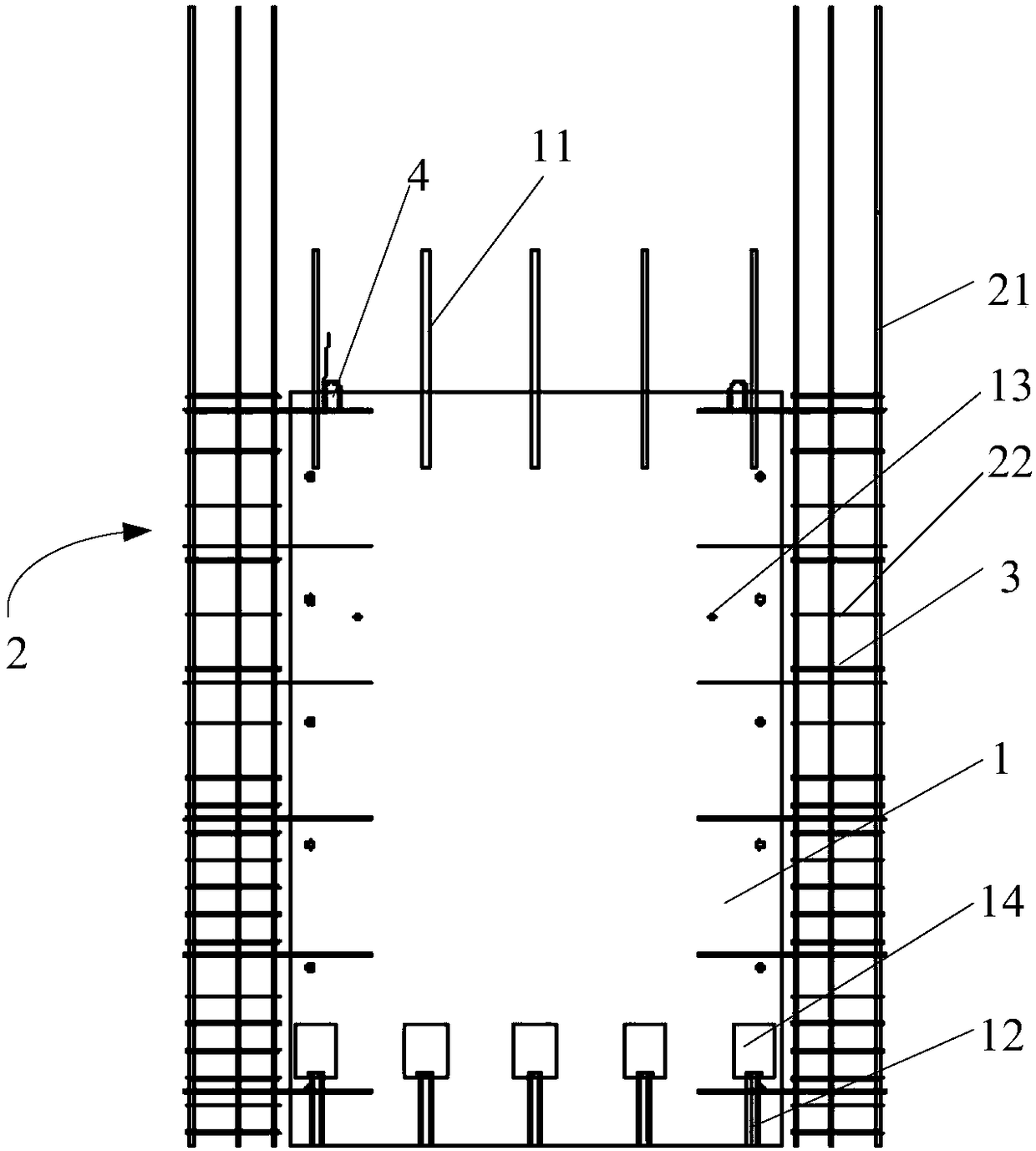

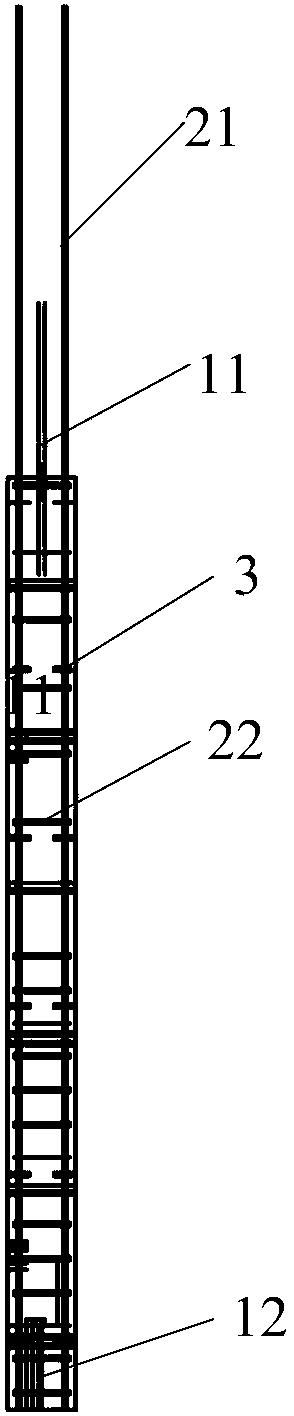

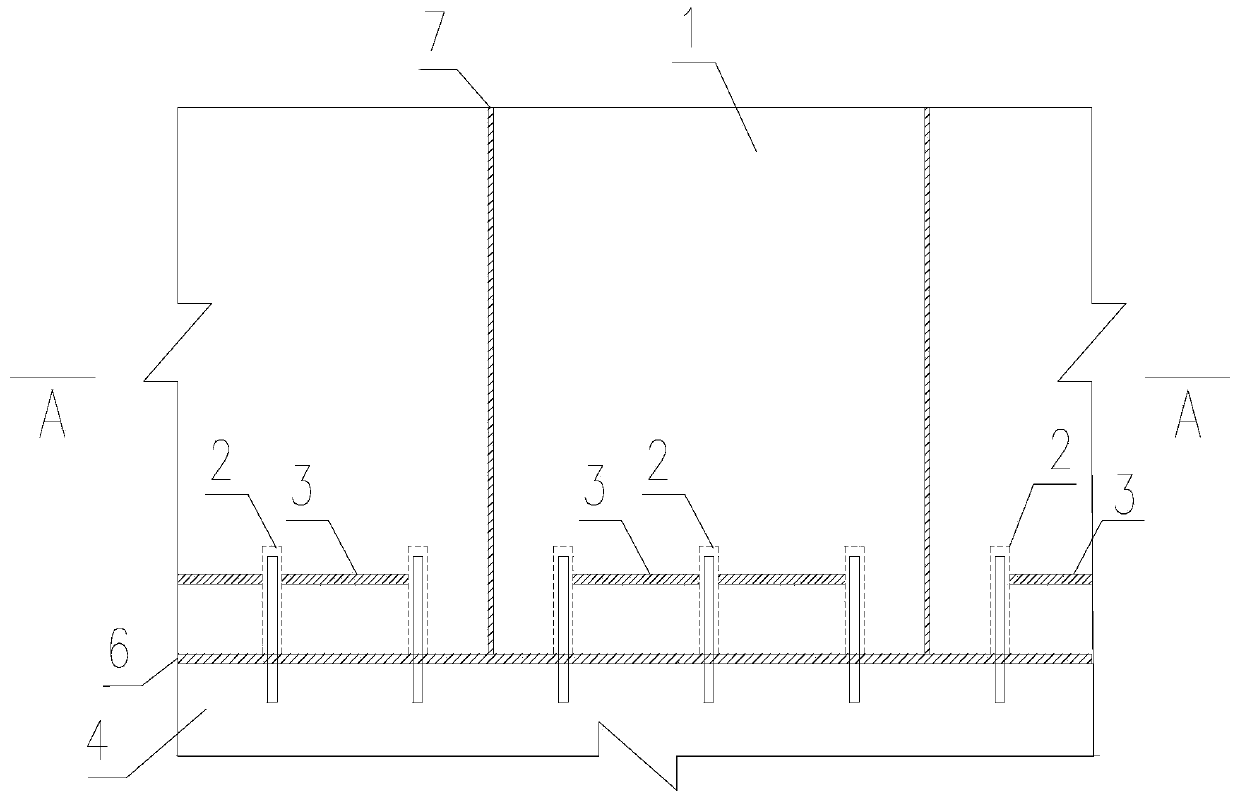

Precast concrete shear wall component and construction method thereof

ActiveCN105839836AEliminates lashing workReduce on-site construction proceduresConstruction materialWallsRebarTime cost

The invention discloses a precast concrete shear wall component and a construction method thereof. The precast concrete shear wall component comprises a precast concrete wall panel, embedded column reinforcement cages and protecting shells, wherein the embedded column reinforcement cages are positioned on two sides of the precast concrete wall panel, and the protecting shells sleeve the embedded column reinforcement cages. A plurality of reserved joint bars are arranged above the precast concrete wall panel, and a plurality of reserved bolt holes matched with the reserved joint bars in position are formed below the precast concrete wall panel. Compared with the prior art, the precast concrete shear wall component and the construction method thereof have the advantages that binding the embedded column reinforcement cages on two sides of the precast concrete wall panel on site is omitted, so that on-site construction process steps are decreased and on-site construction time is shortened; on-site connection between the precast concrete wall panel and the bound embedded column reinforcement cages is omitted, so that construction efficiency is improved and construction space is reduced; a construction period is shortened and labor and time costs are saved; construction industrialization and mechanization degree is enhanced, and dependency on increasingly intense labor resource is reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

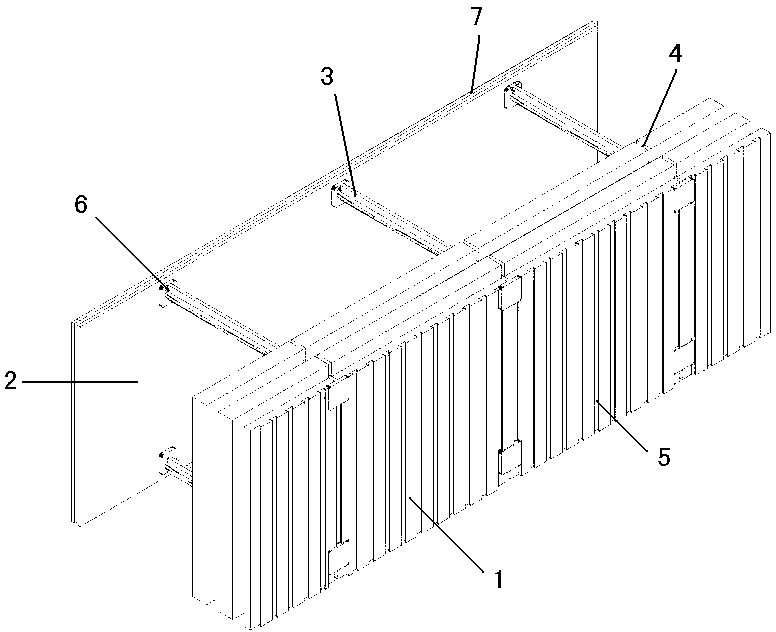

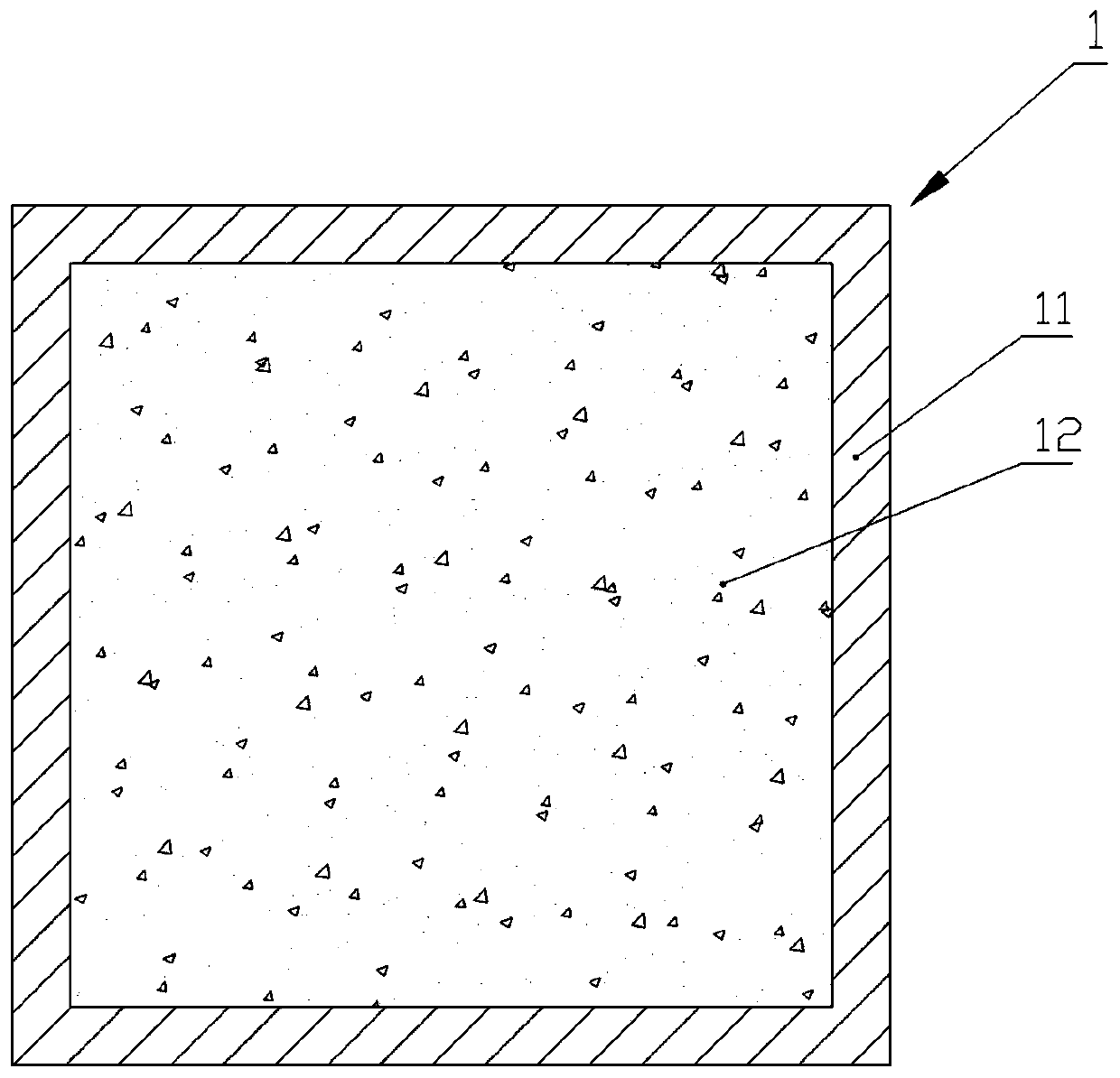

Insulating layer and inner wall surface combined type wall body module

InactiveCN103306407AAvoid damageReduce on-site construction proceduresWallsHeat proofingHigh densityThermal insulation

The invention provides an insulating layer and inner wall surface combined type wall body module, which comprises outer formworks, inner formworks and cross structures, wherein an inserting groove and an inserting tenon which are mutually matched are arranged on every two corresponding sides of each inner formwork and each outer formwork; the outer formworks are heat preservation boards made of thermal insulation material and provided with grooves distributed on the surfaces; the inner formworks are a high density plate, a fiber magnesium plate and a fireproof plate, and are provided with plane surfaces, inner walls incapable of absorbing water and inserting tongue-and-grooves; one end of each cross structure is provided with an insert plate, and the other end of each cross structure is provided with a plane end plate; cross structure inserting grooves are formed in each outer formwork; the end, provided with the insert plate, of each cross structure is inserted into each cross structure inserting groove; the end, provided with the plane end plate, of each cross structure is connected with each inner formwork through a bolt. According to the invention, the bearing, heat preservation and the inner wall surface of the wall body can be constructed through one step, the construction procedures on field can be reduced, and the damage to the formworks caused by the on-site insertion between the cross structures and the formworks can be avoided.

Owner:HARBIN HONGSHENG ROOM ENERGY SAVING SYST RES CENT

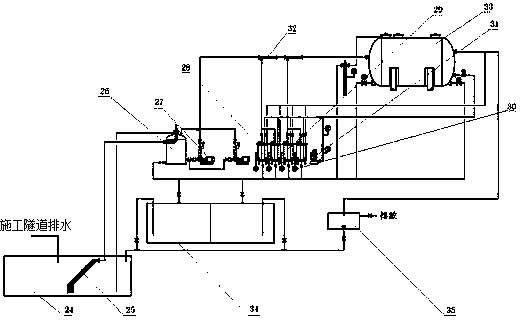

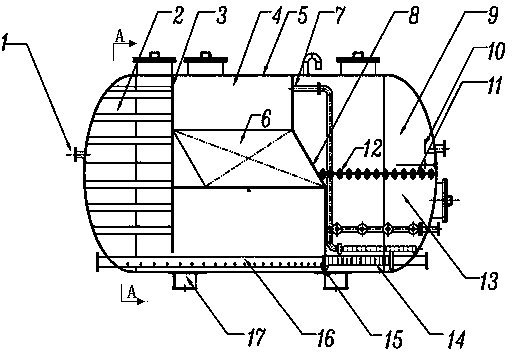

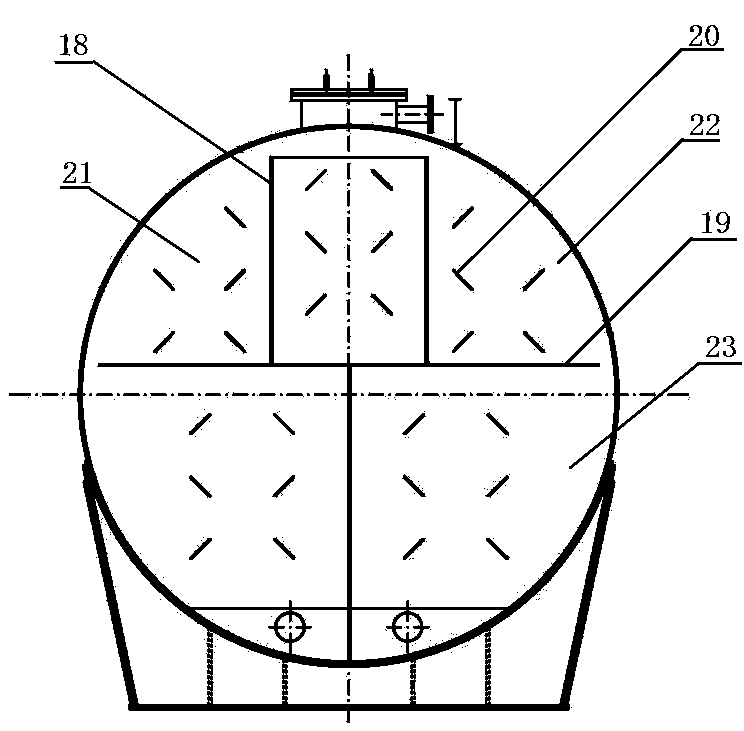

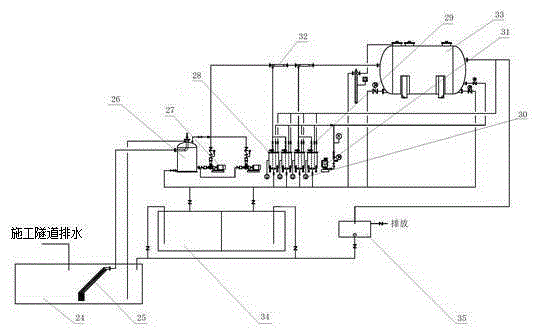

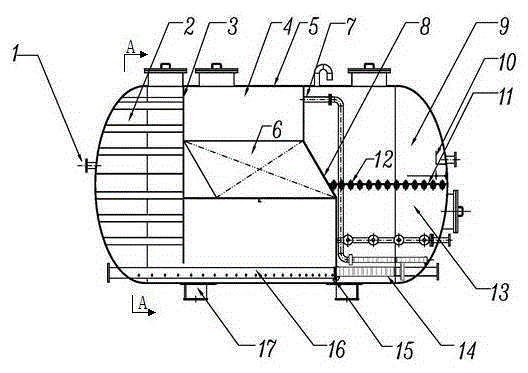

Tunnel construction drainage treatment method and treatment device thereof

ActiveCN104276638AImprove controllabilityReduce consumptionWater/sewage treatment by flocculation/precipitationSludgeSewage

The invention discloses a tunnel construction drainage treatment method and a treatment device thereof. The treatment device comprises a vacuum diverting device, a lifting pump, a pipe type mixer and a drainage treatment unit; the treatment method comprises the following steps: (a) constructing a regulating basin, a sludge discharge and drainage collecting basin and a monitoring basin in a construction site, starting the vacuum diverting device and the lifting pump, pumping sewage to the pipe type mixer, then flowing into the drainage treatment unit; (b) respectively adding a coagulant and a flocculant into a medicinal liquor dissolving tank, weighing the medicinal liquor through a metering pump and then mixing together with sewage in the pipe type mixture; (c) draining the sewage through the drainage treatment unit, and then flowing in the monitoring basin, detecting the effluent water of the monitoring basin, and draining if the effluent water is qualified and reflowing in the regulating basin if the effluent water is unqualified; and (d) settling and flowing in the sludge discharge and drainage collection basin, standing and layering, enabling a supernatant liquid to flow in the regulating basin, and rinsing and backfilling the settled sludge. The tunnel construction drainage treatment method and the treatment device thereof are high in automation degree, simple and convenient to operate, and stable in the quality of the effluent water.

Owner:江苏天康能源环境工程有限公司 +1

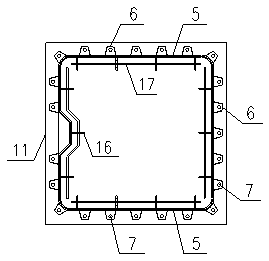

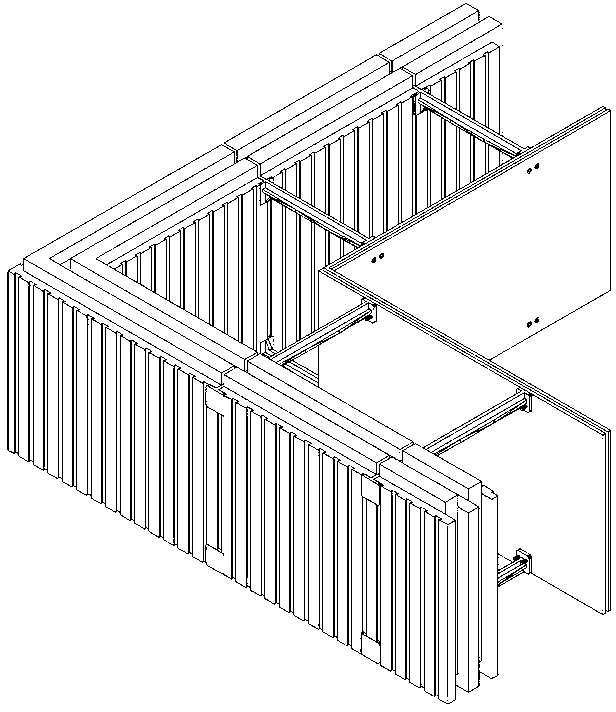

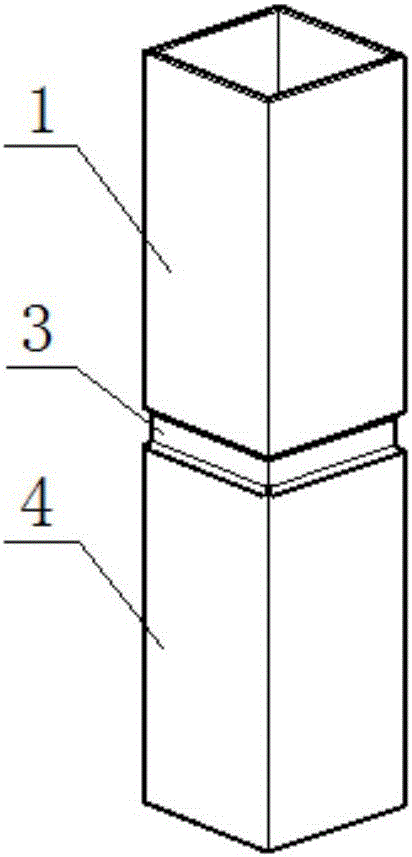

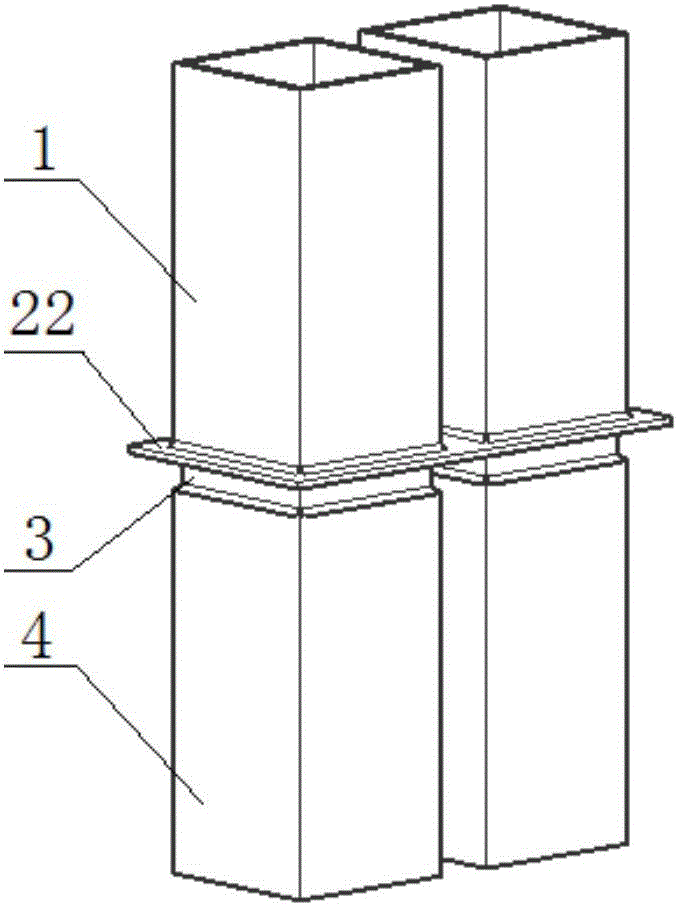

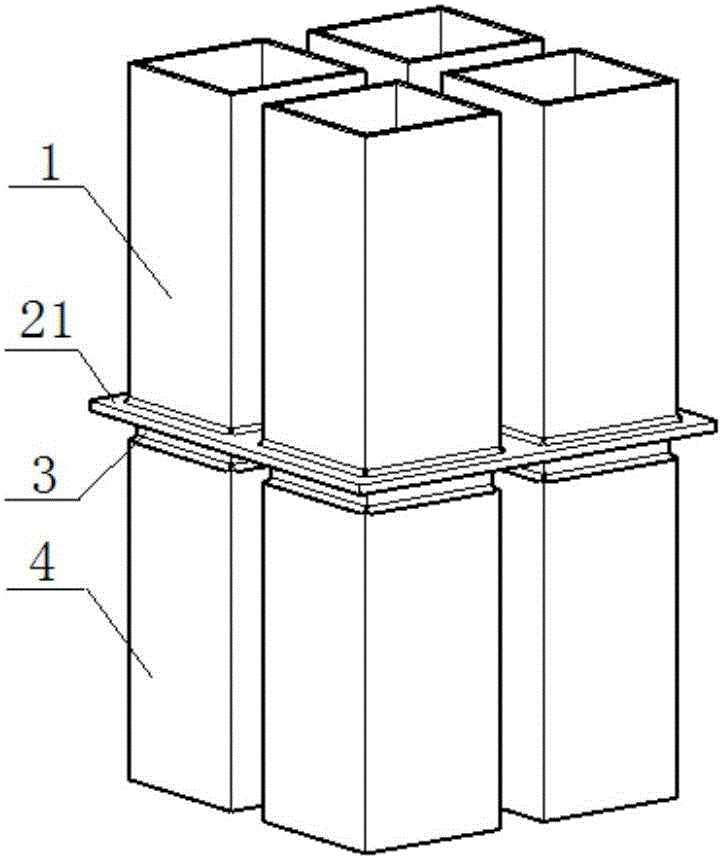

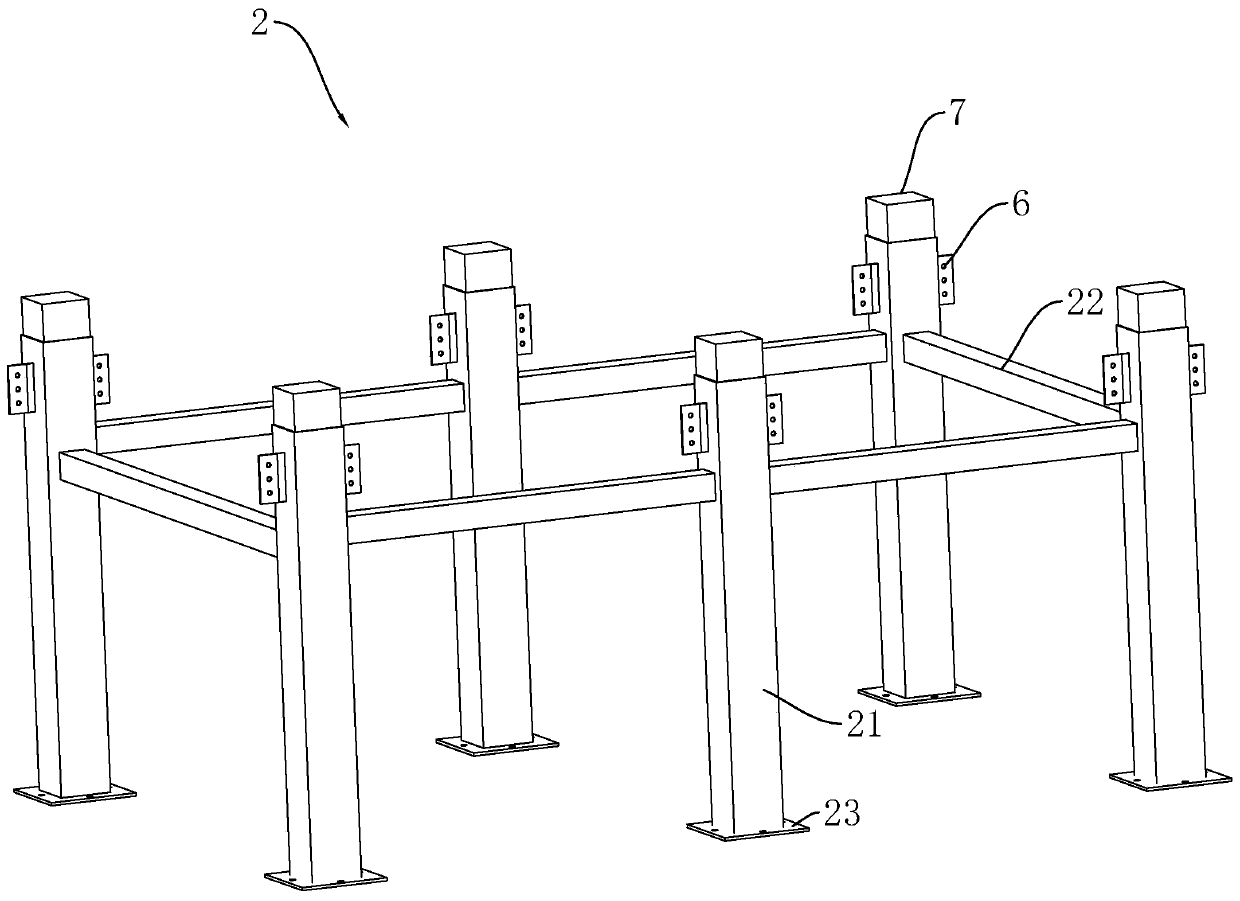

Modular steel frame connection device and connection method thereof

ActiveCN106522363AOmit fixed wayReduce on-site construction proceduresBuilding constructionsEngineeringSteel frame

The invention relates to a modular steel frame connection device. the modular steel frame connection device at least comprises a first square steel tubular column and a second square steel tubular column which are internally hollow and are connected through an inner sleeve. The inner sleeve is in clearance fit with the second square steel tubular column. the periphery of the inner sleeve is annularly provided with locating blocks parallel to the column opening of the first square steel tubular column and the column opening of the second square steel tubular column. the modular steel frame connection device further comprises a connection plate provided with an assembly hole matched with the inner sleeve. modular steel frames are connected in an inner sleeve mode, the fixing mode of screws or bolts is omitted, procedures of site construction are omitted, and the construction time is shortened. the modular steel frames and inner sleeves are welded, the firm degree between the frames is enhanced, and risks caused by loosening of the screws or the bolts are avoided. The modular steel frames are partially machined in a factory in advance and then constructed in a construction site, so that the site construction time is shortened greatly, and too many influences on the site environment are avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

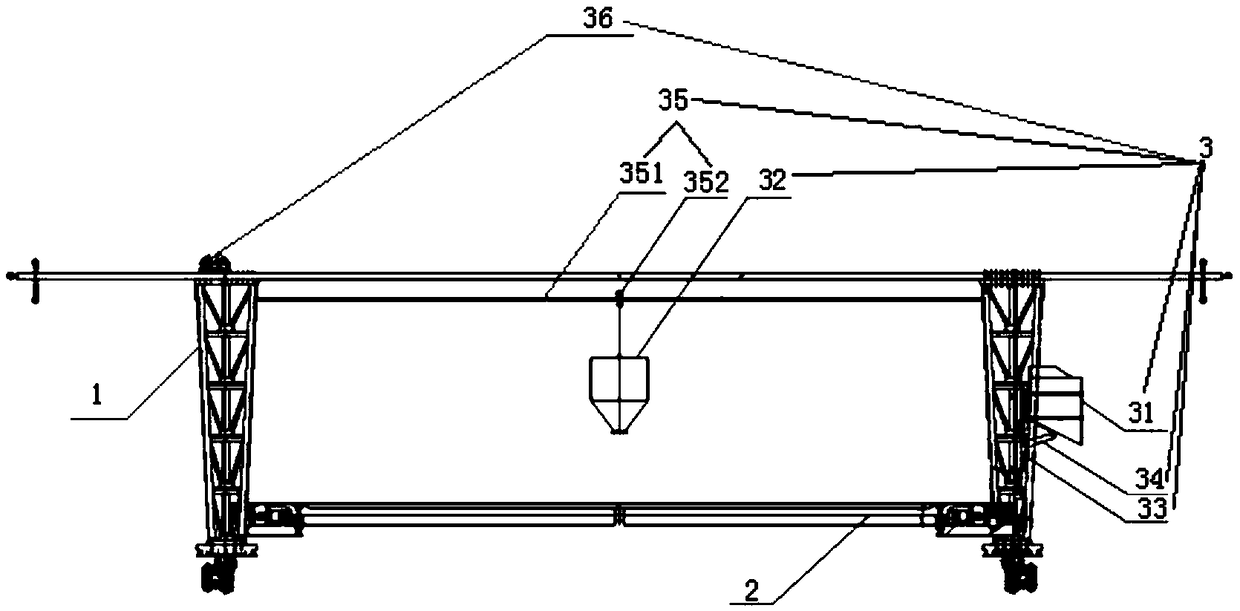

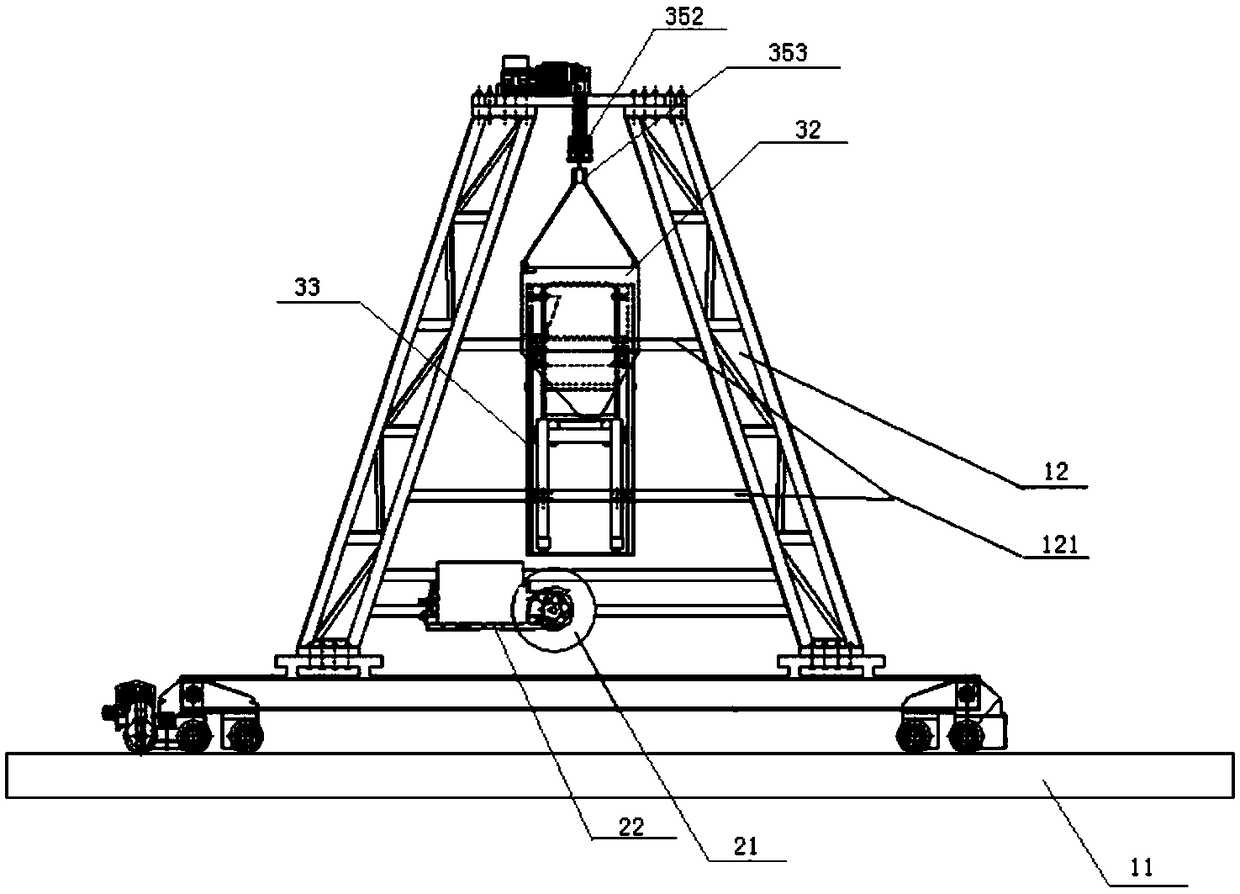

Steel bridge deck prefabricated paving equipment

ActiveCN109306649AReduce construction proceduresReduce the impactBridge structural detailsBridge erection/assemblyBridge deckPortal frame

The invention discloses steel bridge deck prefabricated paving equipment. The steel bridge deck prefabricated paving equipment can change the traditional steel bridge deck pavement construction procedure and technology. The steel bridge deck subjected to sand blasting and anti-rust coat and tack coat spraying can be paved with asphalt concrete in a factory, and is conveyed to a construction site for bridge deck assembling after forming. After assembling, the SMA asphalt mixture and other surface materials can be directly paved on the steel bridge deck. On-site construction procedures are reduced, construction difficulty is lowered, influence on construction by weather is avoided, and steel bridge paving quality and efficiency are effectively improved. The steel bridge deck prefabricated paving equipment comprises a walking machine frame and a paving mechanism, and is provided with a moving material cabin. The walking machine frame comprises a moving portal frame, a guide rail and the like. The paving mechanism comprises a spiral material arranging machine, an ironing plate and an ironing plate lifting device. The moving material cabin comprises a vertical lifting material cabin anda horizontal paving material cabin.

Owner:CHANGAN UNIV

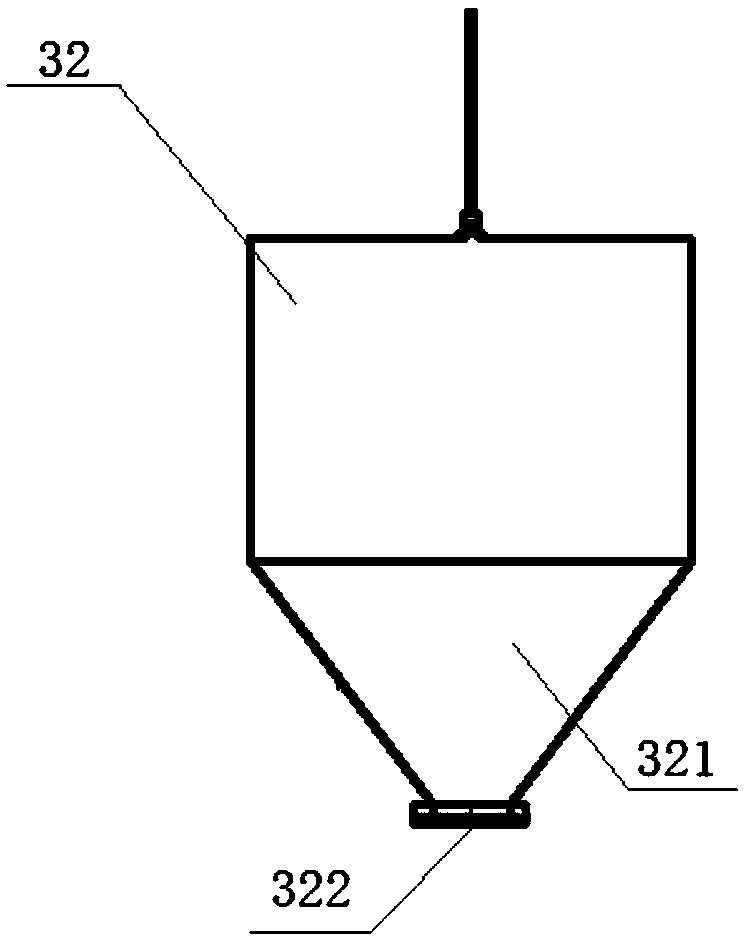

Wear-resistant prefabricated brick for cement-kiln grate-cooler low wall

The invention relates to a wear-resistant prefabricated brick for a cement-kiln grate-cooler low wall, which comprises a metal anchoring nail and a prefabricated-brick body, wherein one end of the metal anchoring nail is preliminarily placed in the prefabricated-brick body; and the wear-resistant prefabricated brick has the advantages that: the wear-resistant prefabricated bricks for the cement-kiln grate-cooler low wall are piled up on site, so that the working procedures of site construction are decreased, for example, anchoring-nail welding, molding, pouring, demoulding, curing and roasting are not needed, the construction time is shortened, and the requirement of a cement plant for short maintenance time is met; and after the roasting of the wear-resistant prefabricated brick, a product has high strength and strong high-temperature resistant and abrasion-resistant performances, the use effect and the service life of the cement-kiln grate-cooler low wall are respectively improved and prolonged, and the wear-resistant prefabricated brick is more convenient to maintain and replace.

Owner:长兴兴鹰新型耐火建材有限公司

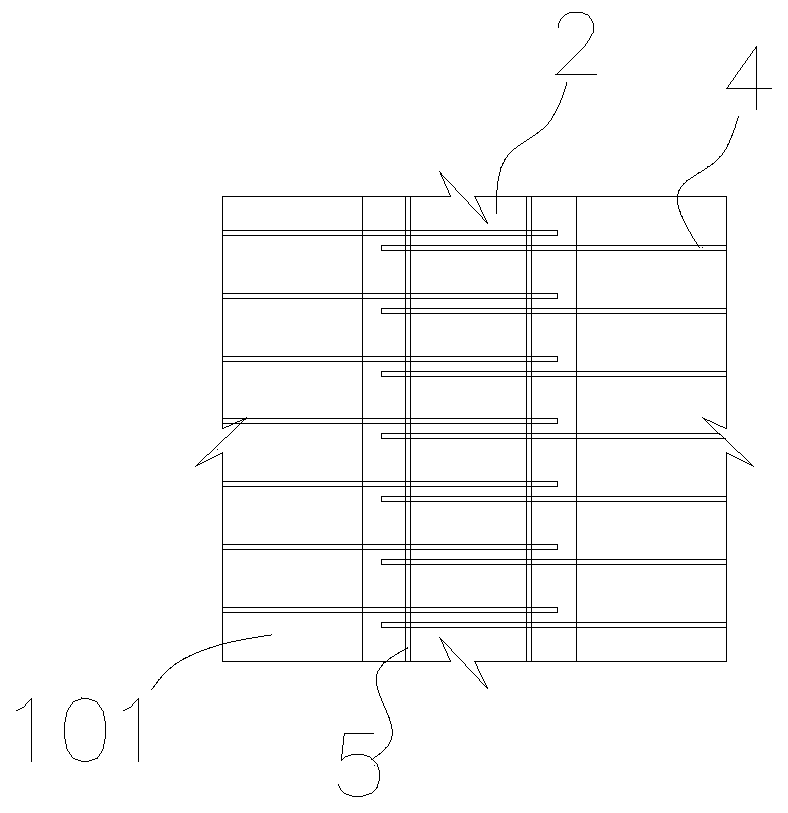

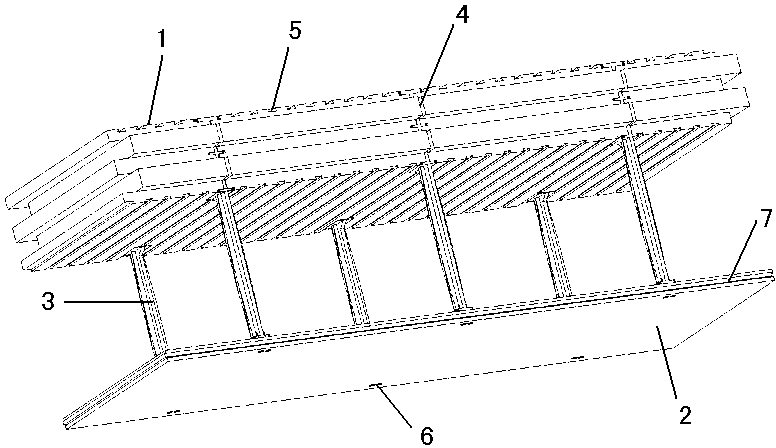

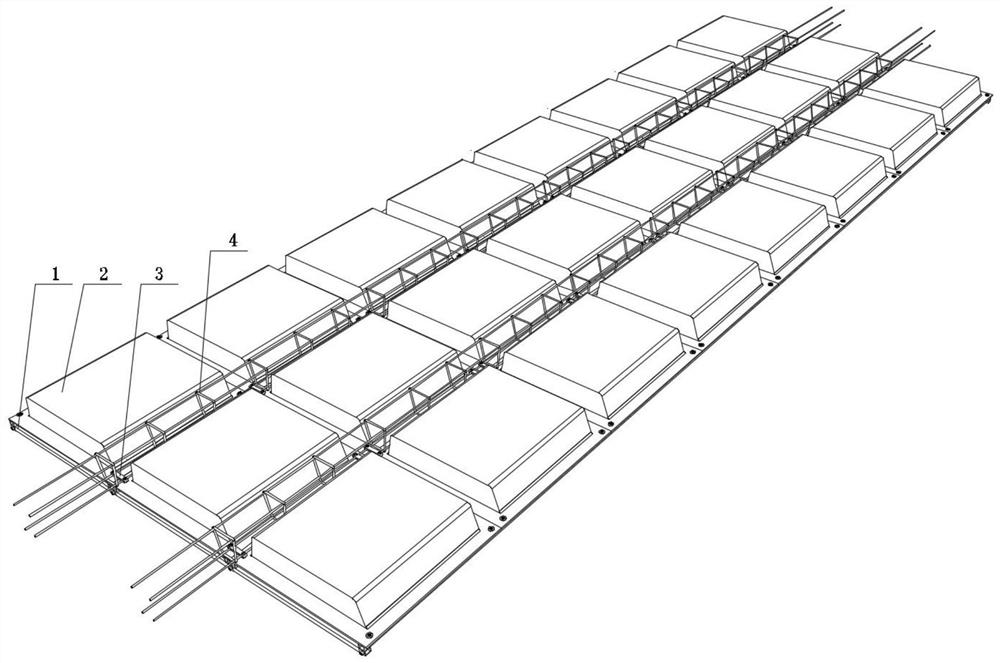

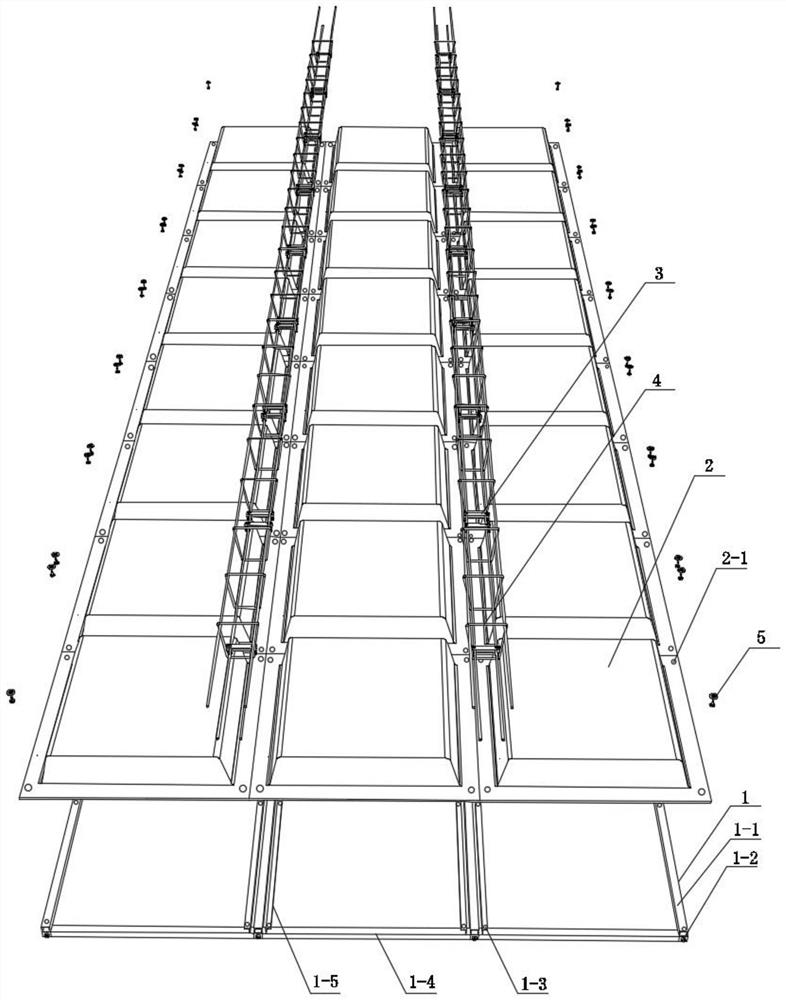

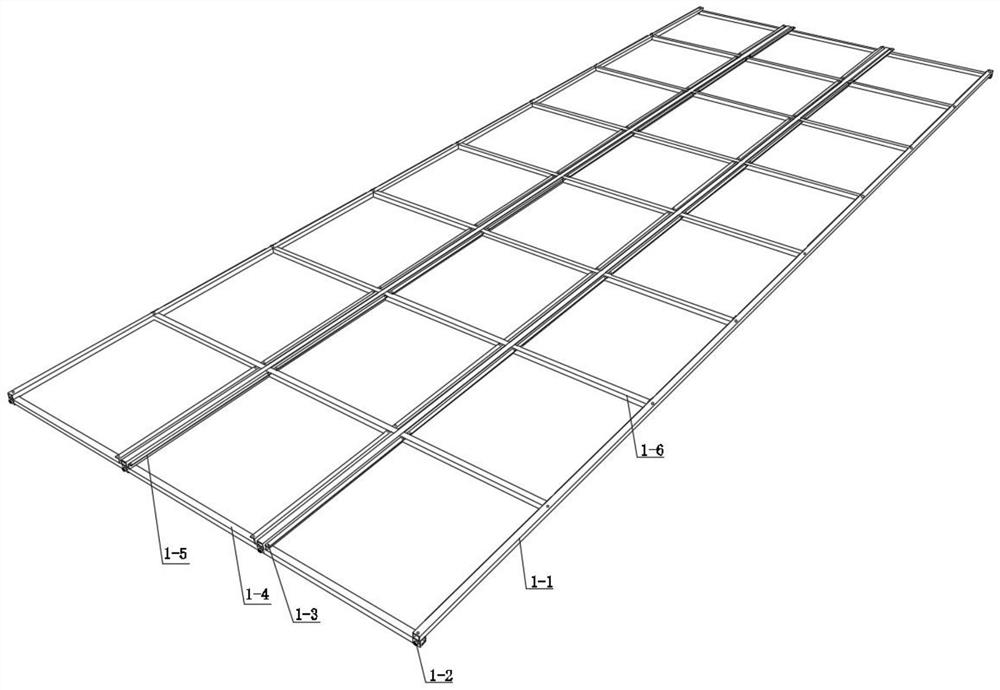

Ribbed supporting-free unit formwork device and mounting method

The invention relates to a ribbed supporting-free unit formwork device including an unit formwork frame, formwork shells, steel reinforcement cages, and fixing parts. The unit formwork frame is of a grid-shaped grille, the formwork shells are laid on the upper surface of the unit formwork frame successively, the fixing parts are evenly distributed on the steel reinforcement cages at intervals, thesteel reinforcement cages are arranged on the flanging edges of the formwork shells, and the steel reinforcement cages, the unit formwork frame, and the formwork shells are connected to form a wholethrough fixing parts. The invention further provides a mounting method of the ribbed supporting-free unit formwork device, so that the mounting is convenient, the assembly can be carried out on the scene, the recycling utilization can be achieved, the construction costs can be lowered, the device can simplify construction processes of full laying or strip laying and steel reinforcement cage binding on the scene, the splicing and fixing are convenient, and the device can be circularly utilized in ribbed beam floor cap construction.

Owner:天津洪晟基业建材有限公司

A prefabricated concrete shear wall component and its construction method

ActiveCN105839836BEliminates lashing workReduce on-site construction proceduresConstruction materialWallsTime costRebar

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

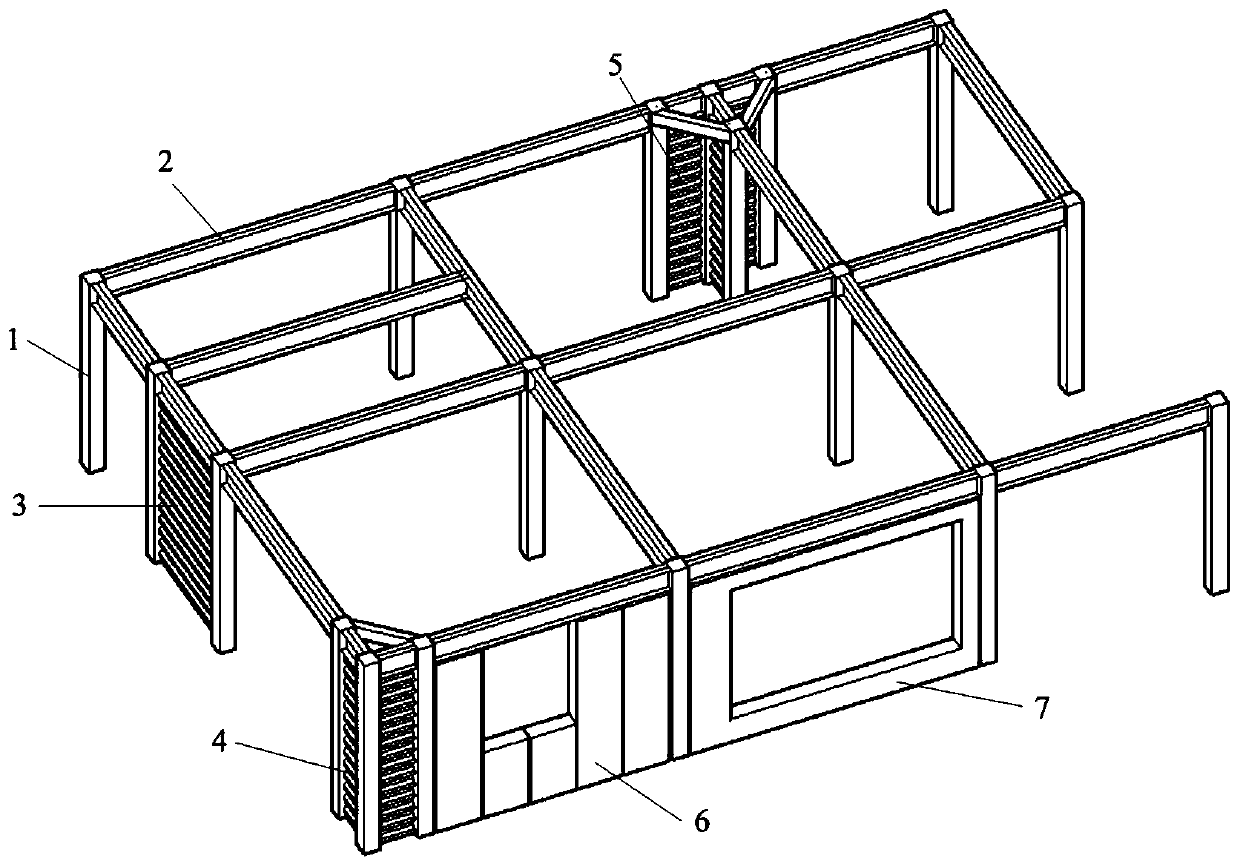

Fabricated steel structure residence system and construction method thereof

PendingCN110439103AApplicable use requirementsStable horizontal lateral resistanceStrutsWallsResidenceVertical load

The invention discloses a fabricated steel structure residence system and a construction method thereof. The fabricated steel structure residence system includes a vertical unit, horizontal beams anda fabricated wall panel; the vertical unit includes a concrete-filled steel tube single column, a corrugated plate shear wall unit and a short-limb special-shaped corrugated plate shear wall unit; thecorrugated plate shear wall unit and the short-limb special-shaped corrugated plate shear wall unit include concrete-filled steel tube stand columns, connecting beams and transverse rib corrugated plates, and restraint frames of corrugated plates are formed by the concrete-filled steel tube columns in the units and the connecting beams at the floor heights; the horizontal beams are connected withvertical members to form an overall structure; and the fabricated wall panel is fixed between the upper layer horizontal beams and the lower horizontal beams by adopting bolts. According to the fabricated steel structure residence system, the small size concrete-filled steel tube columns are adopted as vertical load bearing members, the members are filled with concrete in a factory, and the corrugated plate shear walls provide structural lateral resistance; the fabricated steel structure residence system and the construction method have the beneficial effects that full prefabrication of mainstructural members can be realized, and site construction processes are reduced; the corrugated plate wall can reduce the use amount of steel and ensures lateral resistance; and the vertical members can be hidden in a wall body, and the residence building use demands are met.

Owner:CENT SOUTH UNIV

Total precast lower structure of bridge and construction method

ActiveCN107165038ASatisfy the height limitFulfil requirementsBridge structural detailsBridge erection/assemblyPre stressHigh intensity

The invention discloses a total precast lower structure of a bridge and a construction method. The structure is mainly composed of single whole precast lower components, a precast base plate, a prestressed steel strand and aseismic ribbed bars; single precast components which are precast in a factory overall are composed of cover beams, pier columns and enlarged foundations; the cover beams of the whole single precast components are reserved with corrugated pipes, and the prestressed steel strand is connected with the components in series through the reserved corrugated pipes in site assembly; concrete cast-in-site segments are arranged between the enlarged foundations of the single precast components, and the enlarged foundations of the single precast components are integrally connected in site construction; the whole precast base plate is arranged on the bottom of a whole foundation; when main beams to be precast is reserved on the tops of the cover beams of the precast components, the tops of the cover beams extend into the aseismic ribbed bars of main beam reserved holes. According to the total precast lower structure of the bridge and the construction method, the mode is simple, and the structure is suitable for a high intensity seismic zone.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

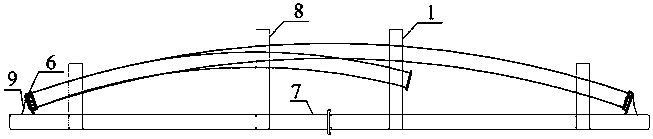

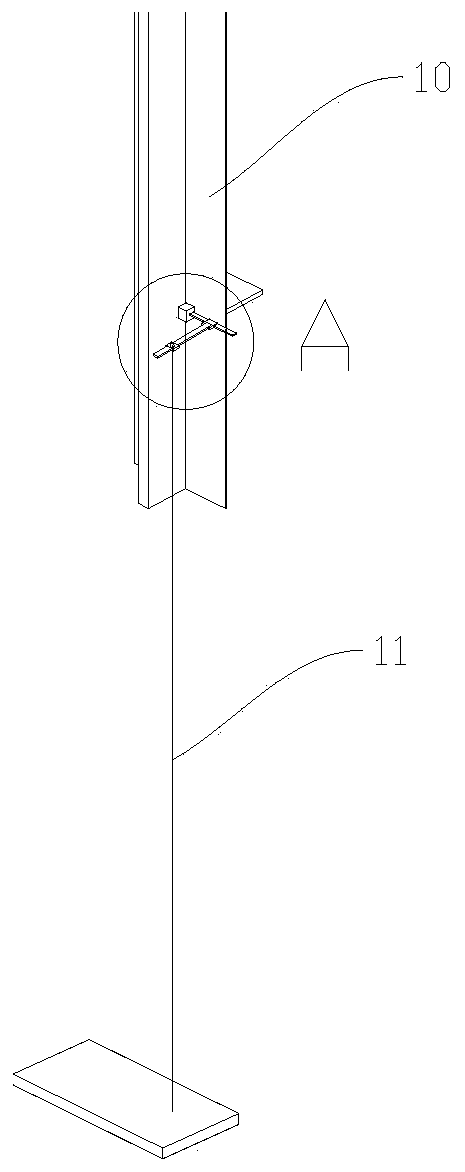

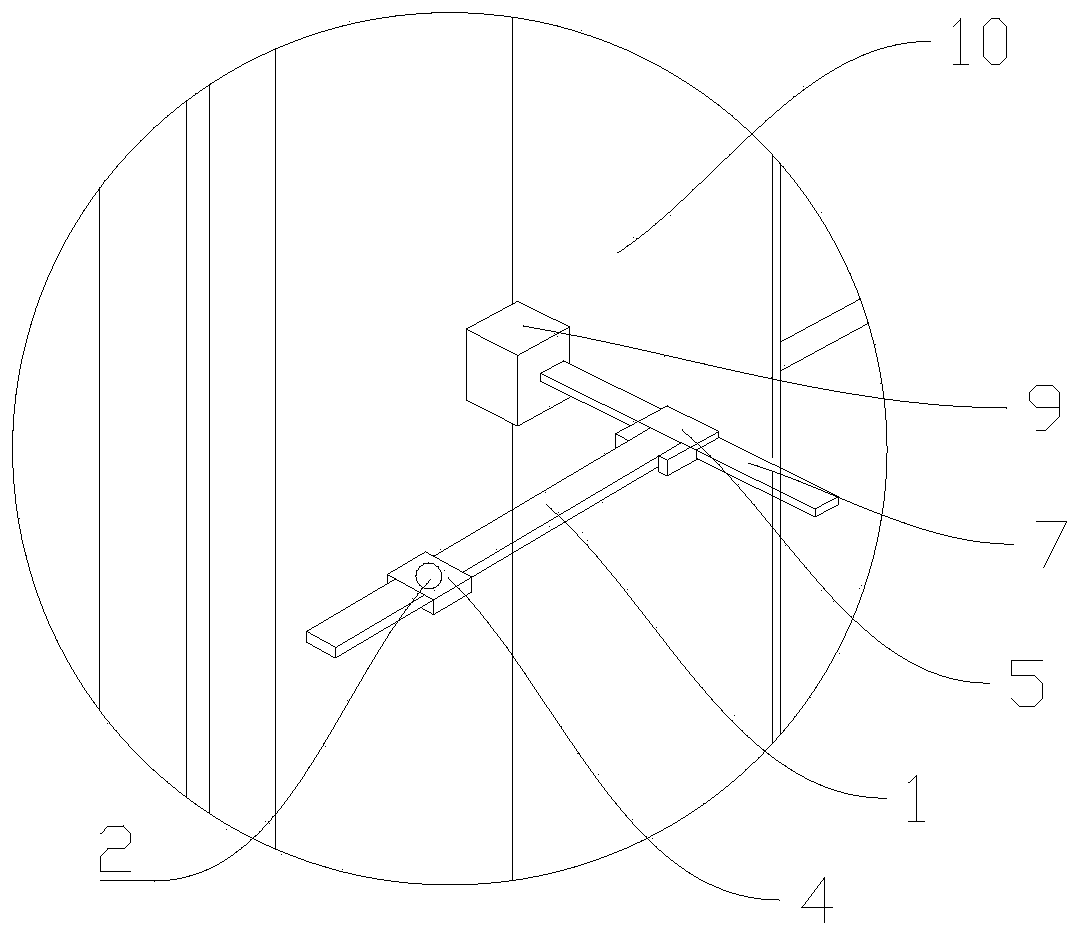

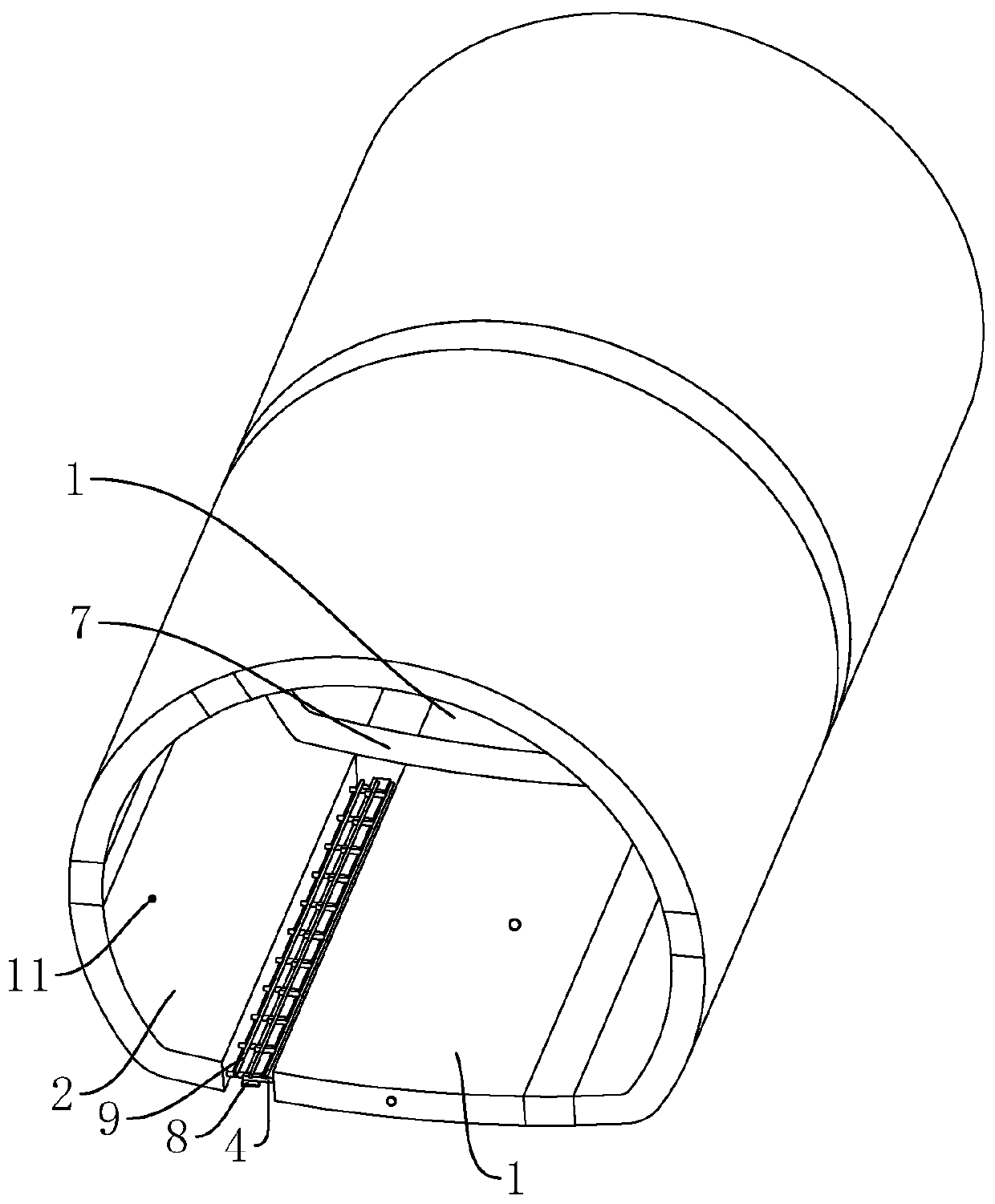

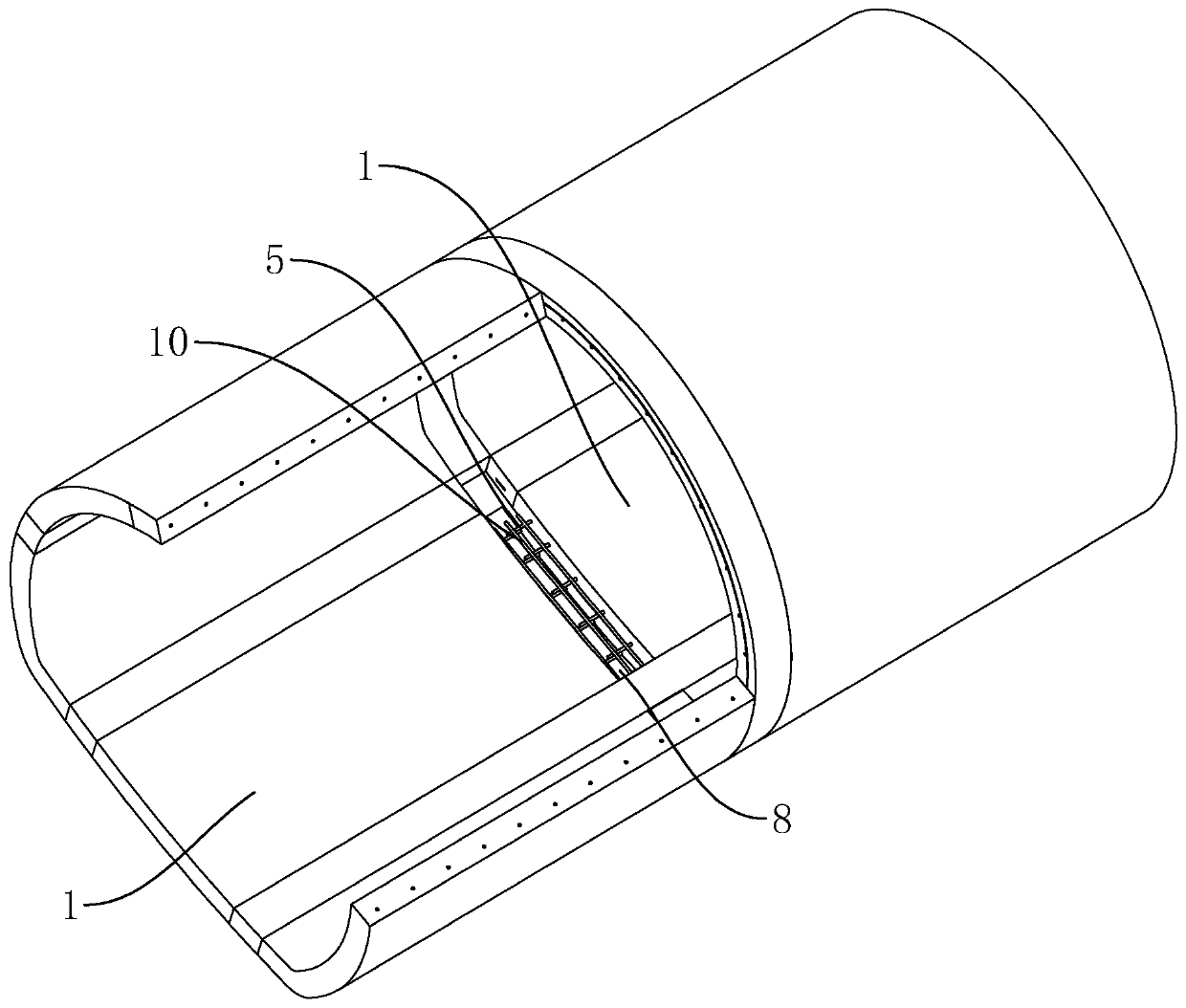

Intelligent installing method of underground engineering standardized assembled confined concrete arching frame

ActiveCN108119165AHigh load-carrying propertiesReduce on-site construction proceduresUnderground chambersTunnel liningEngineeringRock bolt

The invention discloses an intelligent installing method of an underground engineering standardized assembled confined concrete arching frame. The method comprises the steps of conducting concrete pre-pouring on a single-joint arching frame outside a tunnel, precisely welding an assembled joint with the arching frame for arching frame trial assembling, folding to form an assembled arching frame, using arching installing equipment to erect the arching frame after hoisting the arching frame to a heading face of the tunnel, making the arching frame connected with a longitudinal locating device, using a laser locating instrument and an arching frame lifting device to precisely locate the whole truss of the arching frame, using a laser distance measuring device to conduct fracture surface rechecking, drilling feet-lock bolts, and then executing other work procedures. By means of the intelligent installing method of the underground engineering standardized assembled confined concrete archingframe, a confined concrete arching frame pre-pouring key technology is implemented, suspension and one-time erection of the whole truss of the arching frame are achieved, the construction efficiencyis improved, and the construction safety is guaranteed.

Owner:SHANDONG UNIV +1

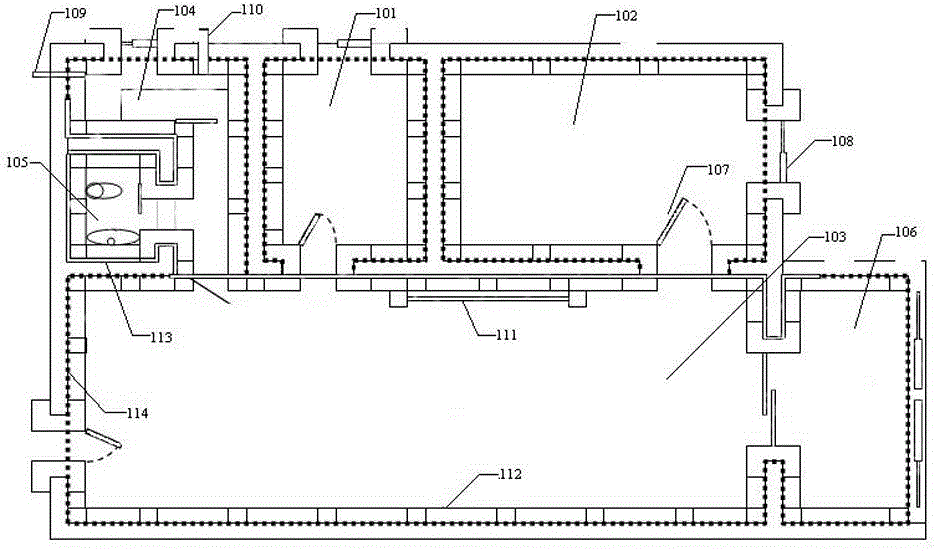

Split mounting technique of quick home-decoration split mounting engineering

ActiveCN103982042AQuick assemblyFast home improvementCovering/liningsBuilding material handlingEngineeringHome improvement

The invention discloses a split mounting technique of a quick home-decoration split mounting engineering. A quick home-decoration split mounting engineering main body comprises quick split mounting roof splits, quick split mounting wall surface splits, quick split mounting floor splits, quick split mounting door frames / window frames, wherein the quick split mounting roof splits comprise roof supports, roof bottom / surface plates and roof accessories; the quick split mounting wall surface splits comprise wall surface supports, a wall surface bottom plate, wall surface face plates and wall surface accessories; the quick split mounting floor splits comprise a base plate, a rubber layer and floor tiles; the quick split mounting door frames / window frames comprise door frame / window frame bottom plates, as well as upper, lower, left and right door frames / window frames; a loop circuit is additionally provided; the quick split mounting wall surface splits, the quick split mounting roof splits, the quick split mounting floor splits, the quick split mounting door frames / window frames, the loop circuit, and the like are subjected to split mounting to form a basic structure, a bathroom structure and a kitchen structure, and then are further subjected to combination and split mounting, so that home decoration engineering is accomplished. The split mounting technique disclosed by the invention does not destroy a house blank, is capable of reducing site construction procedures and shortening a construction period, is available for all-day construction, and can easily realize industrialized production.

Owner:赵永前

Full-prefabricated concrete anti-collision guardrail and construction method

ActiveCN109763424AImprove installation efficiencyReduce construction proceduresBridge structural detailsBridge erection/assemblyRebarEngineering

The invention discloses a full-prefabricated concrete anti-collision guardrail and a construction method. The guardrail comprises a plurality of spliced prefabricated concrete anti-collision guardrailsections, wherein a connecting device is arranged at the bottom of each prefabricated concrete anti-collision guardrail section; the connecting device is connected with the top plate of a bridge surface; the connecting devices comprise steel casings, pulp inlet tubes and pulp outlet tubes; bridge surface reserved reinforcing steel ribs are sleeved by the steel casings; the pulp inlet tubes and the pulp outlet tubes are respectively connected with the steel casings. The mounting efficiency can be improved, full prefabrication of a concrete anti-collision guardrail can be achieved, on-site construction procedures can be reduced, and the mounting time can be shortened.

Owner:WISDRI ENG & RES INC LTD +1

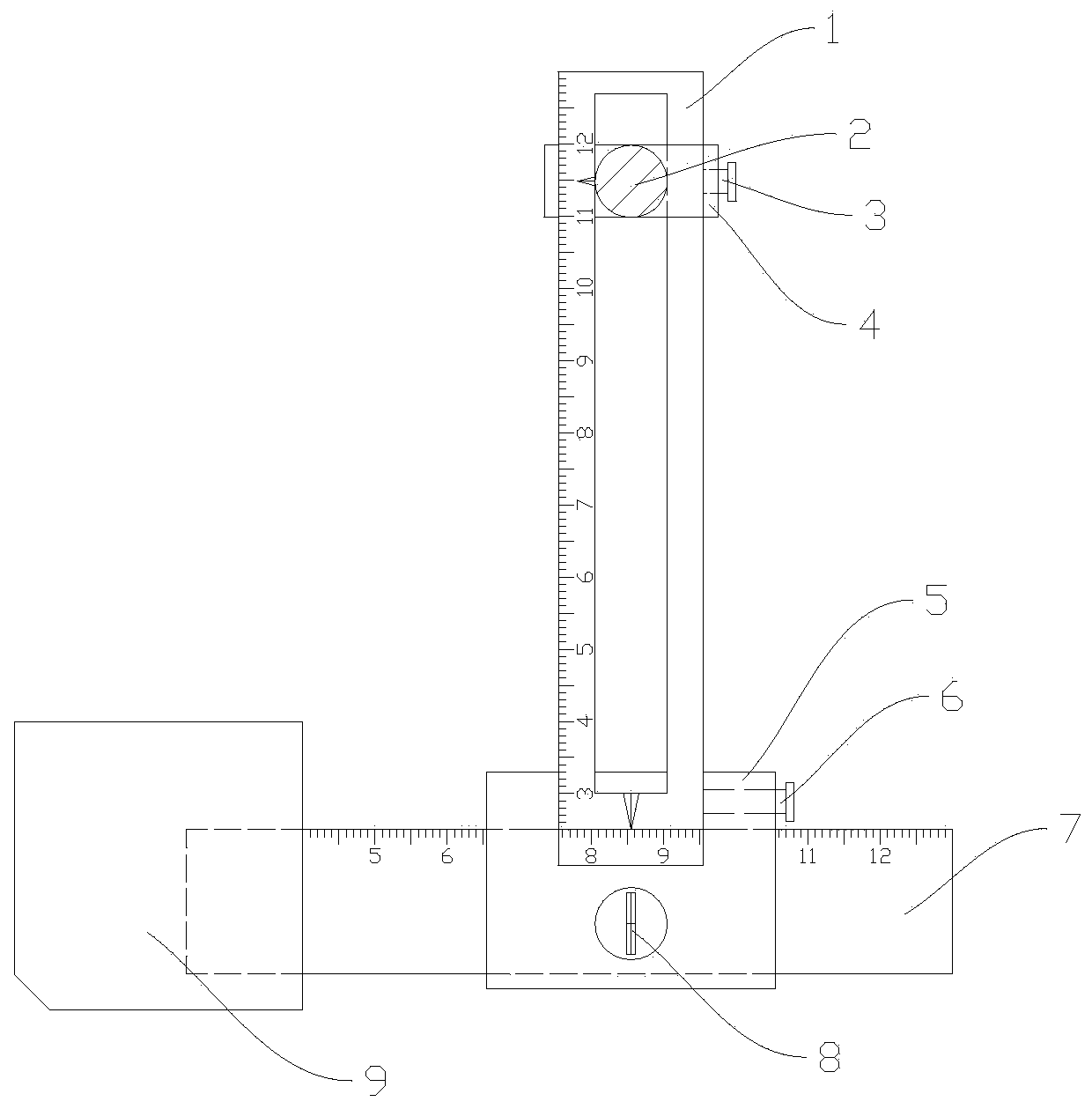

Container cabin bottom fixing part bottom cone center alignment method

InactiveCN111457906AReduce on-site construction proceduresImprove installation efficiencyActive open surveying meansEngineeringMechanical engineering

The invention provides a container cabin bottom fixing part bottom cone center alignment method. The method comprises the following steps of: 1, determining a distance value from a cargo hold guide rail installation face to the center of a container foot; 2, adjusting an alignment tool, wherein the alignment tool comprises a first ruler, a second ruler and a laser device, the second ruler is arranged on the first ruler in a sliding mode and perpendicular to the first ruler, the laser device is arranged on the second ruler in a sliding mode, firstly, the second ruler is adjusted in a sliding mode to slide to the scale corresponding to the first distance value, and the second ruler and the first ruler are locked; the laser device is slidably adjusted along the second scale again, and when the vertical intersection of the laser device and the first scale and the second scale is a second distance value, the laser device and the second scale are locked; and 3, positioning the scale startingend of the first scale on the cargo hold guide rail mounting surface, starting a laser device to emit a laser, wherein the laser irradiates the cargo hold to form an illumination point, and the illumination point is the center of the bottom cone of the fixing piece.

Owner:JIANGNAN SHIPYARD GRP CO LTD

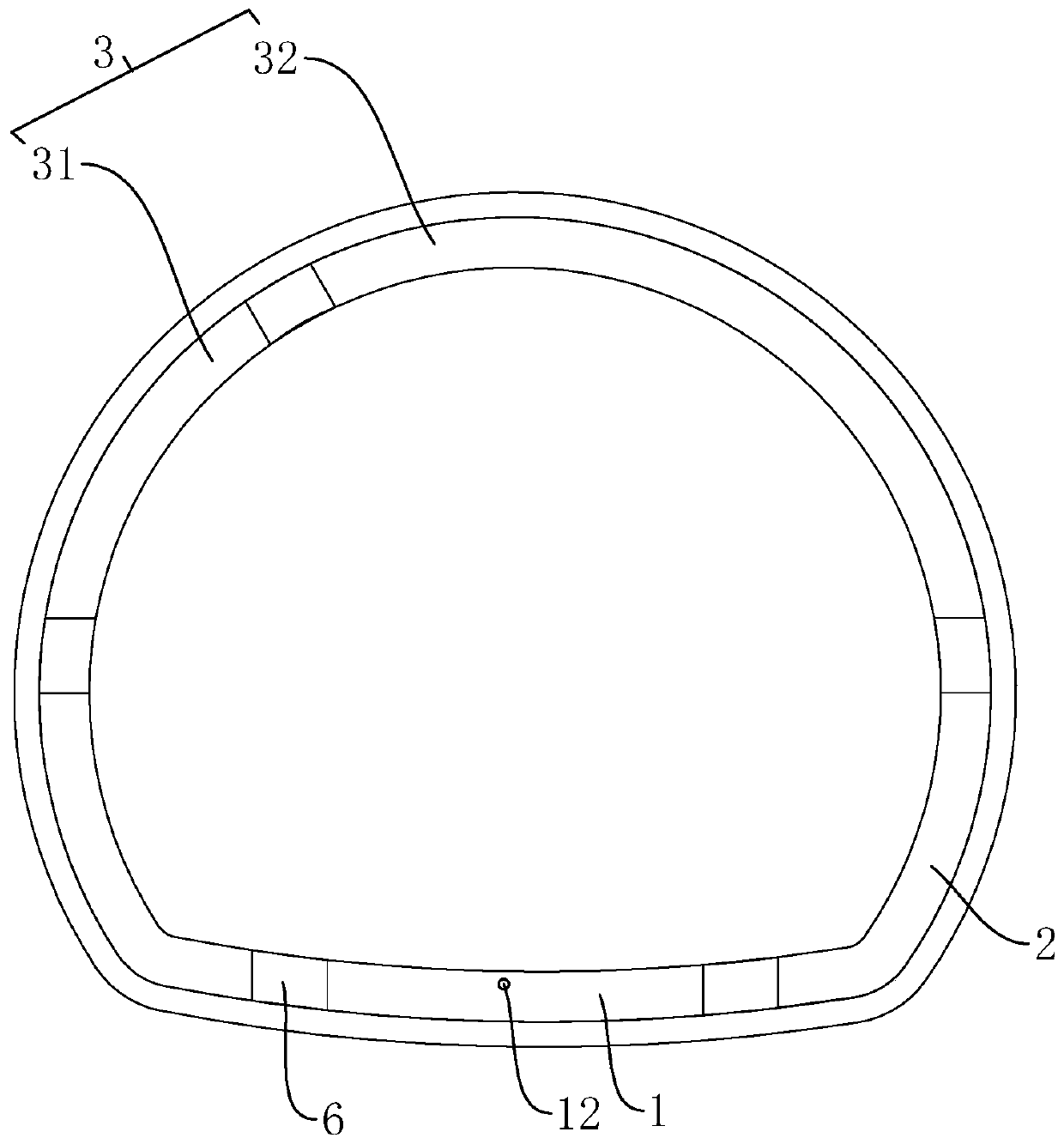

Tunnel secondary lining structure and construction method thereof

InactiveCN111287764AGuaranteed integrityGuaranteed tightnessUnderground chambersDrainageReinforced concreteClassical mechanics

The invention relates to a tunnel secondary lining structure, and relates to the technical field of tunnel construction. The tunnel secondary lining structure comprises a plurality of tunnel units which are arranged in sequence in the extension direction of a tunnel and are mutually connected, and the tunnel units comprise inverted arcs, arc walls arranged on the two sides of the inverted arcs, and arc rings arranged at the upper ends of the arc walls; the inverted arcs, the arc walls and the arc rings are of a reinforced concrete prefabricated structure; cross connecting ribs stretch out of connection parts of the inverted arcs and the arc walls and connection parts of the arc walls and the arc rings; the cross connecting ribs are mutually connected correspondingly; and back pouring beltsare arranged at the cross connecting ribs. The tunnel secondary lining structure has the advantages that the assembly rate is high, construction efficiency is improved, the construction cycle is shortened, integrality of the lining structure is good, and protective properties are good.

Owner:北京泰德市政工程有限公司

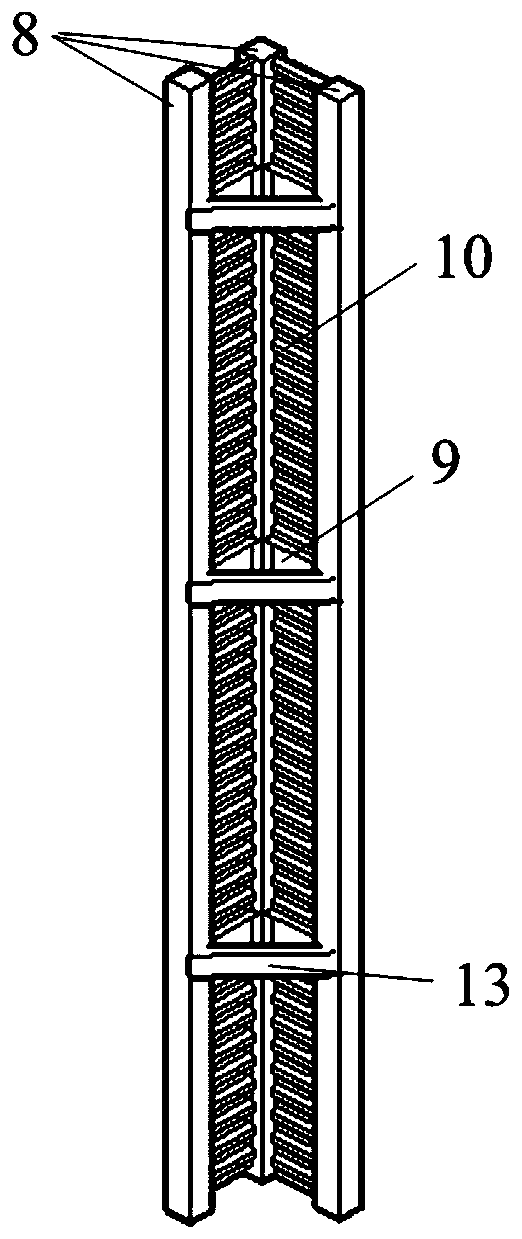

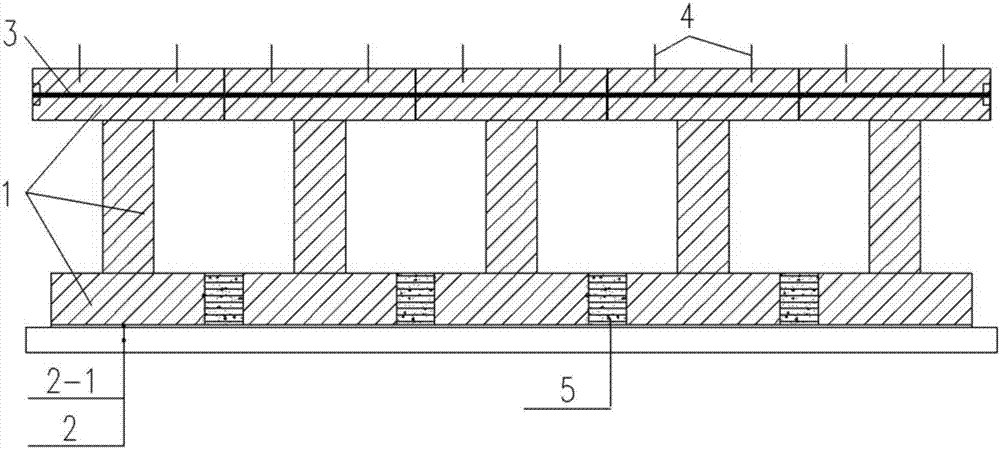

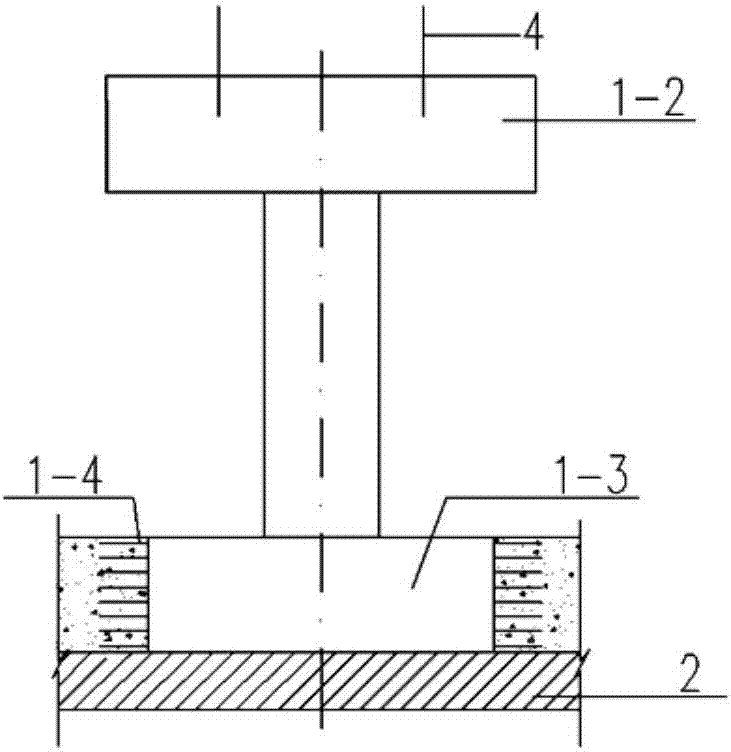

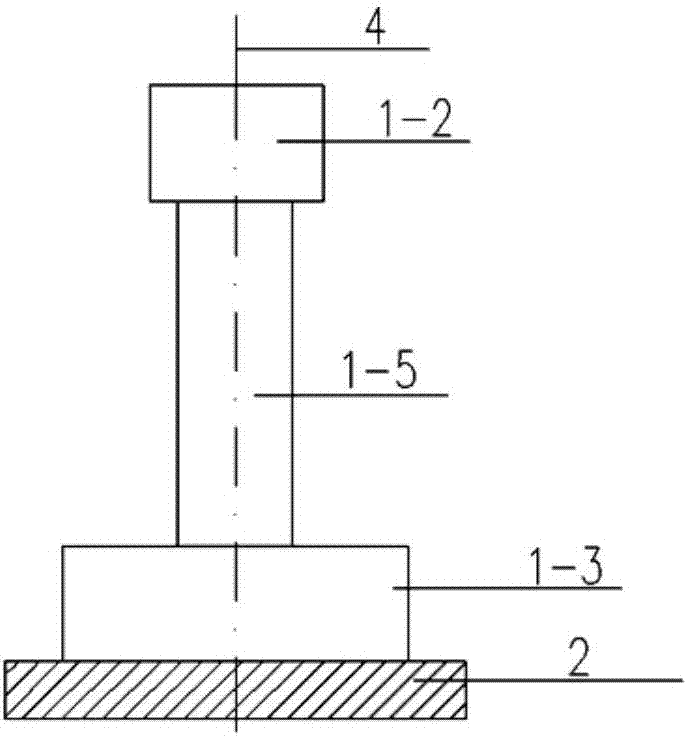

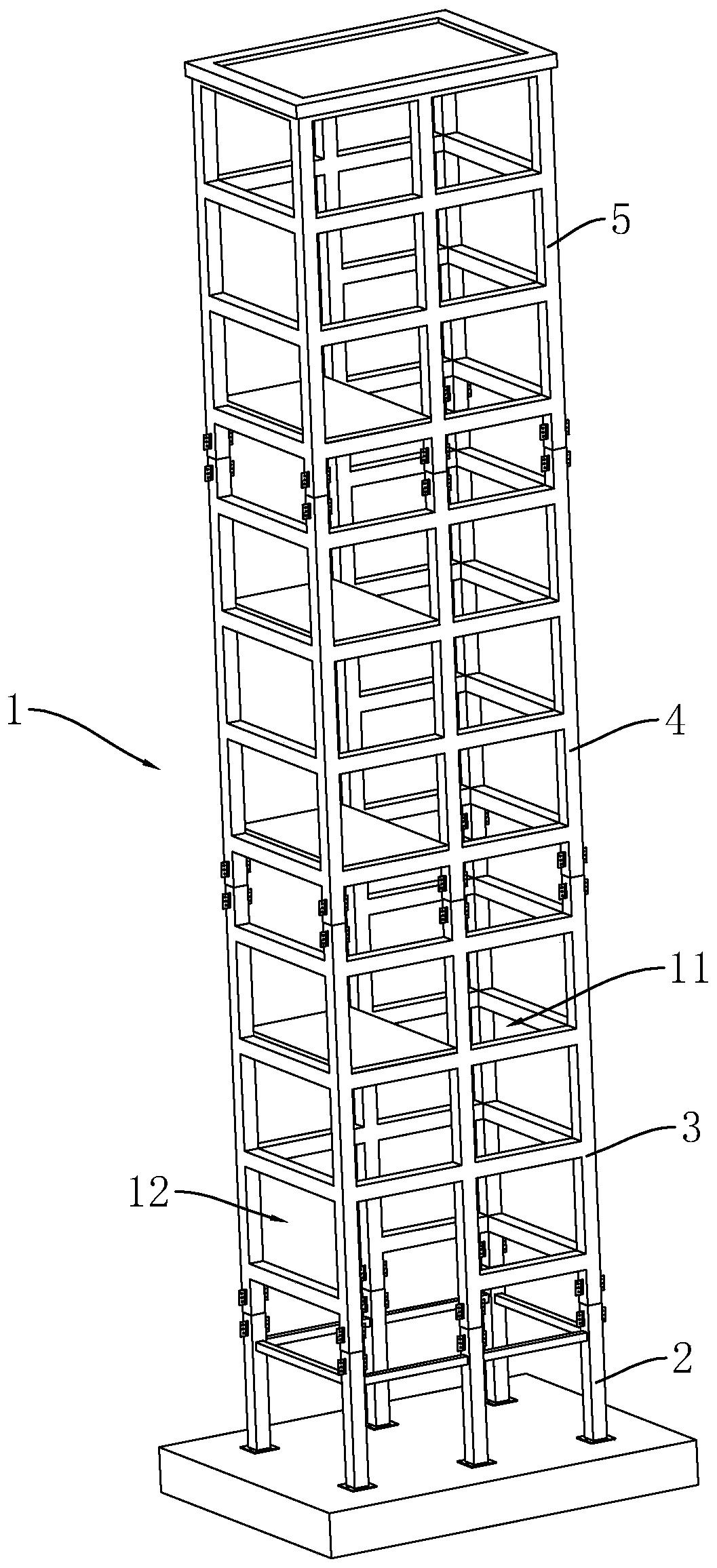

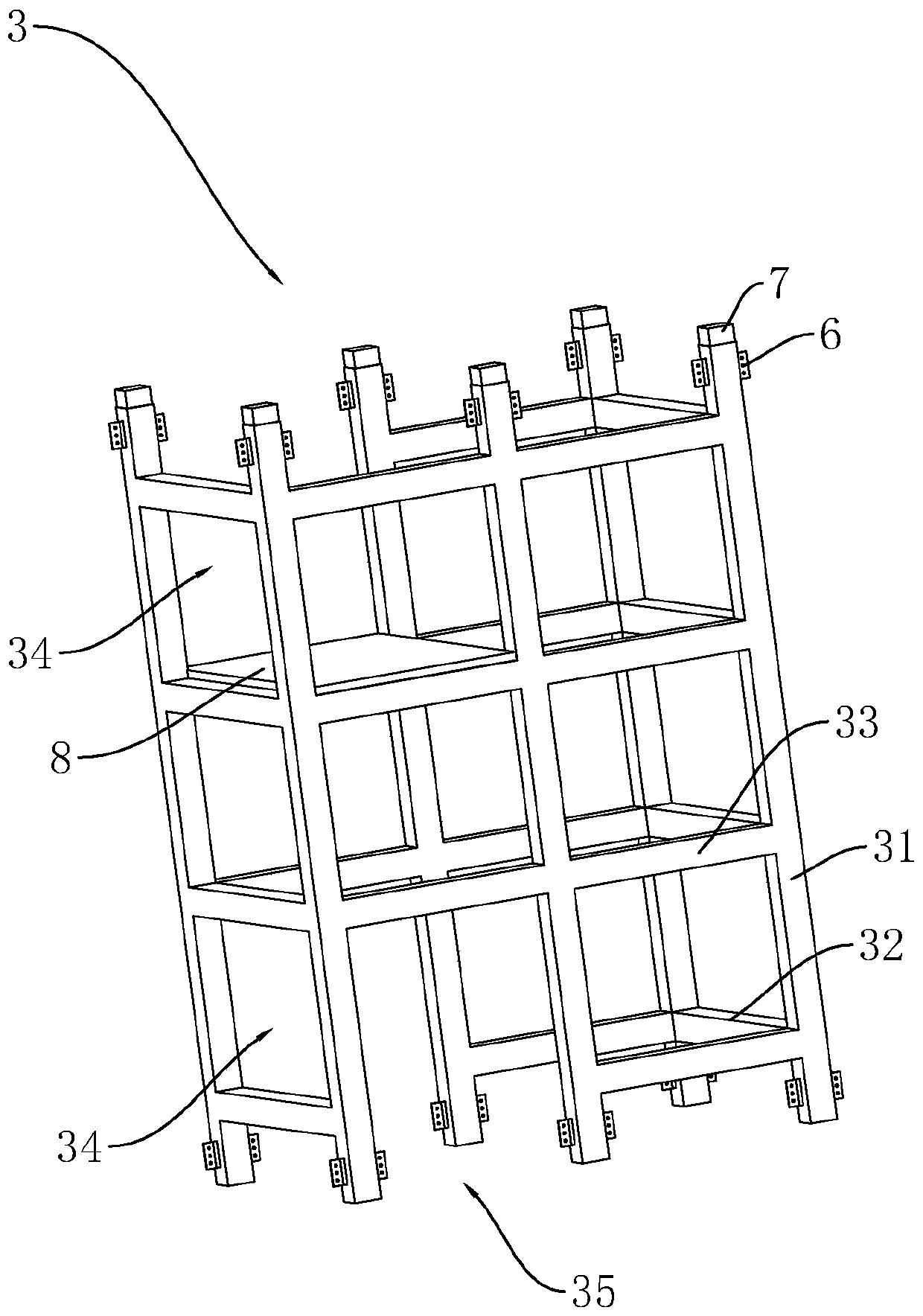

Integrated steel structure shaft with lift halls and construction process thereof

PendingCN110924630AImprove assembly rateGood assembly rateVertical ductsClassical mechanicsEngineering

The invention relates to an integrated steel structure shaft with lift halls for an elevator added to the exterior of an existing building. The integrated steel structure shaft comprises a steel structure shaft body. The steel structure shaft body comprises a bottom layer module, multiple sections of standard modules and a top layer module. The bottom layer module, the standard modules and the toplayer module are fixedly connected with one another. Each unit module comprises six stand columns which are arrayed in a rectangular shape and beams which are fixedly arranged between every two adjacent stand columns and at the upper ends and the lower ends of the stand columns correspondingly, wherein at least one group of reinforcing beams are arranged between the middles of every two adjacentstand columns, a rectangular first shaft body for placing an elevator is formed among four adjacent stand columns, and a second shaft body for arranging the corresponding lift hall is formed between the first shaft body and the other two stand columns. The integrated steel structure shaft has the advantages of carrying the lift halls and being independent of the existing building, high in stability, assembly rate and construction efficiency.

Owner:北京亟光电梯科技有限公司

A kind of tunnel construction drainage treatment method and its treatment device

ActiveCN104276638BImprove controllabilityReduce consumptionWater/sewage treatment by flocculation/precipitationSludgeSewage

The invention discloses a tunnel construction drainage treatment method and a treatment device thereof. The treatment device comprises a vacuum diverting device, a lifting pump, a pipe type mixer and a drainage treatment unit; the treatment method comprises the following steps: (a) constructing a regulating basin, a sludge discharge and drainage collecting basin and a monitoring basin in a construction site, starting the vacuum diverting device and the lifting pump, pumping sewage to the pipe type mixer, then flowing into the drainage treatment unit; (b) respectively adding a coagulant and a flocculant into a medicinal liquor dissolving tank, weighing the medicinal liquor through a metering pump and then mixing together with sewage in the pipe type mixture; (c) draining the sewage through the drainage treatment unit, and then flowing in the monitoring basin, detecting the effluent water of the monitoring basin, and draining if the effluent water is qualified and reflowing in the regulating basin if the effluent water is unqualified; and (d) settling and flowing in the sludge discharge and drainage collection basin, standing and layering, enabling a supernatant liquid to flow in the regulating basin, and rinsing and backfilling the settled sludge. The tunnel construction drainage treatment method and the treatment device thereof are high in automation degree, simple and convenient to operate, and stable in the quality of the effluent water.

Owner:江苏天康能源环境工程有限公司 +1

Non-purlin bolt ball node grid structure and manufacturing method thereof

ActiveCN102003028BSave steelReduce on-site construction proceduresRoof covering using slabs/sheetsBuilding roofsPurlinSteel tube

The invention relates to a non-purlin bolt ball node grid structure. The non-purlin bolt ball node grid structure comprises upper chord members, web members, lower chord members and bolt ball nodes. The bolt ball nodes comprise high-strength bolts, sleeves, solid spheres and pins, the upper chord members, the web members and the lower chord members pass through the solid spheres, the upper chord members adopt square steel tubes or rectangular steel tubes, two sides of the upper chord members are horizontally arranged and two sides are vertically arranged, and the diameter of the bolt ball nodes connecting the upper chord members is less than the vertical side length of the upper chord members. In the invention, all of the members can realize industrial production and are connected by the bolts on field, field welding is avoided, construction period and construction cost are shortened, purlines are not arranged at the same time, steel products are saved, and construction costs are reduced.

Owner:TIANJIN UNIV

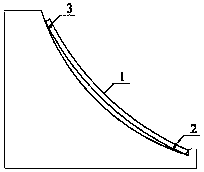

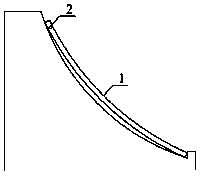

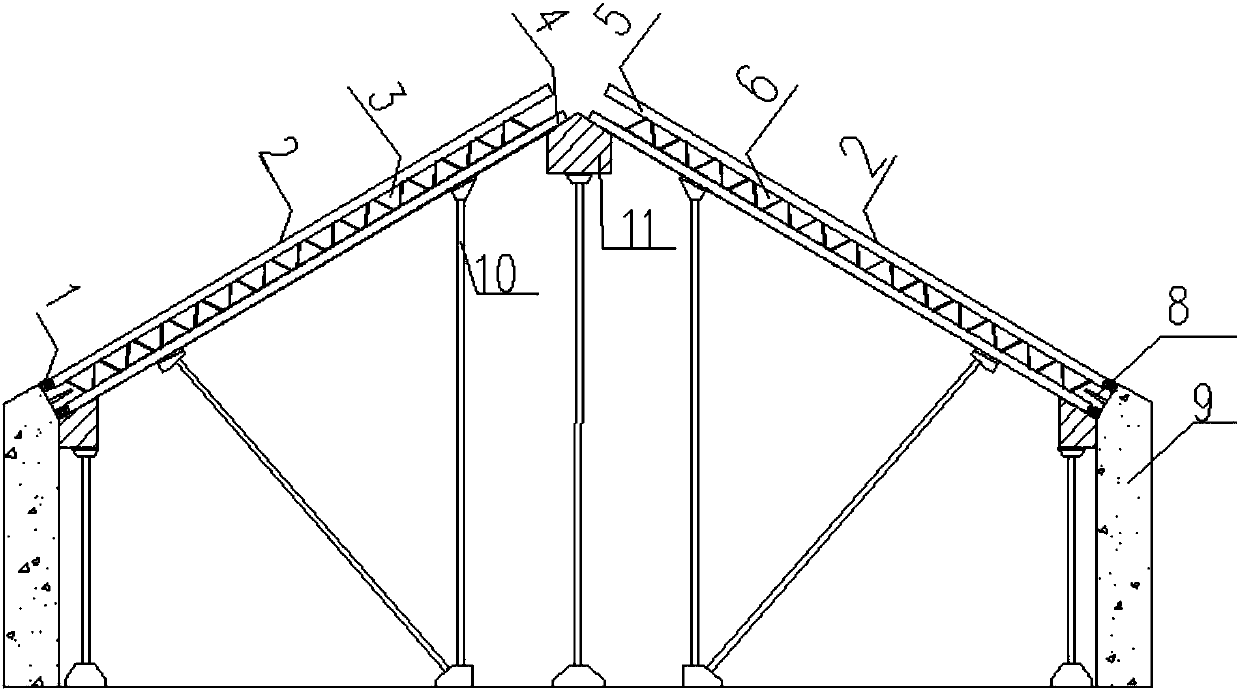

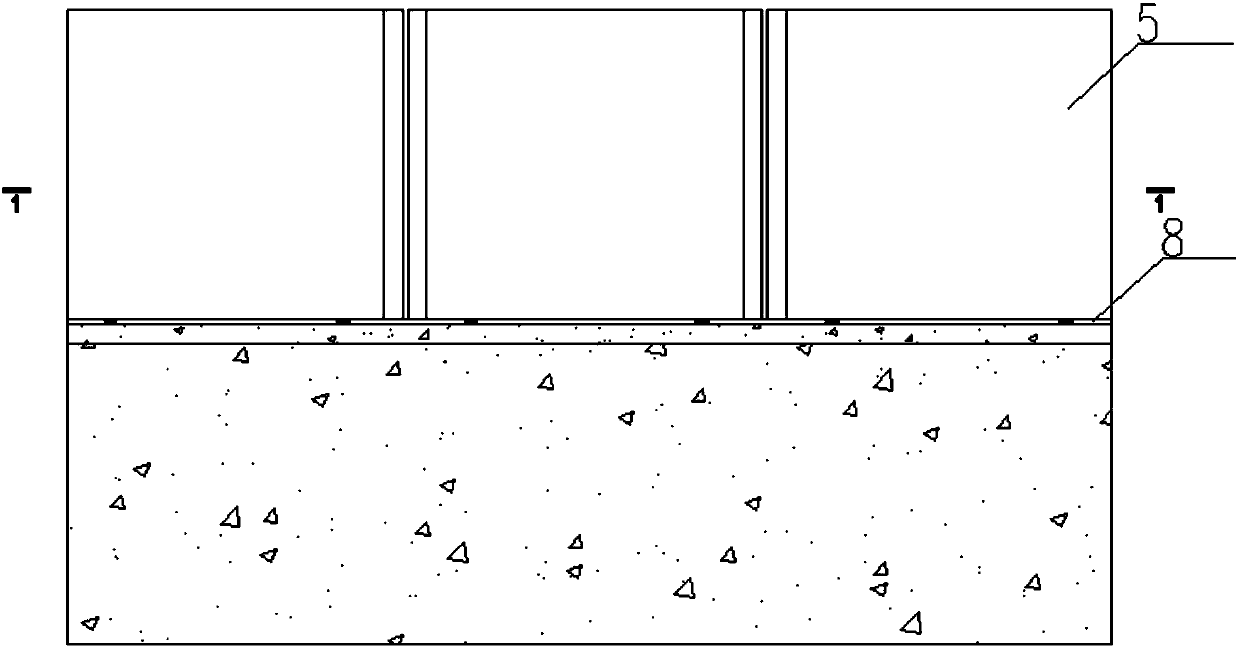

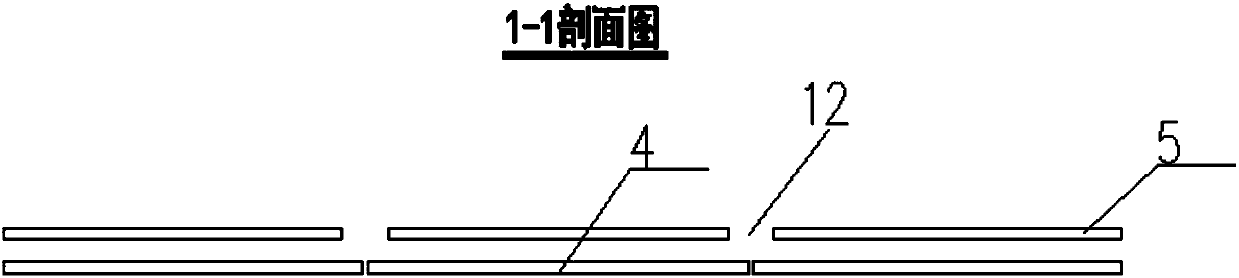

Prefabricated laminated wallboard sloping roof system and installing method thereof

PendingCN107663917ASolving Difficult-to-Pour ProblemsReduce on-site construction proceduresBuilding roofsArchitectural engineeringRebar

The invention relates to a prefabricated laminated wallboard sloping roof system, which comprises a roof sloping surface structure, inclined supporters, a wood pad block, a gasket and a water stop steel plate, wherein the roof sloping surface structure is formed by splicing a plurality of prefabricated lamination wall boards; each prefabricated lamination wall board comprises an outer prefabricated wall board and an inner prefabricated wall board; the inner and outer prefabricated wall boards are connected through truss bars; a certain gap is formed between the adjacent outer prefabricated wall boards and forms a clamp opening; the clamp opening is a cast-in-place inlet or one of the cast-in-place inlets; the wood pad block is arranged at the lower part of the slope top position of the prefabricated lamination wall boards; a vertical support rod is arranged under the wood pad block; the inclined supporters are arranged at the lower part of the slope surfaces of the prefabricated lamination wall boards; the vertical supporter, the inclined supporters and the base plane are connected and fixed; the gasket is clamped between the prefabricated lamination wall boards and the wall body,is used as a supporting point of the prefabricated lamination wall board and can be used for regulating the installation errors of the prefabricated lamination wall board.

Owner:SHANGHAI BAOYUE RESIDENTIAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com