Modular steel frame connection device and connection method thereof

A connection device and steel frame technology, which is applied in the direction of construction and building construction, can solve the problems of reducing the bearing capacity of buildings, increasing the risk of loosening, and increasing the number of connection positions, so as to shorten construction time, save procedures, and enhance firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific embodiments.

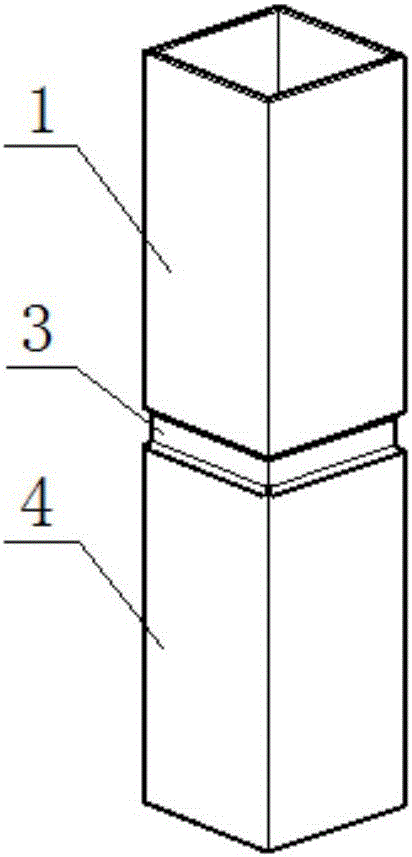

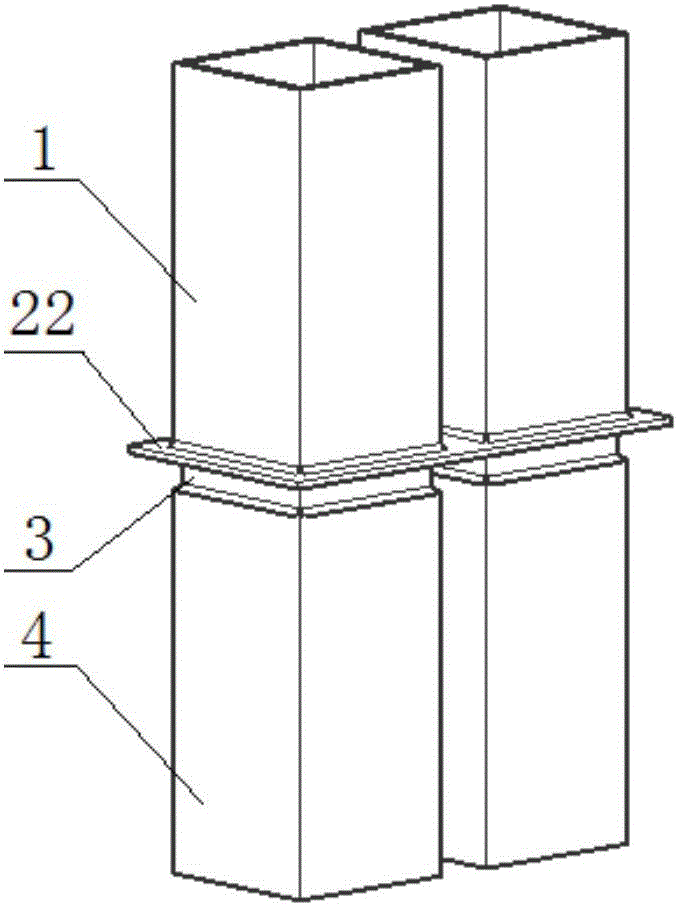

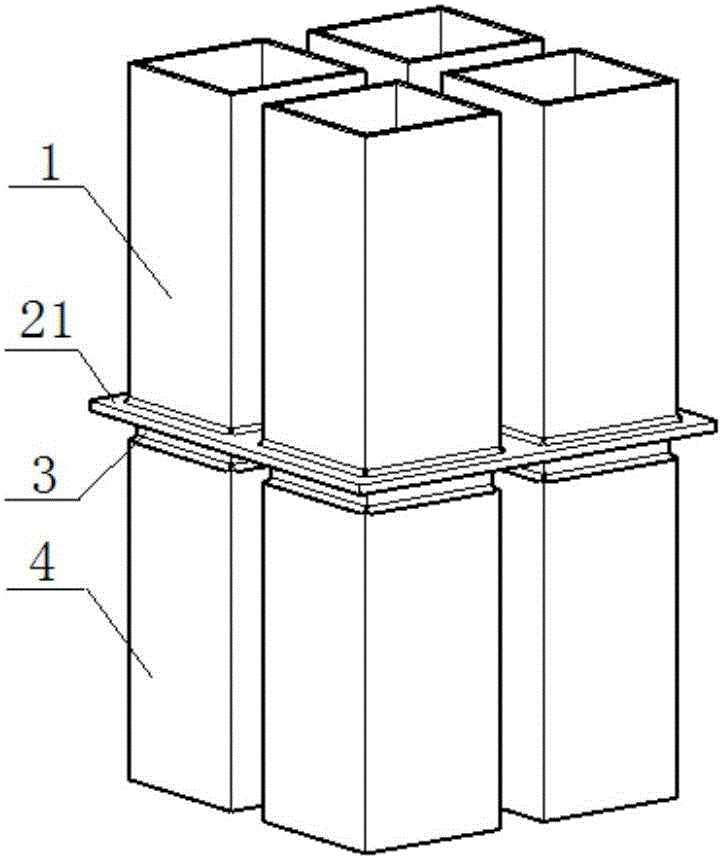

[0051] Such as figure 1 A modular steel frame connection device shown at least includes a first square steel pipe column 1 and a second square steel pipe column 4 which are hollow inside, and an inner sleeve is passed between the first square steel pipe column 1 and the second square steel pipe column 4 3 are connected, and the inner sleeve 3 is in clearance fit with the first square steel pipe column 1 and the second square steel pipe column 4, such as Figure 5 The outer peripheral ring of the inner sleeve 3 shown is provided with a positioning block 5 parallel to the openings of the first square steel pipe column 1 and the second square steel pipe column 4 .

[0052] A preferred embodiment is that the positioning block 5 has at least two upper and lower layers. Wherein, the upper positioning block 51 is used to hold the connecting plate 2 , and the lower positioning bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com