A connector with reduced plugging force and easy plugging

A technology of connectors and plugging force, which is applied in the direction of connection, parts of connecting devices, electrical components, etc., can solve the problems of increasing the size of the connector, reducing the strength and life of the pin, and large plugging force, etc., to achieve Reduce the difficulty of manufacturing and processing, avoid wear or deformation, and make the connection firm and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

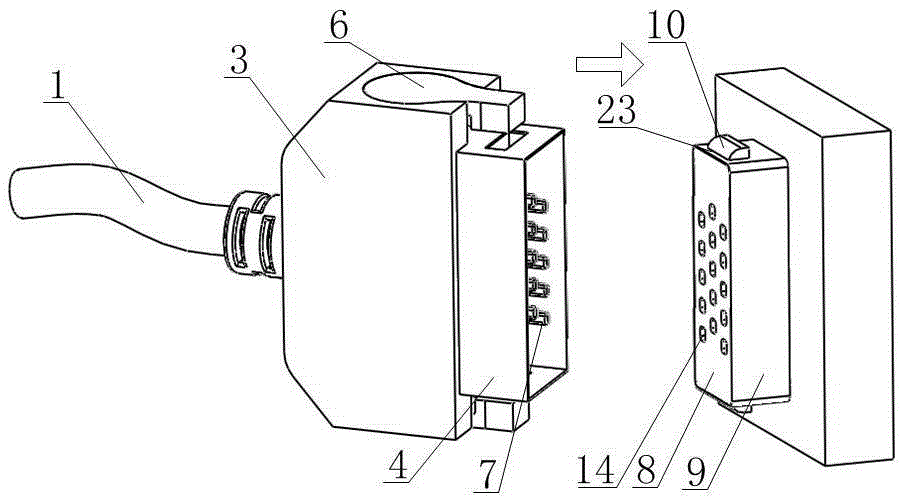

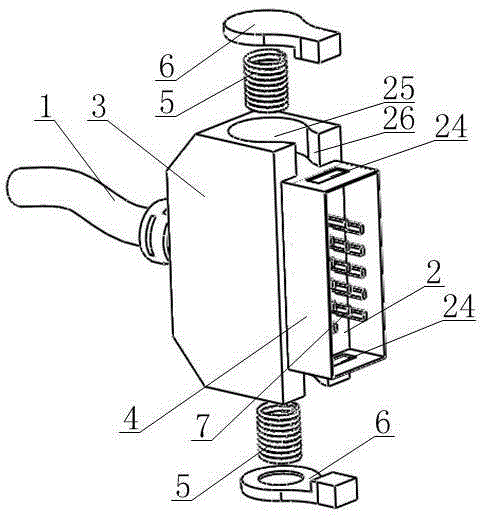

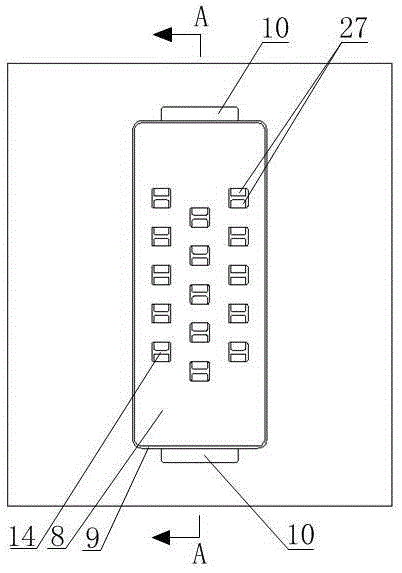

[0026] Such as figure 1 As shown, a connector that reduces the plugging force and is easy to plug and unplug, it includes a plug and a socket, and the direction of movement of the plug relative to the socket during insertion is the mating direction, that is figure 1 In the direction indicated by the arrow, combined with figure 2 As shown, the plug includes a signal line 1, a fixed insulating plate 2, a plastic shell 3, a guide metal shell 4, a button spring 5 and a button 6, and a plurality of pins 7 are installed on the fixed insulating plate 2, and the pins 7 are Flat flakes, the length of the common pin 7, the pin 7 is located at the rear end of the mating direction and connected to the signal line 1, the signal line 1 is the original electronic system, no change, when the plug and the socket ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com