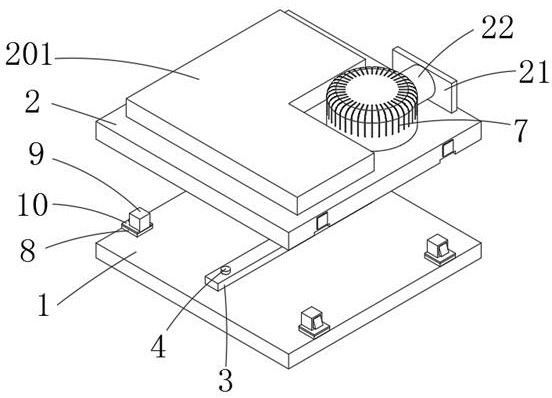

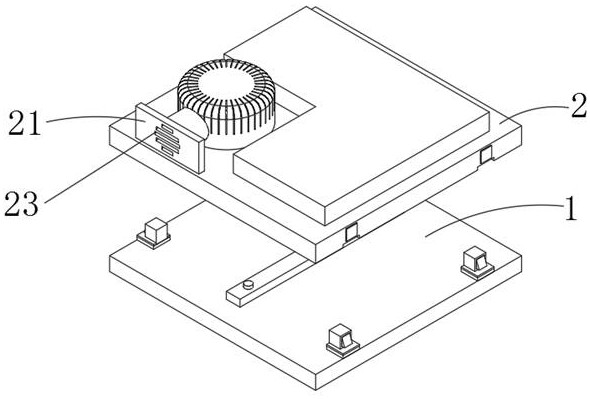

A heat dissipation assembly structure of a switching power supply

A technology of assembly structure and switching power supply, which is applied to the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., can solve the problems of time-consuming and labor-consuming, low installation efficiency, dust accumulation in heat dissipation structure, etc., and achieve improvement Heat dissipation effect, high installation efficiency and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

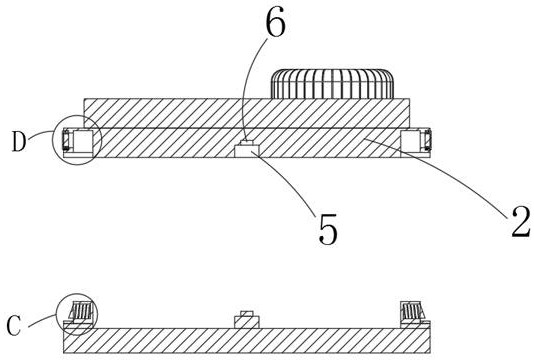

[0038] Embodiment: When installing the mounting plate 2, the fixing plate 3 snaps into the plate groove 5, and the fixing plate 3 limits the mounting plate 2 to prevent the mounting plate 2 from shaking during installation. At the same time, the fixing column 4 snaps into the column groove 6 to lift The fixing effect of the fixing plate 3, the post 9 is inserted in the slot 15, the backing plate 8 is used for auxiliary fixing, the buffer pad 10 improves the cushioning effect, when the post 9 is inserted into the slot 15, the block 13 is squeezed by the slot 15, the second A spring 12 is deformed, and the block 13 is pressed into the spring slot 11. When the post 9 is fully inserted, the position of the spring slot 11 is aligned with the slot 16, the first spring 12 recovers, and the block 13 pops out, and the slot 13 is aligned with the slot. 16 snap fit, firmly fix the mounting plate 2 and the support frame 1; when it is necessary to disassemble the mounting plate 2 and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com