Controller with elastically compacting structure

A technology of elastic compression and controller, applied to the circuit arrangement on the support structure, the shell with display/control unit, elastic/clamping device, etc., can solve the problems of low safety, low production and assembly efficiency, etc. Achieve the effects of improving product quality, improving production and assembly efficiency, and eliminating hidden dangers of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

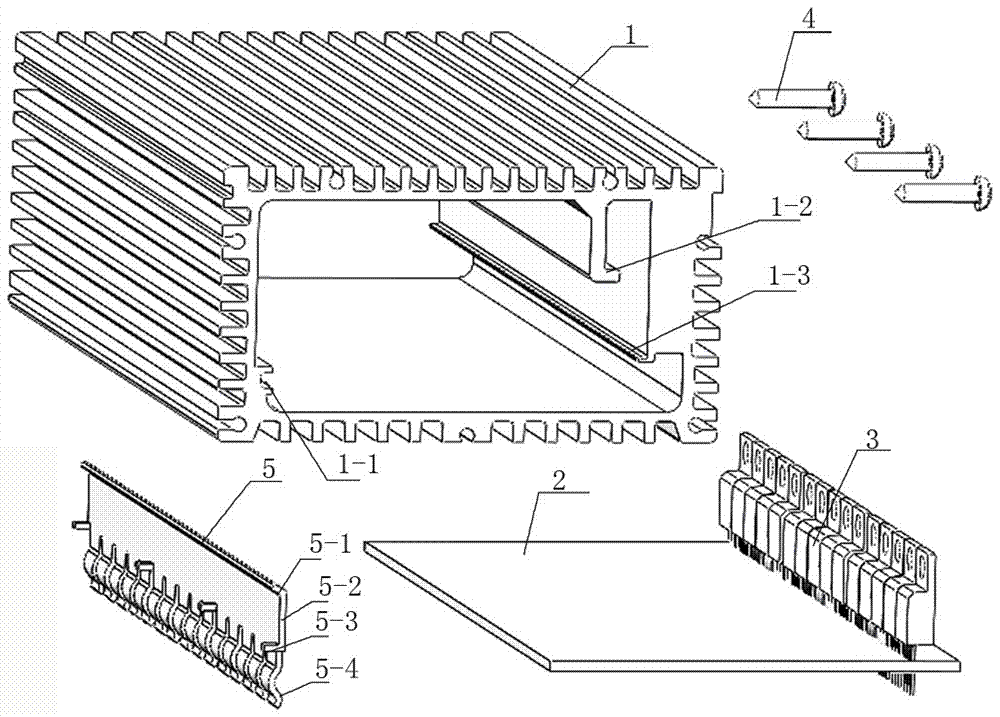

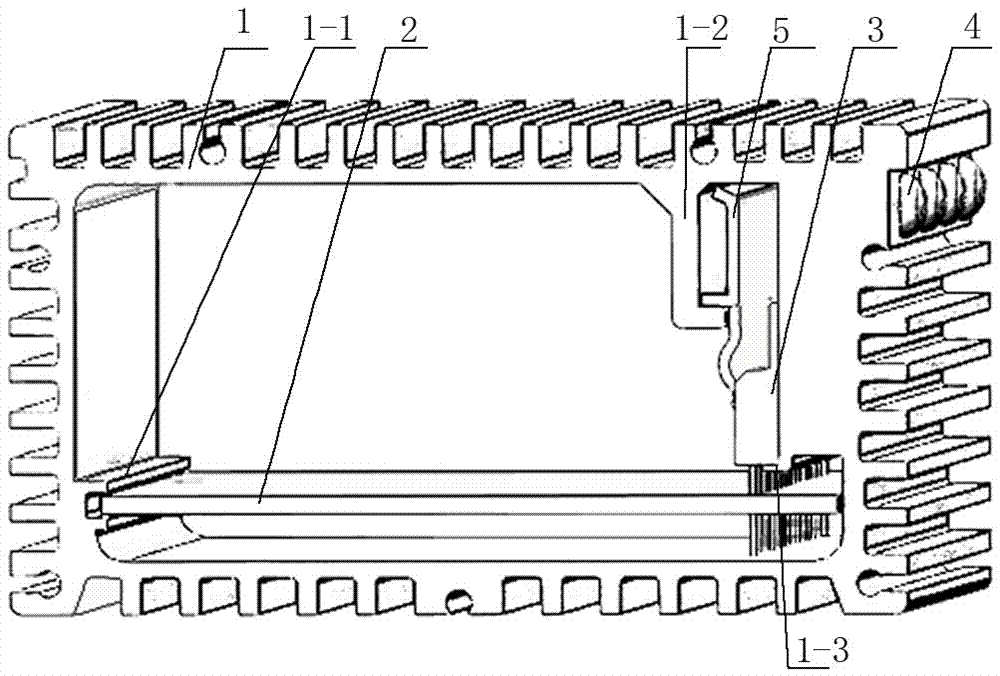

[0014] as attached figure 1 As shown, a controller with an elastic compression structure is composed of an aluminum profile shell 1, a PCB main board 2, a MOS tube 3, a spring pressure piece 5 and a pressure screw 4, and a spring pressure piece holder is arranged inside the shell 1 Groove 1-2, MOS tube support slot 1-3 and PCB main board card slot 1-1, described MOS tube 3 is vertically installed on one side of PCB main board 2; Described PCB supervisory card slot 1-1 and MOS tube support slot 1-3 are respectively placed on both sides of the shell 1, and the spring pressing bracket 1-2 is set close to the side of the MOS tube bracket 1-3. When the PCB main board 2 is inserted horizontally with the PCB main board slot 1-1, The bottom edge of the outside of the MOS tube 3 is supported on the MOS tube bracket 1-3, the spring pressing piece 5 is supported by the spring pressing piece bracket 1-2 and the bottom of the spring pressing piece 5 is pressed against the inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com