Non-purlin bolt ball node grid structure and manufacturing method thereof

A grid structure and bolt ball technology, which is applied to building components, building structures, roof coverings, etc., can solve the problems of increasing the types and quantities of components, wasting steel materials, and high construction costs, so as to reduce on-site construction procedures and save costs. The construction cost and the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

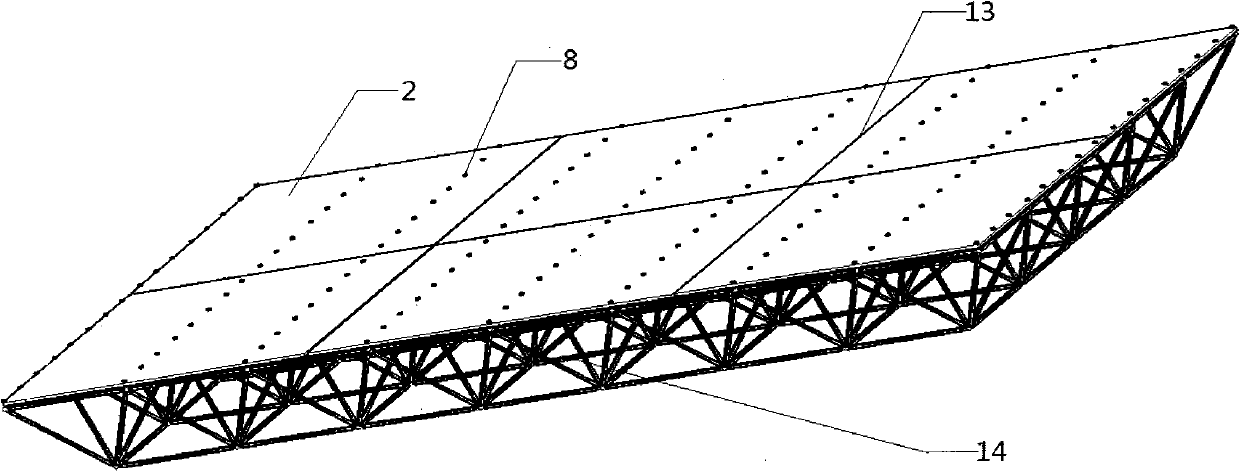

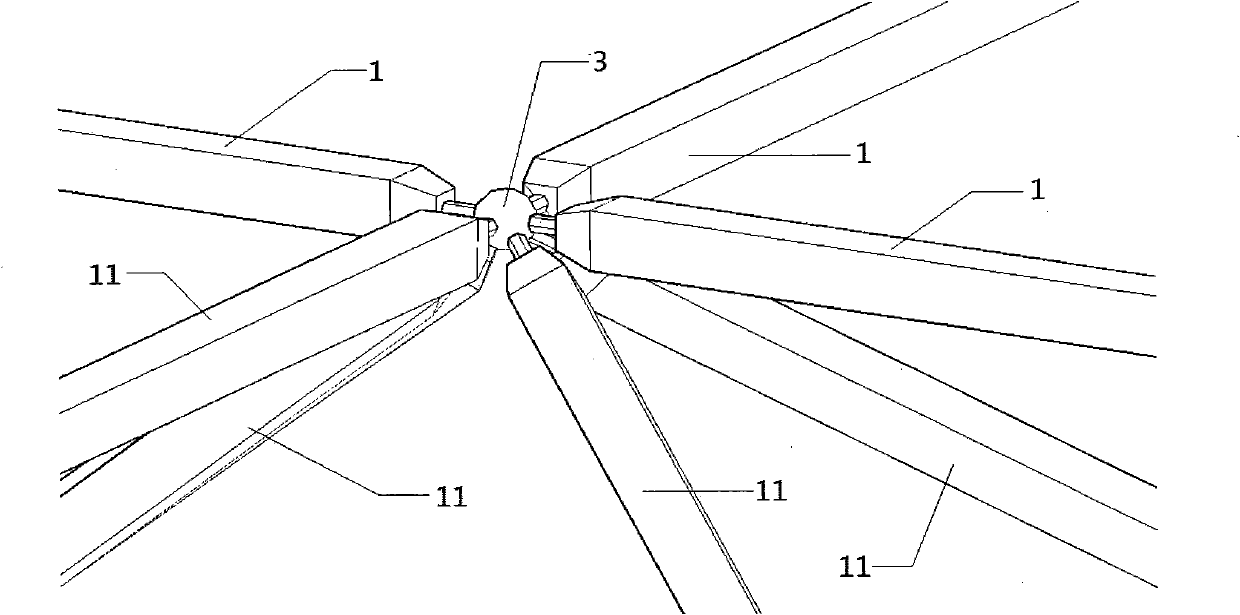

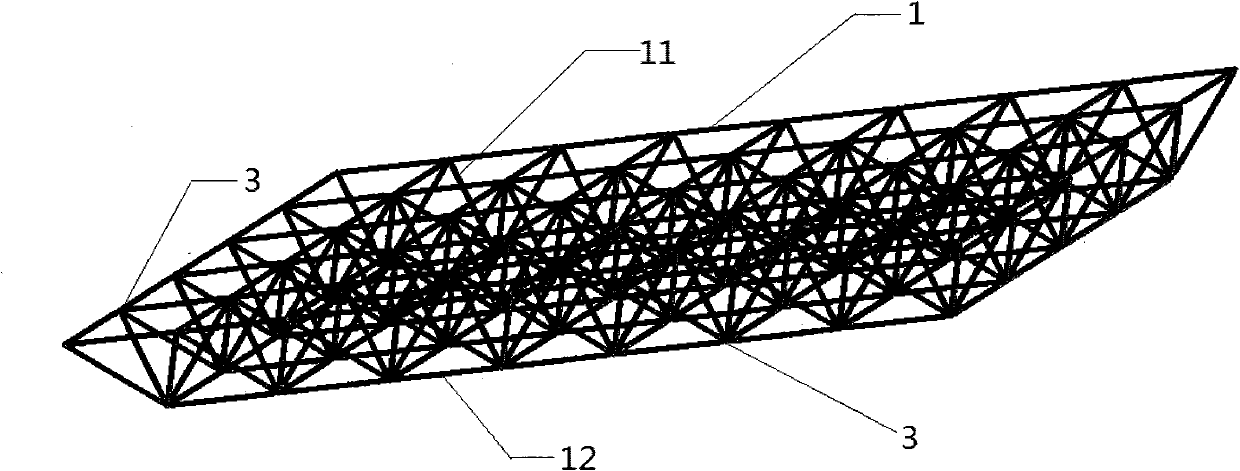

[0028] like Figure 1-11 As shown, the bolt ball joint network frame 14 is formed by connecting the upper chord 1, the web 11 and the lower chord 12 through the bolt ball joint 3, and the bolt ball joint 3 is composed of a sleeve 15, a solid sphere 16, high-strength bolts 17 and pins 18 The axes of the upper chord, web and lower chord pass through the center of the solid sphere; the upper chord, the web and the lower chord all have cone heads 4 and sealing plates 5 at the ends, and the sealing plates reserve holes for high-strength bolts through which the high-strength bolts and screws pass For the reserved hole of the sealing plate, the high-strength bolts are screwed into the solid sphere of the reserved threaded hole by screwing the sleeve, and the nut part is blocked by the sealing plate inside the rod; the upper chord is made of square steel pipe or rectangular steel pipe, and the upper chord is The two sides are set horizontally and the two sides are vertical, and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com