Wear-resistant prefabricated brick for cement-kiln grate-cooler low wall

A technology of prefabricated bricks and grate coolers, which is applied to furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of inability to guarantee the quality of the low walls of the grate coolers of cement kilns, many processes, and long construction and maintenance time, etc. Use effect and service life, meet maintenance time, and reduce the effect of on-site construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

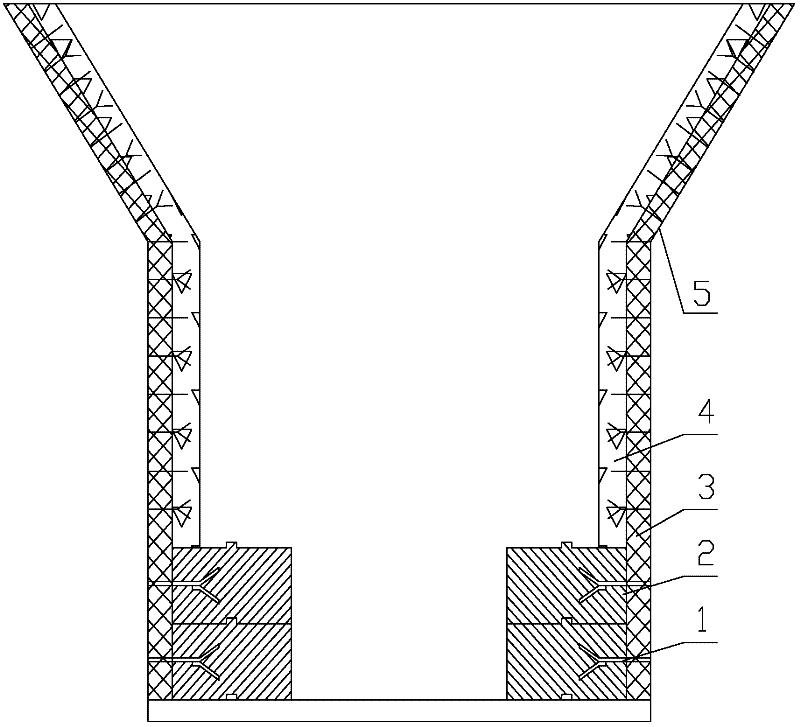

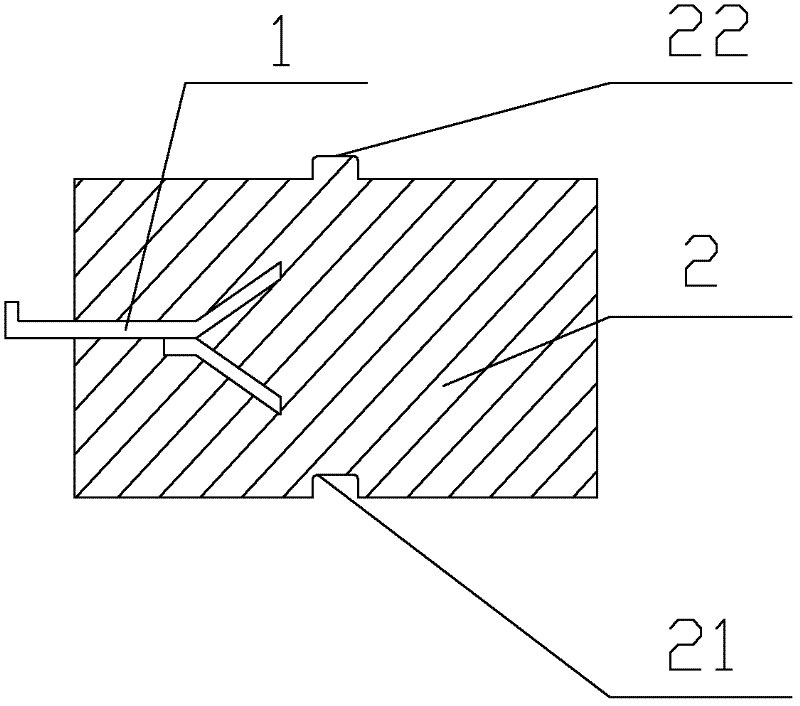

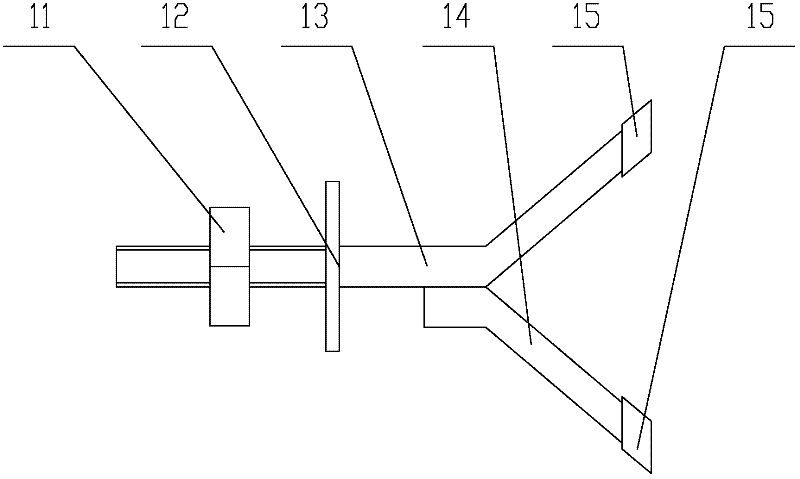

[0017] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a wear-resistant prefabricated brick for the low wall of the cement kiln grate cooler, including a metal anchor nail 1 and a prefabricated brick body 2, one end of the metal anchor nail 1 is preset in the prefabricated brick body 2, through a plurality of resistant The combination of grinding and prefabricated bricks makes the low wall of the grate cooler of the cement kiln detachable, can be installed on site, and can be replaced and used repeatedly. The strip 22, through the cooperation of the groove and the convex strip, makes the disassembly and installation of the prefabricated brick easy. The metal anchor 1 includes a first metal reinforcement 13 and a second metal reinforcement 14, and one end of the first metal reinforcement 13 is upturned , one end of the second metal reinforcement 14 is warped downward, the horizontal length of the first metal reinforcement 13 is longer than the horizontal portion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com