Integrated steel structure shaft with lift halls and construction process thereof

A technology for steel structures and elevator halls, applied in vertical pipelines, building components, building structures, etc., can solve the problems of increasing the space occupied by building roads with elevators, affecting the effective space of roads, and greatly affecting residents, so as to ensure Effective traffic space, high construction efficiency, and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

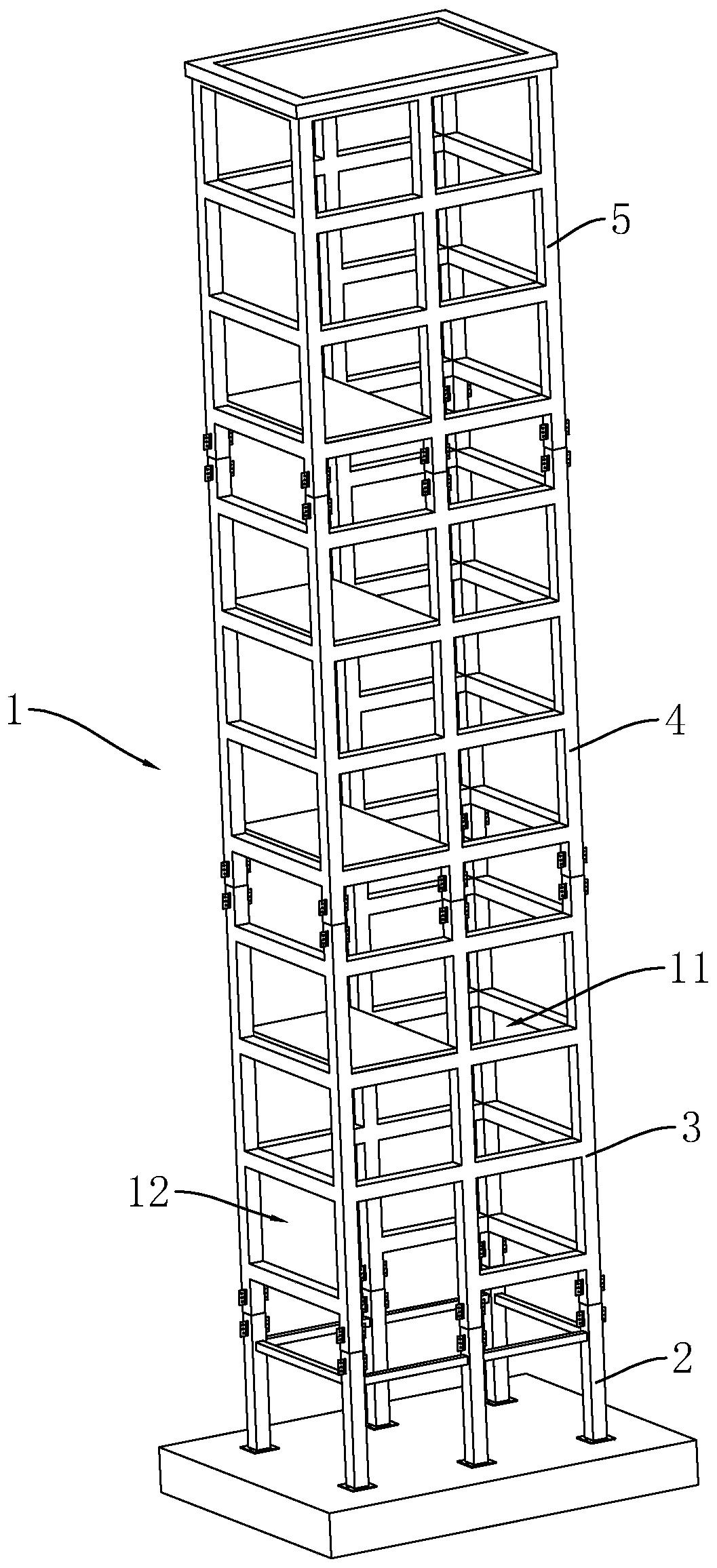

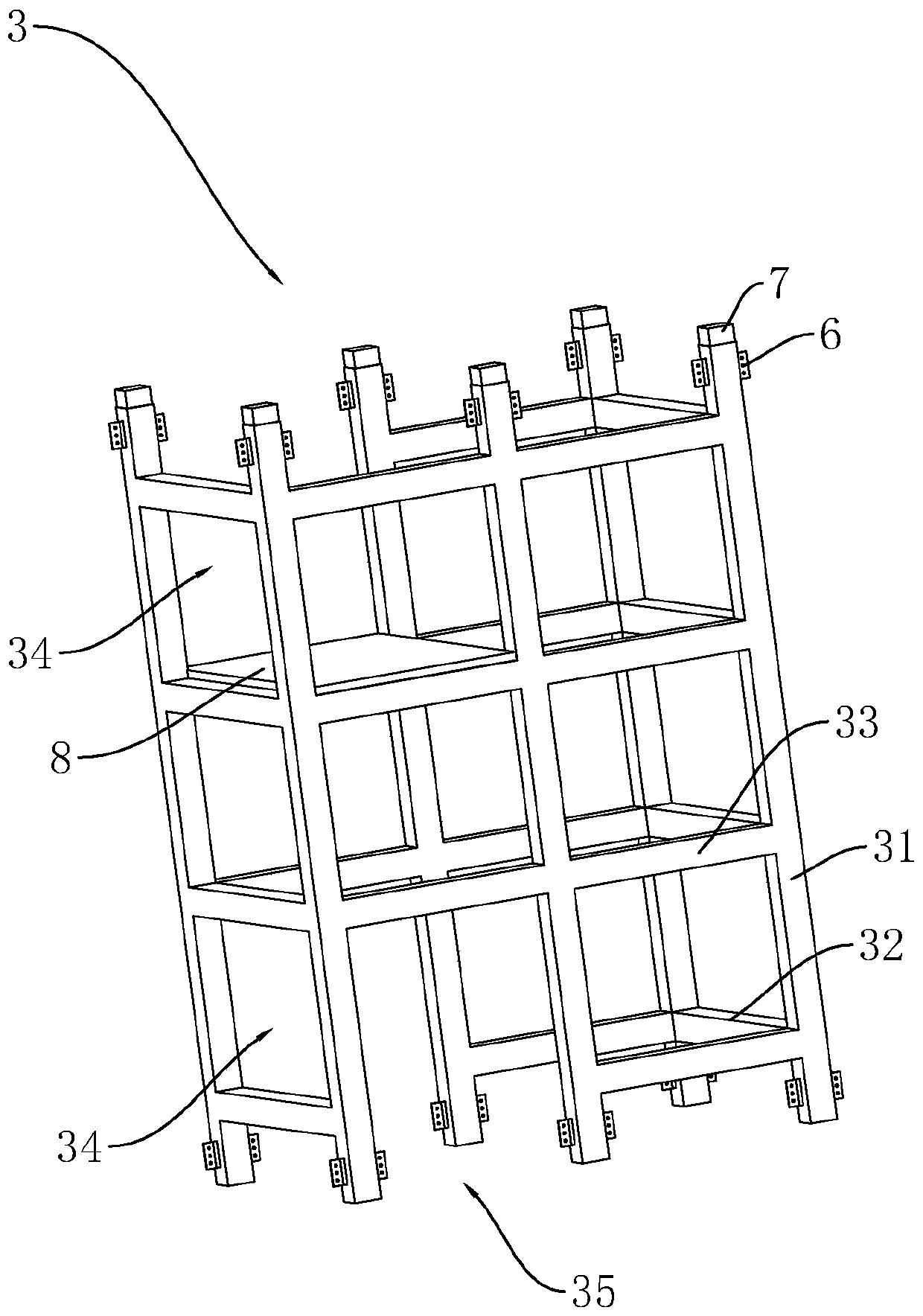

[0041] refer to figure 1 , is an integrated steel structure hoistway with a waiting hall disclosed in the present invention, including a steel structure hoistway 1, and the steel structure hoistway 1 includes a basic frame 2, a bottom module 3, a multi-section standard module 4, The top module 5 and the roof 51 , the base frame 2 , the bottom module 3 , the standard module 4 and the top module 5 are welded and fixed by the socket sleeve 7 , and the roof 51 is fixed on the upper end of the top module 5 . The bottom module 3 , the standard module 4 and the top module 5 are respectively covered with an enclosure structure, which can be glass, aluminum plate, thermal insulation integrated board, etc.

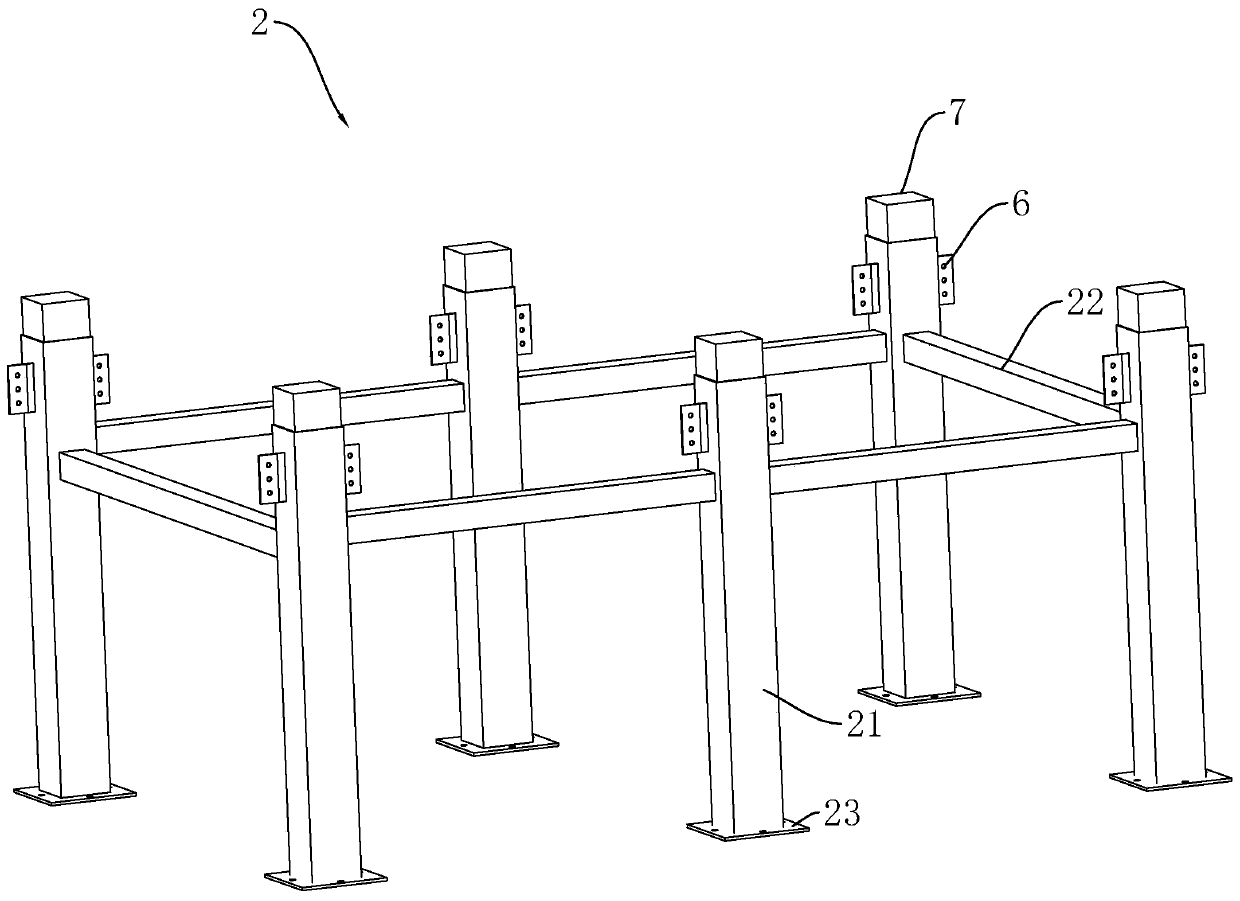

[0042] refer to figure 2 , the basic frame 2 includes six square columns 21, and the six square columns 21 are arranged in a rectangle, and a square beam 22 is welded at the upper end of the square column 21 between adjacent square columns 21, and a square steel plate 23 is welded o...

Embodiment 2

[0049] A construction process for an integrated steel structure hoistway with a waiting hall, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com