Integrated assembly type light floor and construction method thereof

A construction method and prefabricated technology, applied in floors, buildings, building components, etc., can solve the problem of the integrity of steel columns on the force transmission effect of vertical force-bearing components, the amount of welding of truss-type steel beams, and the overall height of integrated floors. and other issues, to achieve the advantages of reducing the construction period, reducing the on-site process, and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

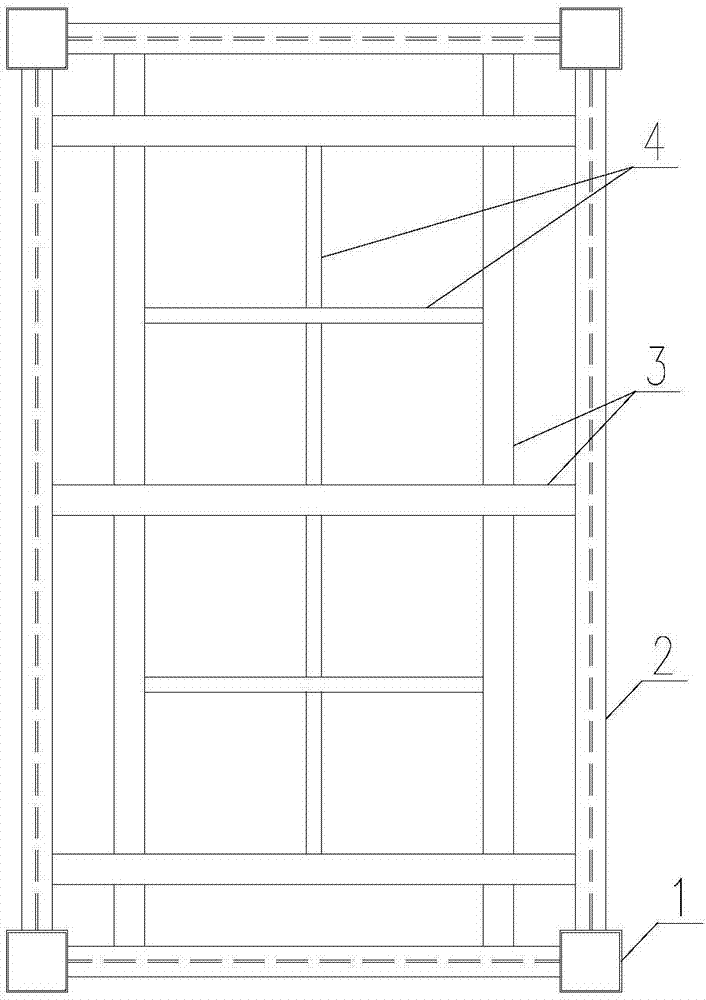

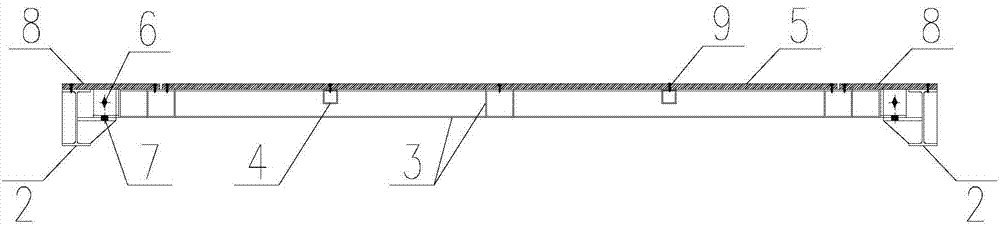

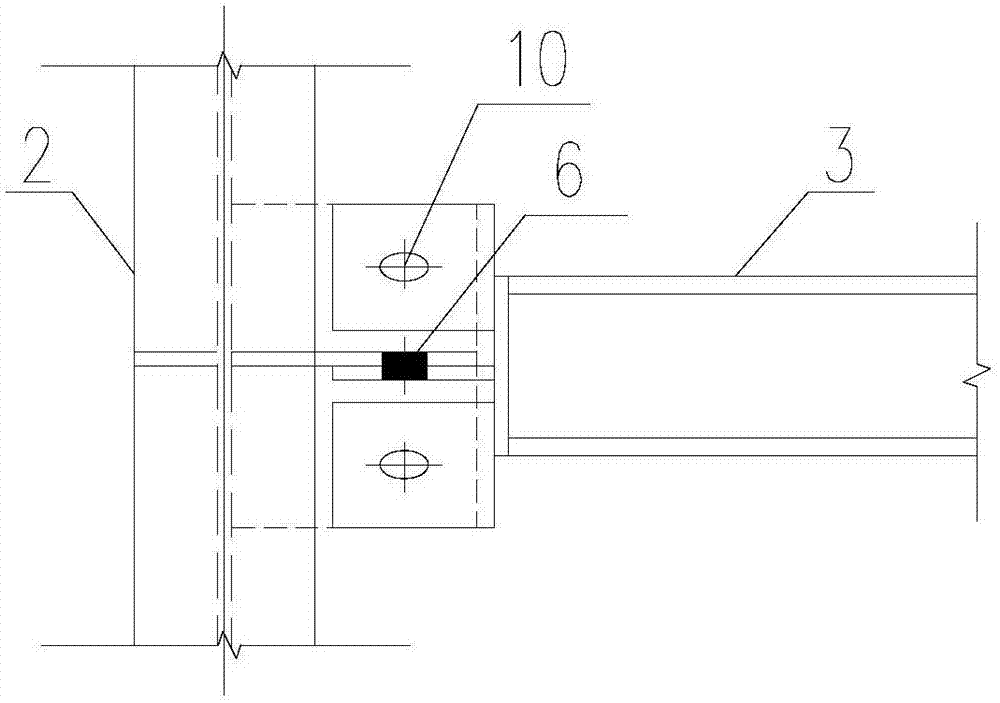

[0040] Such as Figure 1~3 As shown, an integrated assembled lightweight floor slab includes cement fiber board 5, steel structure well-shaped beam 3 and steel structure keel 4; It is 100mm ~ 150mm, determined by design calculation, effectively increasing the indoor net height. A steel structure keel 4 is laid on the steel structure well-shaped beam 3, and the steel structure well-shaped beam 3 and the steel structure keel 4 form the main structure of the floor slab. face comfort. Steel structure well-shaped beams and steel structure keels are commonly used finished steel pipes in the market, which are easy to purchase. The cement fiberboard 5 is used as the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com