Fabricated light composite beam simply-supported variable-structure continuous structure and construction method thereof

A prefabricated and variable structure technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., to ensure the quality of manufacturing, reduce procedures, and enhance the performance of compression stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

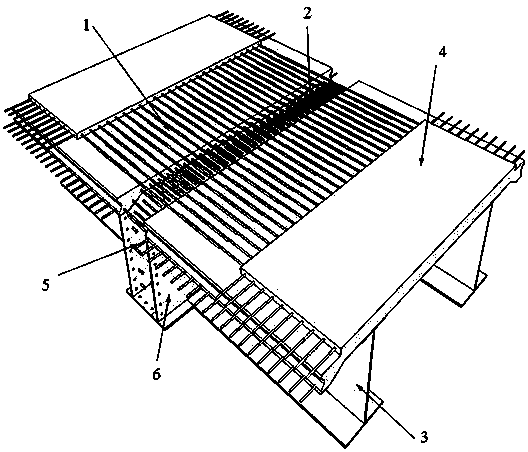

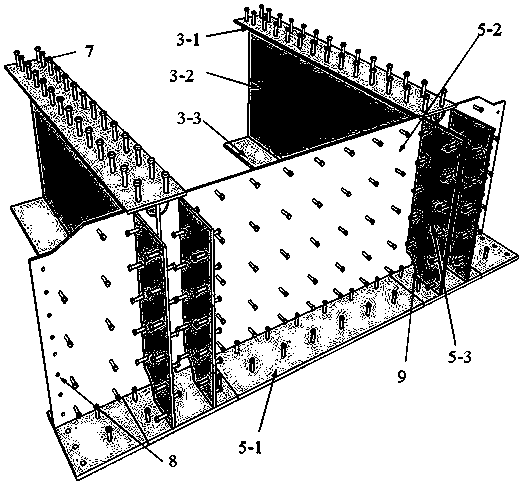

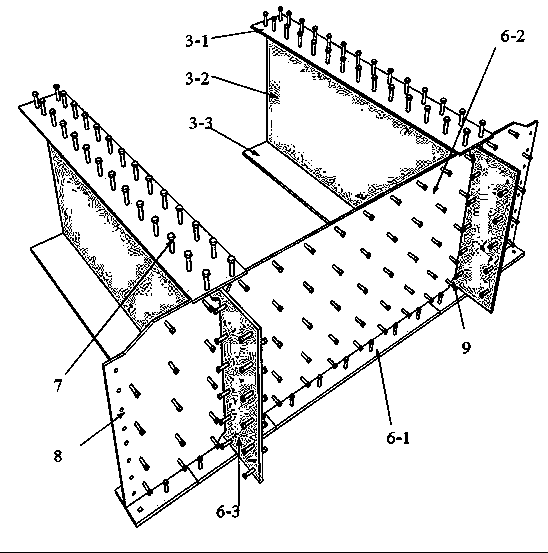

[0053] This embodiment is an assembled light-duty composite beam simple-supported variable structure continuous structure, including two-span steel-ultra-high-performance concrete light-duty composite simple-supported beam prefabricated unit 1 set opposite to each other and a cast-in-place super high-performance unit set between them Concrete pier top crossbeam 2, each prefabricated unit 1 includes two I-shaped steel beams 3 arranged in parallel, a bridge deck 4 arranged on the I-shaped steel beams 3 and a connecting part arranged at the ends of the I-shaped steel beams 3, so The connecting part includes a first connecting part 5 arranged at the end of one prefabricated unit 1 and a second connecting part 6 arranged on the other prefabricated unit 1, and the first connecting part 5 and the second connecting part 6 cooperate to form a concrete pier top The beam 2 is poured in the area, and the ultra-high performance concrete is cast in place to form the beam 2 at the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com