Fabricated steel structure residence system and construction method thereof

A prefabricated, steel structure technology, applied in building structures, buildings, building components, etc., can solve the problems of large column cross-section size, increased cost, unfavorable use of residential interior space, aesthetics and comfort requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

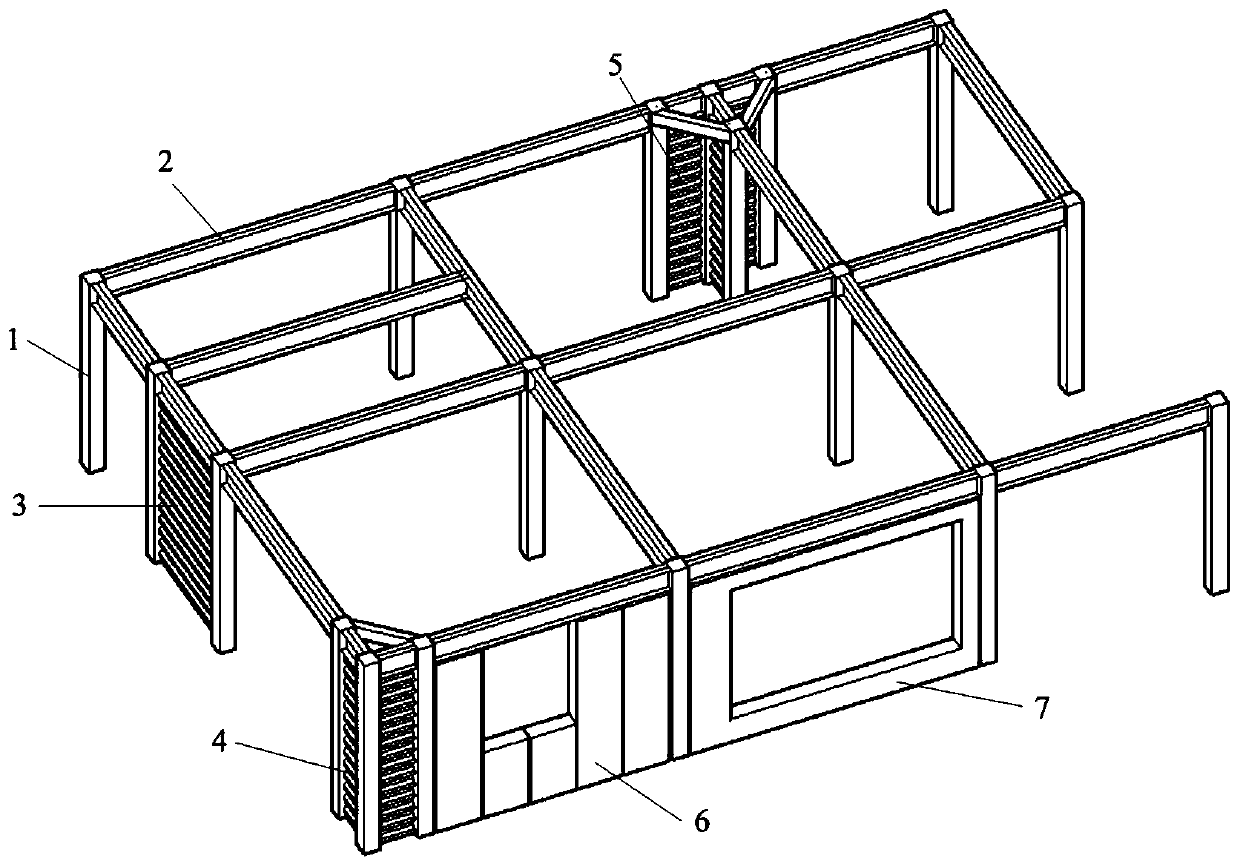

[0035] The prefabricated steel structure residential system disclosed in this embodiment is composed of vertical units and horizontal beams 2 to form a main skeleton, and prefabricated wall panels are used as interior and exterior wall filling.

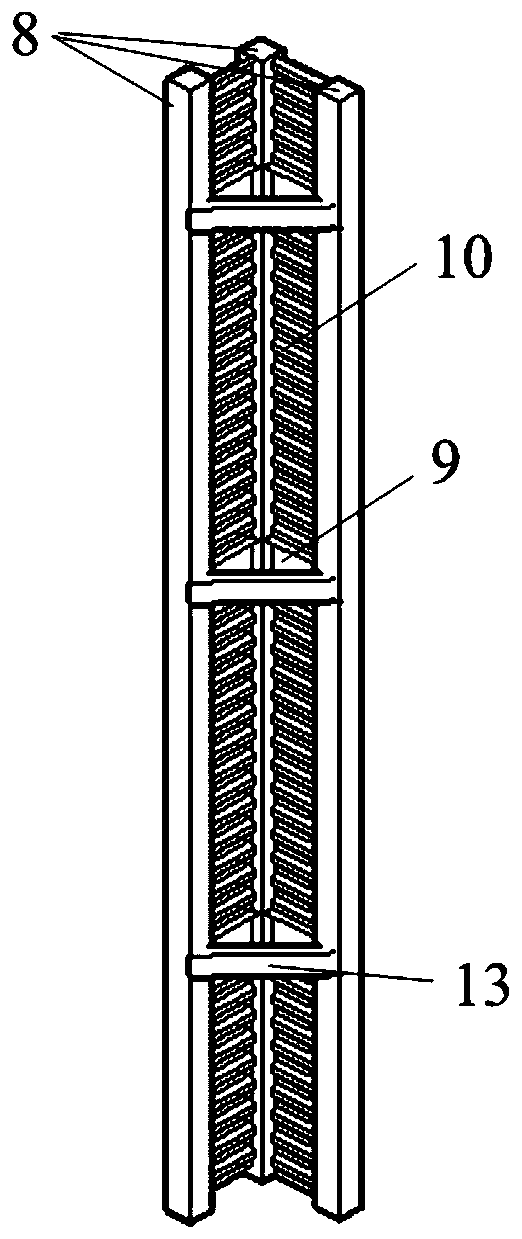

[0036] Such as figure 1 As shown, the vertical unit includes a steel tube concrete single column 1, and a corrugated plate shear wall unit, wherein the corrugated plate shear wall unit includes a corrugated plate shear wall 3, an L-shaped short-leg corrugated plate shear wall 4 and a T-shaped The short-leg corrugated plate shear wall 5, the horizontal beam 2 adopts I-beams, and the upper and lower horizontal beams use bolts to connect the prefabricated wall panels. plate 7.

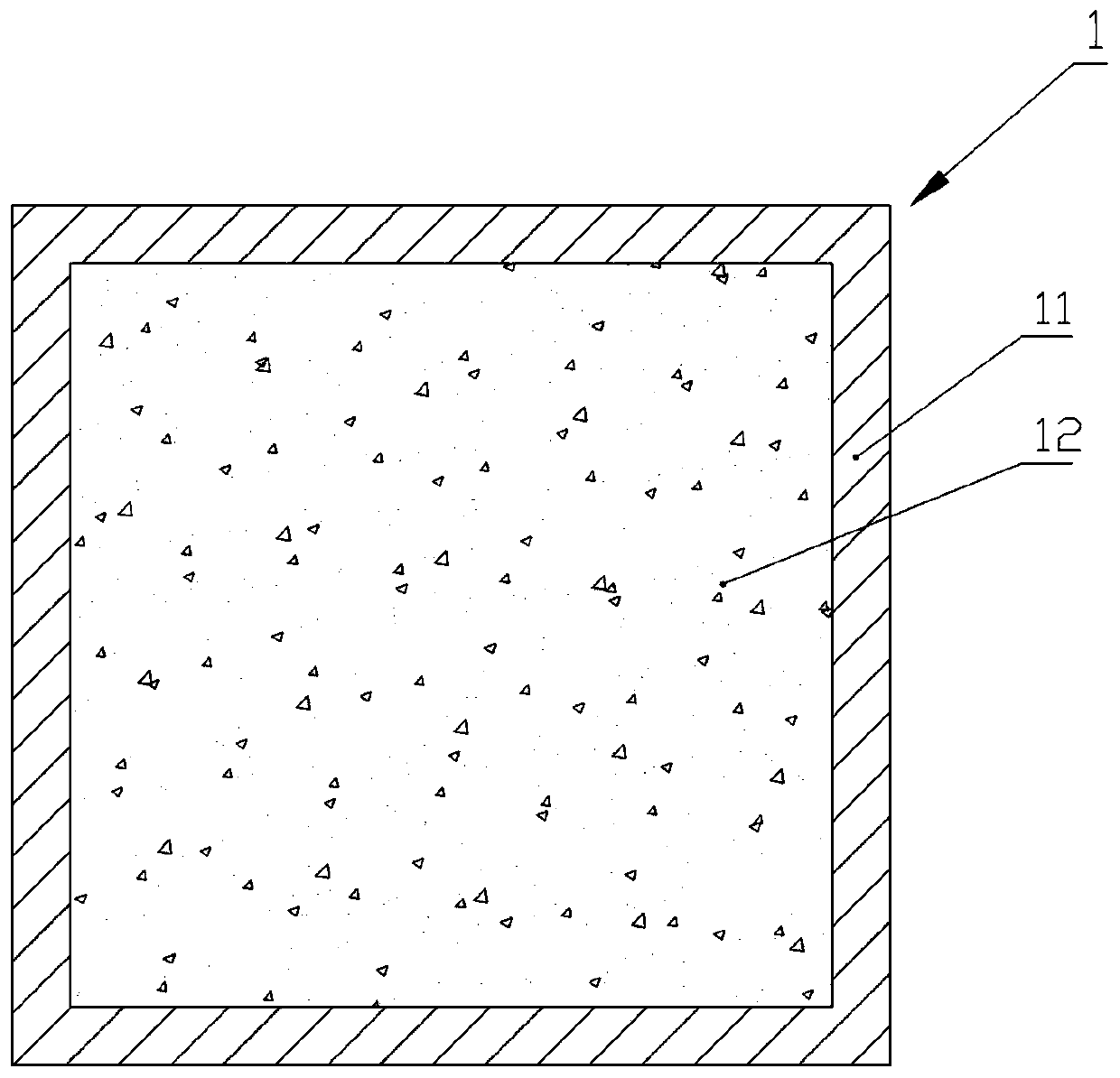

[0037] figure 2 Shown is a cross-sectional schematic diagram of a single column 1 of steel pipe concrete and a unit column 8 of a shear wall. Its periphery is a square steel pipe 11, and its inner core is concrete 12 poured in the steel pipe. Both the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com